Flexible glue feeding mechanism

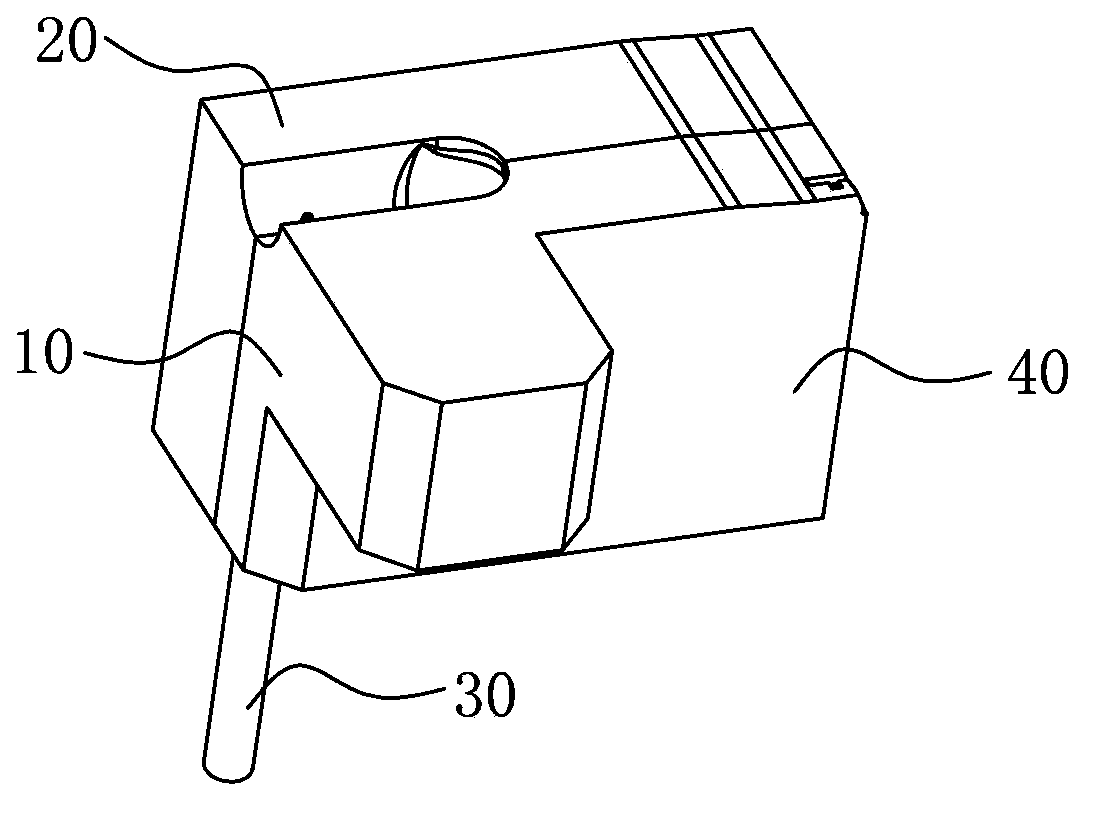

A glue-feeding and soft-glue technology, which is applied in the field of horn-inserted glue-feeding mechanisms, can solve problems such as thimble 30 jamming, thimble jamming, and impact on mass production of products, to prevent jamming and breakage, convenient loading and unloading, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

