Device for carrying out adiabatic calorimetric measurement at high temperature and high pressure

A technology of adiabatic calorimetry, high temperature and high pressure, applied in the field of adiabatic calorimetry measurement devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

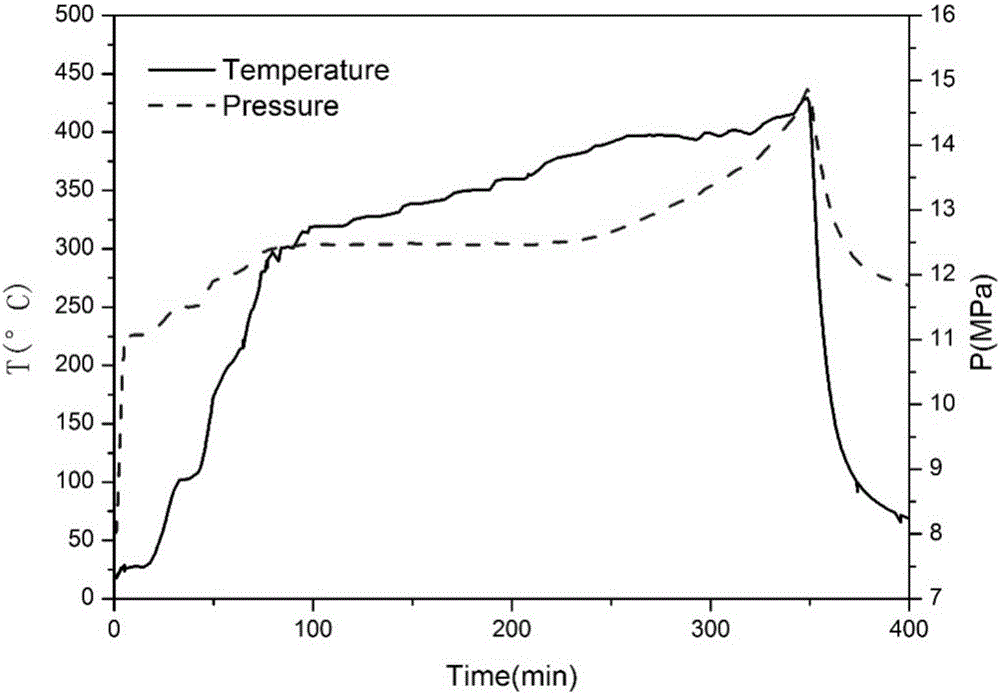

[0024] The invention provides a device capable of performing calorimetric testing at temperatures below 800°C and below 20 MPa, capable of performing calorimetric measurement in adiabatic mode and isothermal mode, capable of implementing precise control over the reaction process and capable of collecting and analyzing data in real time.

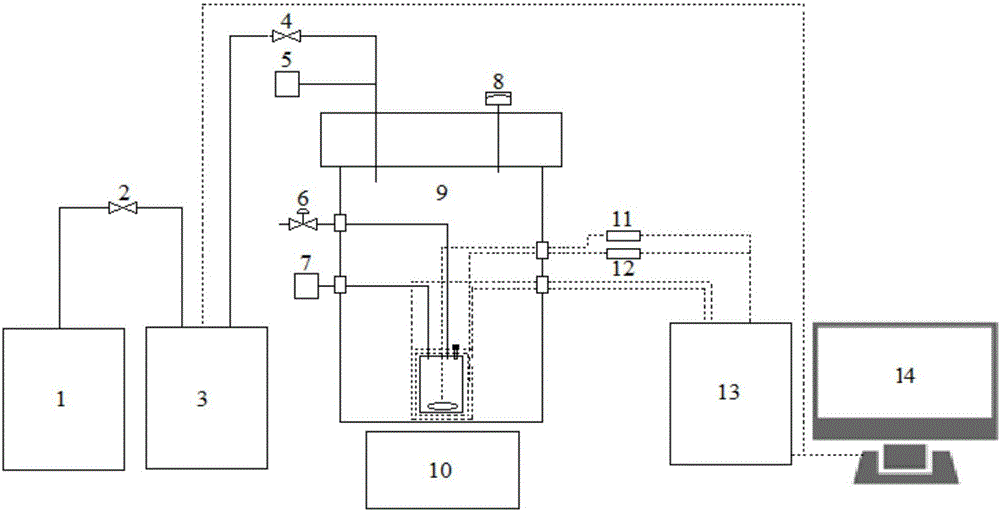

[0025] The device is mainly composed of the following parts (such as figure 1 shown):

[0026] Central control system: generally consists of a signal acquisition card, a digital-to-analog converter and pre-programmed computer software.

