Processing method for machining main studs of large and medium-sized rotor spiders by utilizing rotating tire

A rotor bracket and main vertical rib technology, which is applied in the field of large and medium-sized rotor brackets using rotating tires to process the main vertical ribs, which can solve the difficulty in realizing the integrity of the main vertical ribs of the rotor bracket, the unfavorable stacking of the rotor yoke, and the workload of adjustment Large and other problems, to achieve the effect of shortening the production cycle, short construction period and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention is a process method for processing main vertical ribs of a large and medium-sized rotor support by rotating tires. While ensuring the processing quality, the production cycle is shortened, and the operation is simple and convenient. Technical scheme of the present invention is:

[0016] a) Select equipment: select a suitable boring machine, clean the machine tool platform, and adjust the equipment to the optimal state;

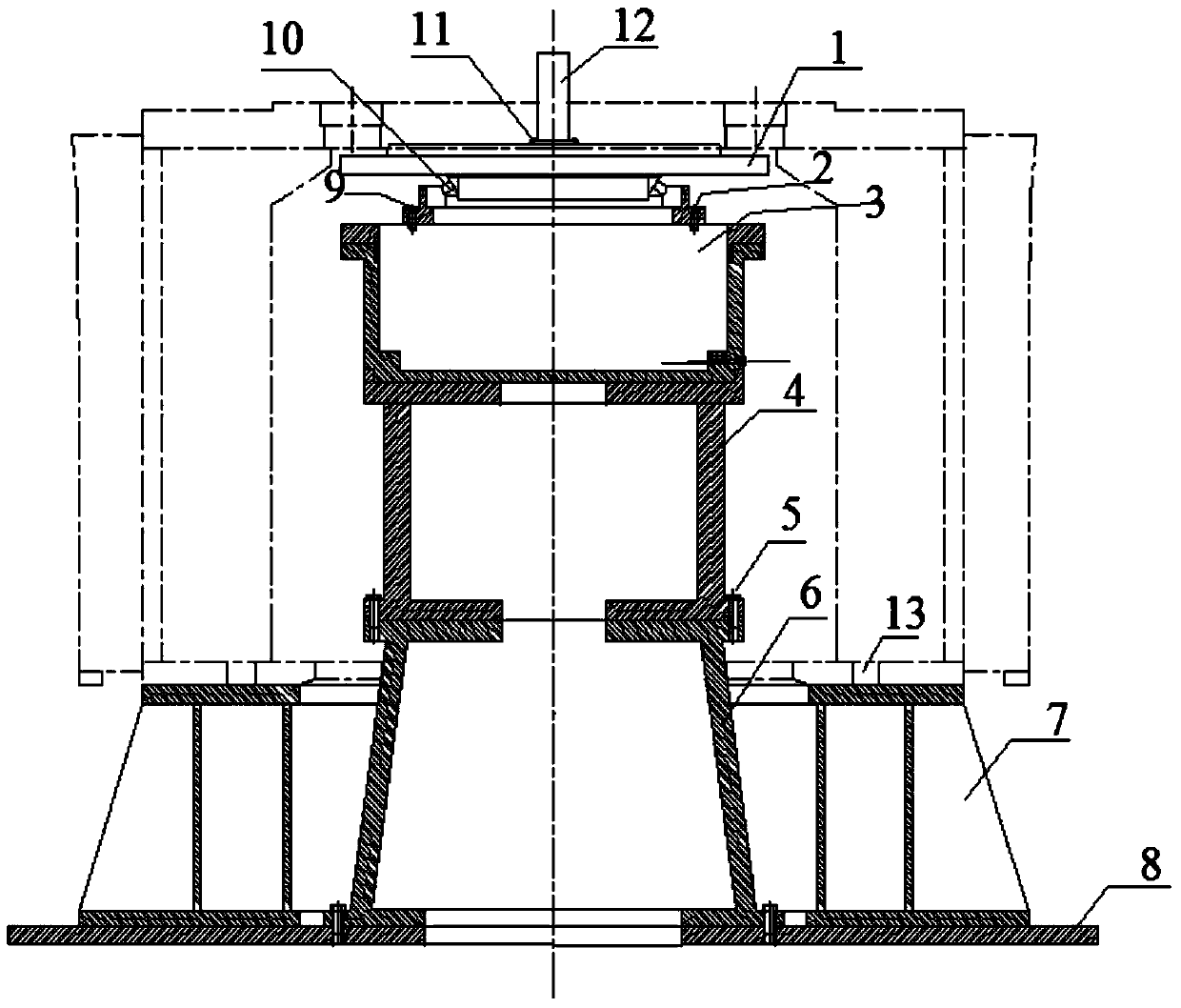

[0017] b) Rotary tire assembly: Place the rotary tire bottom plate 8 on the machine tool platform, combine the second pillar 6 and the bottom plate 8 through bolts, install the base 7 on the bottom plate 8, and adjust the level of its upper plane, and combine the first pillar 4 with bolts 5 It is integrated with the second pillar 6, and the oil cylinder 3 is placed in the first pillar 4 by using the seam positioning, and the bearing seat 2 is assembled on the oil cylinder 3 with the hexagon socket head screw 9, and the thrust self-aligning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com