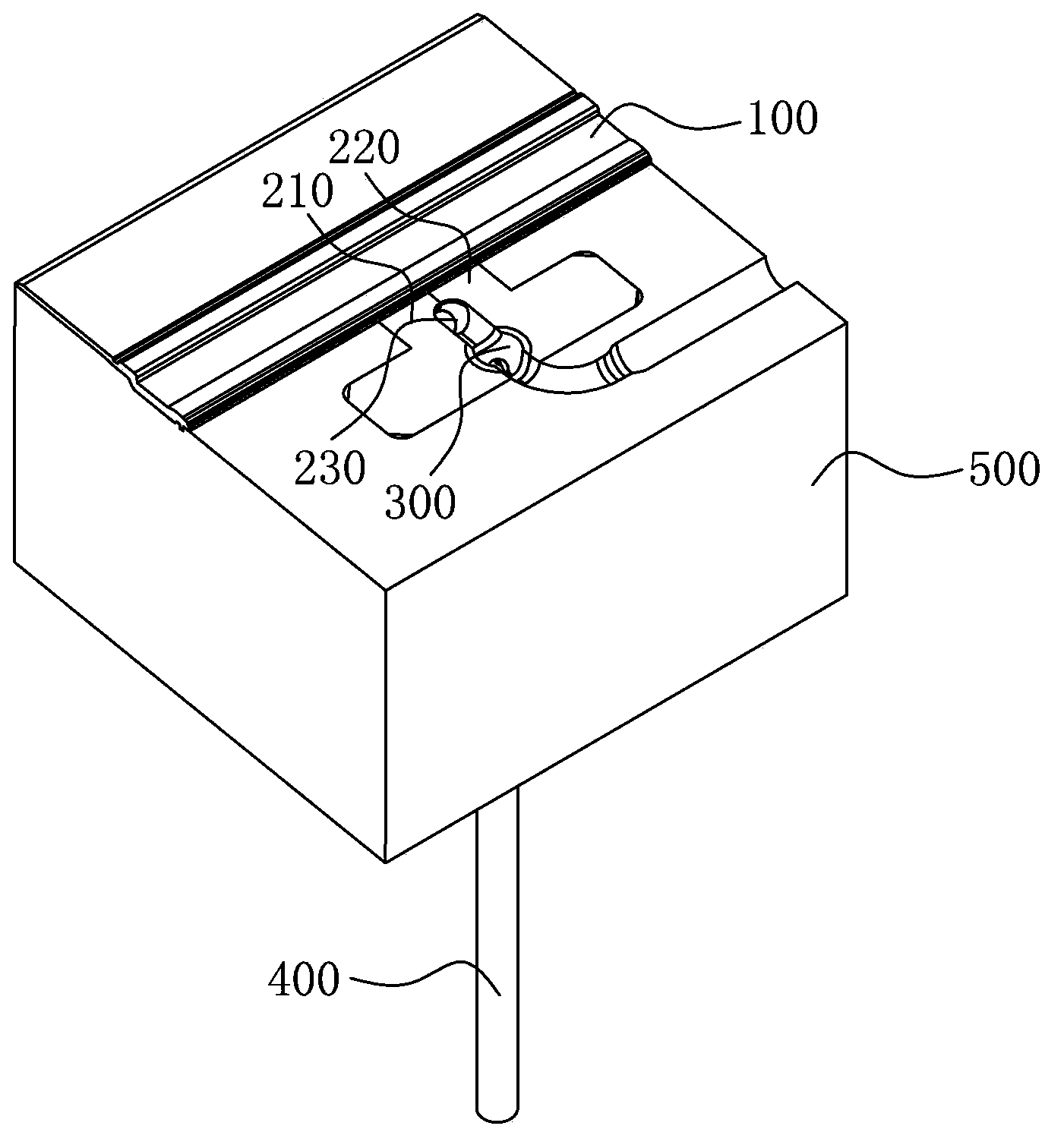

[0019] Please refer to figure 2 and image 3 As shown, the soft glue feeding mechanism of the present invention is applied to a product 100 that requires latent glue feeding in a two-color mold. The mold includes a female mold and a male mold 500 that can be opened and closed. The soft glue feeding mechanism includes:

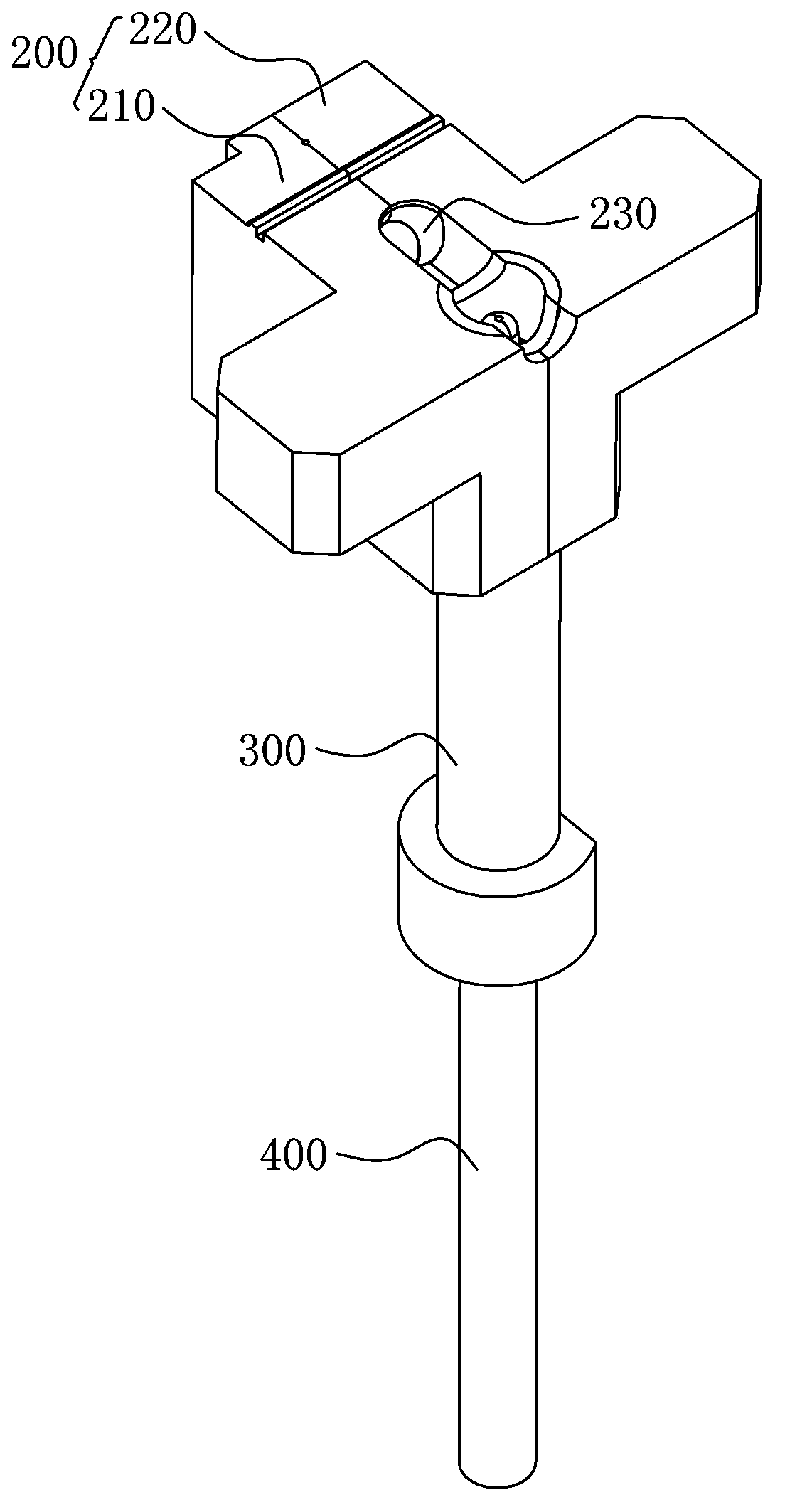

[0020] Horn insert 200, which is composed of two insert monomers 210 and 220, and the horn insert 200 is set in the male mold 500;

[0021] Horn flow channel 230, which is arranged at the junction of the two inlet sub-units 210 and 220, the shape of the horn flow channel 230 is like a horn-like smooth curved cone, and the front end of the horn flow channel 230 is connected to the product 100;

[0022] Inlet 300, the upper end of which is passed through the horn inlet 200 and cooperates with the junction of the two inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com