Patents

Literature

85results about How to "Guaranteed Tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

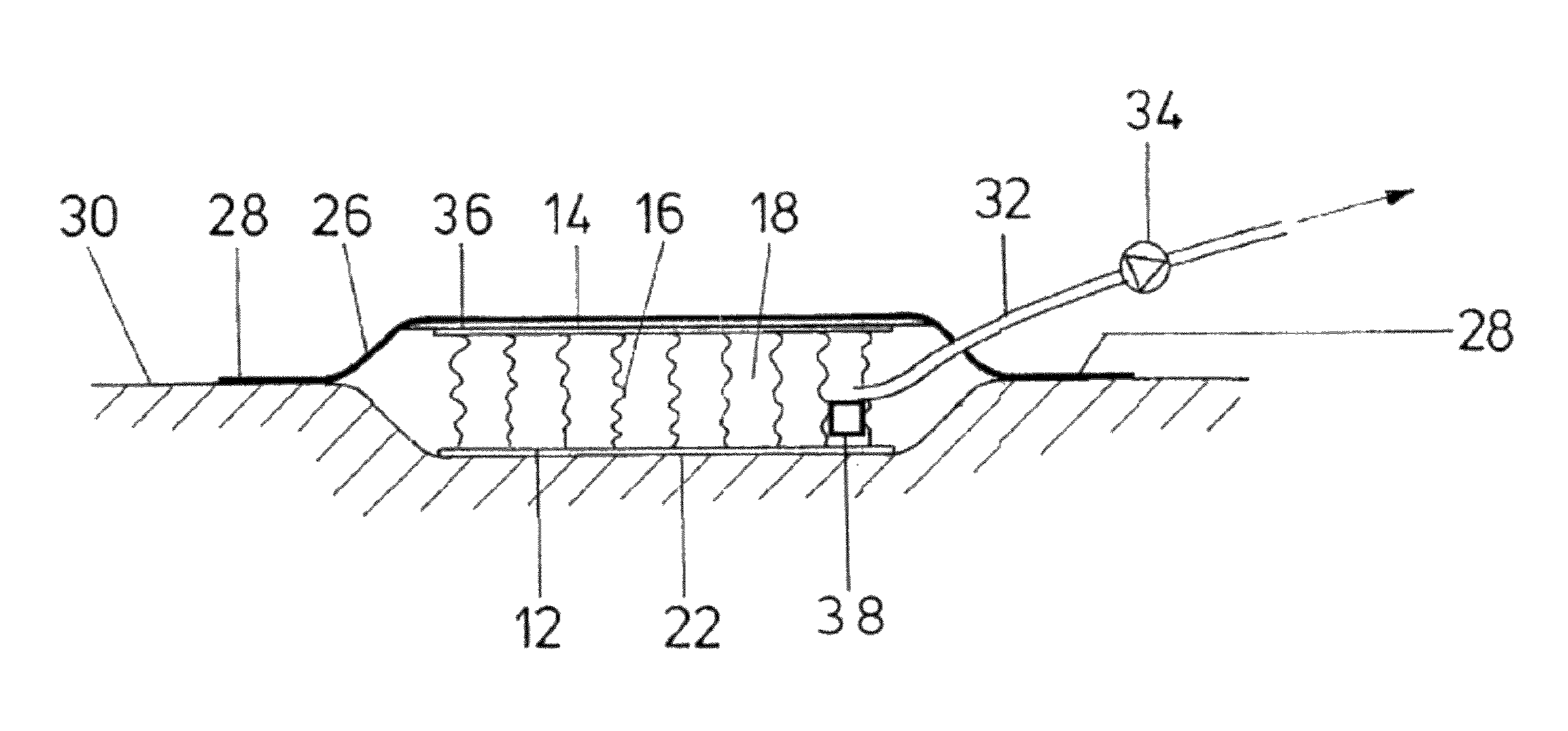

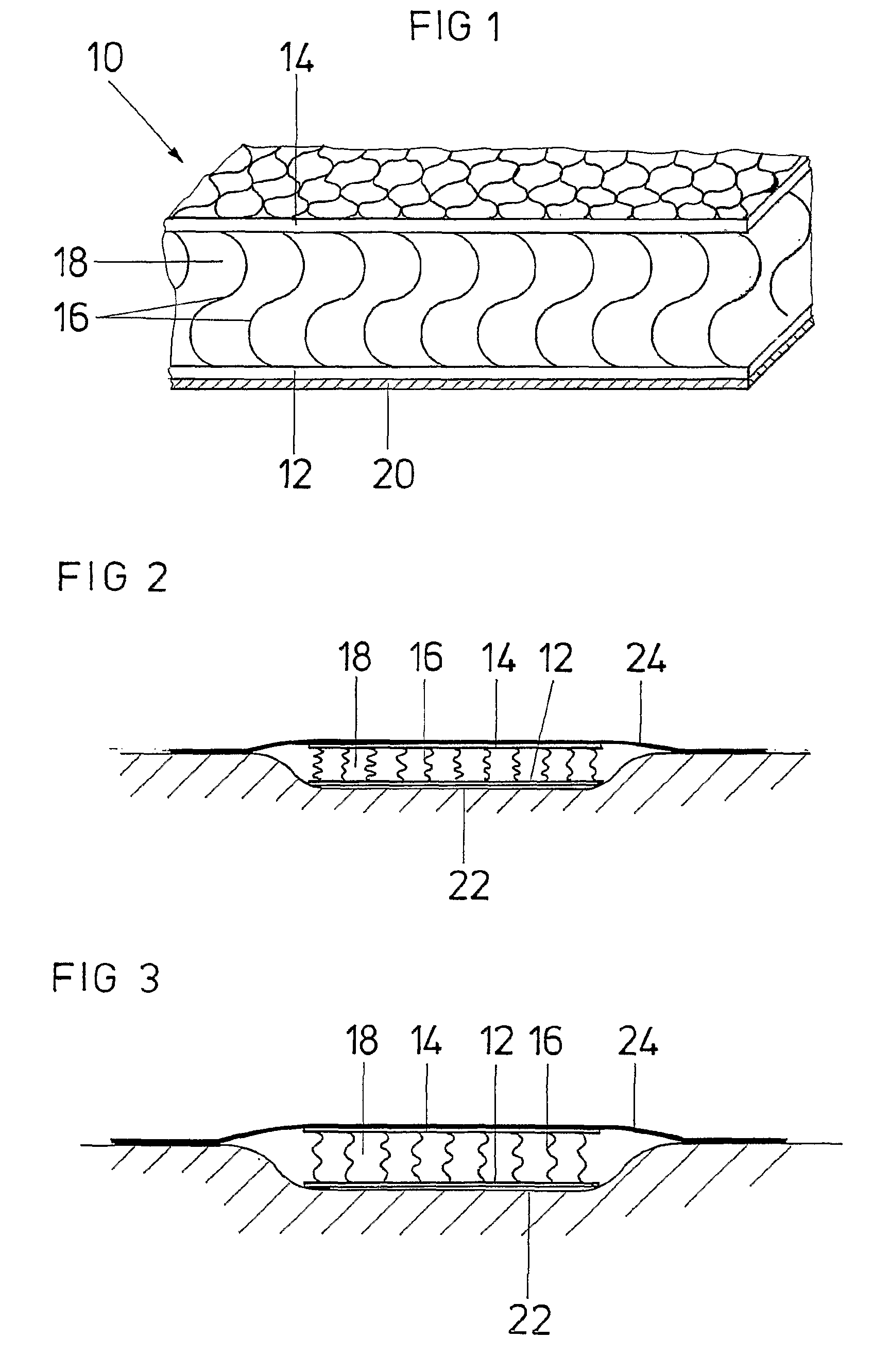

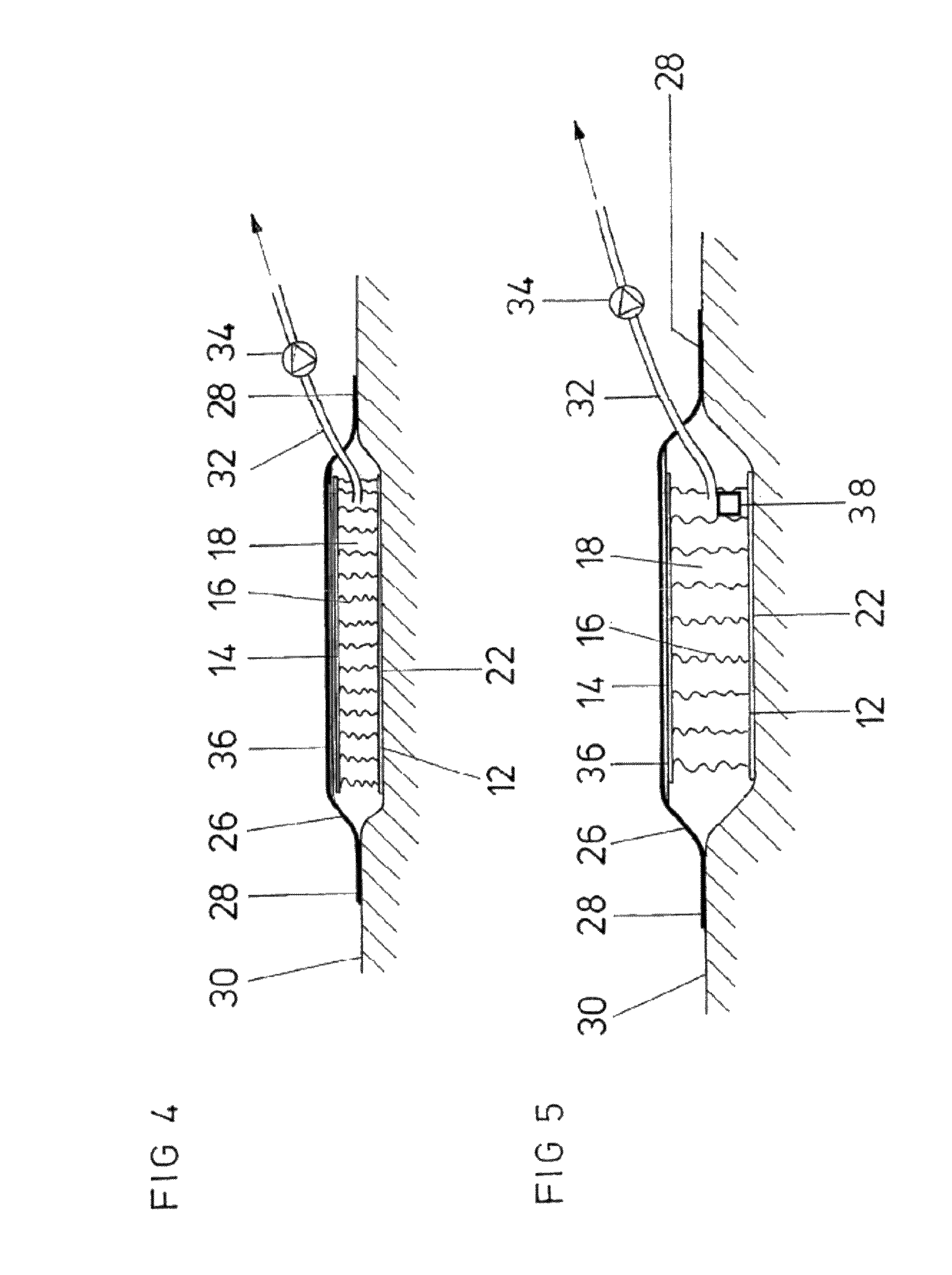

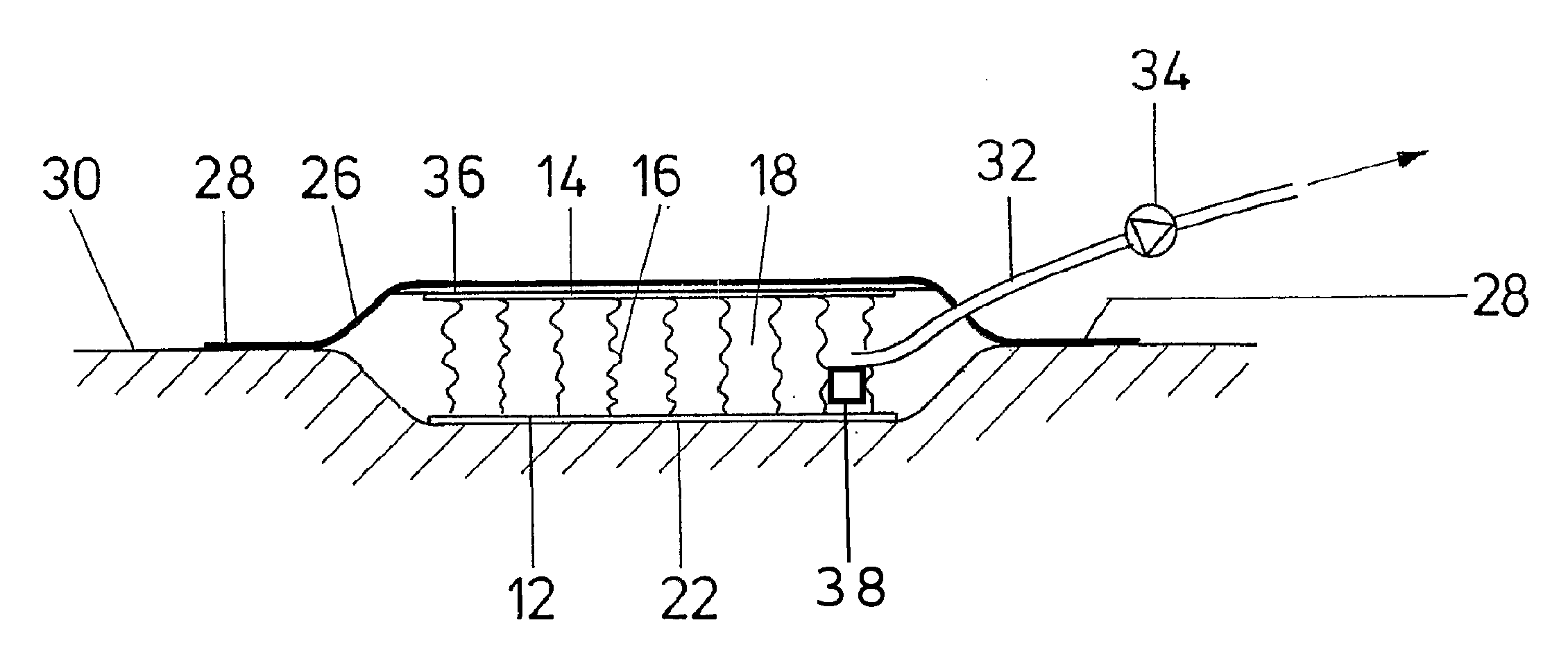

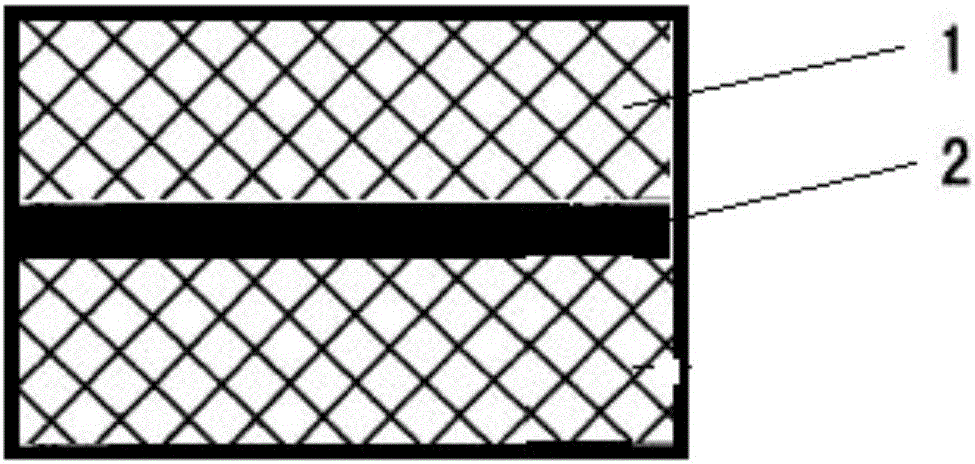

Wound treatment device

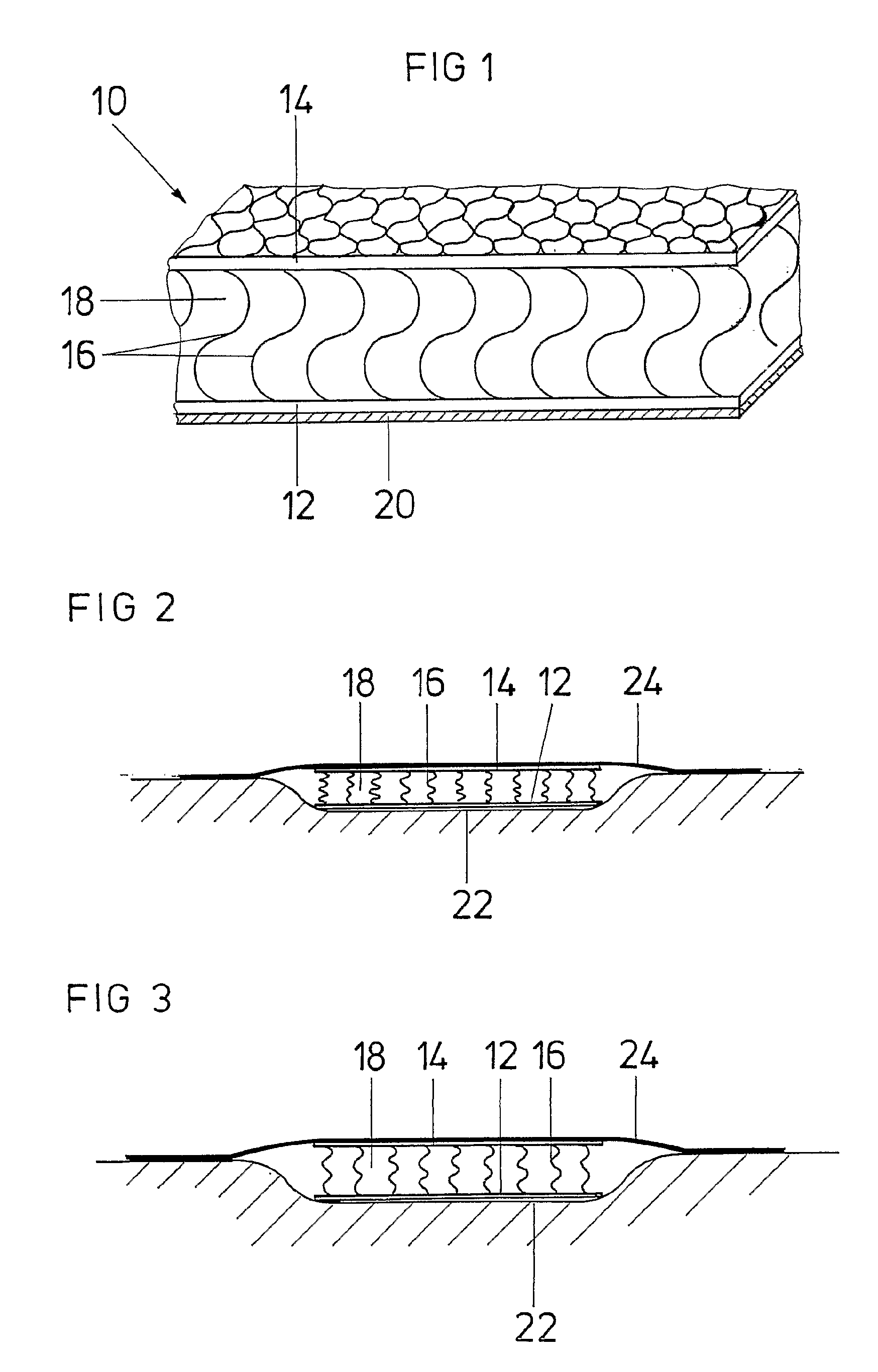

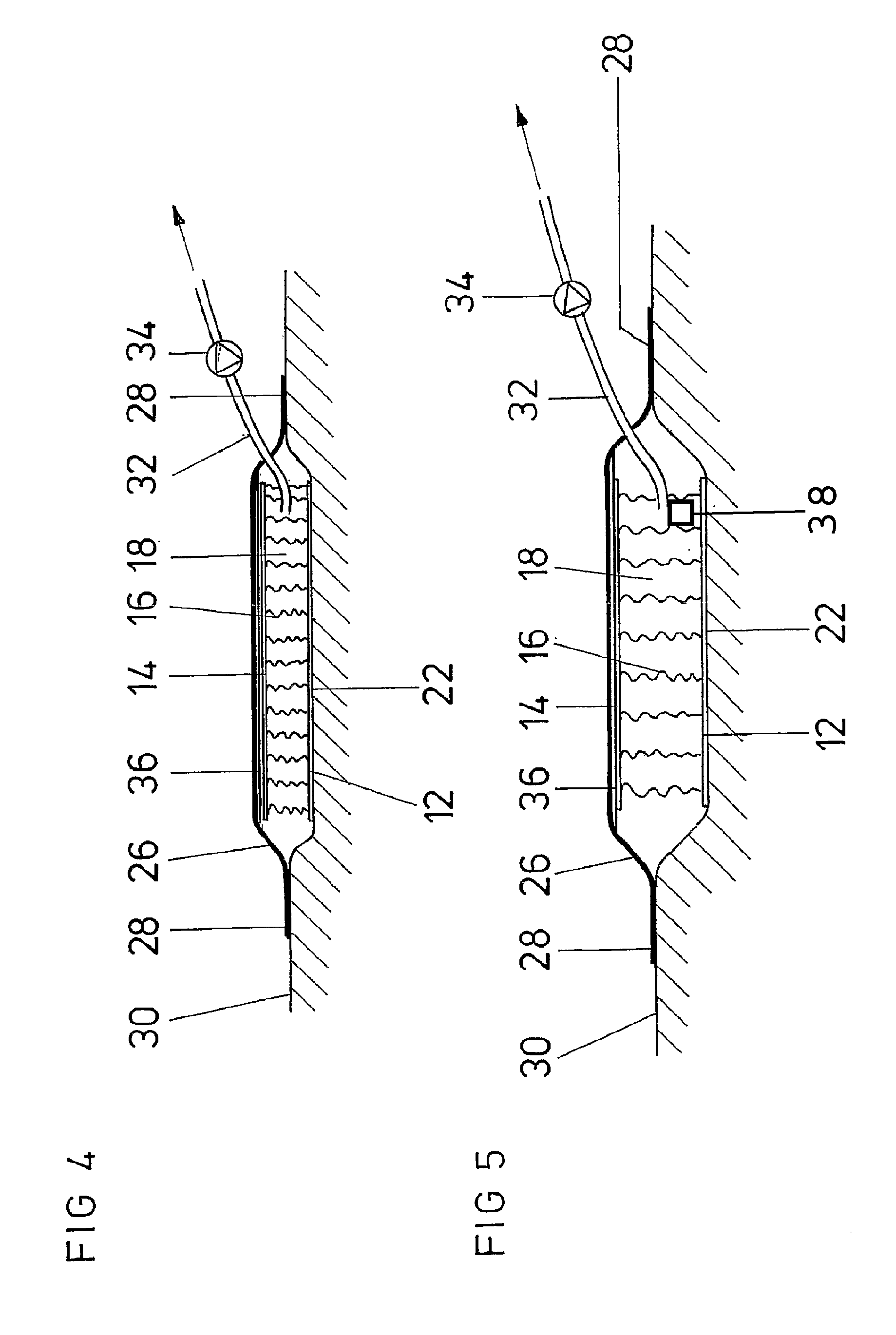

InactiveUS8376972B2Promote healingIncrease displacementOrnamental textile articlesLayered productsSurface layerWound surface

A wound treatment device comprises a wound surface contacting plug (10) and a cover (24) for covering the wound surface (22) and the plug (10), wherein said plug (10) consists of a flat textile isolating material comprising at least one first surface layer (12), one second surface layer (14) and one intermediate space (18) arranged between said surface layers (12, 14). At least the first surface layer (12) is provided with a biocompatible surface and a structure which enables a liquid to pass and prevents a wound tissue from growing in said structure. The intermediate space (18) is provided with isolating threads (16) elastically holding the first surface layer (12) and the second surface layer at a certain distance from each other.

Owner:T J SMITH & NEPHEW

Wound treatment device

ActiveUS20130116635A1Increase displacementPrevents in-growthOrnamental textile articlesLayered productsSurface layerWound surface

A wound treatment device comprises a wound surface contacting plug and a cover for covering the wound surface and the plug, wherein said plug consists of a flat textile isolating material comprising at least one first surface layer, one second surface layer and one intermediate space arranged between said surface layers. At least the first surface layer is provided with a biocompatible surface and a structure which enables a liquid to pass and prevents a wound tissue from growing in said structure. The intermediate space is provided with isolating threads elastically holding the first surface layer and the second surface layer at a certain distance from each other.

