Die-casting forming mold of music gift box baseplate

A technology of die-casting and bottom plate, which is applied in the field of die-casting molds, can solve the problems of low production efficiency, poor sound quality of the musical instrument, and large tolerance of the position of threaded holes, etc., and achieves the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

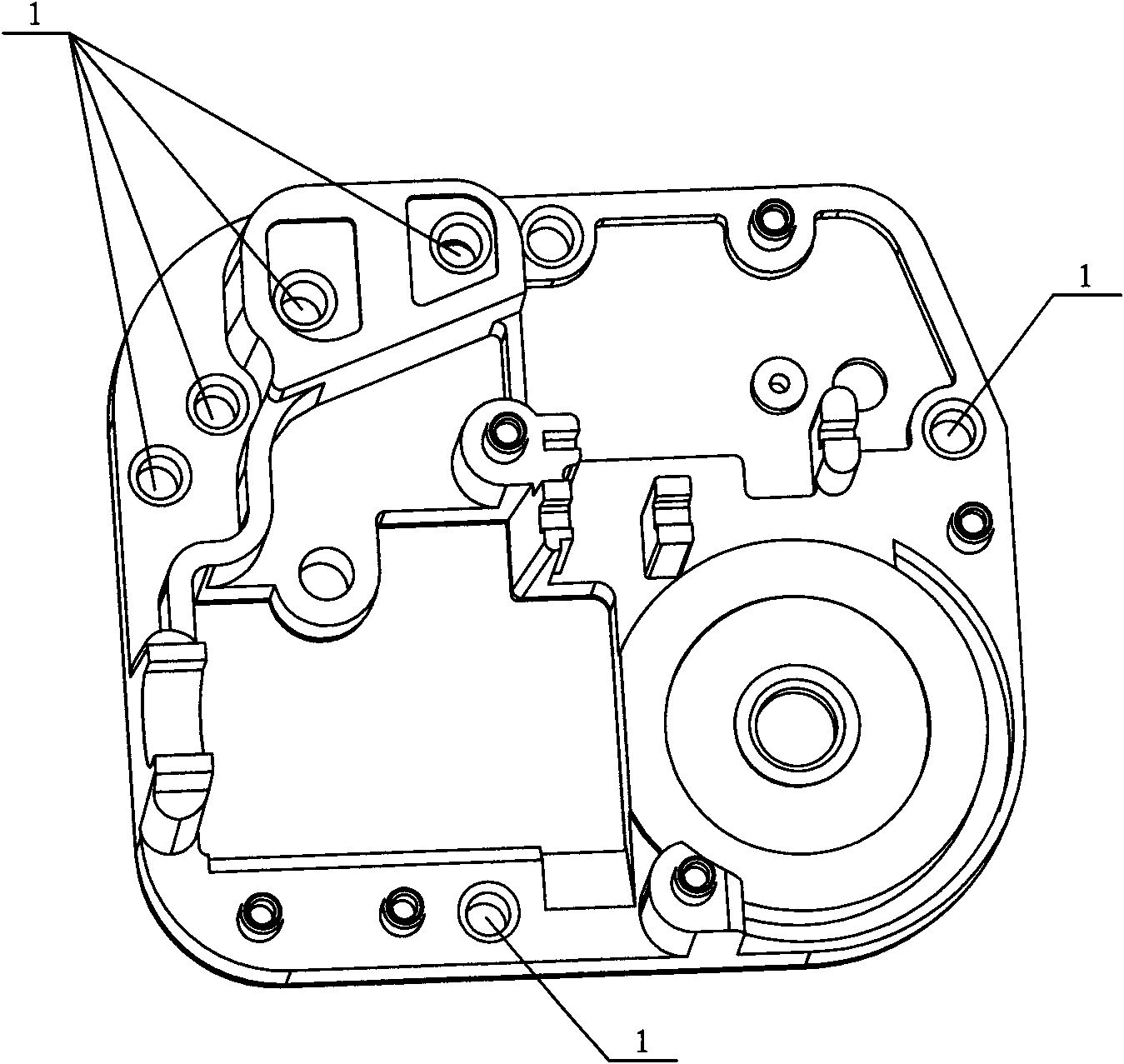

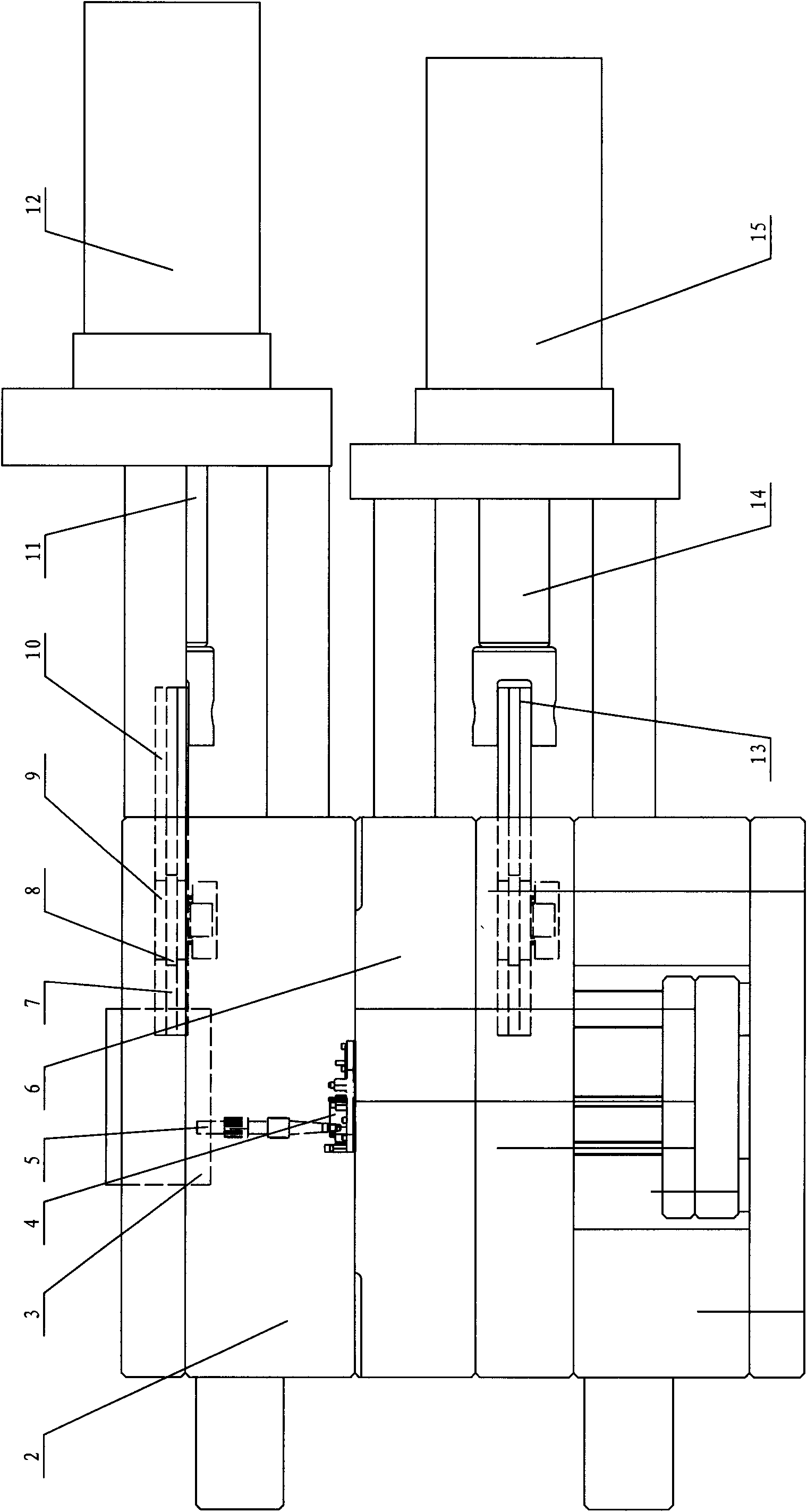

