Flame-retardant insulated composite material and preparation technology thereof

An insulating composite material and preparation technology, applied in the field of materials, can solve problems such as inability to guarantee flame retardancy and high temperature resistance, and achieve the effect of ensuring tolerance, strong high temperature resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

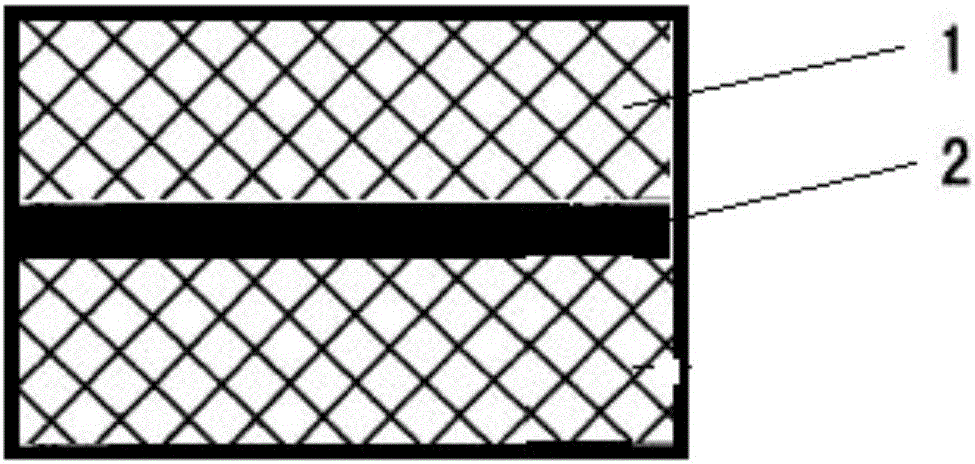

[0025] exist figure 1 In the shown embodiment, the present invention includes meta-aramid paper 1, temperature-resistant chemical film 2, and meta-aramid paper 1 which are in contact with each other in sequence.

[0026] In the embodiment, the meta-aramid paper 1 is composed of 1313 aramid chopped fiber, 1313 aramid precipitated fiber, and 1313 aramid pulp with an absolute mass ratio of 5:8:3; Compared with the meta-aramid paper with compound components, the overall composition of the product is simple, and it is not doped with any chemical substances that can affect the electrical insulation, so the electrical insulation and its stability are excellent.

[0027] In the embodiment, the thickness of the meta-aramid paper 1 is 100 μm; when used in electrical products, controlling the thickness of the meta-aramid paper 1 to 100 μm can not only play the protective function of flame retardant and heat insulation, but also facilitate the Forming of flame-retardant insulating compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com