Owner:T J SMITH & NEPHEW

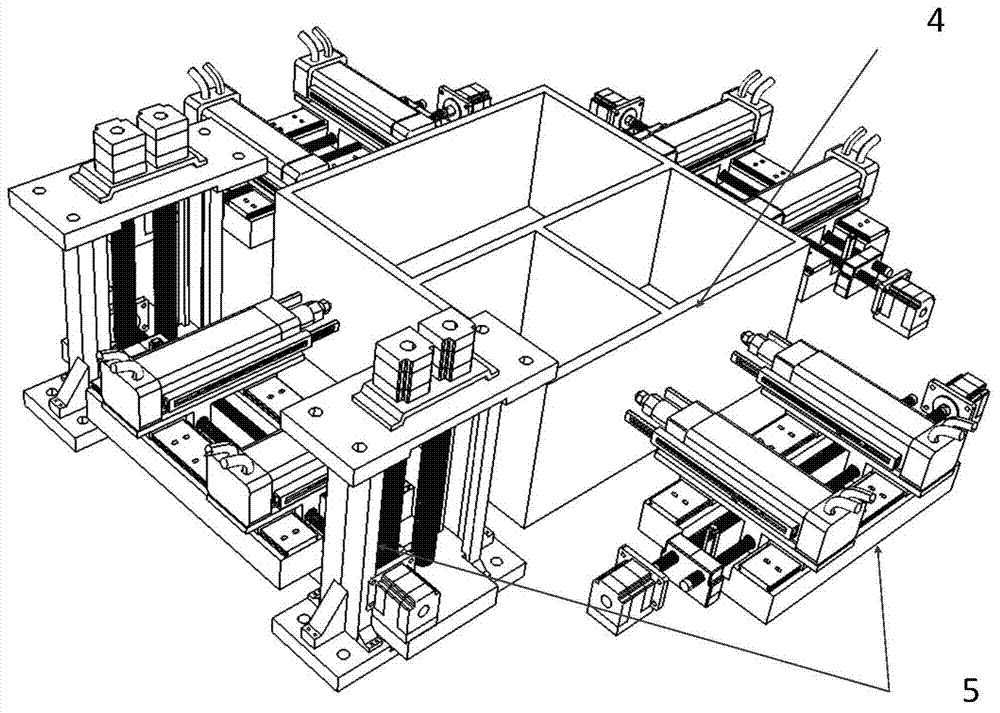

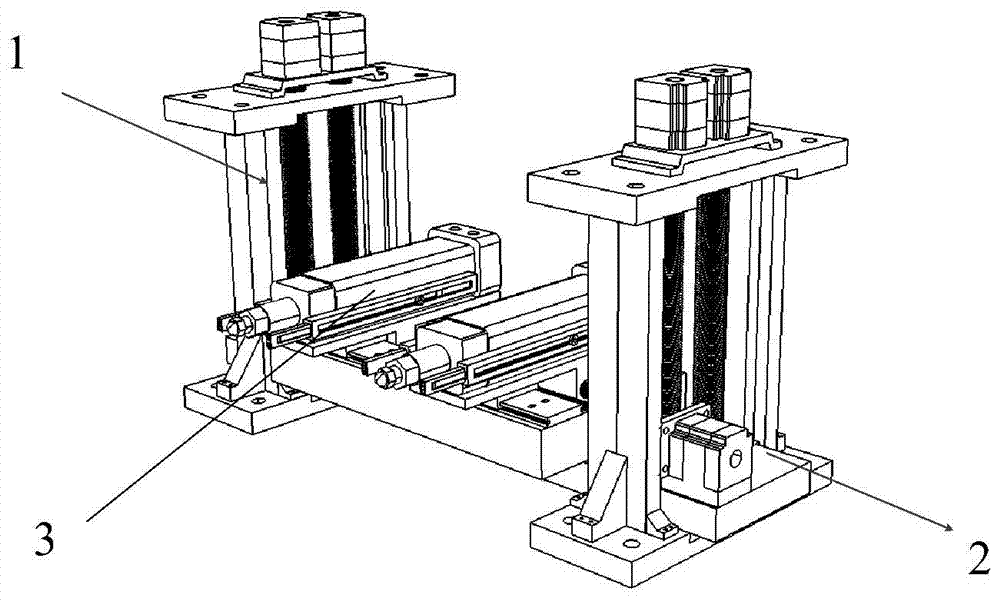

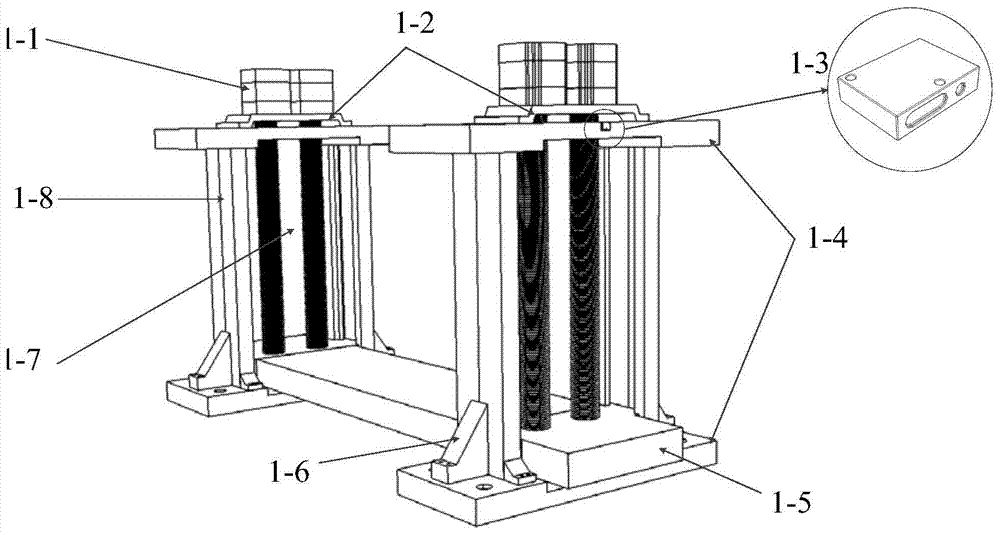

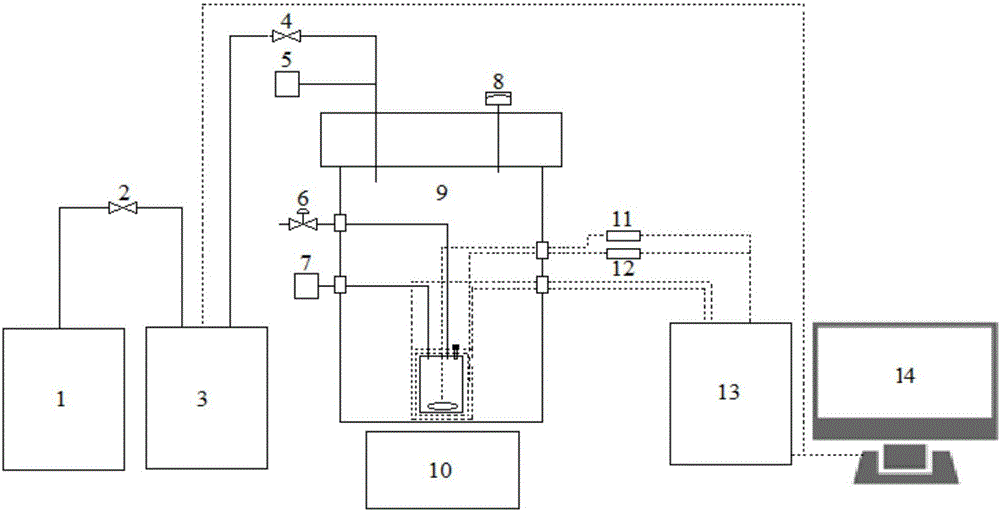

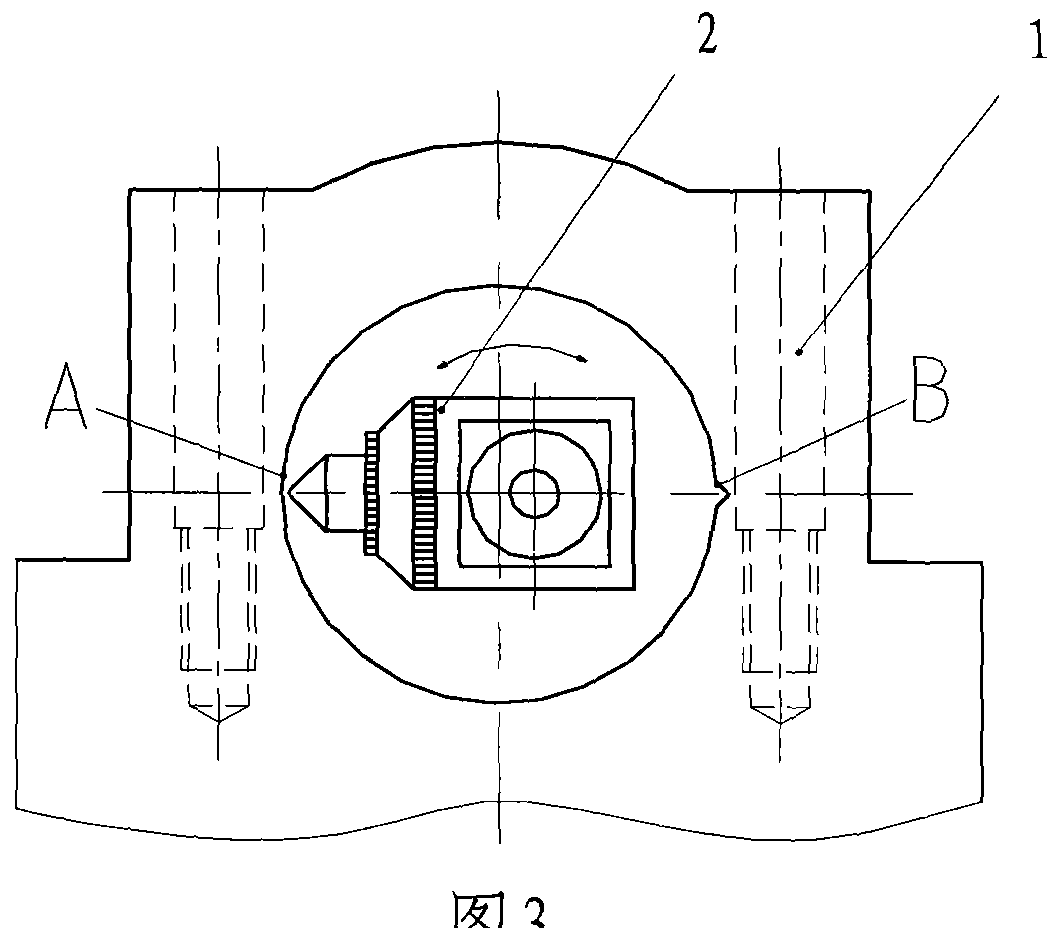

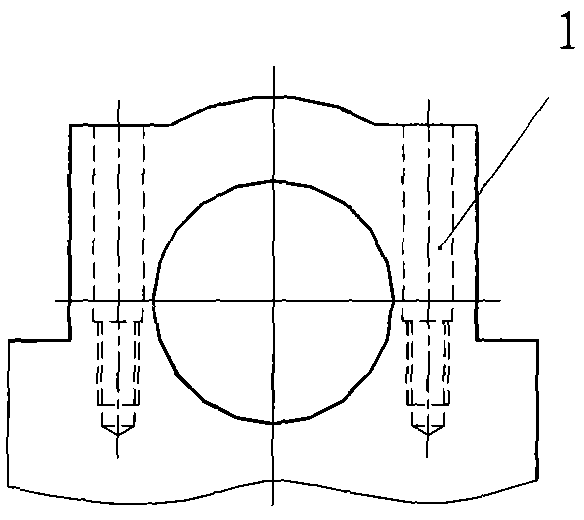

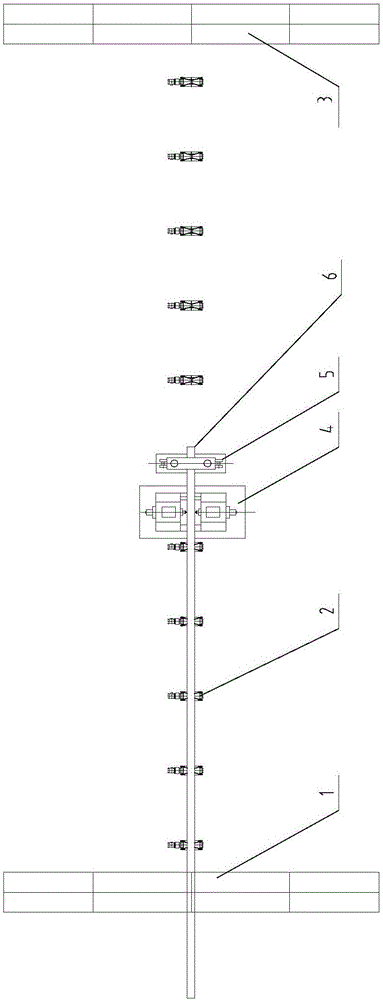

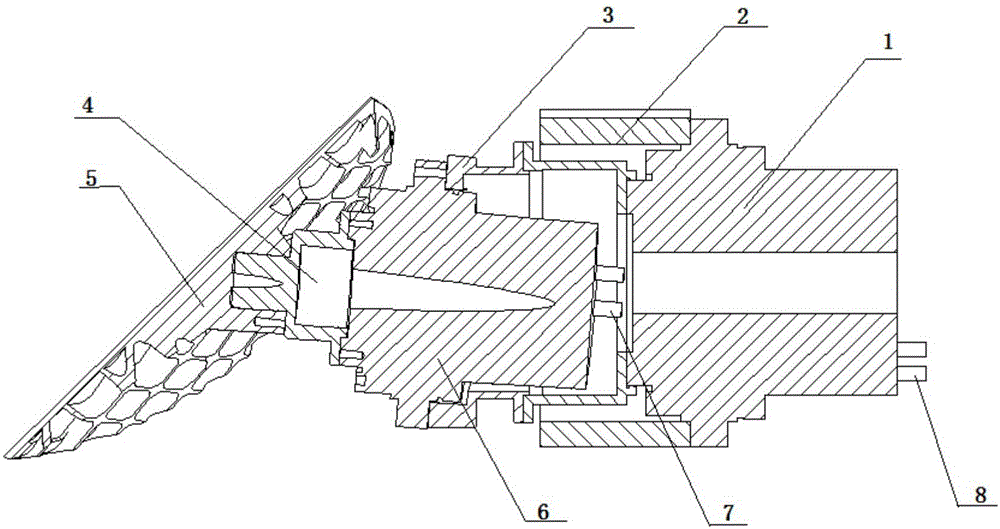

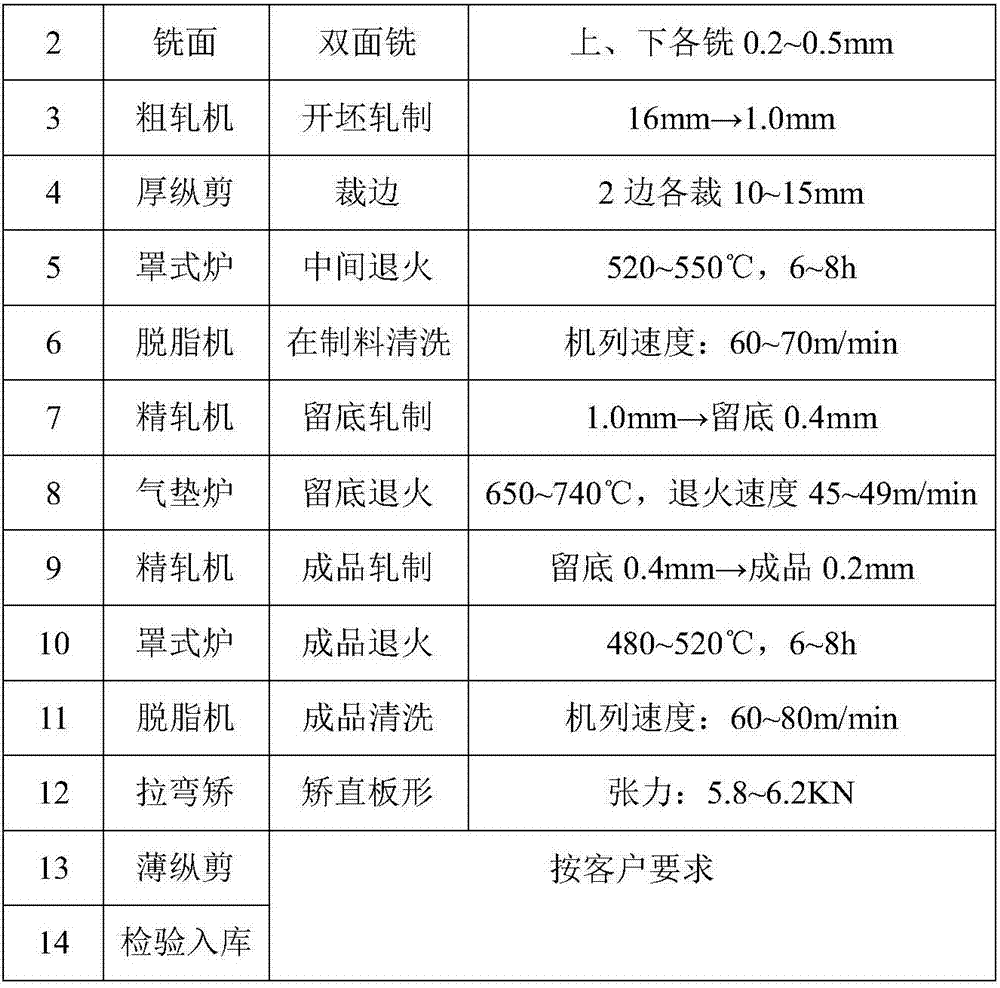

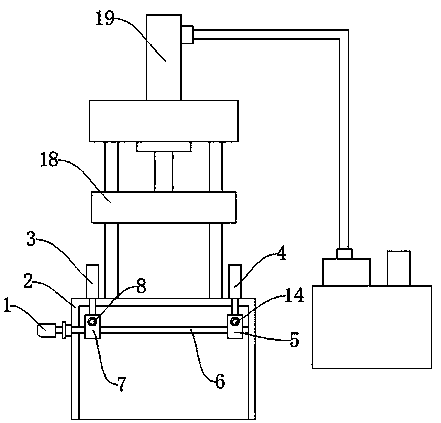

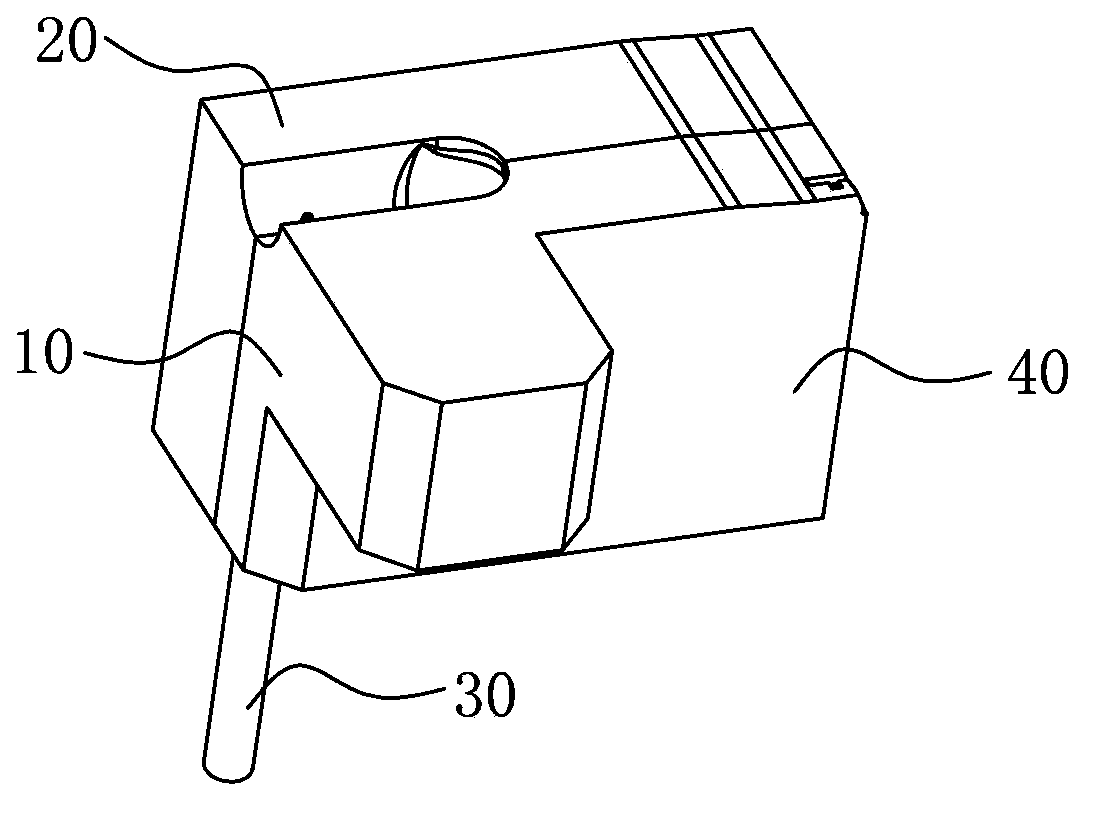

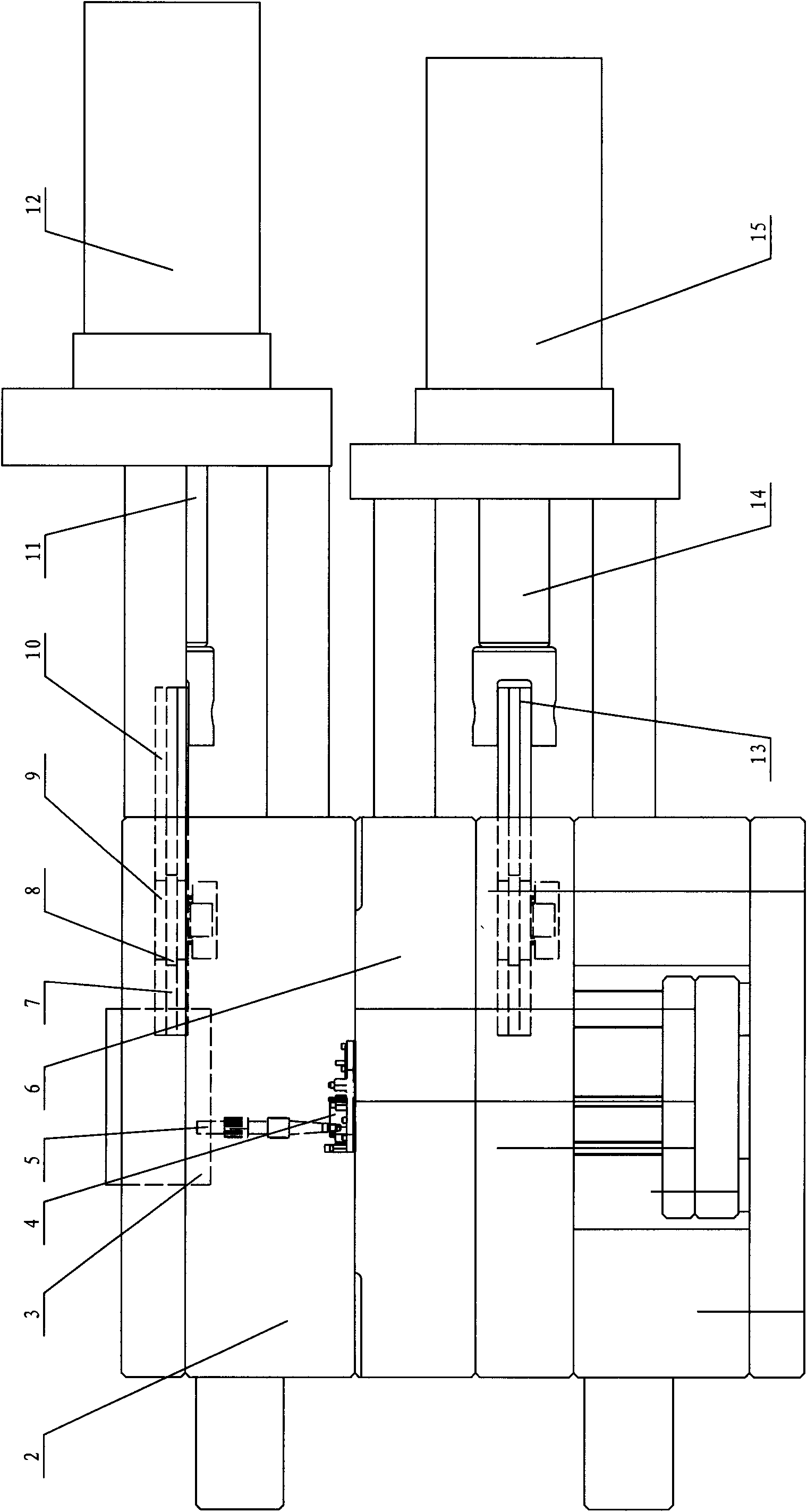

Flexible clamp device for weak rigidity workpieces

InactiveCN103481094AGuaranteed ToleranceReduce distortionMeasurement/indication equipmentsLarge fixed membersMachining vibrationsPersonal computer

The invention provides a flexible clamp device for weak rigidity workpieces. The flexible clamp device for the weak rigidity workpieces is formed by a plurality of clamp assemblies jointly; every clamp assembly is formed by an execution module, an information collection module and a control module; every execution module comprises a clamping mechanism, a lifting mechanism and a horizontal moving mechanism; the clamping mechanisms are driven by the lifting mechanisms and the horizontal moving mechanisms to ascend, descend and horizontally move; every lifting mechanism comprises a lifting platform; the horizontal moving mechanisms are fixedly arranged on the lifting mechanisms; the clamping mechanisms are fixedly arranged on the horizontal moving mechanisms; every information collection module comprises a vibration displacement sensor, a vertical displacement sensor, a horizontal displacement sensor and a pressure sensor; every control module comprises an information collection card, a PC (Personal Computer) machine and a controller; the information collection cards are connected with the sensors; the PC machines are used for processing information of the information collection modules; the operation of the mechanisms is controlled by the controllers. According to the flexible clamp device for the weak rigidity workpieces, the size of clamping force and the position the clamping force taking effect on can be adjusted automatically, the integral deformation of the workpieces is reduced, and meanwhile the machining vibration of the workpieces is restrained and the milling stability of the workpieces is improved.

