Hydraulic support oil cylinder refabrication method based on CMT (Cold Metal Transition)

A hydraulic support and remanufacturing technology, which is applied in the field of metal surface engineering, can solve the problems of high cost, waste of resources, and large thermal deformation of oil cylinders, etc., and achieve the effects of improving service life, reducing overall cost, and reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

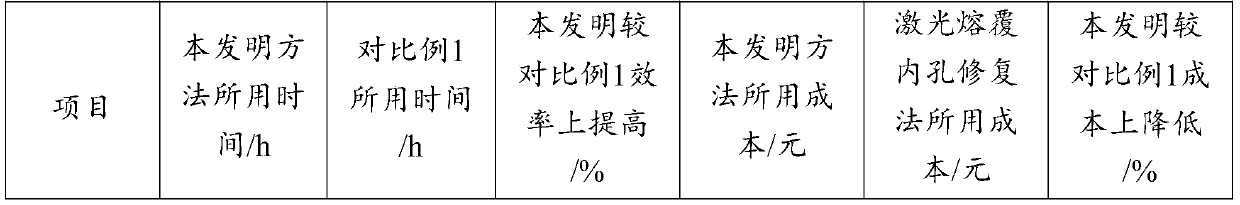

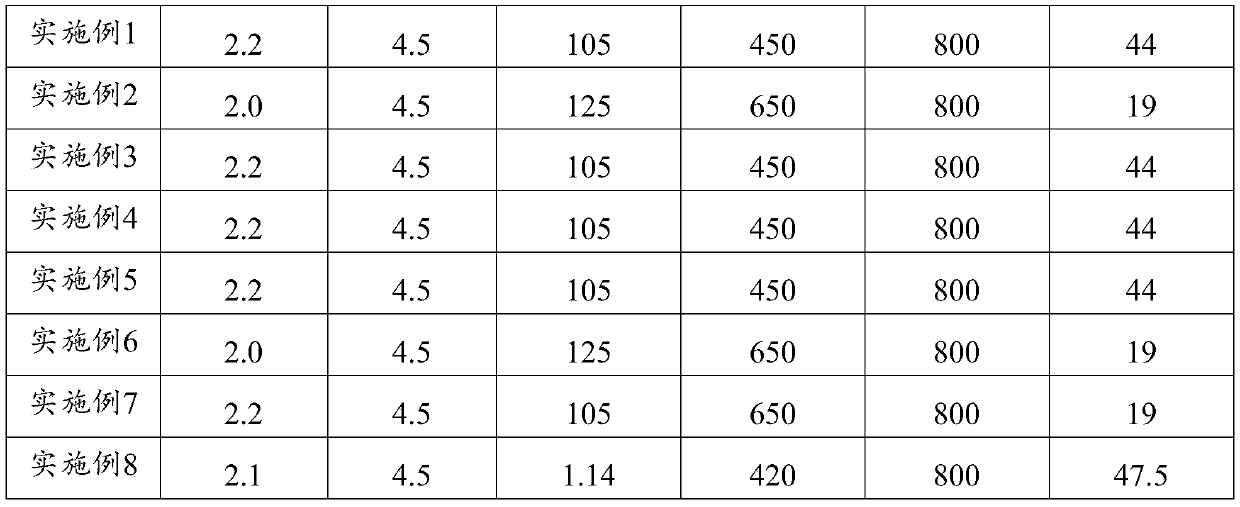

Examples

Embodiment 1

[0034] (1) Remove the corrosion fatigue layer on the inner wall of the oil cylinder to be repaired by machining, and the single-side processing amount of the machining is 1 mm; use absolute ethanol to clean the inner wall of the oil cylinder, remove oxides, oil stains and other impurities on the surface, and obtain a pretreated hydraulic support oil cylinder ;

[0035] (2) Carry out CMT welding on the inner wall of the pretreatment hydraulic support cylinder. The welding wire selected for CMT welding is 316L stainless steel welding wire with a diameter of 1.0mm; the welding process parameters are: gas flow rate is 10L / min, argon gas purity is 99.99%, welding current The welding voltage is 140A, the welding voltage is 12V, the welding speed is 200mm / min, and the DC is reversed; the welding torch angle α is controlled to 83°, the welding position angle β is 5°, and the welding wire extension length is 10mm; the special extended welding torch penetrates into the oil cylinder hole...

Embodiment 2

[0039] (1) Remove the corrosion fatigue layer on the inner wall of the oil cylinder to be repaired by machining, with a single-side processing amount of 2mm; use absolute alcohol to clean the inner wall of the oil cylinder, remove oxides, oil stains and other impurities on the surface, and obtain a pretreated hydraulic support oil cylinder;

[0040] (2) Carry out CMT welding on the inner wall of the pretreatment hydraulic support cylinder. The welding wire selected for CMT welding is 316L stainless steel welding wire with a diameter of 1.2mm; the welding process parameters are: gas flow rate is 15L / min, argon gas purity is 99.99%, welding current The welding voltage is 180A, the welding voltage is 16V, the welding speed is 220mm / min, and the DC is reversed; the welding torch angle α is controlled to 87°, the welding position angle β is 7°, and the welding wire extension length is 15mm; the special extended welding torch penetrates into the oil cylinder hole, to achieve CMT weld...

Embodiment 3

[0044] (1) Remove the corrosion fatigue layer on the inner wall of the oil cylinder to be repaired by machining, with a single-side processing amount of 1 mm; use absolute alcohol to clean the inner wall of the oil cylinder, remove oxides, oil stains and other impurities on the surface, and obtain a pretreated hydraulic support oil cylinder;

[0045] (2) Carry out CMT welding on the inner wall of the pretreatment hydraulic support cylinder. The welding wire selected for CMT welding is 316L stainless steel welding wire with a diameter of 1.0mm; the welding process parameters are: gas flow rate is 12L / min, argon gas purity is 99.99%, welding current The welding voltage is 150A, the welding voltage is 14V, the welding speed is 200mm / min, and the DC is reversed; the angle α of the welding torch is controlled to 84°, the angle β of the welding position is 7°, and the length of the welding wire is 10mm; the special extended welding torch penetrates into the oil cylinder hole, to achi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com