3D switching type PCB and manufacturing method thereof

The technology of a kind of PCB board and manufacturing method is applied in the field of 3D transfer type PCB board and its production, which can solve the problems of inability to make transfer type PCB board, unreasonable design of transfer type PCB board, and difficulty in manufacturing, etc., and achieve reduction Wick effect, avoid burrs, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

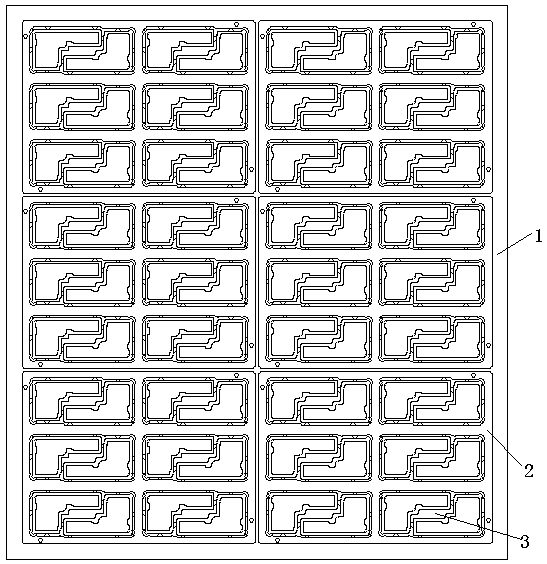

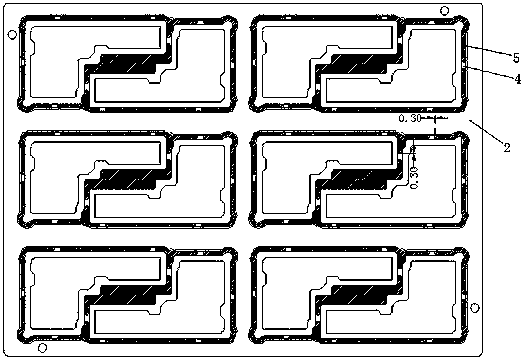

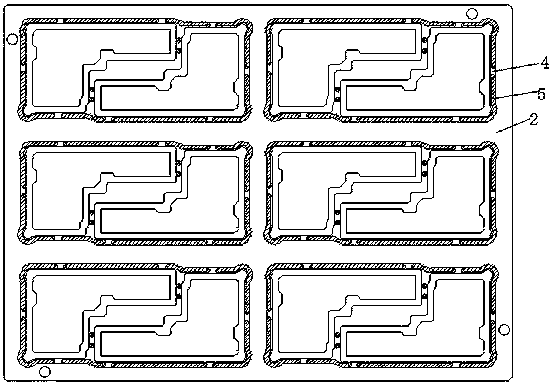

[0033] With reference to the accompanying drawings, a 3D transfer PCB board includes a PNL board 1 and a PCB board 3 located on the PNL board. The PCB is provided with at least one inner groove 6, and the edge of the inner groove 6 is provided with Edge wrapping groove 5 and connection position 4, the connection position is used to connect between each inner groove, and between the inner groove and the PNL board. Reference attached figure 1 The PNL board is composed of 6 SET boards 2, each SET board includes 12 PCB boards, and each PCB board is provided with an inner groove 6.

[0034] A method for manufacturing a 3D transfer type PCB board, the PNL board is followed by the following steps:

[0035] S1: Carry out cutting, baking, copper reduction and drilling on the PNL board in sequence. PNL board cutting substrate is made of high TG and CAF-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com