Owner:WUHAN UNIV OF TECH

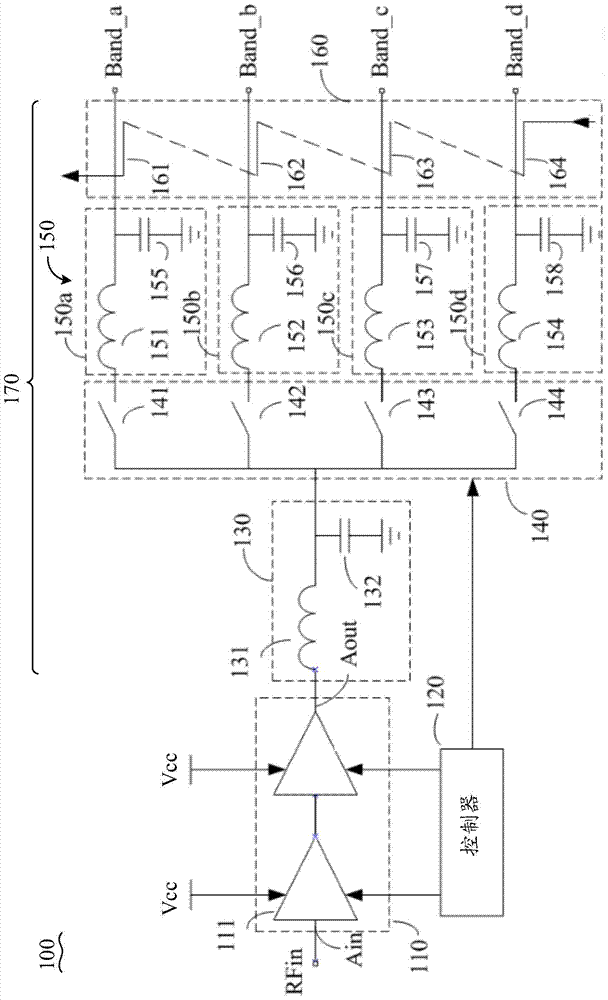

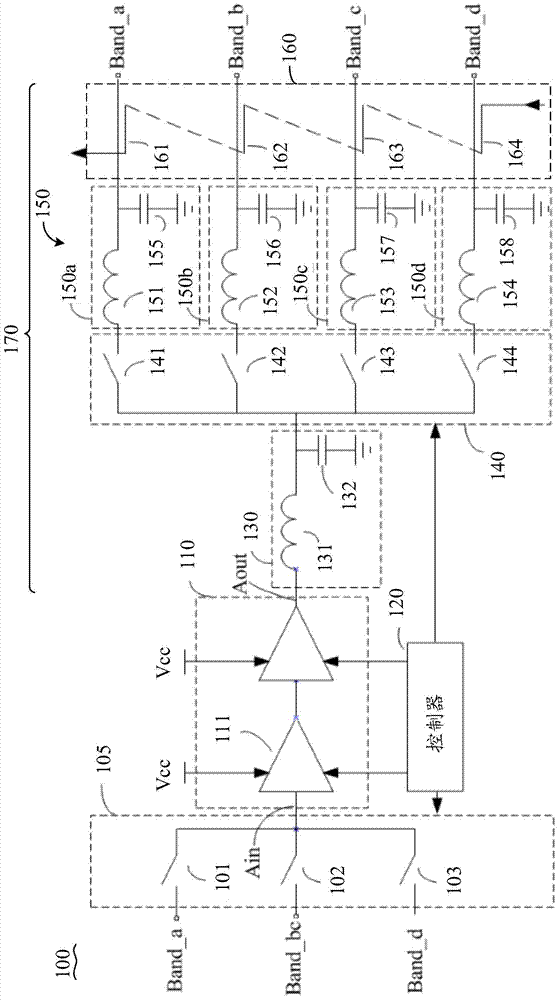

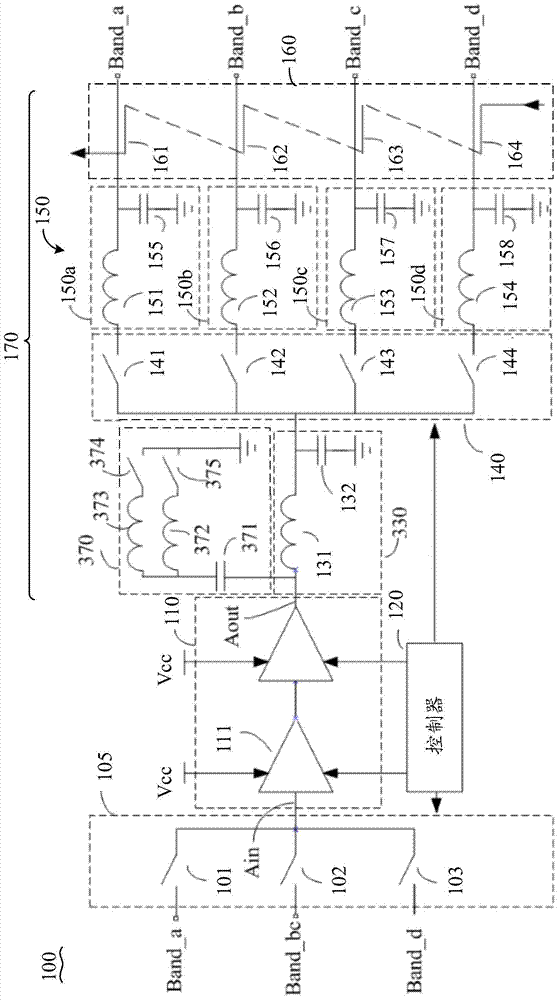

Multimode multi-frequency power amplifier

ActiveCN104753476AMiniaturizationLow costPower amplifiersAmplifier combinationsAudio power amplifierControl signal

Provided is a multi-mode multi-frequency power amplifier (100), comprising: a controller (120) for receiving and outputting control signals based on external signals; a broadband amplifier channel (110) for receiving single-frequency or multi-frequency radio-frequency (RF) signals via an input end, conducting power amplification on the RF signals, and outputting the signals via an output end; a fundamental wave impedance convertor (170) comprising a first segment (130) shared by RF signals in respective frequency bands, a second segment (150) dedicated for RF signals in each frequency band, and a switch circuit (140), the switch circuit (140) being controlled by the controller (120) to switchably separate the RF signals with amplified power to the second segment (150) for multiple outputs.

Owner:LANSUS TECH INC

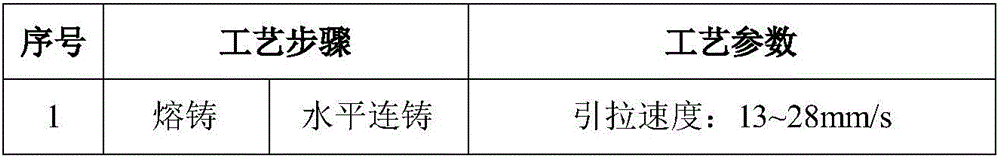

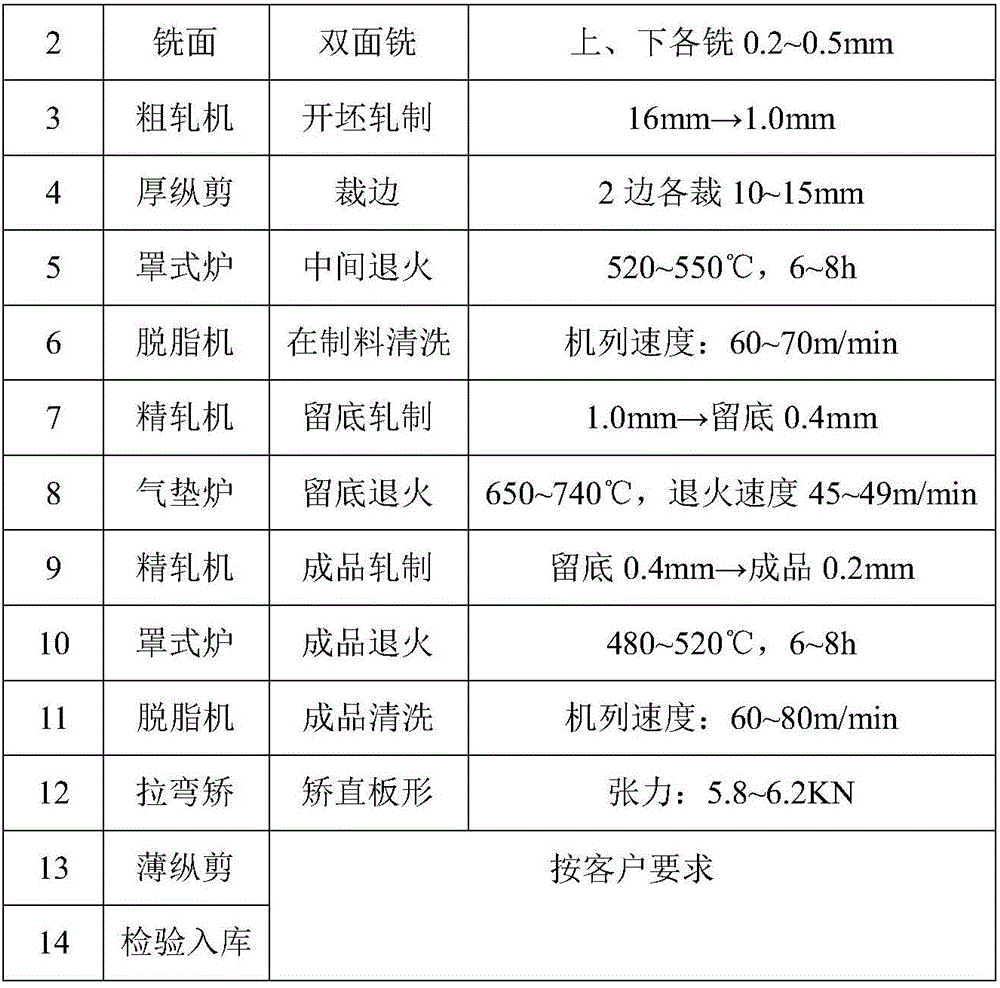

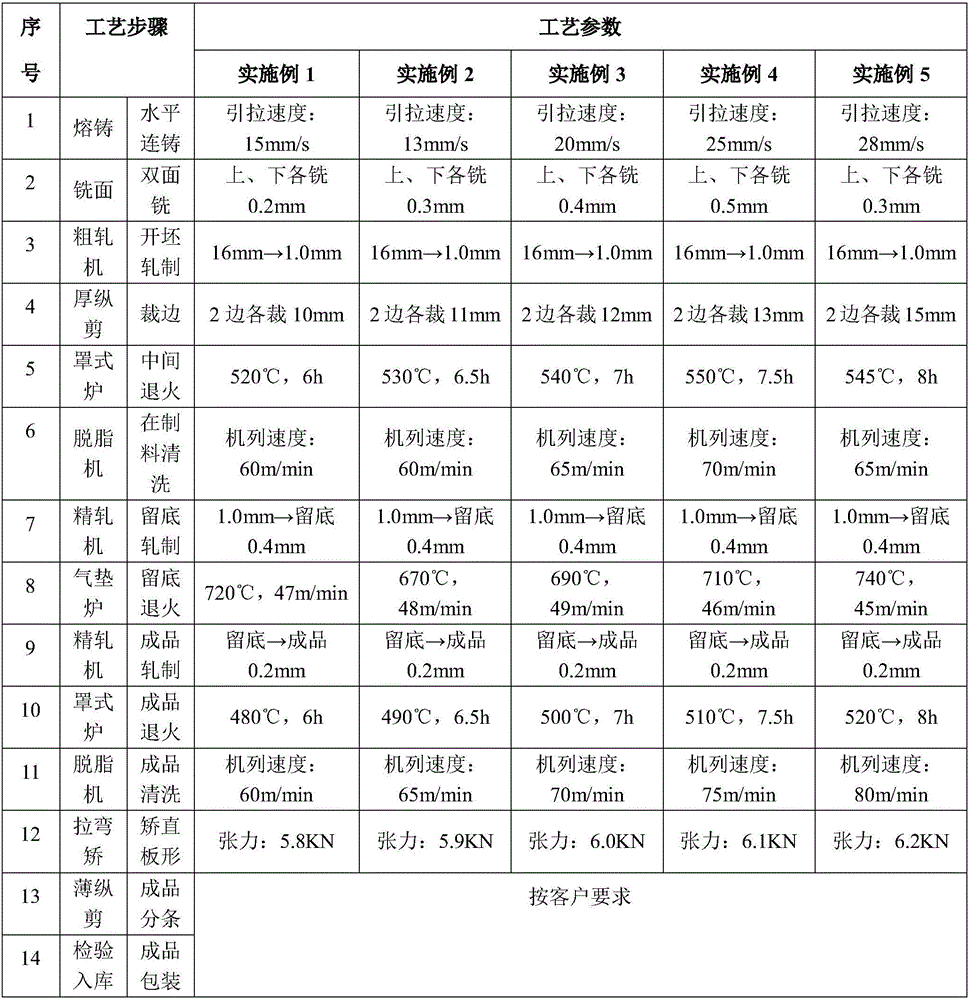

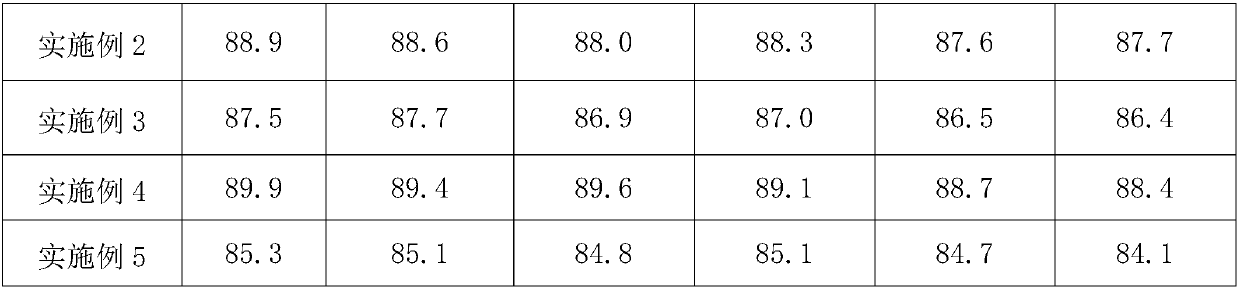

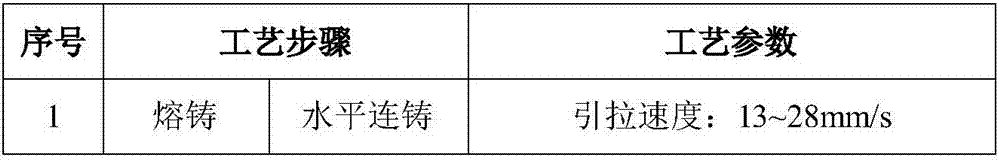

High-performance tin-phosphor bronze strip and production method thereof

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

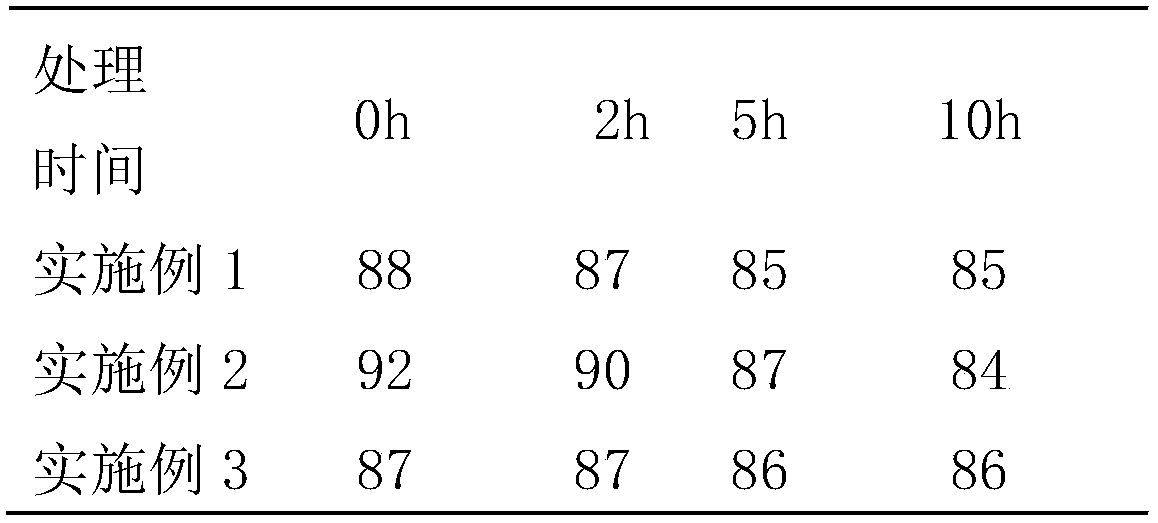

Compact chlorine-resistant composite nano-filtration membrane preparation method

InactiveCN107899434AImprove chlorine resistanceImprove interception effectSemi-permeable membranesMembranesFiltration membraneHydroxy compound

The invention relates to a compact chlorine-resistant composite nano-filtration membrane and a preparation method thereof, wherein the compact chlorine-resistant composite nano-filtration membrane comprises a non-woven fabric, a polysulfone support layer and a chlorine-resistant separation layer. According to the present invention, the polypiperazine amide nano-filtration membrane with excellent chlorine resistance is prepared by selecting conventional piperazine / trimesoyl chloride interfacial polymerization, and the compact separation layer with excellent chlorine resistance is formed by using the reaction between the residual acyl chloride at the initial stage of the interfacial polymerization and a hydroxyl-containing macromolecule membrane material with excellent chlorine resistance; the selected membrane materials are chlorine resistant, such that the prepared nano-filtration membrane integrates the high inorganic salt removal rate of the conventional poly aromatic amide compositenano-filtration membrane and the excellent sodium hypochlorite tolerance of the conventional polypiperazine amide composite nano-filtration membrane; and the production method is simple, and the prepared compact chlorine-resistant composite nano-filtration membrane is suitable for wastewater treatment and other fields.

Owner:ZHEJIANG SCI-TECH UNIV

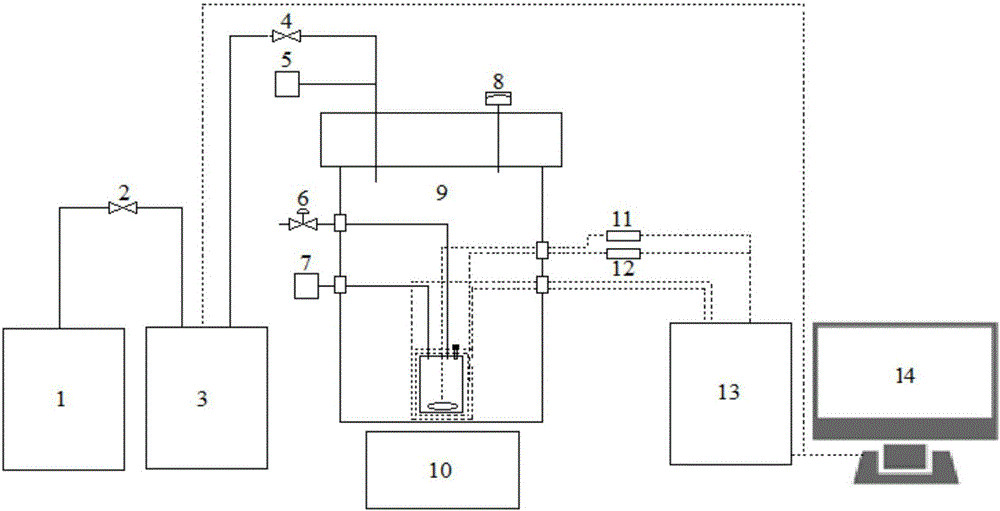

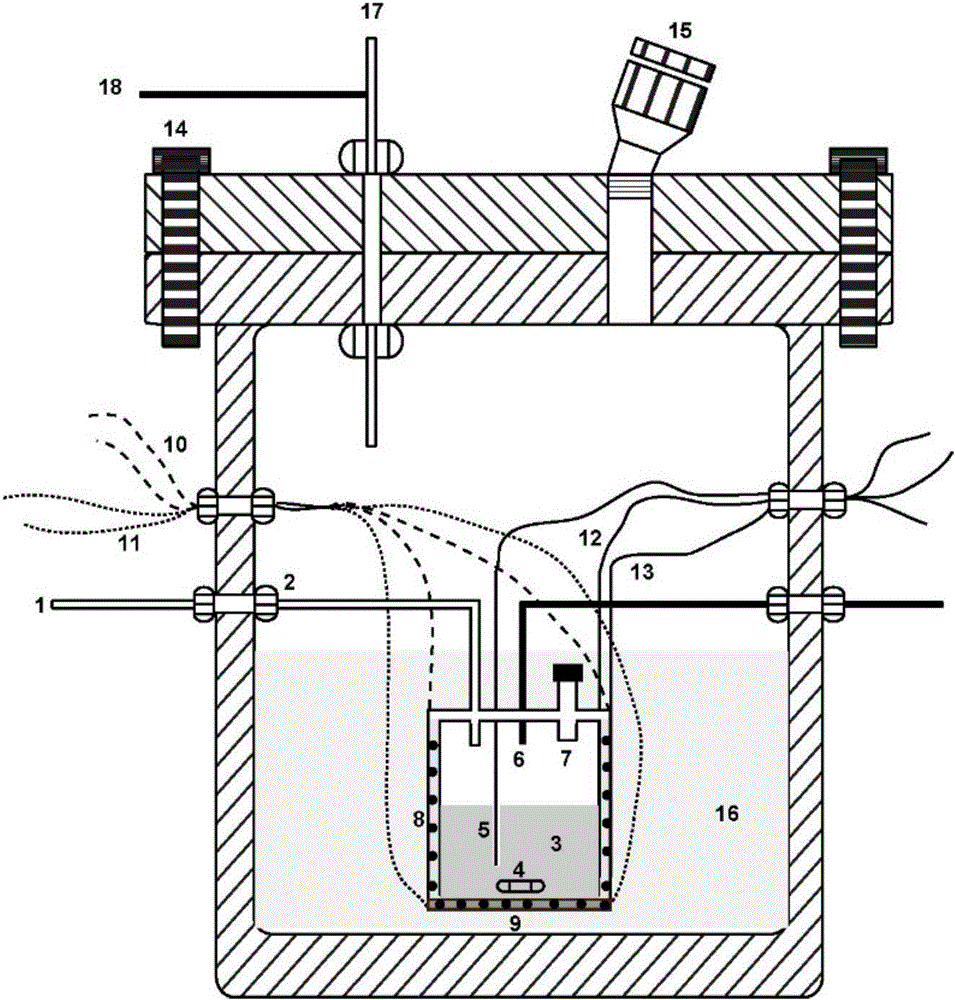

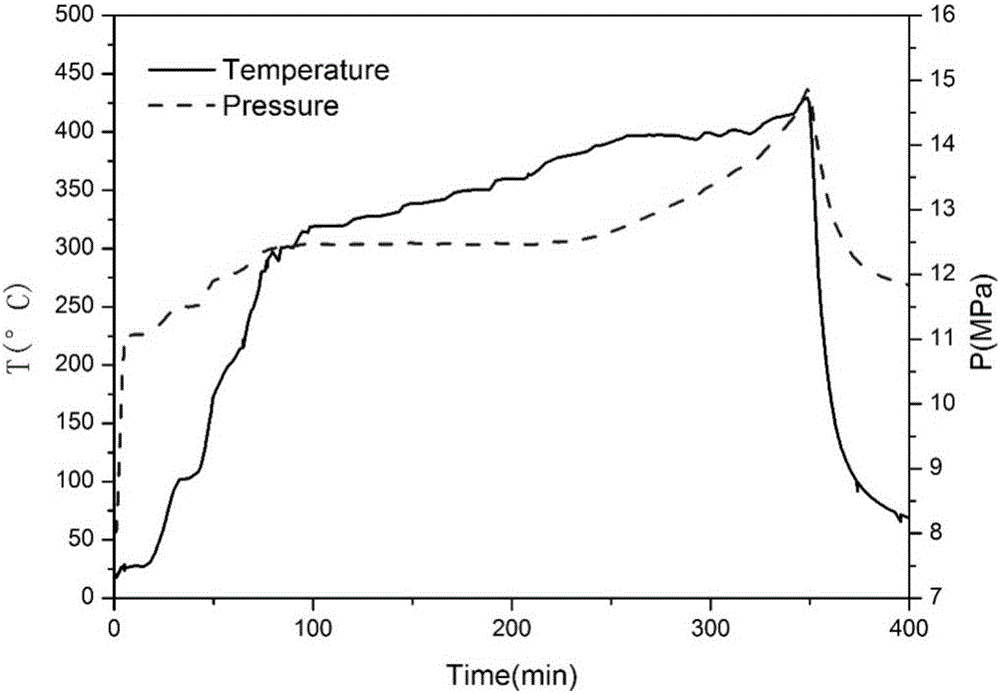

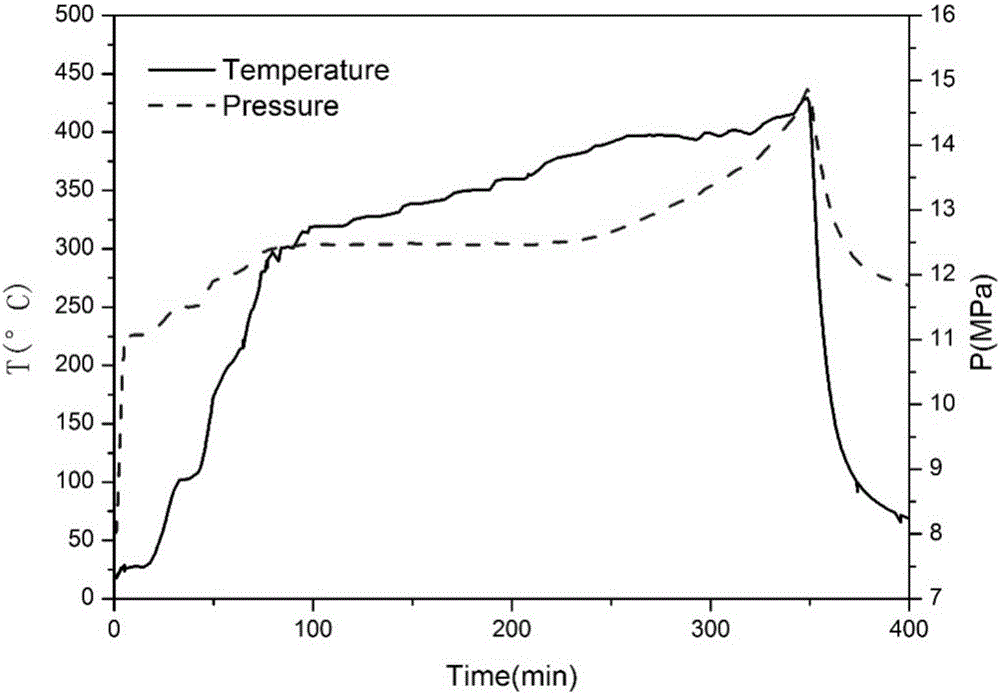

Method for thermally measuring heat insulation amount at high temperature and high pressure

InactiveCN106290462AGuaranteed ToleranceMaterial heat developmentTemperature controlThermal insulation

The invention relates to a method for thermally measuring the heat insulation amount at high temperature and high pressure. The method mainly solves the problem that a method for thermally measuring the heat insulation amount at high temperature and high pressure is not available in the prior art. According to the method for thermally measuring the heat insulation amount at high temperature and high pressure, a calorimetry test can be carried out on a device for thermally measuring the heat insulation amount according to a heat insulation mode and an isothermy mode at the temperature below 800 DEG C and the pressure below 20 MPa, the reaction process can be precisely controlled, and data can be acquired and analyzed in real time. According to the technical scheme, the device comprises a central control system, a pressure control unit, a temperature control unit and a reaction still, the problems are well solved, and method can be used for thermally measuring the heat insulation amount at high temperature and high pressure.

