Flexible clamp device for weak rigidity workpieces

A flexible fixture and weak rigid technology, applied in the field of workpiece processing and clamping, can solve problems such as machining vibration and deformation, and achieve the effects of suppressing machining vibration, improving dynamic machinability, and achieving transient response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

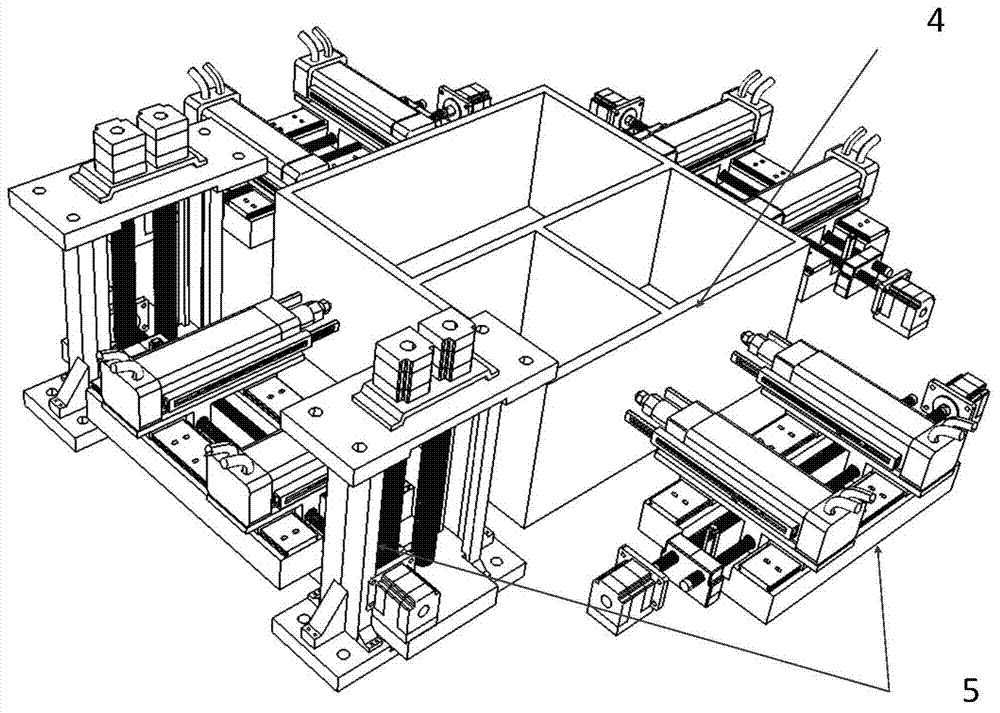

[0025] Such as figure 1 As shown, the weakly rigid workpiece flexible fixture device designed by the present invention is composed of a plurality of fixture assemblies 5 , and the number of fixture assemblies 5 depends on the shape of the workpiece 4 . During work, the fixture assembly 5 surrounds the workpiece 4 and clamps it.

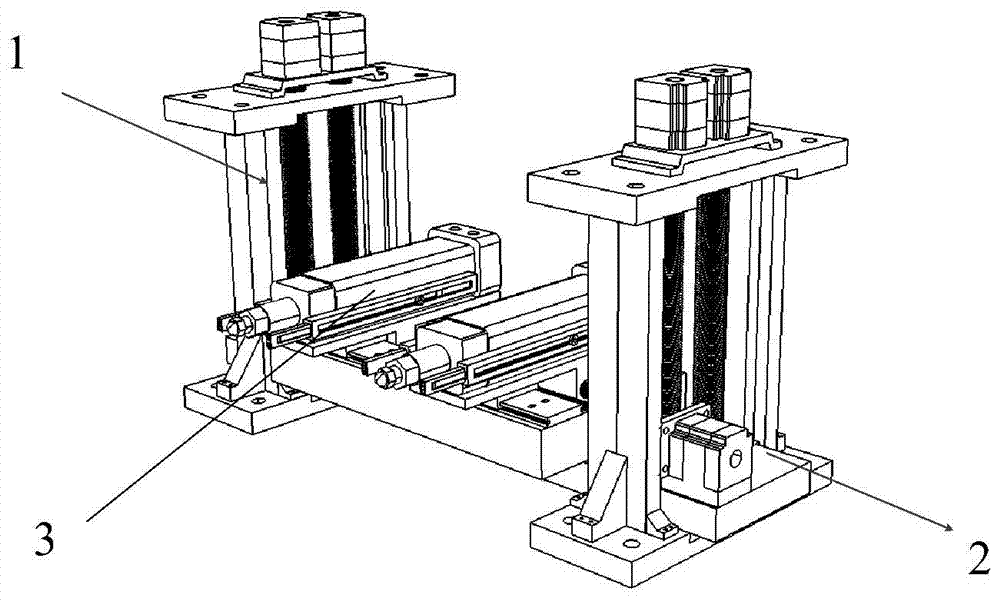

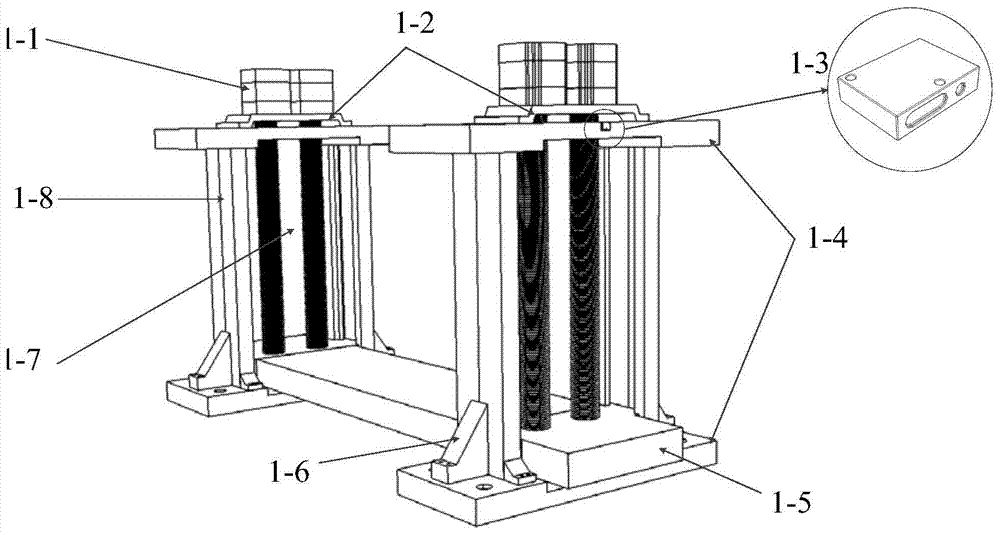

[0026] Such as figure 2 As shown, each clamp assembly 5 includes a clamping mechanism 3, and also includes a lifting mechanism 1 and a horizontal moving mechanism 2 that respectively drive the clamping mechanism 3 to lift and translate. The lifting mechanism includes lifting platforms 1-5, the horizontal moving mechanism 2 is fixedly installed on the lifting platform 1-5, and the clamping mechanism 3 is fixedly installed on the horizontal moving mechanism 2.

[0027] Each fixture assembly 5 is composed of an executi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com