Coining die for outer strip of nuclear fuel assembly positioning grid frame

A technology for nuclear fuel assemblies and spacer grids, which is used in manufacturing tools, forming tools, metal processing equipment, etc., and can solve problems such as the processing technology of strips without spacer grids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A stamping mold for the outer band of the nuclear fuel component positioning grid, including a stamping mold for the overall shape, a bending and chamfering mold for the end of the outer strip, a right-angle bending mold, and a lapping bending mold;

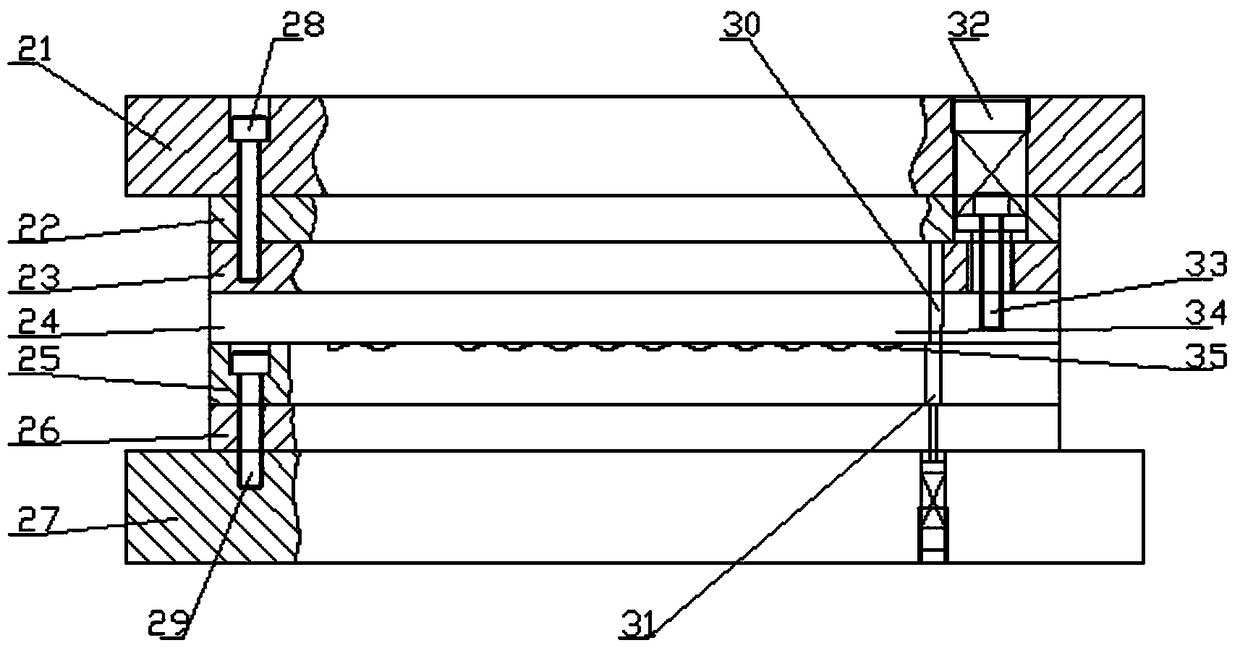

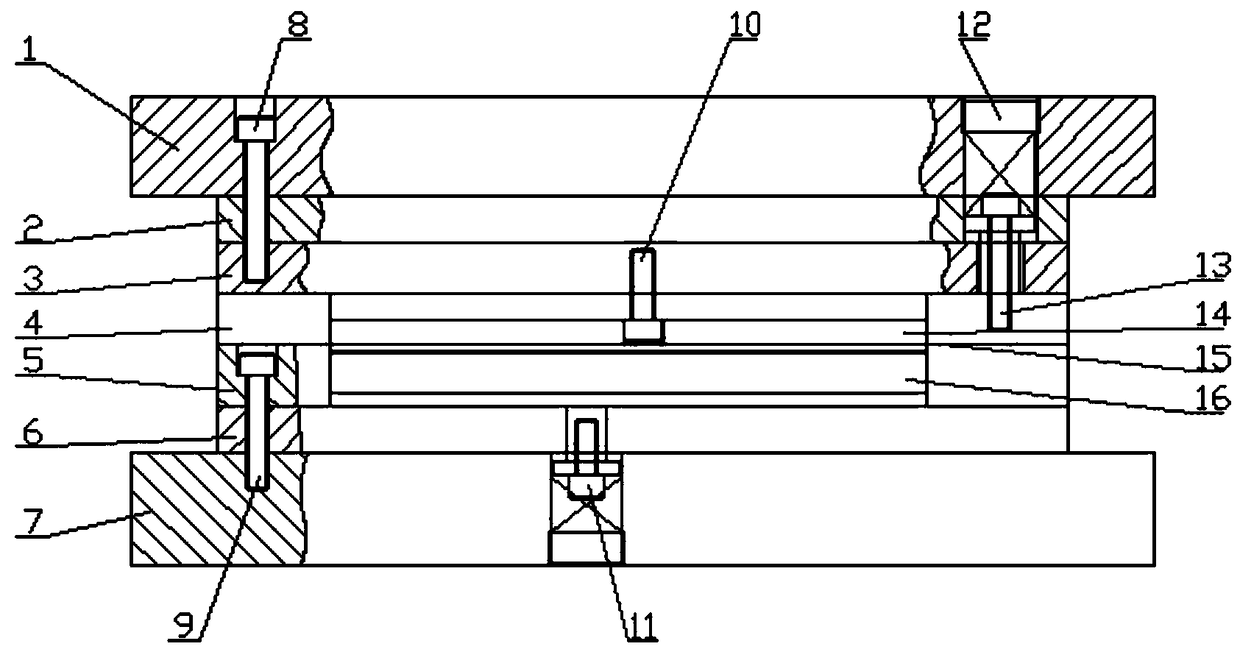

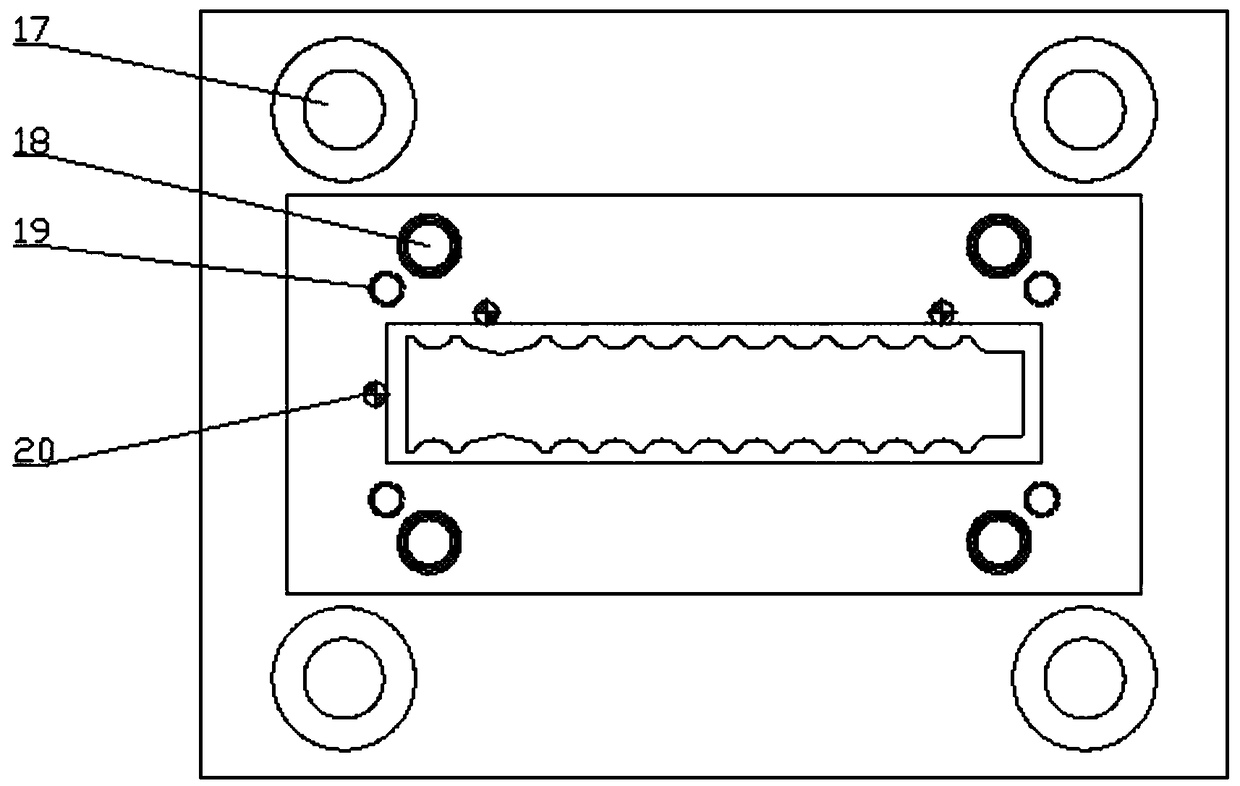

[0025] figure 1 Shown is the structure diagram of the stamping die for the overall shape of the outer strip. The stamping die for the overall shape includes the upper die base A1, the upper die backing plate A2, and the upper die plate A3. The upper die base A1, the upper die backing plate A2, and the upper die plate A3 pass through The bolt AA8 is connected, the upper formwork A3 and the unloading plate A4 are connected by the bolt AC10, the limit column A13 is located in the holes corresponding to the upper formwork backing plate A2, the upper formwork A3 and the unloading plate A4, and the plug screw A12 is located in the upper die base A1 The upper and lower formwork A5, the lower mold backing plate A6, and the lower m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com