Owner:CHINA PETROLEUM & CHEM CORP +1

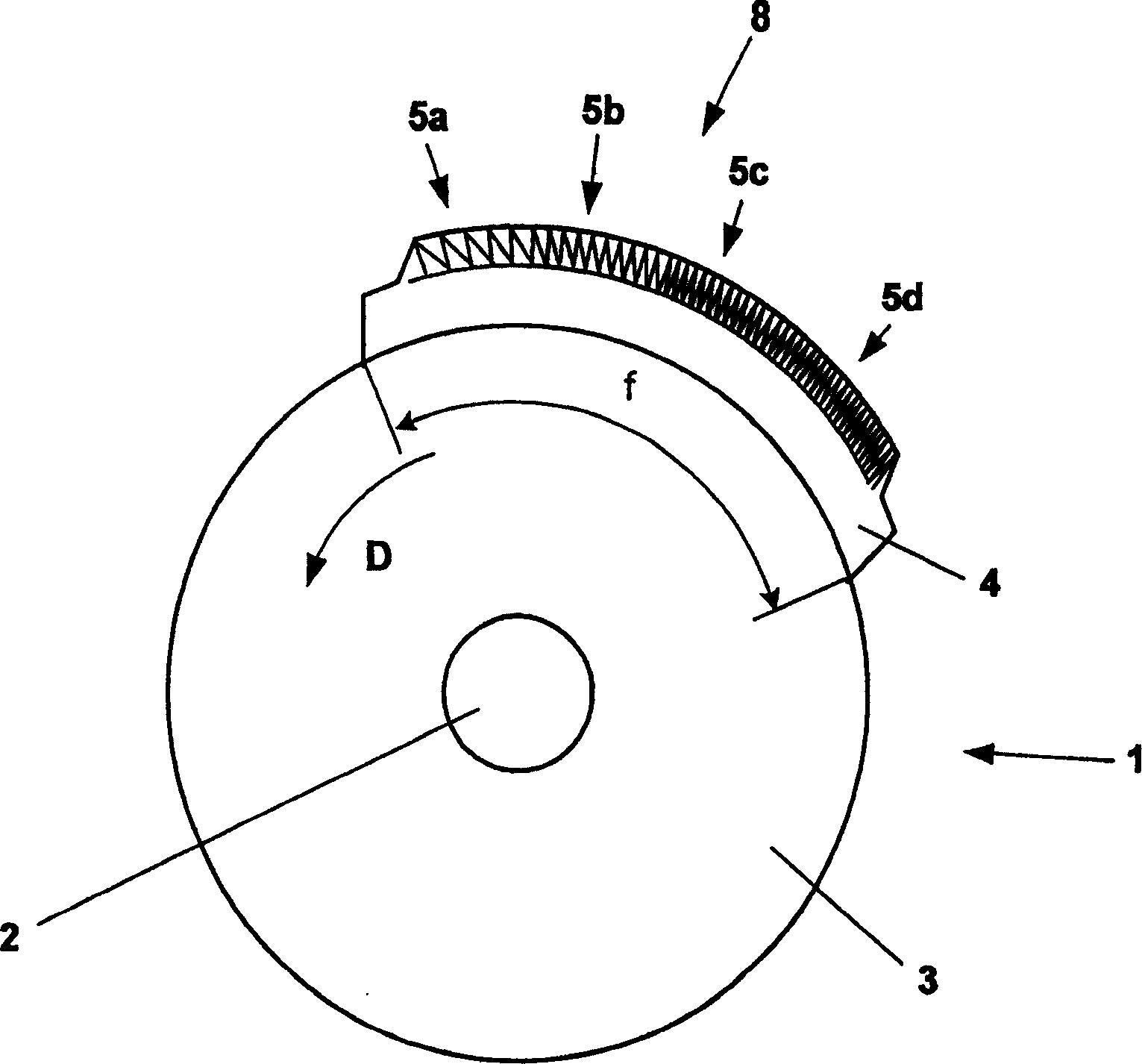

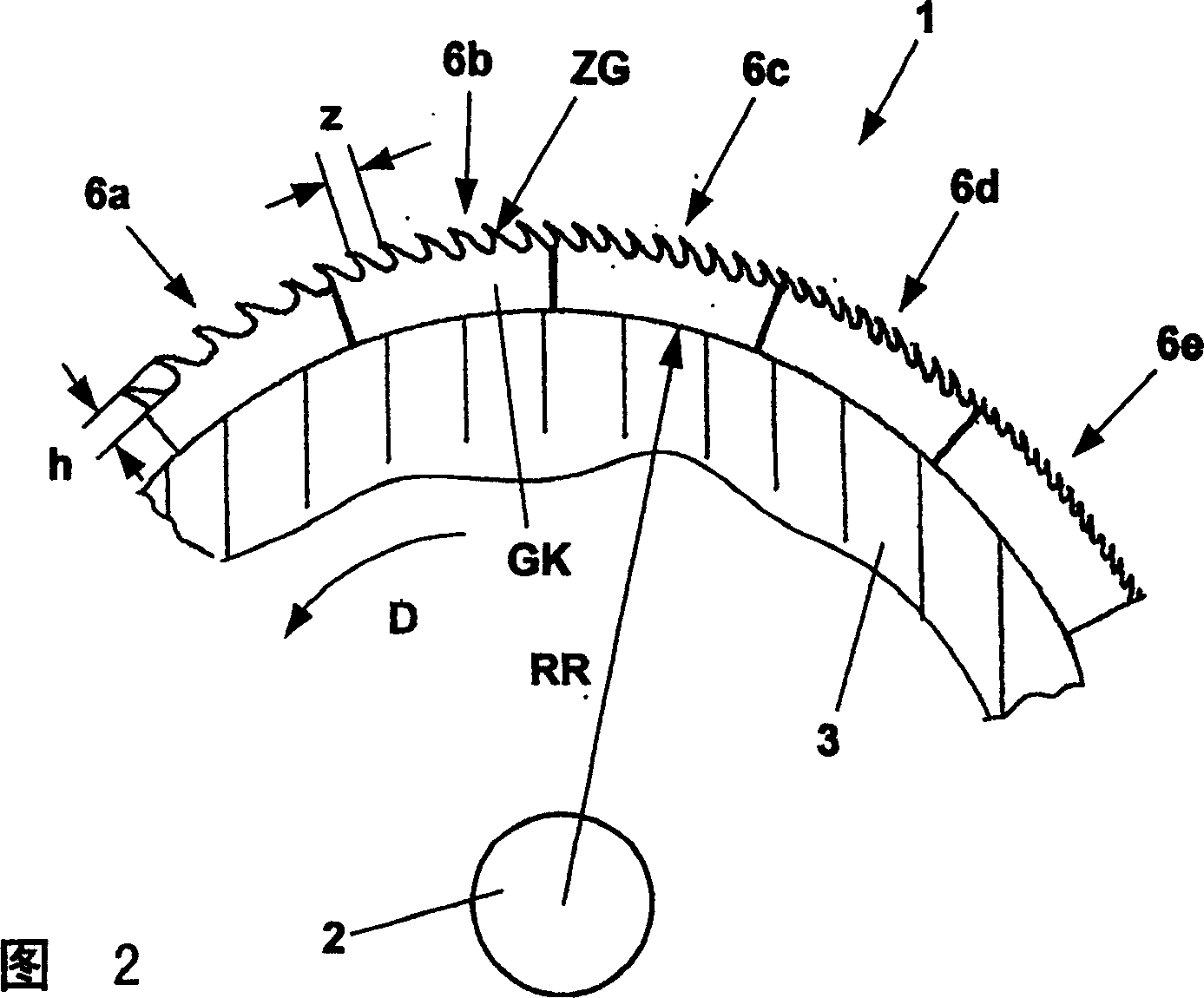

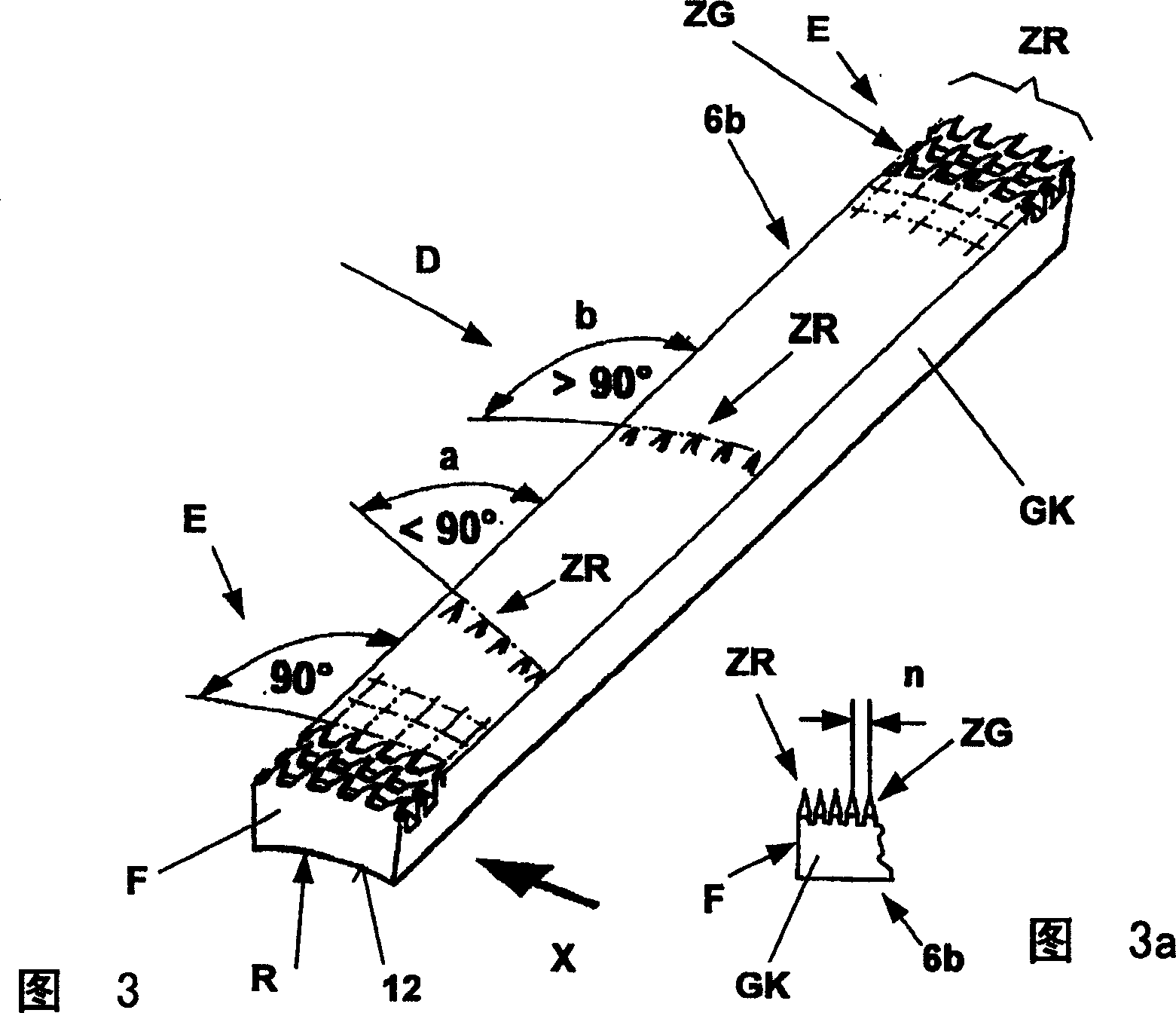

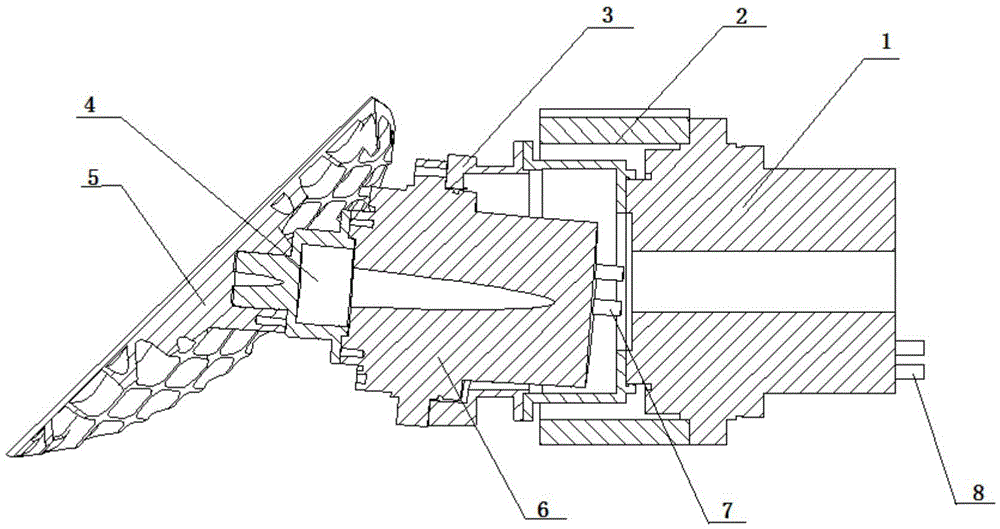

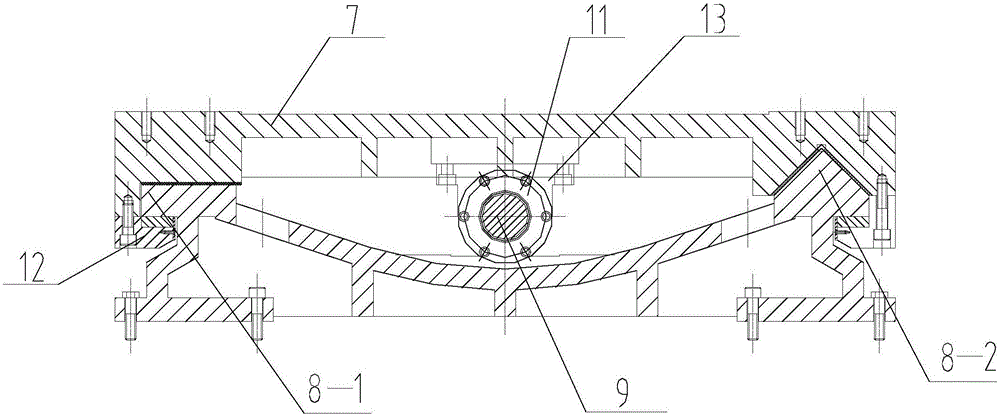

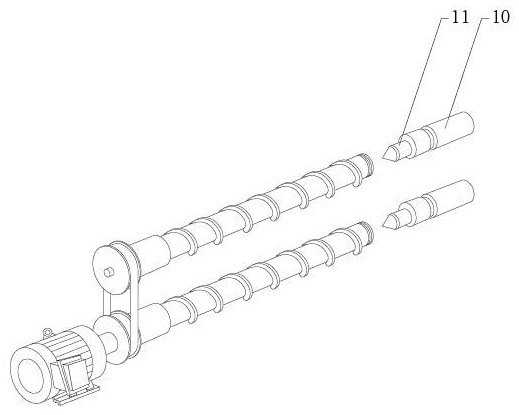

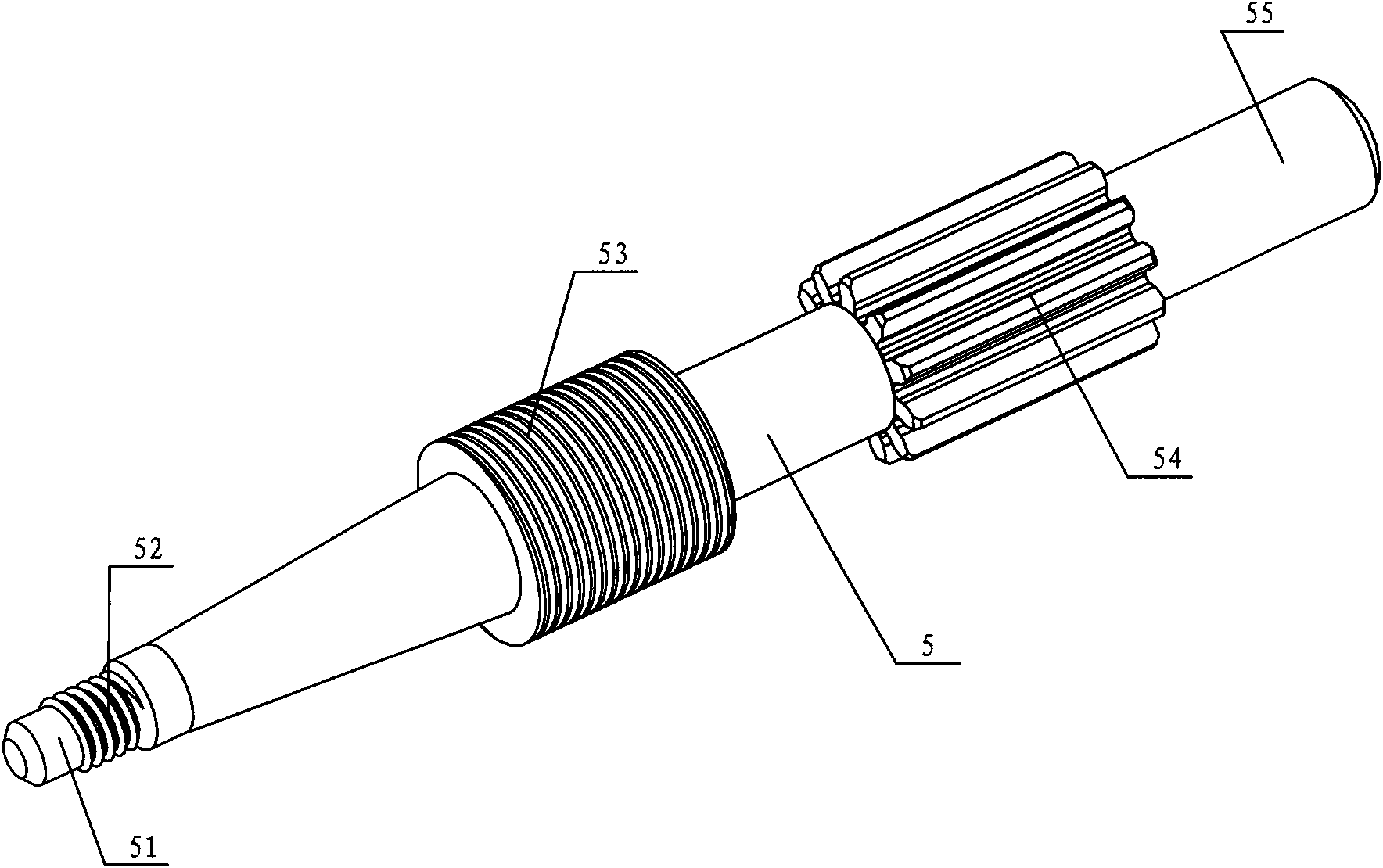

Combing cylinder with clothing elements

InactiveCN1616728AImprove combing effectCombing Effect ExpectationsCombing machinesCarding machinesEngineeringSerration

The invention relates to a circular comb (1) for a combing machine with a circular comb carrier (3), which is fastened on a shaft (2) in a torsion-proof manner and on a part of its circumference, the sawtooth fittings Or the clothings (5a-5d) are fastened to the base body (4, GK). In order to simplify the assembly and disassembly of such toothed wires, and to expand the variation possibilities of the toothed wires themselves, it is proposed that the base body (GK) and the toothed wires (ZR) be a single piece, and in the direction of rotation of the circular comb (1) As seen in (D), it consists of at least two consecutive clothing elements (6a-6e).

Owner:MASCHINENFABRIK RIETER AG

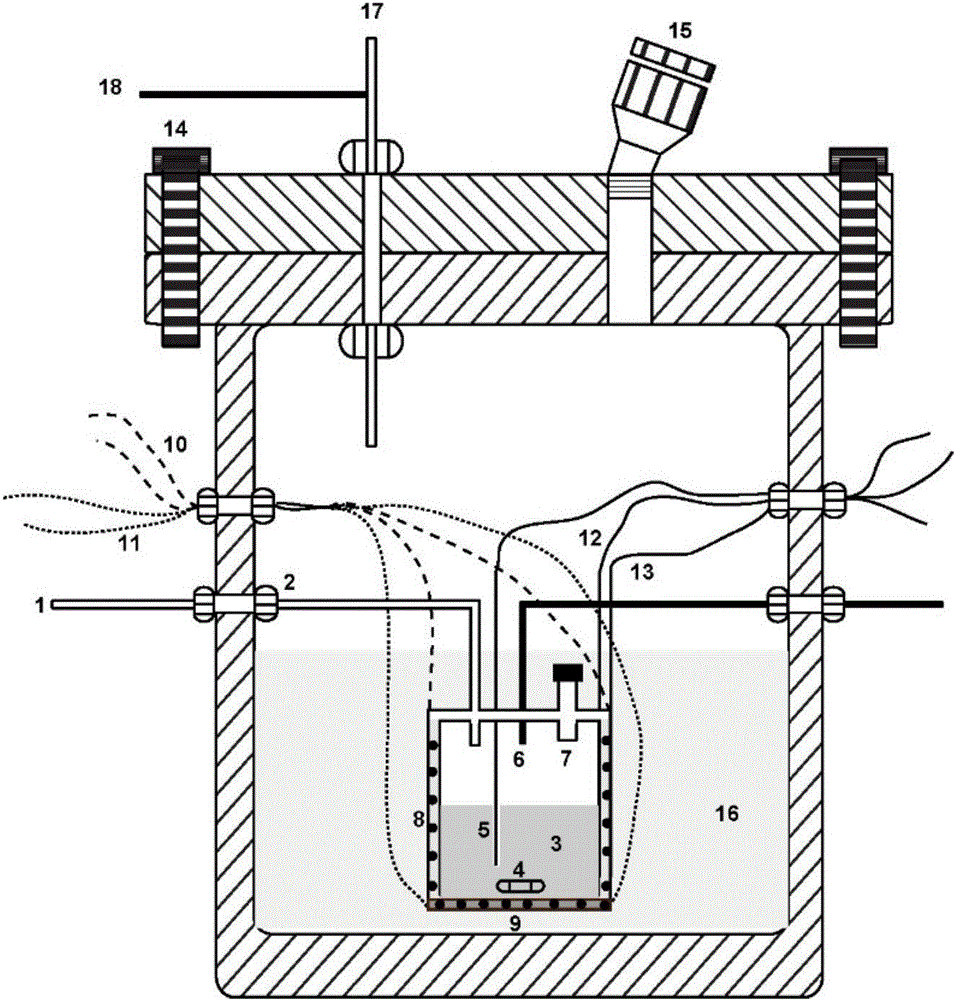

Device for carrying out adiabatic calorimetric measurement at high temperature and high pressure

The invention relates to a device for carrying out adiabatic calorimetric measurement at high temperature and high pressure, mainly aiming at solving the problem that methods for carrying out adiabatic calorimetric measurement at high temperature and high pressure do not exist yet in the prior art. The device for carrying out adiabatic calorimetric measurement at high temperature and high pressure can carry out calorimetric testing at 800 DEG C and 20MPa according to an adiabatic model and an isothermal model and can implement precise control on the reaction process and collect and analyze data in real time. The device comprises a central control system, a pressure control unit, a temperature control unit and a reaction kettle. The device has the effect of better solving the problem and can be used for carrying out adiabatic calorimetric measurement at high temperature and high pressure.