[0027] Pressure control unit: connected to the compensation gas (usually nitrogen) gas source, through the opening and closing of the solenoid valve to control the compensation pressure in the kettle;

[0028] Temperature control unit: control the start-stop and power of the heating and heat preservation unit so that the actual temperature conforms to the set value;

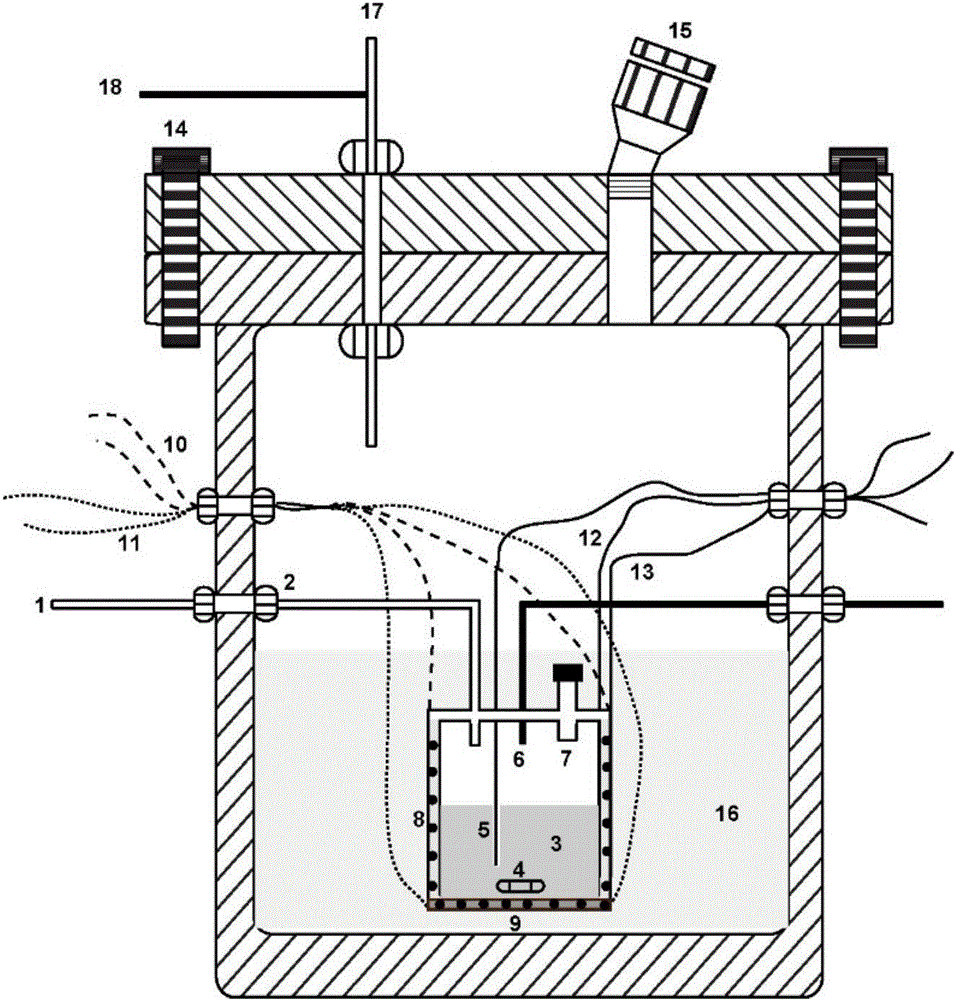

[0029] Reactor (which is the key part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com