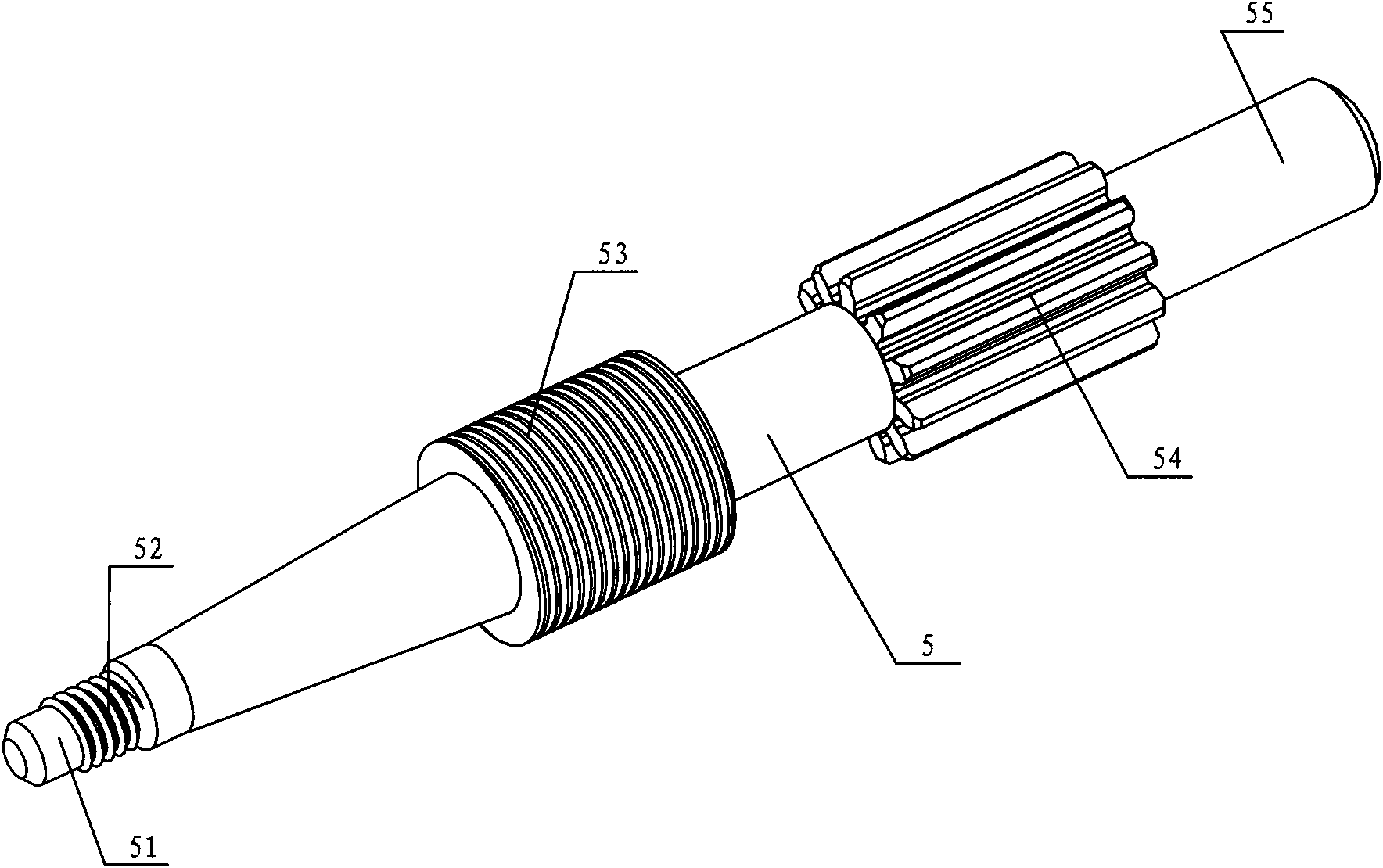

[0024] Depend on Figure 1 to Figure 5 As can be seen from the structural schematic diagram of the die-casting mold of the shown octave bottom plate, it includes a main hot runner 18, an upper template 2 with an upper mold core and a lower template 6 with a lower mold core, and the upper and lower mold cores are combined An octave bottom plate cavity 4 is formed, and the main hot runner 18 communicates with the octave bottom plate cavity 4 . The molding die also includes an upper mold oil cylinder 12 and a gear box 3, wherein the gear box 3 is fixed on the top of the upper template 2, and the gear box 3 is rotatably connected with a plurality of cylinders that can extend into the cavity 4 of the musical instrument bottom plate. Threaded pin 5, the front end of the threaded pin 5 is located at the position of the threaded hole 1 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com