Owner:CHINA PETROLEUM & CHEM CORP +1

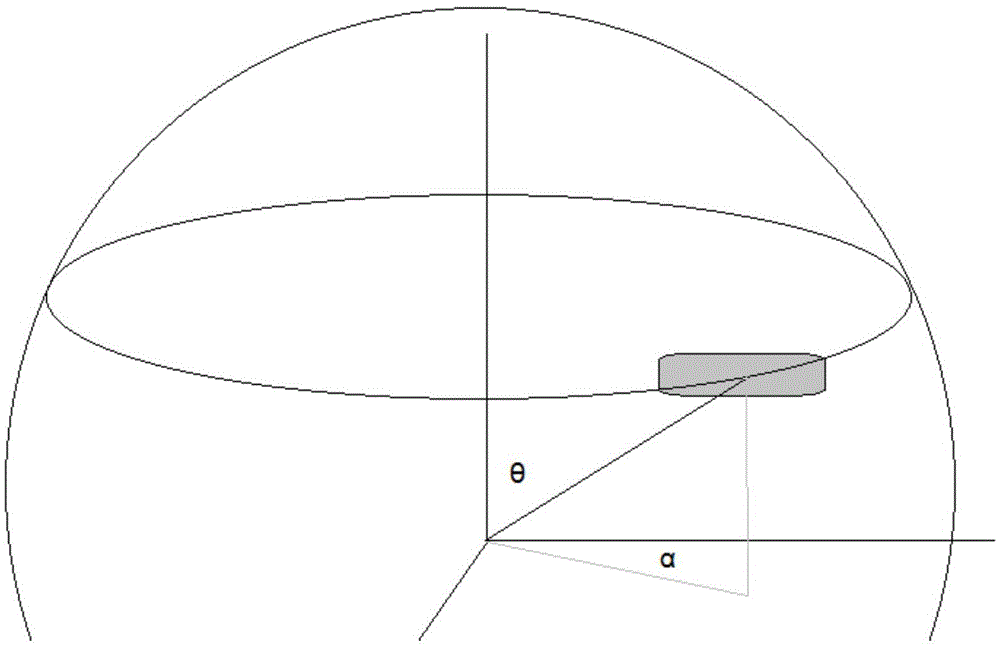

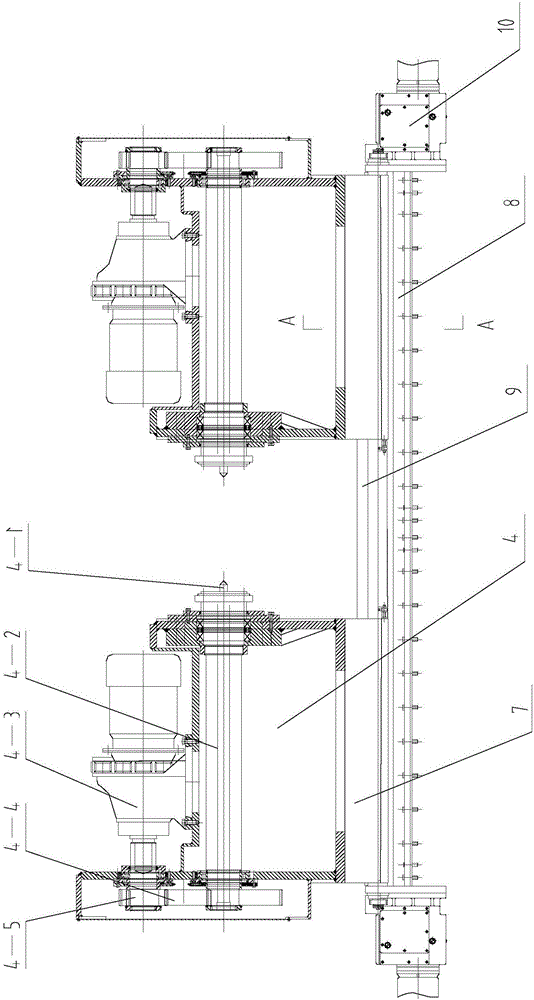

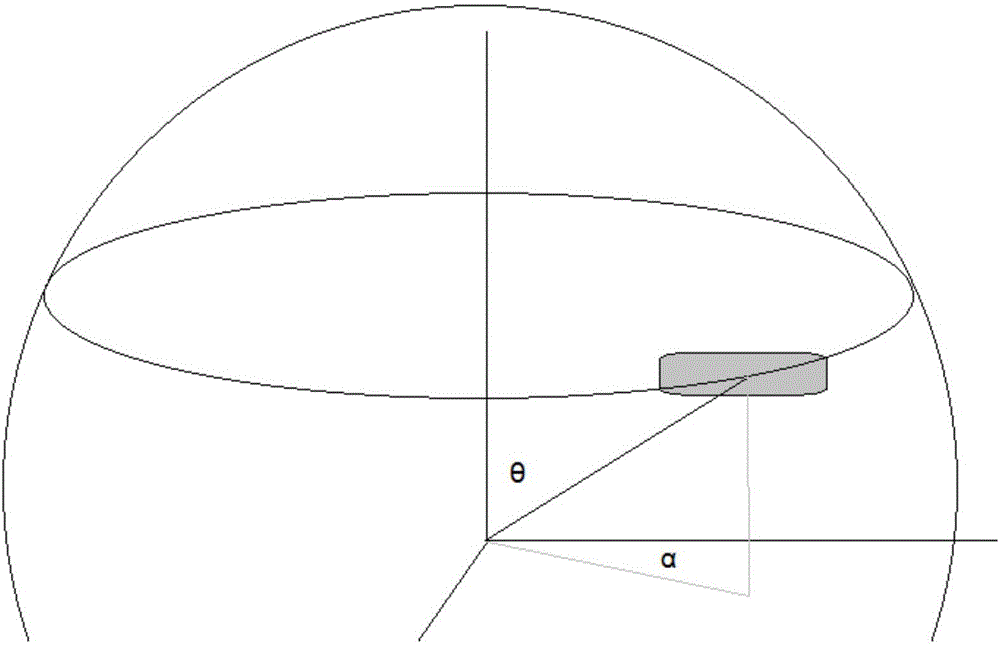

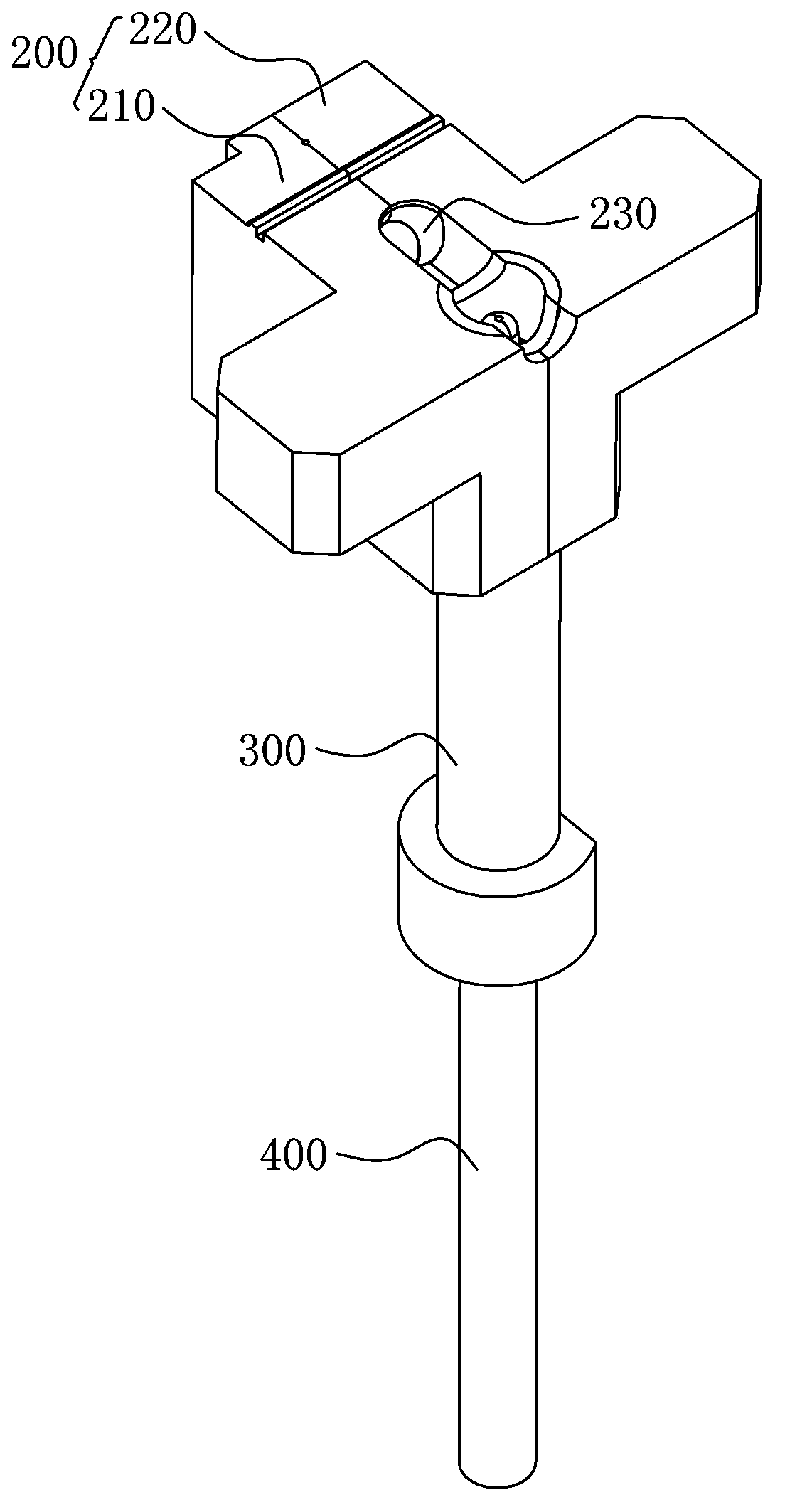

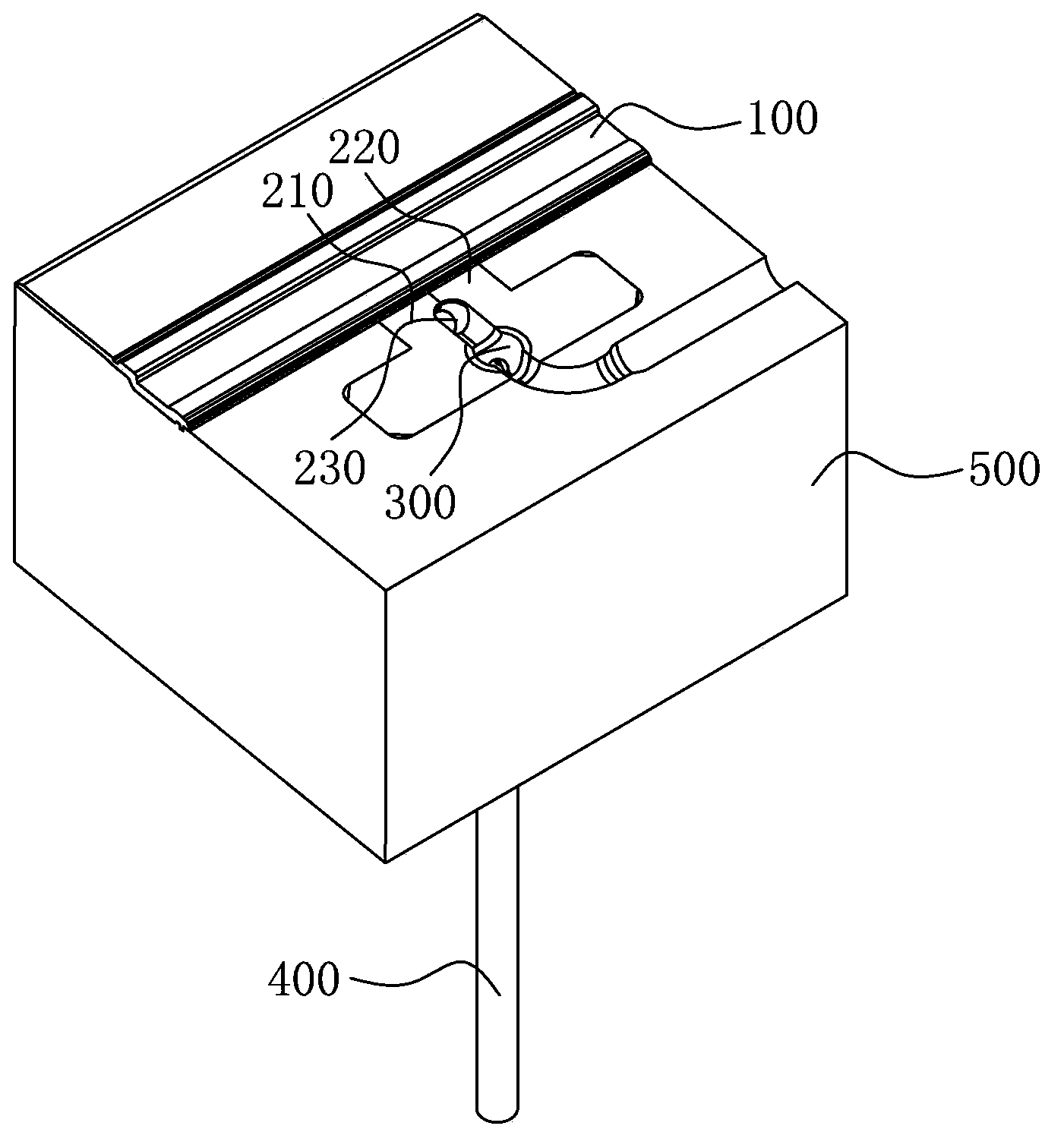

Two-dimensional pointing mechanism for space optical remote sensing instrument

InactiveCN105415371AExpand the scope of observationSimple structureProgramme-controlled manipulatorEngineeringAzimuth

The invention discloses a two-dimensional pointing mechanism for a space optical remote sensing instrument. The two-dimensional pointing mechanism is composed of an installation machine seat, an azimuth axis drive assembly, a pitch axis drive assembly and a pointing mirror assembly, wherein the azimuth axis drive assembly comprises a drive servo motor, a high-accuracy encoder and a harmonic reducer, and the pitch axis drive assembly comprises a servo drive motor, a high-accuracy encoder, a harmonic reducer and an azimuth axis connecting piece. The two-dimensional pointing mechanism has the beneficial effects that compared with a traditional two-dimensional pointing mechanism, the two-dimensional pointing mechanism is high in pointing accuracy, simple in structure, small in load, low in assembling difficulty and the like; and meanwhile, the mechanism can continuously rotate by 360 degrees in one dimension, and the functions of in-orbit calibration and the like of the space optical remote sensing instrument can be achieved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

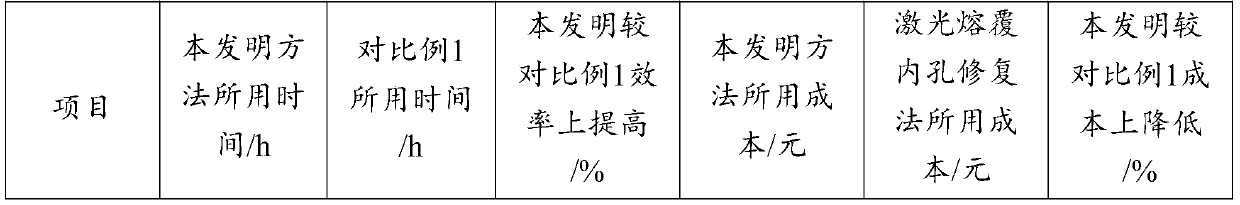

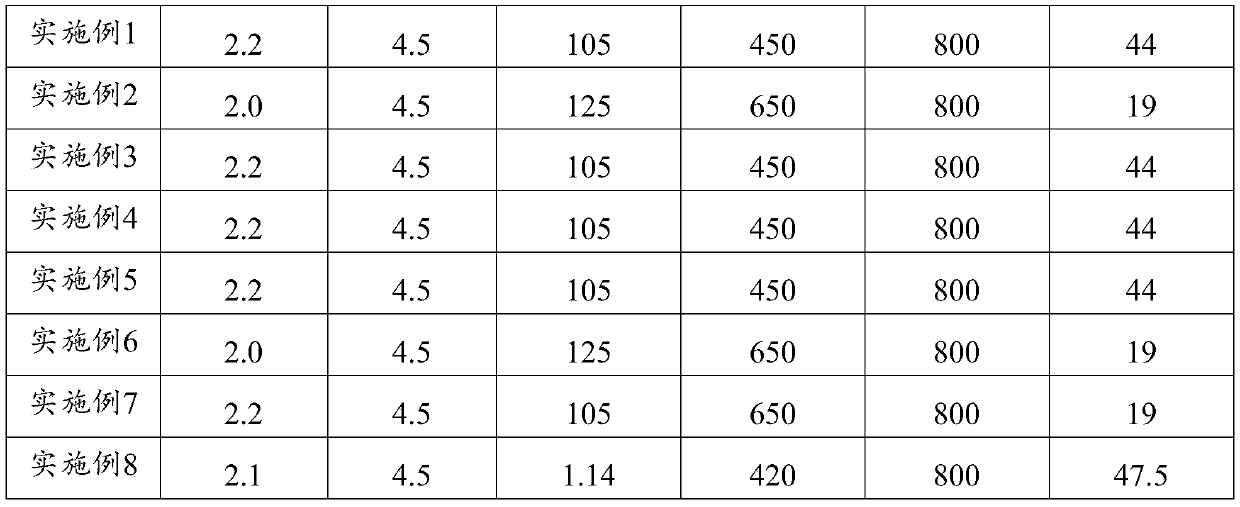

Hydraulic support oil cylinder refabrication method based on CMT (Cold Metal Transition)

The invention provides a hydraulic support oil cylinder refabrication method based on CMT and belongs to the technical field of metal surface engineering. The hydraulic support oil cylinder refabrication method comprises the steps that mechanical machining and cleaning are firstly performed on the oil cylinder inner wall to be repaired in sequence, then CMT welding is performed on the hydraulic support oil cylinder inner wall, finally, the mechanical machining is performed on a CMT weld layer, and a refabricated hydraulic support oil cylinder is obtained. According to the hydraulic support oilcylinder refabrication method based on the CMT, the cold metal transition welding technology is utilized to weld the hydraulic support oil cylinder inner wall, heat input and spatter are less in thewelding peocess, the fact that the refabricated oil cylinder will not lose efficacy due to heat deformation can be guaranteed, and the service life of the oil cylinder is prolonged; by means of the manner that the mechanical machining is performed on the oil cylinder inner wall before and after the welding, the surface smoothness, the size and the tolerance of the oil cylinder all can be guaranteed to meet the drawing requirements; and meanwhile, the refabrication method provided by the invention is low in cost and high in efficiency, and full-automatic production can be realized.

Owner:YANSHAN UNIV

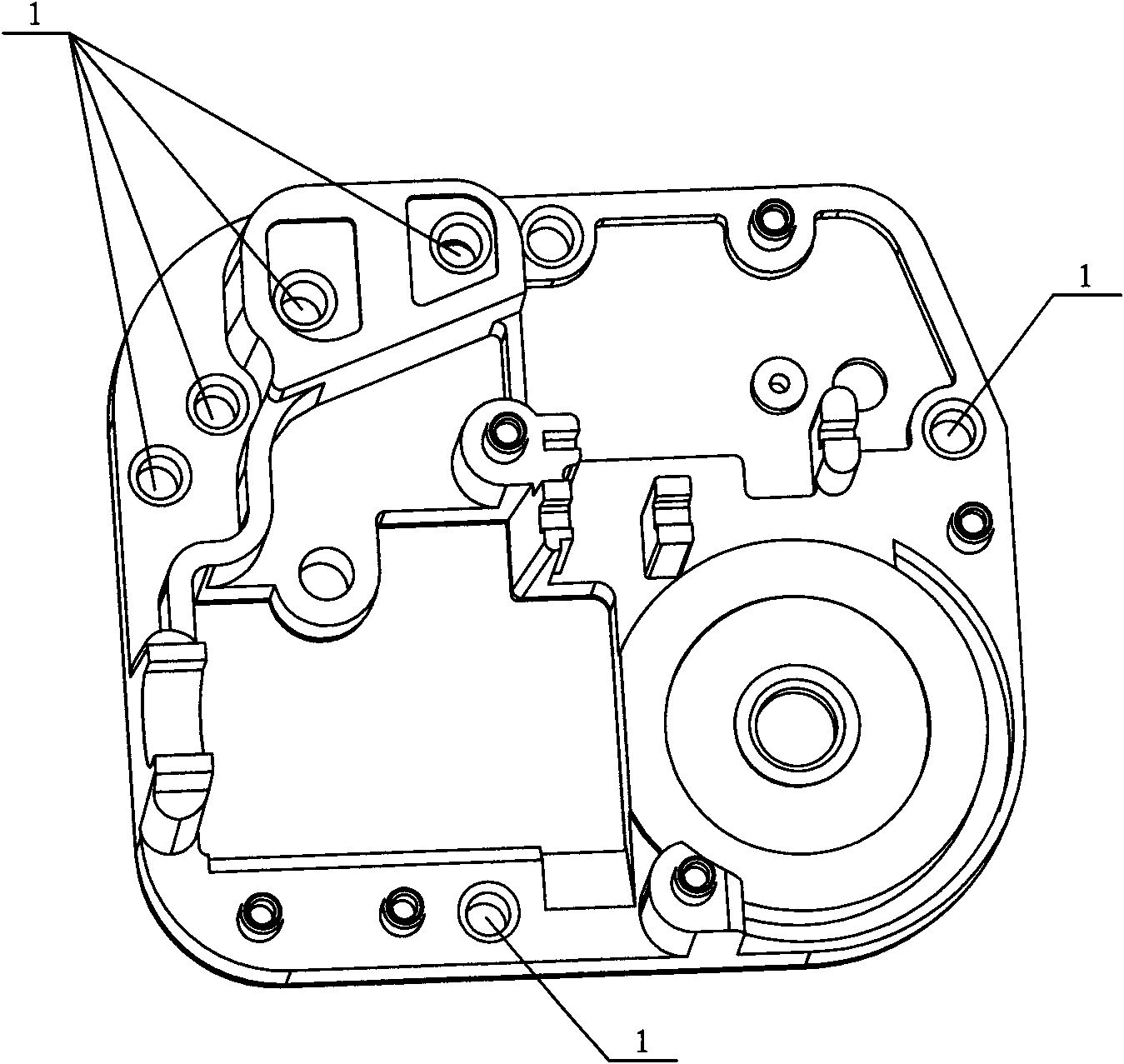

Laser machining apparatus for main-bearing cracker of engine cylinder

InactiveCN101028672AGuaranteed processing sizeGuaranteed ToleranceLaser beam welding apparatusLaser cuttingCylinder block

A laser machining apparatus for machining the splitting slot on master bearing seat for the cylinder body of engine is composed of a mechanical system and a YAG solid laser cutting system. Said mechanical system consists of cylinder body and its machine frame, and bench and its machine frame. Said bench comprises a numerally controlled X-Y bench, an X-axis bench and a Y-axis bench with a laser cutting head driven by a rotary cylinder to rotate by 180 deg.

Owner:JILIN UNIV

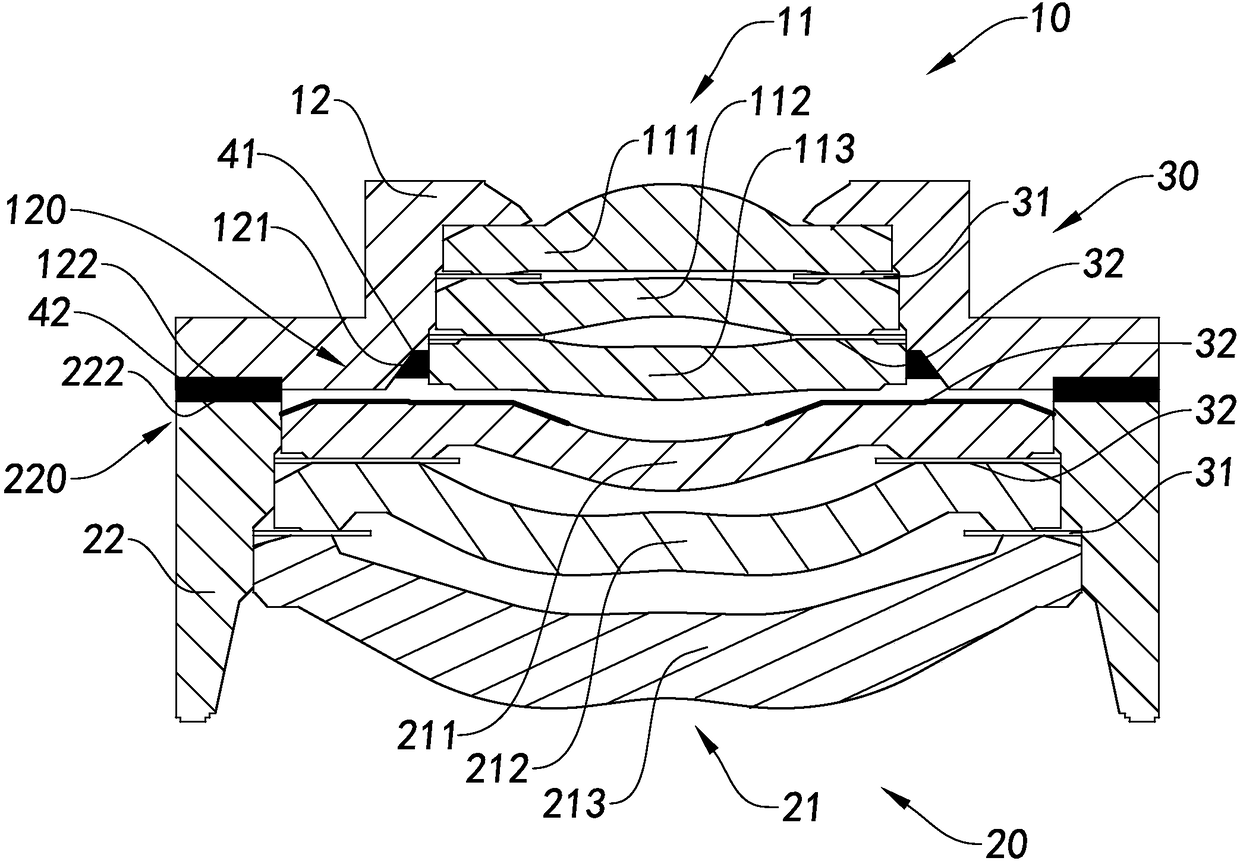

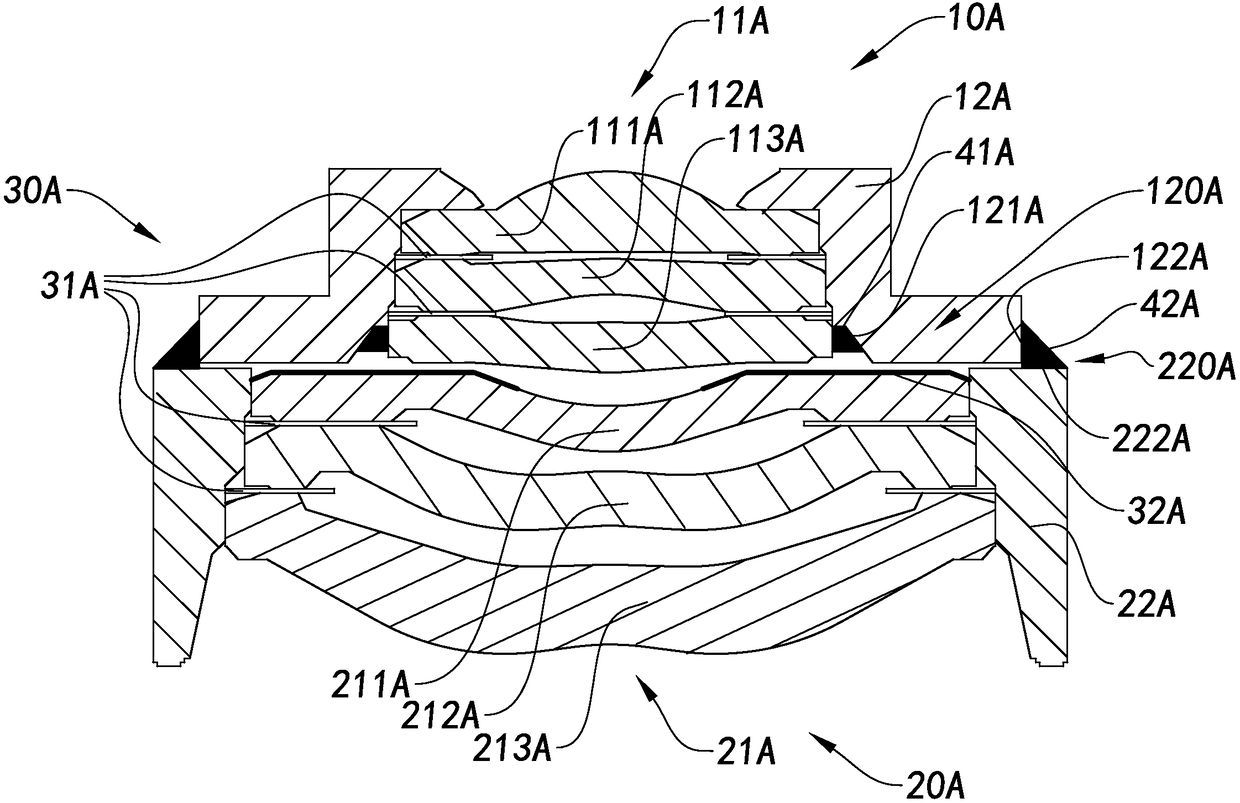

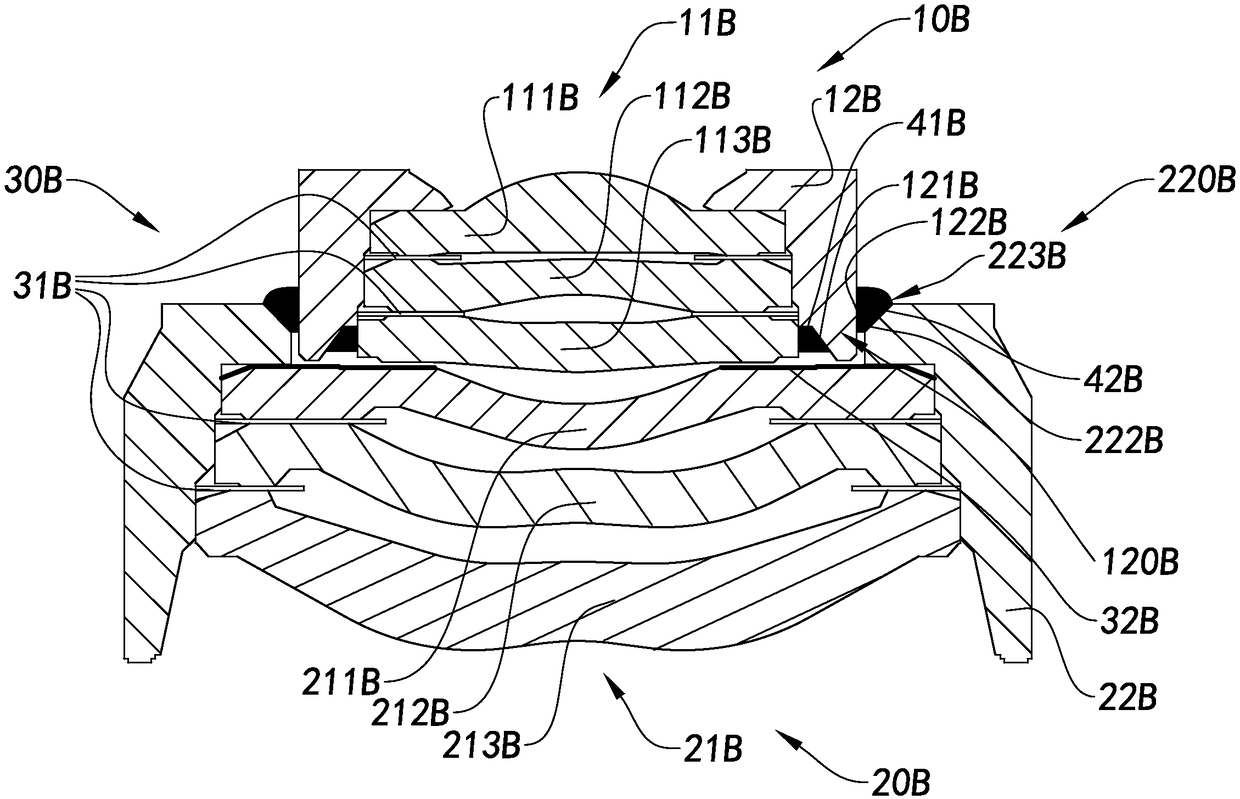

Split lens, camera shooting module and electronic equipment

The invention relates to a split lens, a camera shooting module and electronic equipment. The split lens comprises a first lens group, a second lens group and at least one light shielding element, wherein the first lens group includes at least one lens; the second lens group includes at least one lens; and the light shielding element is arranged between the lens, which is located at the bottom end, of the first lens group and the lens, which is located at the top end, of the second lens group so as to form a predetermined light path between the first lens group and the second lens group, and the light shielding element is stably arranged between the first lens group and the second lens group so as to be matched with the structure of the split lens.

Owner:NINGBO SUNNY OPOTECH CO LTD

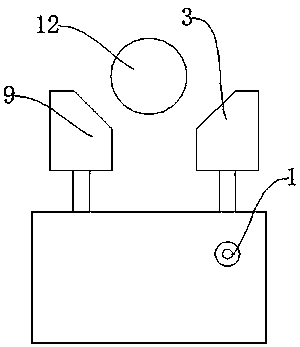

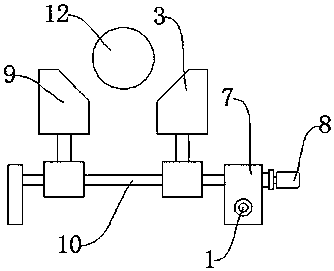

Steel tube perforating machine device and perforating method

ActiveCN106112054AGuaranteed stabilityEnsure safetyTurning machine accessoriesWorkpiecesEngineeringDrive motor

The invention relates to a steel tube perforating machine device and a perforating method. A steel tube perforating machine comprises a tube feeding rack, conveying roller ways, a headstock, a steel tube clamp and a tube discharging rack. The steel tube clamp is adjacent to the headstock. The headstock comprises two symmetrically-arranged perforating machine bodies, sliding tables, a sliding way, a lead screw, a nut and drive motors, wherein the sliding tables, the sliding way, the lead screw, the nut and the drive motors are mounted at the bottoms of the perforating machine bodies. The two perforating machine bodies are fixedly connected with the two sliding tables through bolts correspondingly. The two sliding tables are in sliding connection with the sliding way. The lead screw is in transmission connection with the drive motors and is in screw joint with the nut. The nut is fixedly connected with the sliding tables through a nut seat. The section of one of the two sides, in sliding connection with the sliding tables, of the sliding way is square, and the section of the other of the two sides, in sliding connection with the sliding tables, of the sliding way is angular. According to the steel tube perforating machine device and the perforating method, based on the design of the sliding way of the perforating machine bodies, one side is square, the other side is angular, and therefore it is effectively guaranteed that radial movement does not happen during perforating, and perforating precision is improved; and the requirements of clients for safety, stability and accuracy in the use process are guaranteed.

Owner:中冶辽宁德龙钢管有限公司

Two-dimensional pointing mechanism for space optical remote sensing instrument

InactiveCN105835057ASimple structureGuaranteed dimensional accuracyProgramme-controlled manipulatorReduction driveLow load

The invention discloses a two-dimensional pointing mechanism for a space optical remote sensing instrument. The two-dimensional pointing mechanism consists of a mounting stand, a direction shaft driving module, a pitching shaft driving module and a pointing mirror module, wherein the direction shaft driving module includes a driving servo motor, a high-precision encoder and a harmonic speed reducer; and the pitching shaft driving module includes a servo driving motor, a high-precision encoder, a harmonic speed reducer and a direction shaft connecting piece. The two-dimensional pointing mechanism has the following advantages: compared with a traditional two-dimensional pointing mechanism, the two-dimensional pointing mechanism has such characteristics as high pointing precision, simple structure, low load and low assembly difficulty; and meanwhile, the two-dimensional pointing mechanism can continuously rotate by 360 degrees on one dimension, so that the realization of such functions as on-track calibration of the space remote sensing instrument is convenient.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

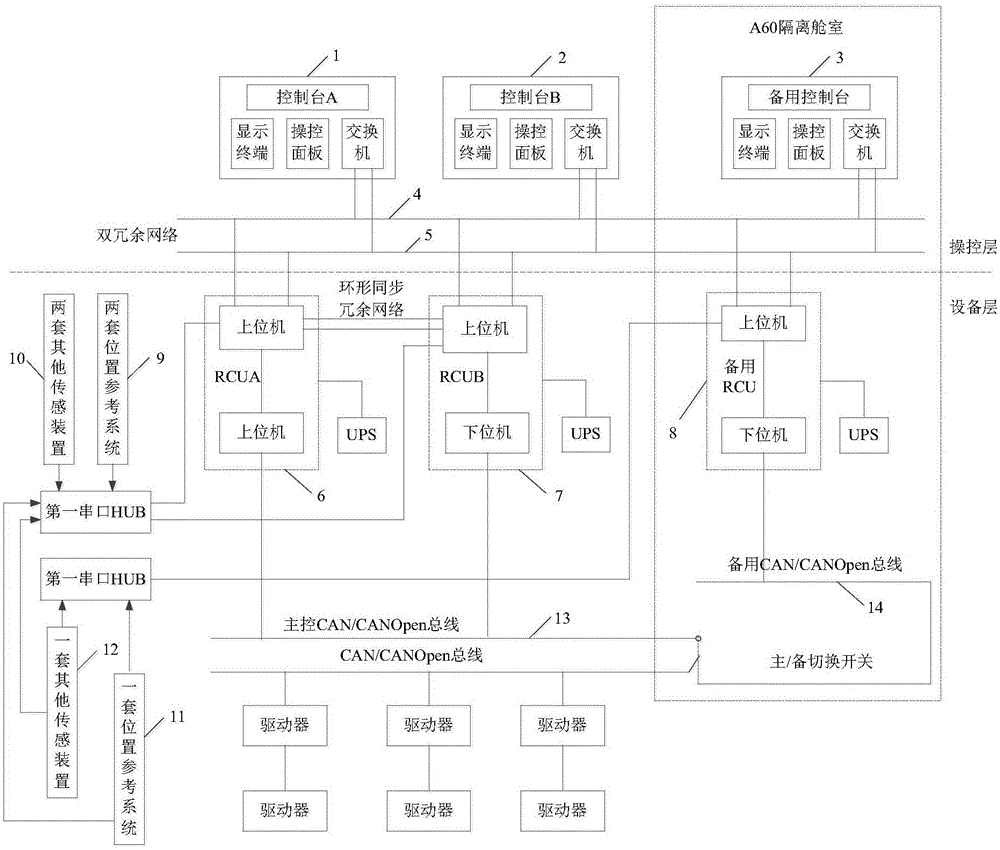

DP-3 level dynamic positioning system and method for guaranteeing positioning work

InactiveCN105676841AGuarantee continuous and stable operationGuaranteed uptimeProgramme controlElectric testing/monitoringPropellerDynamic positioning

The invention relates to a DP-3 level dynamic positioning system and a method for guaranteeing positioning work. The system comprises a first console, a second console, a standby console, a first RCU, a second RCU, a standby RCU, three sensors, double redundancy networks, a first serial port HUB, a second serial port HUB, a master control CAN / CANOpen bus, a standby CAN / CANOpen bus, drivers, and propellers. The three consoles are respectively connected to the three RCUs through the double redundancy networks. The first RCU, the second RCU, and the three sensors are connected to the first serial port HUB. The third sensor and the standby RCU are connected to the second serial port HUB. The first RCU and the second RCU are connected to the master control CAN / CANOpen bus. The standby RCU is connected to the standby CAN / CANOpen bus. The standby CAN / CANOpen bus is connected to the master control CAN / CANOpen bus through a main / standby change over switch. The drivers are connected to the master control CAN / CANOpen bus. The propellers are connected to the drivers. Through reasonable structural arrangement, the tolerance of the DP-3 level dynamic positioning system to an external severe environment and the stability and redundancy of internal data exchange communication are fully guaranteed, and a demand of the DP-3 level dynamic positioning system from the International Marine Organization is satisfied.

Owner:WUHAN UNIV OF TECH +1

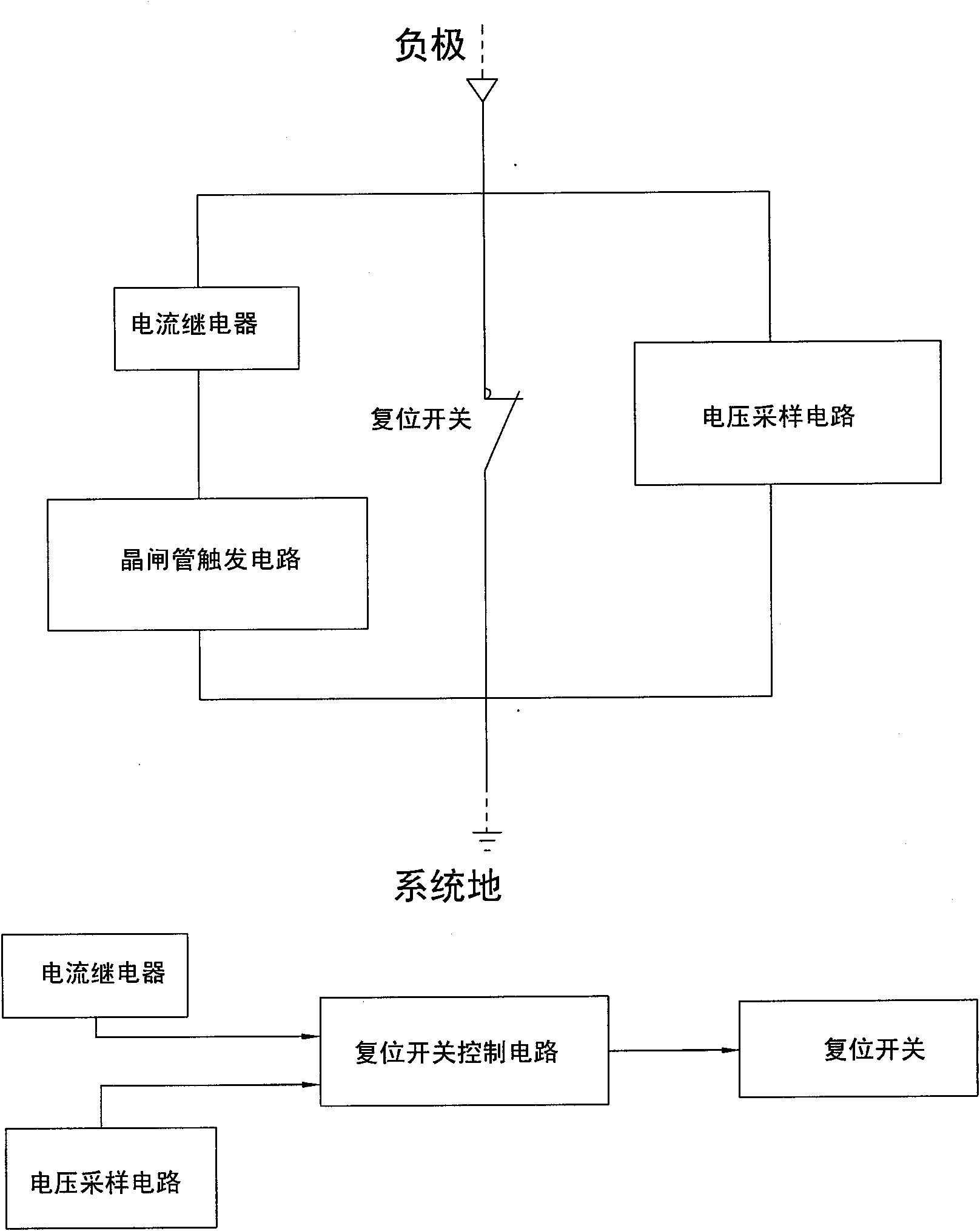

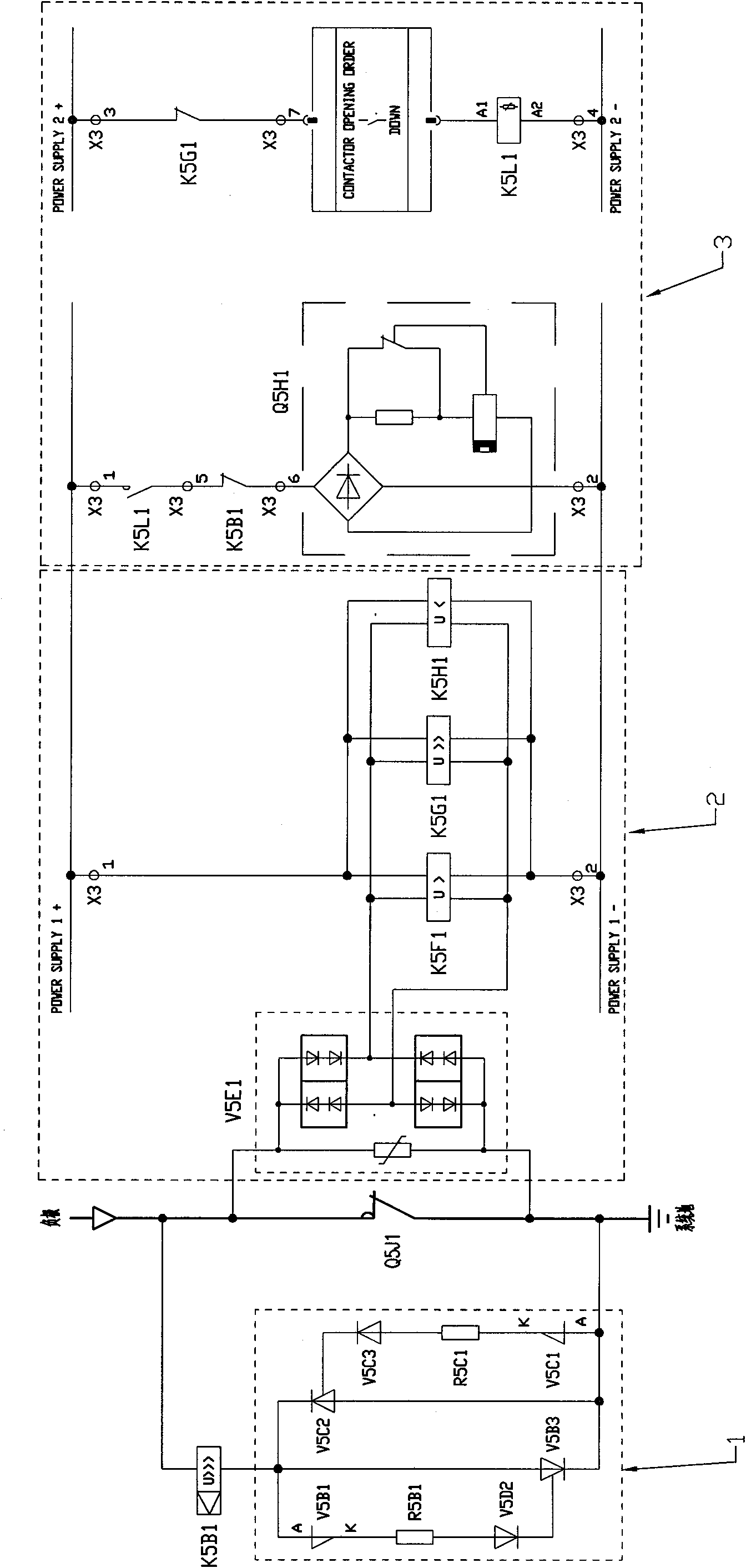

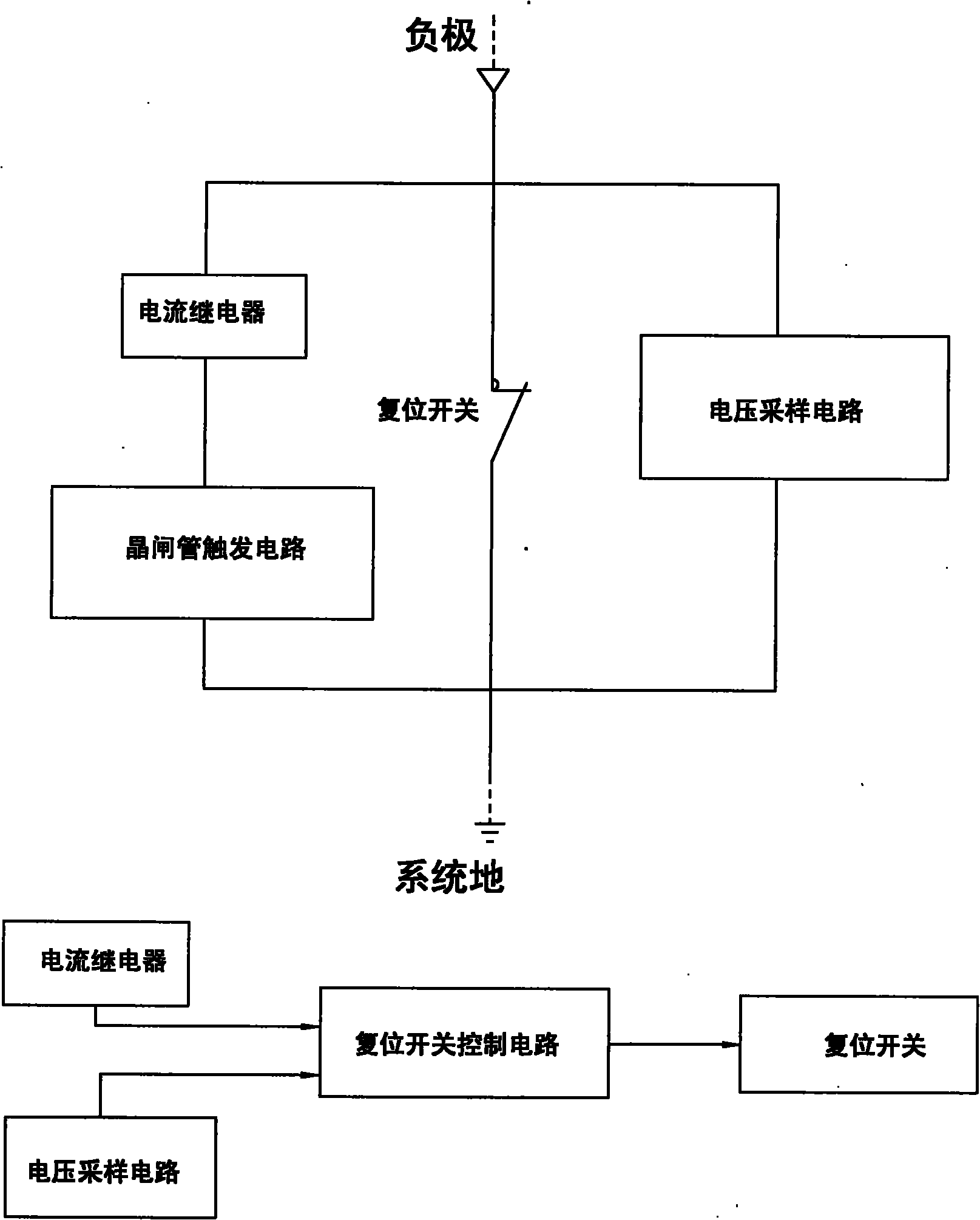

Quick detection and protection device for electric potential of direct-current traction power supply return current rail

InactiveCN101794980AIncreased speed of protective responseGuaranteed toleranceEmergency protective arrangements for automatic disconnectionThyratronOvercurrent relay

The invention relates to a monitoring device of a direct-current traction power supply system of urban rail traffic facilities, in particular to a quick detection and protection device for the electric potential of a direct-current traction power supply return current rail. The device comprises a reset switch, a group of thyristor trigger circuits and a current relay, wherein the reset switch is connected between a cathodal return current rail and the earth, the thyristor trigger circuits are sequentially connected in series, the current relay is connected with the reset switch in parallel between the cathodal return current rail and the earth, and a voltage sampling circuit is also connected between the cathodal return current rail and the earth; and the output signals of the current relay and the voltage sampling circuit are output to a control circuit of the reset switch. By the synergic monitoring of the current relay and the voltage sampling circuit, the invention can relevantly control different electric potential grades between the return current rail and the earth, can enhance the protection response speed under the condition of a potential difference, also ensures a certain tolerance capability of the return current rail to short-circuit current and enhances the operational reliability of the device.

Owner:ZHENJIANG DAQO SECHERON TRACTION POWER

Preparation method of chlorine-resistant composite ceramic nano-filtration membrane

InactiveCN108771979AImprove chlorine resistanceImprove interception effectMembranesSemi-permeable membranesFiltration membraneComposite ceramic

The invention provides a preparation method of a chlorine-resistant composite ceramic nano-filtration membrane. The ceramic nano-filtration membrane with good chlorine resistance is prepared by selecting traditional piperazine / trimesoyl chloride interfacial polymerization; reaction is carried out by utilizing an interface active group and a hydroxyl-containing macromolecular membrane material withthe good chlorine resistance to form an ester group with the good chlorine resistance; the macromolecular membrane material with the good chlorine resistance is introduced so that the tolerance performance of the nano-filtration membrane on sodium hypochlorite is ensured, and the high-interception performance on inorganic salt ions is obtained.

Owner:北京享云智汇科技有限公司

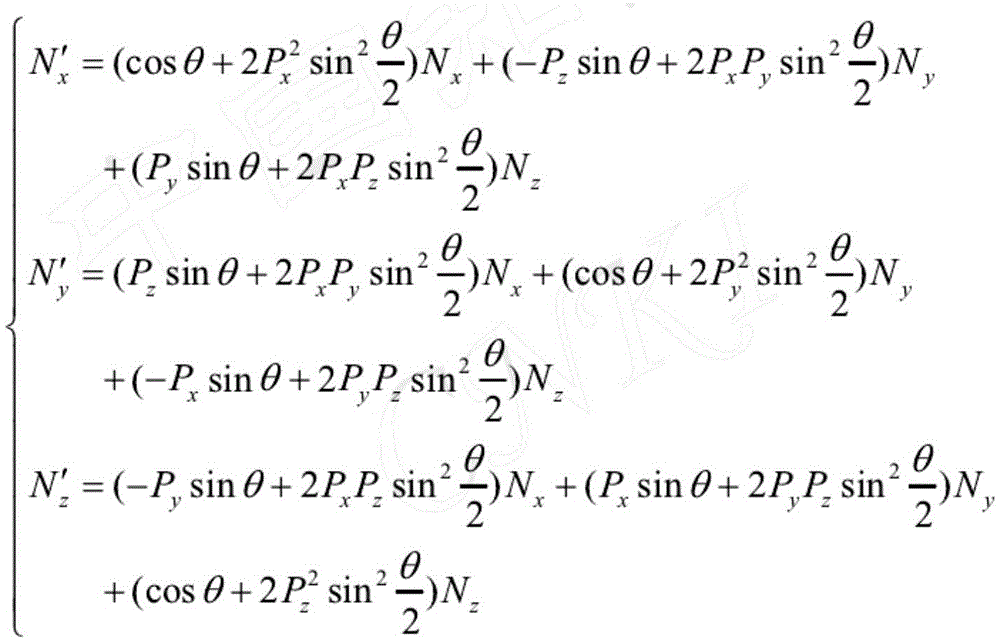

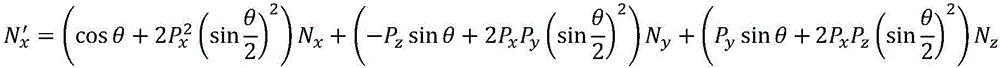

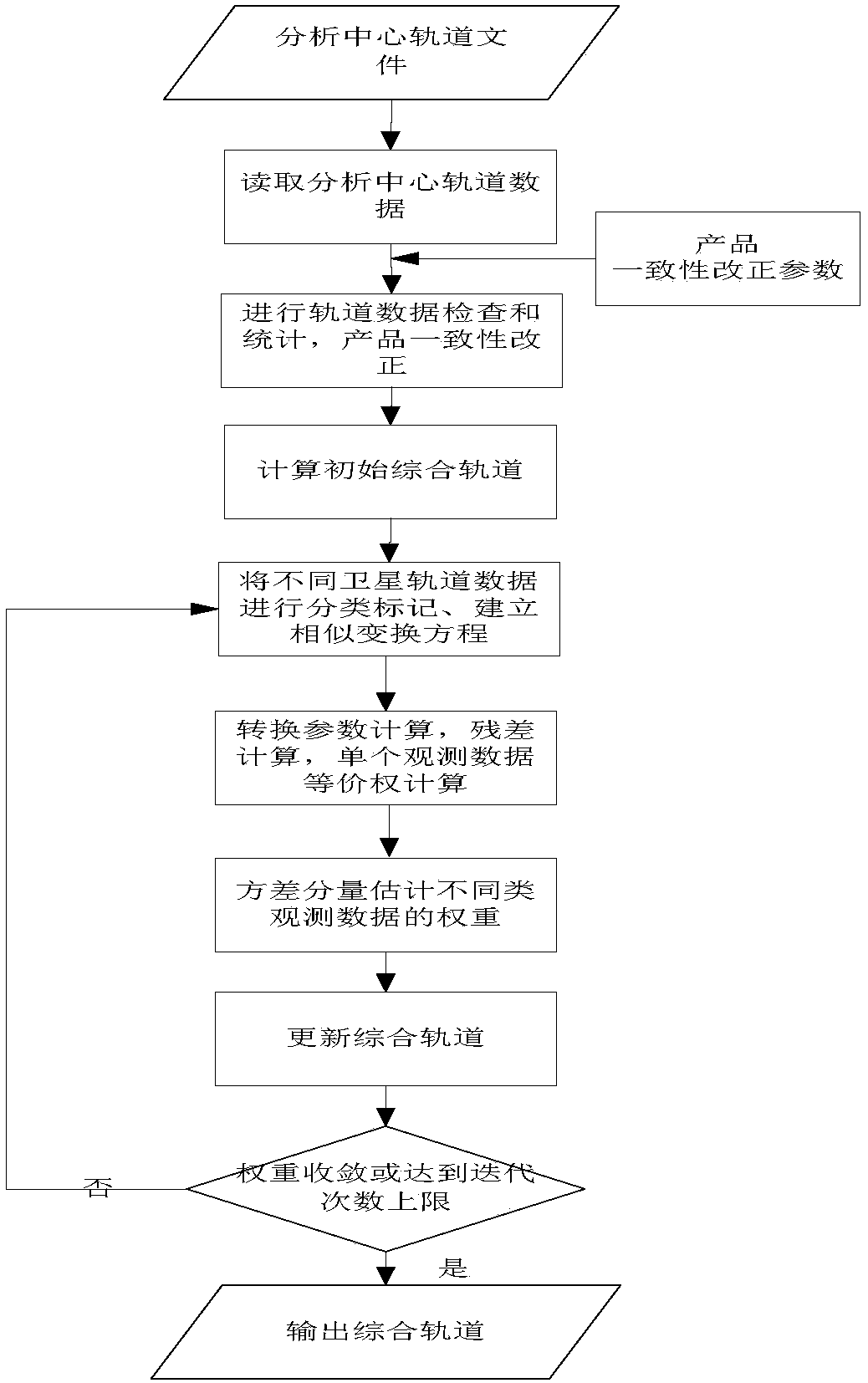

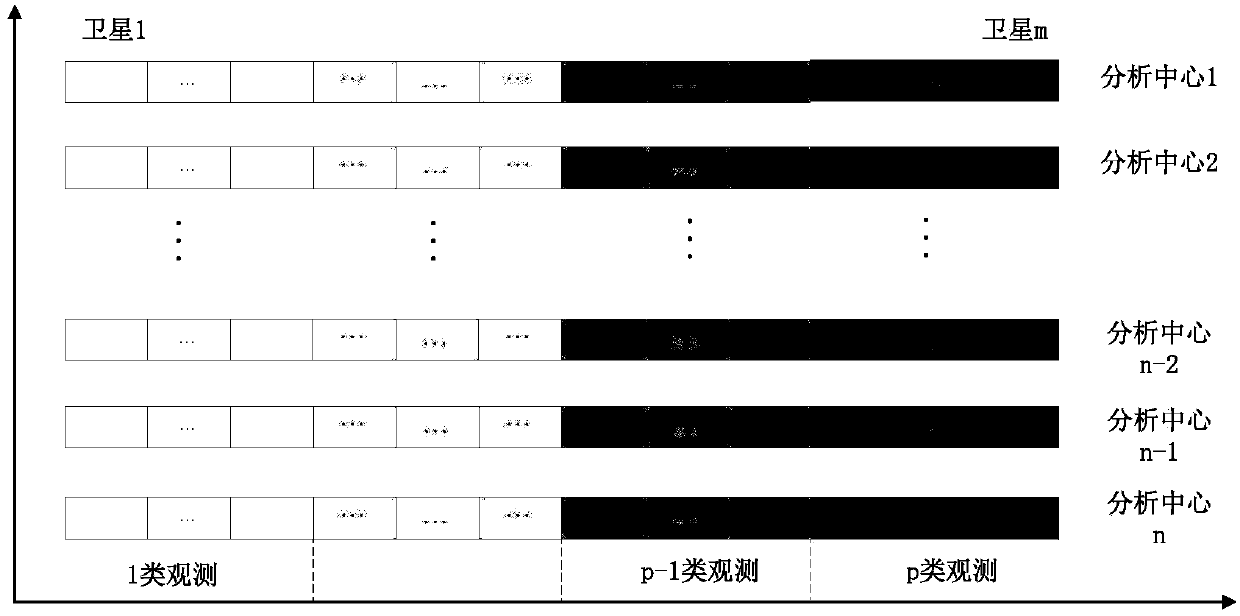

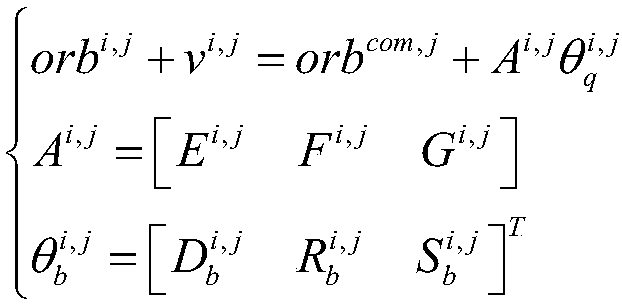

iGMAS multi-analysis center and multi-satellite system precision orbit product integration method

ActiveCN108415039AEliminate systematic errorsGuaranteed ToleranceSatellite radio beaconingTransformation equationEstimation methods

The invention discloses an iGMAS multi-analysis center and multi-satellite system precision orbit product integration method. For a same satellite system, a plurality of analysis centers provide the orbit data of each satellite in the satellite system, according to the orbit data, the preprocessing of a precision orbit product is performed, and an orbit value median of the same satellite in different analysis centers is selected as the initial integration orbit of the satellite. A similarity transformation equation is established between an analysis center orbit and an integration orbit. According to a least square principle, adjustment is performed, similar transformation parameters and a residual error are resolved, a weight function and variance component estimation method is used to estimate the weights of different types of satellites in each analysis center, and according to the weights, the integration orbit is calculated. An observation equation is re-established so as to resolve until convergence. In the invention, a system deviation among the orbit products of the different analysis centers of multiple satellite systems can be corrected so that the acquired integration orbit product can be ensured to possess high reliability, high robustness and high precision.

Owner:NO 63921 UNIT OF PLA +1

Flame-retardant insulated composite material and preparation technology thereof

ActiveCN106531374AStrong high temperature resistance and flame retardant performanceGuaranteed ToleranceInsulating bodiesTemperature resistancePolyimide membrane

The invention discloses a flame-retardant insulated composite material and a preparation technology thereof. The flame-retardant insulated composite material comprises meta-amide paper, a temperature-resisting chemical film and meta-amide paper which are sequentially contacted. The preparation technology is characterized in that 1313 aramid chopped fiber, 1313 aramid fibrid, 1313 aramid pulp are effectively dispersed, subjected to two stages of squeezing and dewatering, drying and high-temperature plasticizing to obtain the meta-amide paper; a formed polyimide film (PI film) and or a polyethylene glycol terephthalate film (PET film) are uniformly coated with a layer of half-curing high-temperature epoxy glue, and then disposed on a high pressure compounding machine for composite forming, so as to obtain the temperature-resisting chemical film; and the temperature-resisting chemical film is disposed between two layers of the meta-amide paper, then coating and high-temperature gapless composite treatment are carried out, so as to obtain the flame-retardant insulated composite material. The flame-retardant insulated composite material has strong high temperature resistance performance and flame retardation performance for high voltages of different frequencies at 220 DEG C to 400 DEG C, so that the survivability of various electrical products can be ensured.

Owner:青岛安信绝缘材料有限公司

A high-performance tin phosphor bronze strip and its production method

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

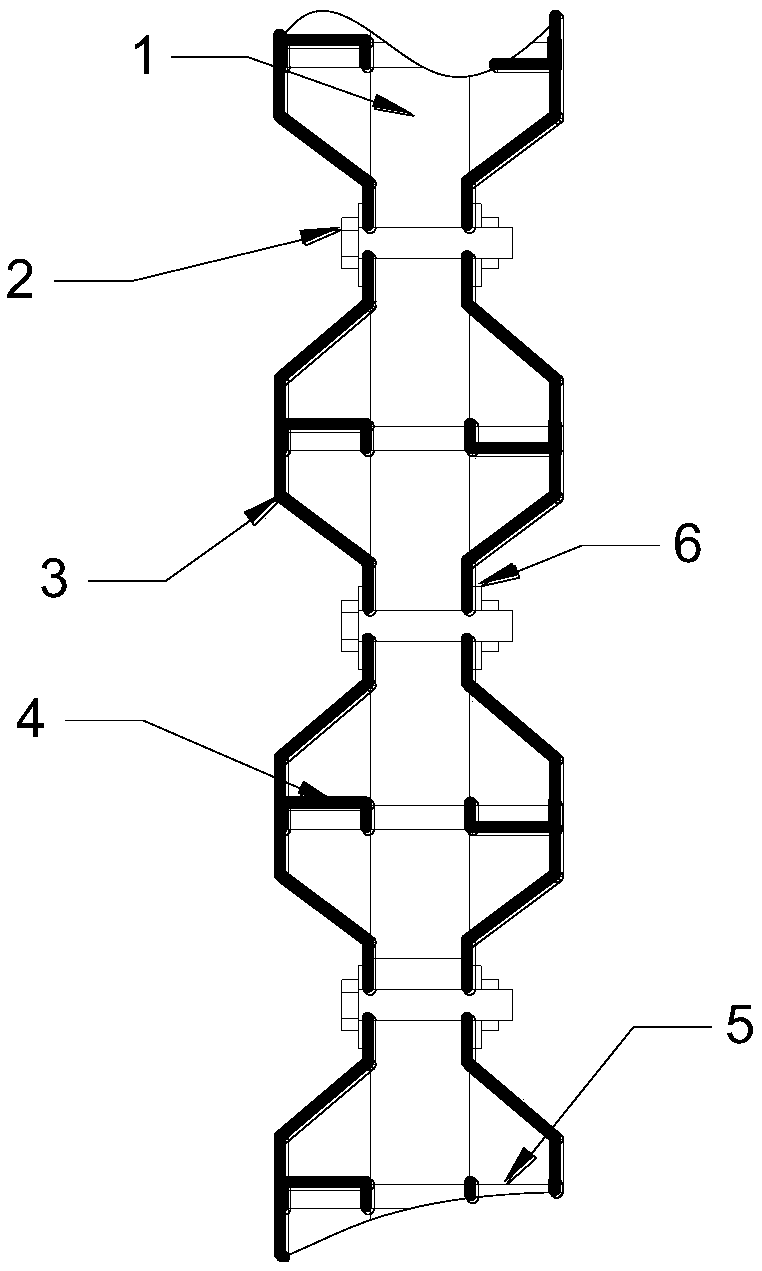

Insulating and flame retardant partition wall

PendingCN109339293AWith supporting strengthEasy constructionWallsHeat proofingUltimate tensile strengthCement mortar

The invention relates to an insulating and flame retardant partition wall, which includes a skeleton and cement mortar painted on the surface of the skeleton. The skeleton includes a middle partitionplate, the left and right sides of the middle partition plate are symmetrically provided with steel meshes containing continuous protrusions, a U-shaped supporting plate is arranged between the protrusion part of each side of the steel meshes and the middle partition plate, a groove part of each side of the steel meshes is provided with a metal batten in the direction of the groove, and the metalbattens on the left and right sides are fixed through fixing bolts; the middle partition plate is prepared through an extrusion process, has very good insulating and flame retardant effects, and has acertain strength of supporting; the fact that a frame is arranged around the wall is not required, construction of walls with various sizes is more convenient, the main function of the U-shaped supporting plates is to strengthen support of the steel meshes and ensure the tolerance of the steel meshes, meanwhile the steel meshes have a basic fixing effect on concrete, and the construction difficulty of the concrete is reduced; and the metal battens ensure stability between the steel meshes and the middle partition plate, golden battens are arranged, the stressed area of the golden battens is large, and the service life of the steel meshes is prolonged.

Owner:云南垒辉新型材料有限公司

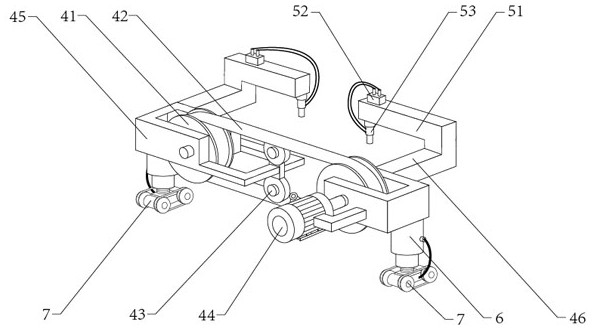

Accurate positioning type forging and pressing device

InactiveCN108500191AEasy to fixGuaranteed ToleranceForging/hammering/pressing machinesForging press detailsElectric controlEngineering

The invention discloses an accurate positioning type forging and pressing device. The accurate positioning type forging and pressing device comprises a first motor, a workbench, an electric control box and a second positioning block. The workbench is provided with the first motor. A first lead screw is arranged on one side of the first motor and provided with a second sliding block. A second motoris arranged on the second sliding block. A second lead screw is arranged on one side of the second motor and provided with a first positioning block. A third positioning block is arranged on one sideof the first positioning block. A first sliding block is arranged on one side of the second sliding block and provided with a third motor. A third lead screw is arranged on one side of the third motor and provided with the second positioning block and a fourth positioning block, and the first positioning block, the second positioning block and the third positioning block are provided with workpieces. The accurate positioning type forging and pressing device has the beneficial effects that the workpieces can be well fixed, the position of a forging and pressing machine is not moved in the forging and pressing process, and tolerance of components is guaranteed.

Owner:长兴法飞德自动化有限公司

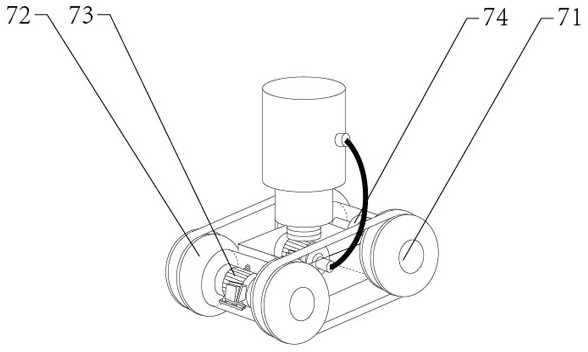

Screw polishing device

PendingCN112247771AControl finishGuaranteed ToleranceGrinding carriagesGrinding drivesHydraulic cylinderDrive wheel

Owner:ZHOUSHAN CHANGJIA PLASTIC MACHINERY CO LTD

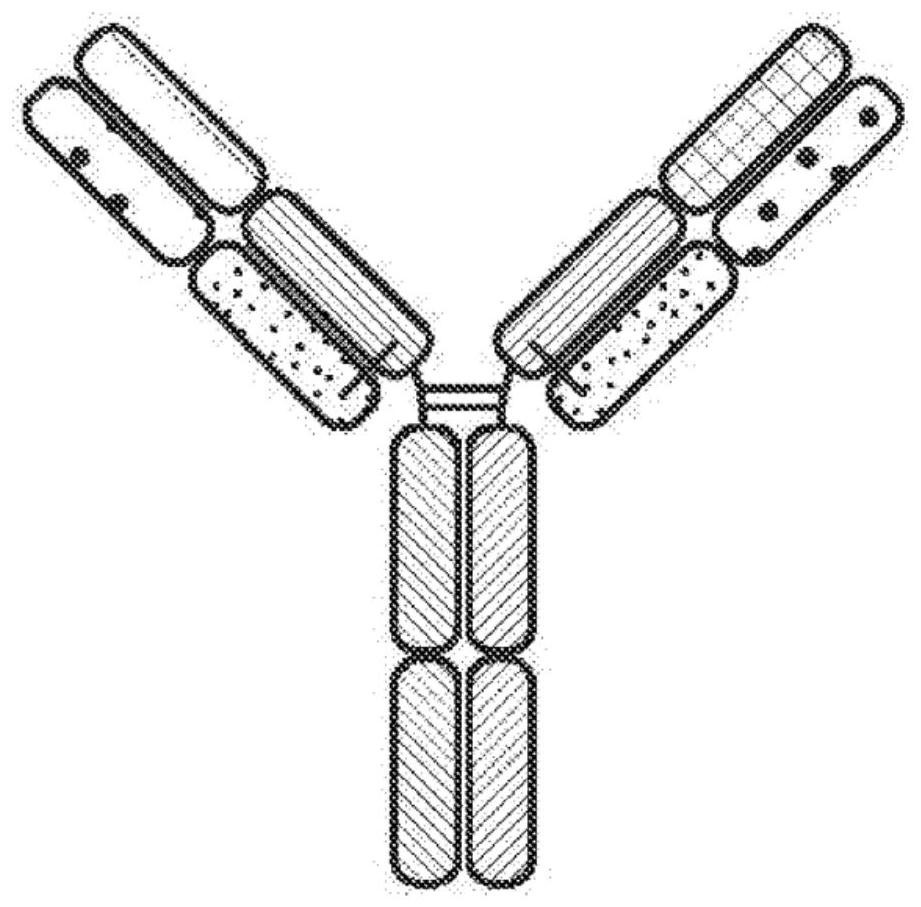

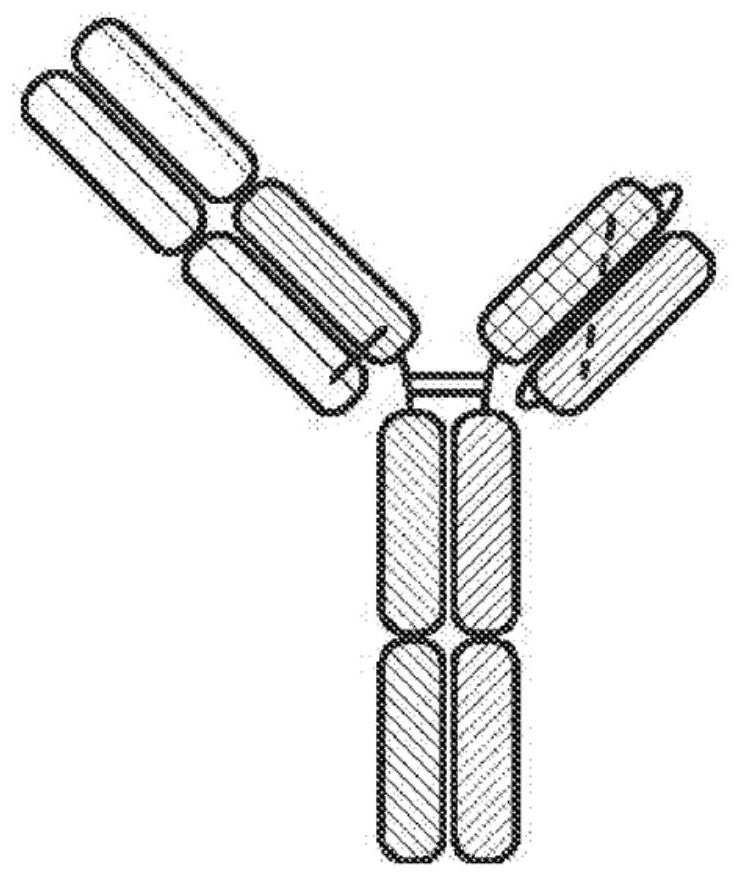

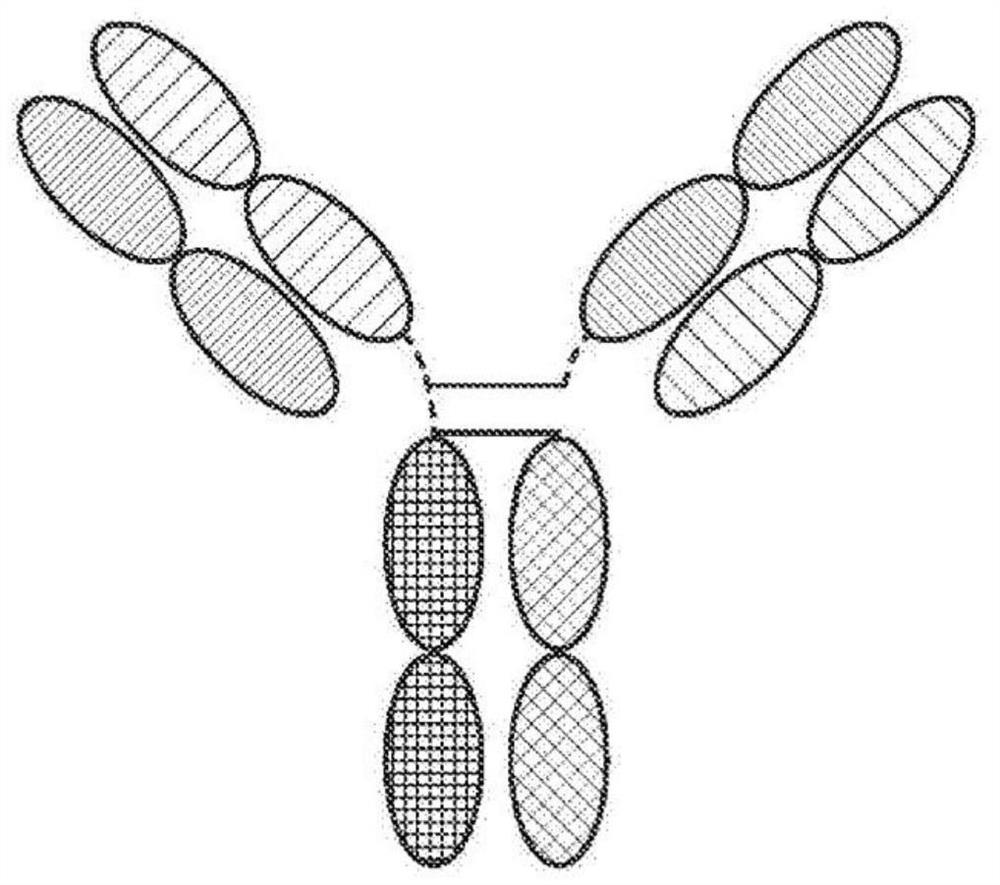

Combination therapy of cancer involving multi-specific binding proteins that activate natural killer cells

PendingCN112040971AGood effectLow efficacyPolypeptide with localisation/targeting motifOrganic active ingredientsAnticarcinogenActivated Natural Killer Cell

A combination therapy of a cancer with a multi-specific binding protein that bind a tumor associated antigen, the NKG2D receptor, and CD16, in combination with a second anti-cancer agent are described. Also described are pharmaceutical compositions of the multi-specific binding protein, and therapeutic methods useful for the treatment of cancer in combination with a second anti-cancer agent.

Owner:DRAGONFLY THERAPEUTICS INC

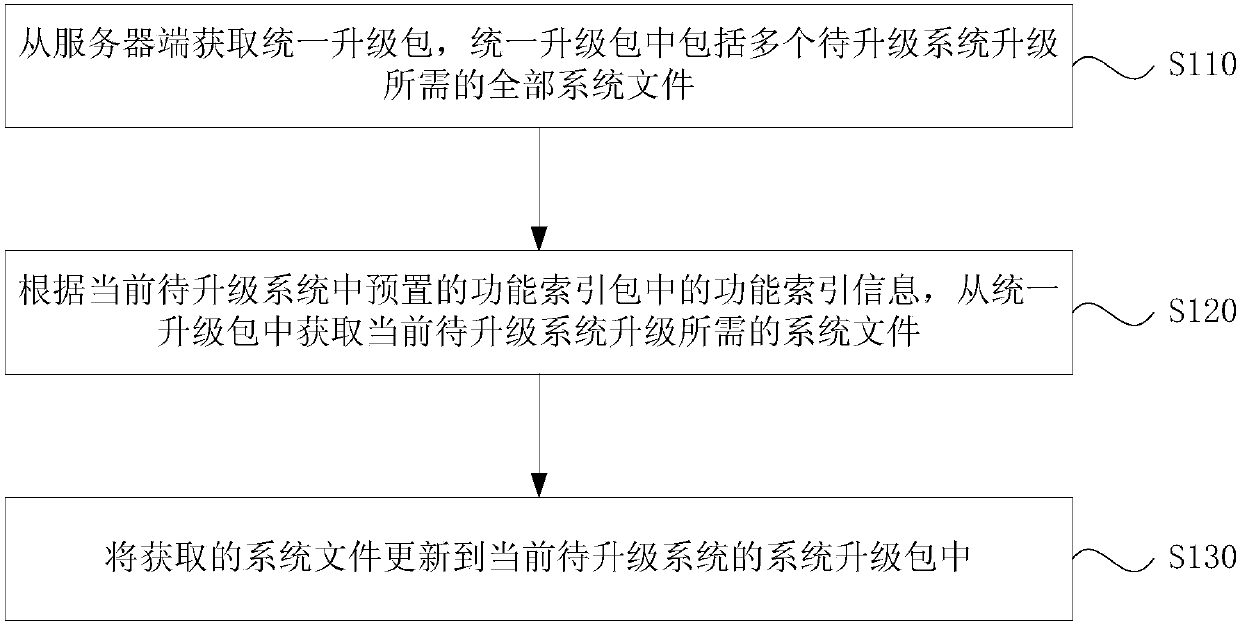

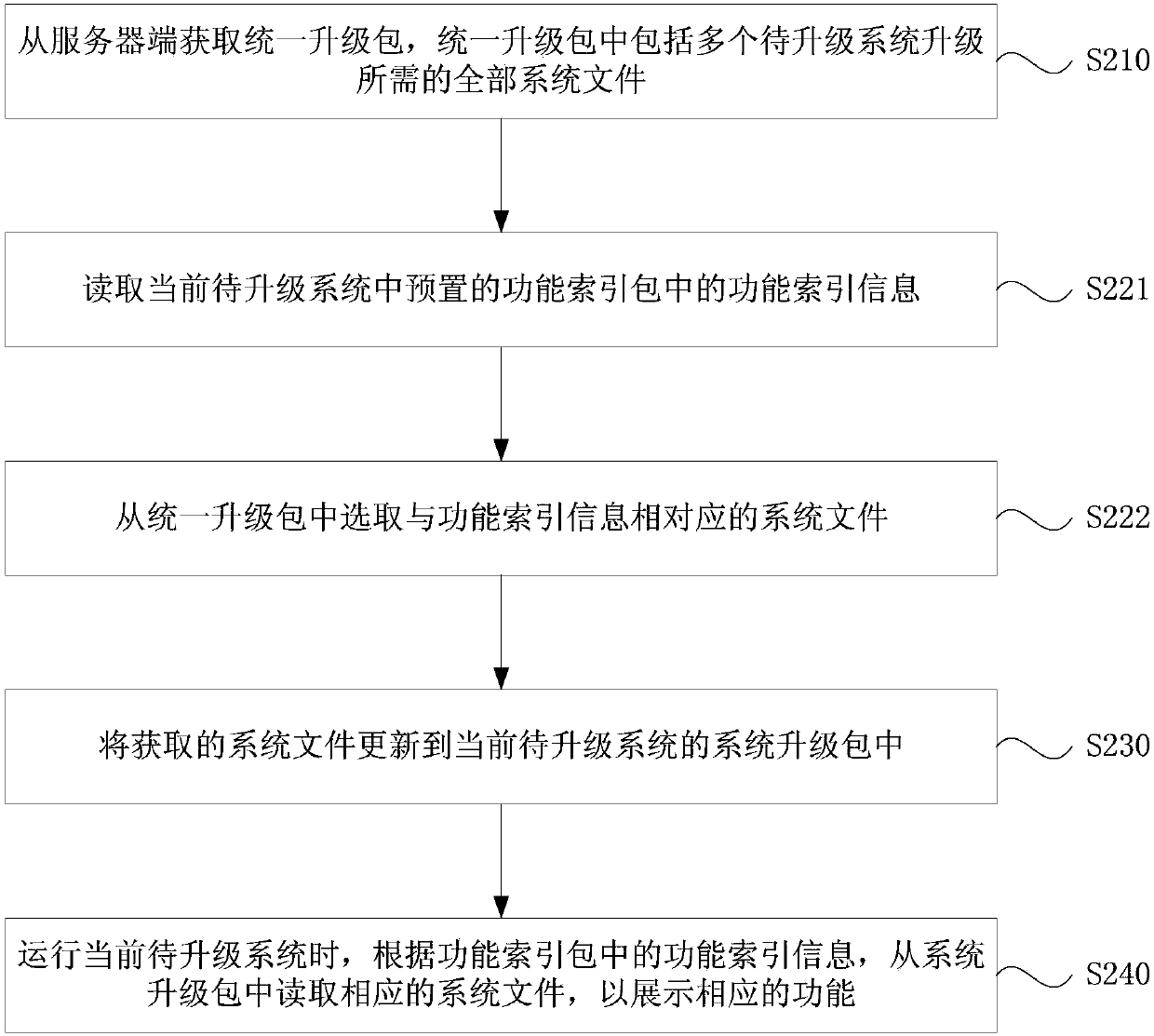

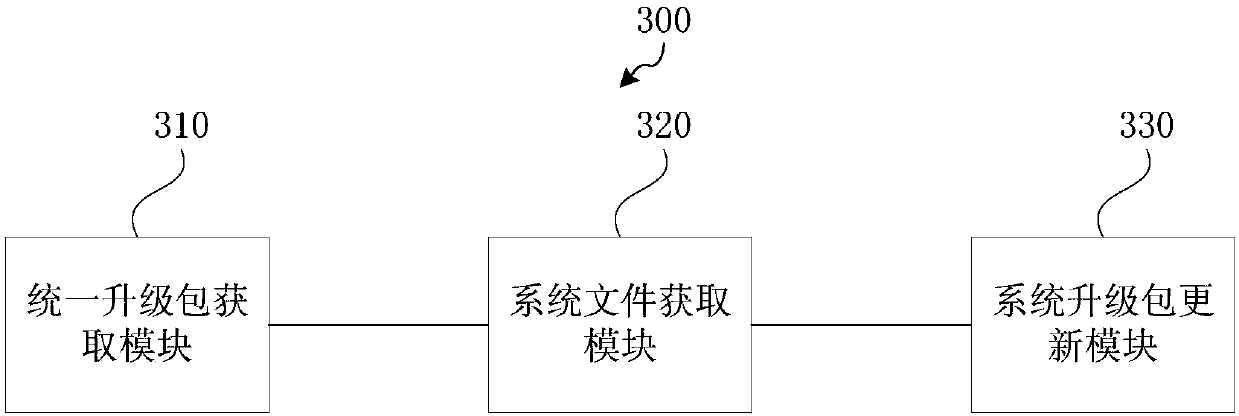

System update method and device

InactiveCN106878812AGuaranteed toleranceReduce maintenance costsProgram loading/initiatingSelective content distributionTerminal systemSystem change

The invention discloses a system update method and device. The method comprises that a uniform update packet is obtained from a server end, the uniform update packet includes all system files needed for update of systems to be updated, a system file needed for update of a present system to be updated is obtained from the uniform update packet according to function index information included in a preset function index packet of the present system to be updated, and the obtained system file is updated to a system update packet of the present system to be updated. According to the function index information included in the preset function index packets, the system to be updated can obtain the needed system files from the uniform update packet and update the obtained system files to the system update packets respectively; and thus, one uniform update packet can be used to carry out iteration and update on the systems to be updated of different models of terminals, tolerance for system change during update is ensured, and the maintenance cost for system update of the terminal is reduced greatly.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Flexible glue feeding mechanism

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

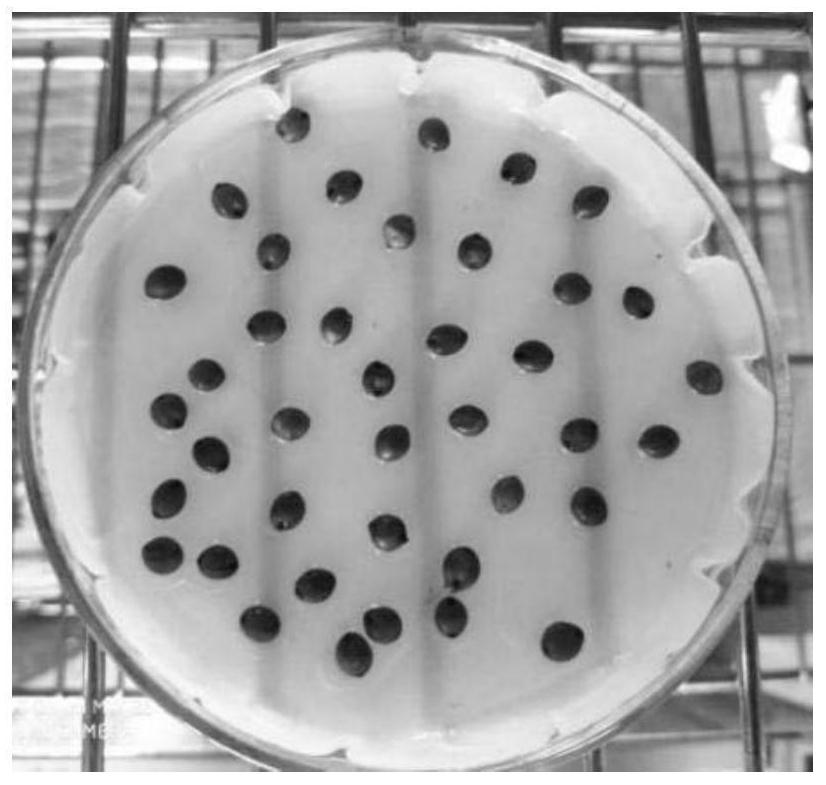

Die-casting forming mold of music gift box baseplate

The invention discloses a die-casting forming mold of a music gift box baseplate, comprising an upper plate (2) and a lower plate (6), an upper mold cylinder (12) and gear boxes (3). The gear boxes (3) are fixed at the top of the upper plate (2), and a plurality of thread pins (5) which can stretches into music gift box baseplate cavities (4) are connected in the gear boxes (3) in a rotary manner.The front ends of the thread pins (5) are positioned on thread holes (1) of the music gift box baseplate. The upper mold cylinder (12) is connected with the side of the upper plate (2), and a pistonrod (11) of the upper mold cylinder (12) is simultaneously connected with the thread pins (5) in the gear boxes (3) by a transmission mechanism. After adopting the above structure, the thread holes can be directly formed after die-casting forming, thus greatly increasing the production efficiency. Meanwhile, the position tolerance between the thread holes is ensured, thus improving the tone quality effect of the music gift box.

Owner:NINGBO DONGHAO DIE CASTING

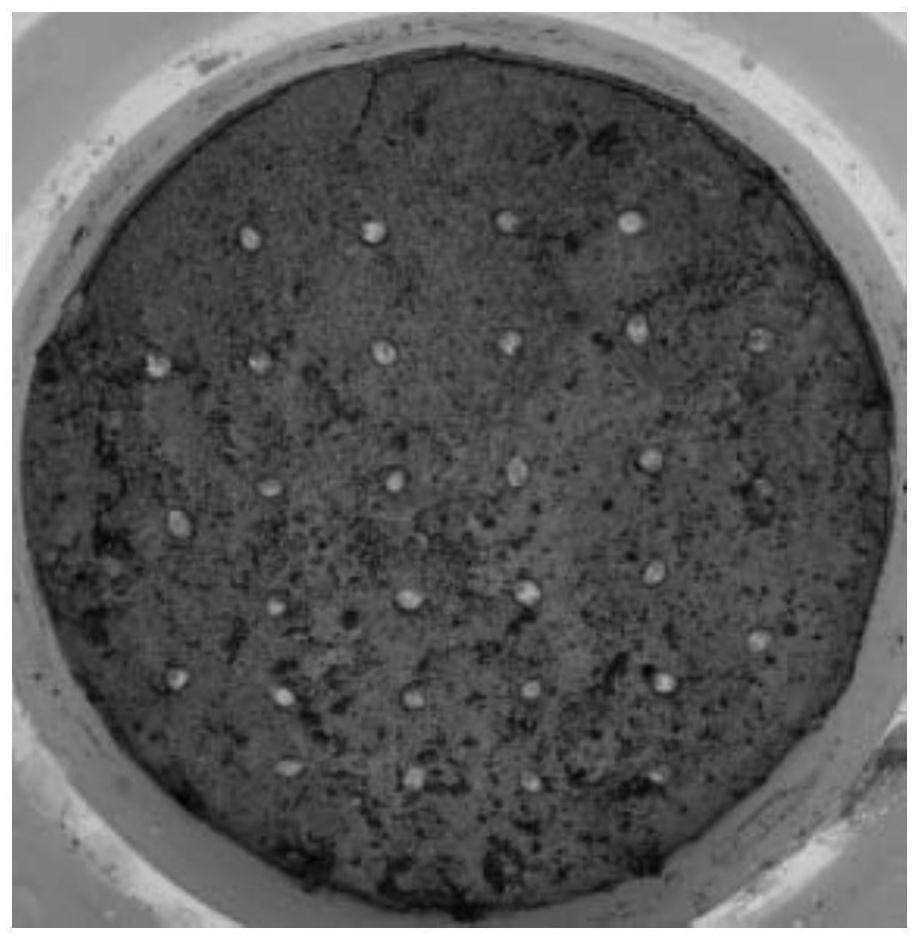

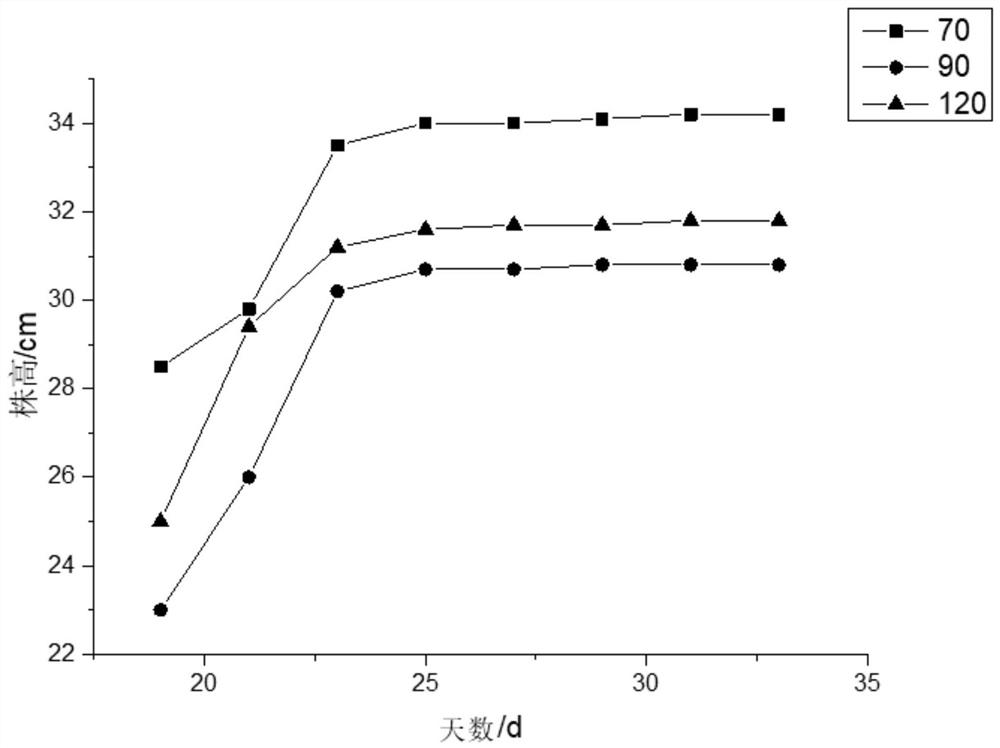

Method for remediating cesium-contaminated soil through forage grasses and method for remediating cesium-contaminated soil through forage grasses and microorganisms

PendingCN113477704AGuaranteed ToleranceImprove survival rateContaminated soil reclamationSorghum sudanenseMicroorganism

The invention discloses a method for remediating cesium-contaminated soil through forage grasses and a method for remediating cesium-contaminated soil through forage grasses and microorganisms, and relates to the field of heavy metal contaminated soil remediation. Forage grasses are planted on cesium-contaminated soil, and cesium in the cesium-contaminated soil is enriched through the forage grasses. The forage grasses are one or more of sorghum sudanense, hybrid pennisetum alopecuroides and Timothy. The germination rate and germination potential of the plants are investigated through early germination experiments, and the tolerance of plant seeds to Cs nuclide pollution is guaranteed. Furthermore, the plant height of the screened pasture plants is measured, the dry weight of the pasture plants at the end of vegetative growth is measured, various enrichment parameters are measured and calculated, and the Cs dominant enrichment plants are screened through comparison of multiple parameters. According to the method, three forage plants with high cesium enrichment capacity are screened out, and cesium-contaminated soil is remediated on the basis of the three forage plants. On the basis of remediating cesium-contaminated soil by forage grasses, remediation by forage grasses and microorganisms together is carried out.

Owner:SOUTHWEAT UNIV OF SCI & TECH

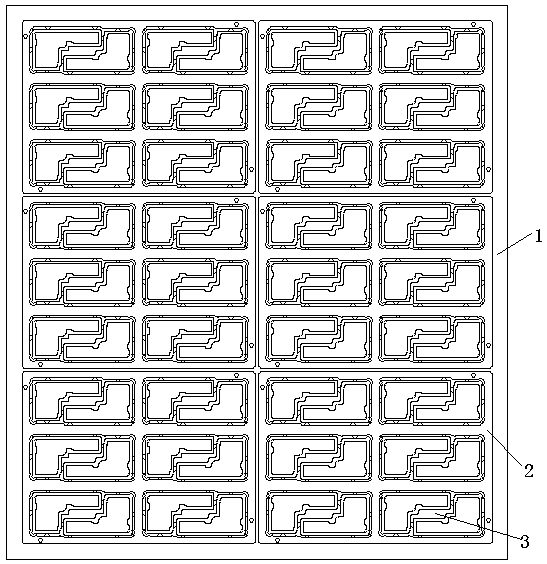

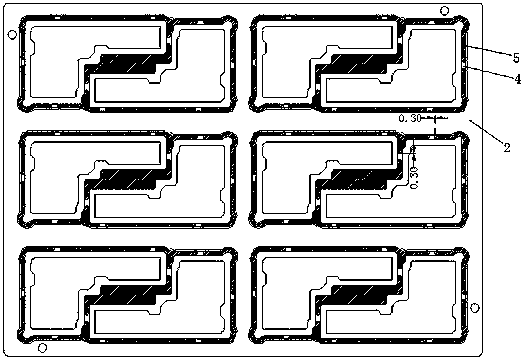

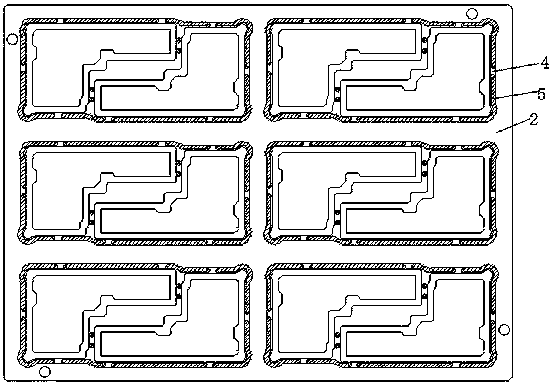

3D switching type PCB and manufacturing method thereof

ActiveCN110896592AAvoid burrsEliminate the effects ofInsulating layers/substrates workingStructural engineeringMechanical engineering

The invention discloses a 3D switching type PCB. The circuit board comprises a PNL board and a PCB arranged on the PNL board. The PCB is provided with at least one inner groove, the edge of each innergroove is provided with an edge covering groove and a connecting position, the connecting positions are used for connecting the inner grooves and connecting the inner grooves and the PNL board, the PCB is reasonable in design, the edge covering grooves can reduce board edge radiation interference, and transmission of high-speed signals is guaranteed. The invention further provides a manufacturingmethod of the 3D switching type PCB, all the steps are easy to control, the problems of burrs and burrs of the edge covering groove are effectively avoided, the precision of the sizes and positions of the edge covering groove and the inner groove is improved, and the reliability of long-term use of a product is improved.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com