Steel tube perforating machine device and perforating method

A technology of punching machine and steel pipe, applied in the field of punching machine, can solve the problems of difficult to guarantee the shape and position tolerance, hidden danger, damage safety of the spreader, etc., and achieve the effect of improving the punching accuracy, ensuring the safety and ensuring the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

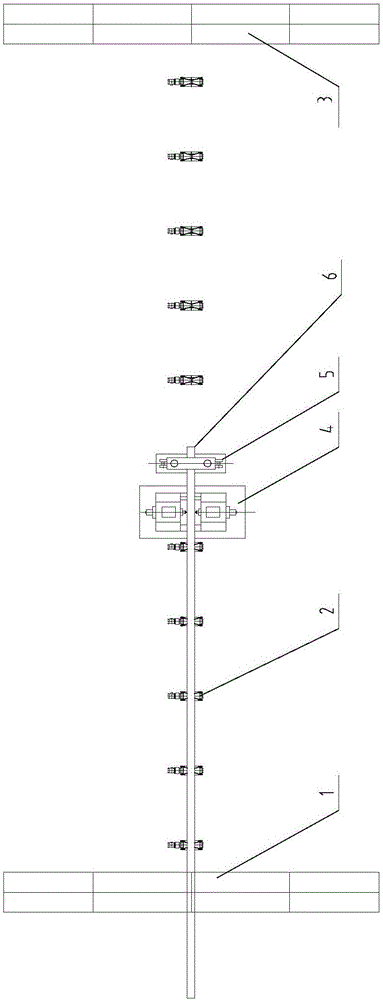

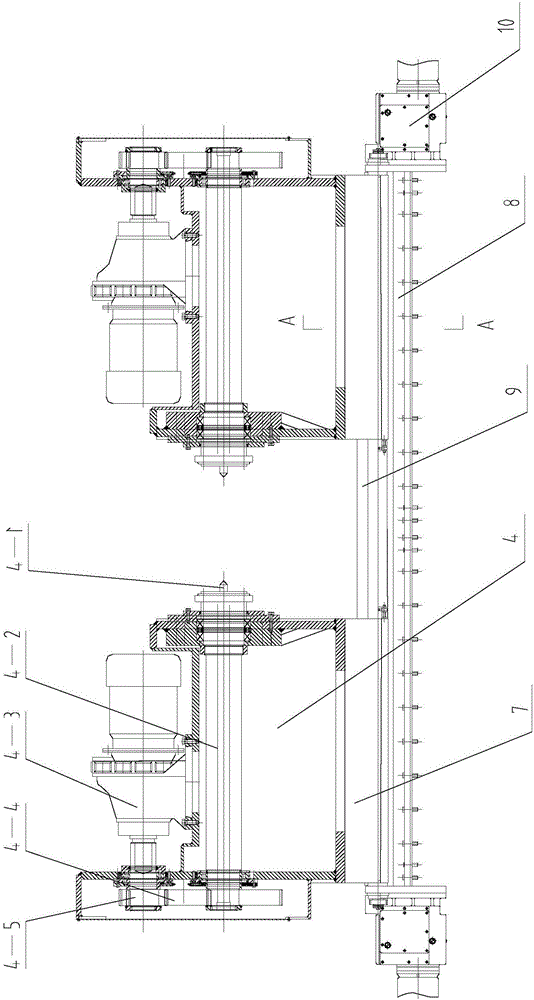

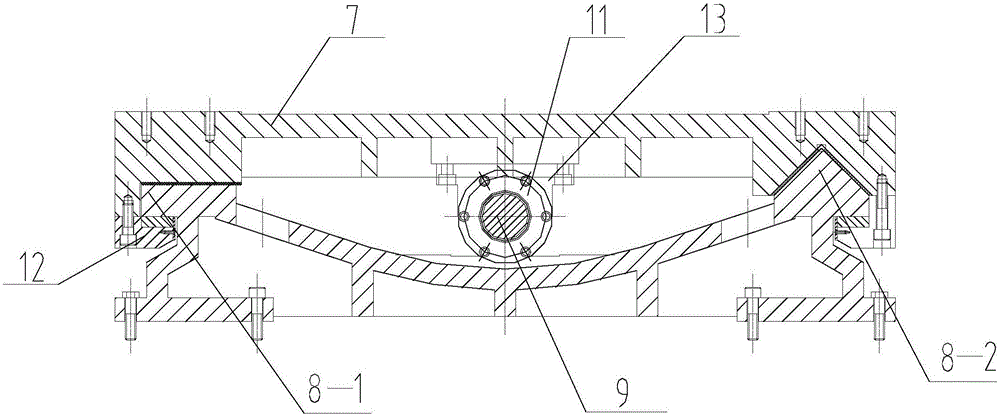

[0023] Such as Figure 1-Figure 4 As shown, a steel pipe punching machine device includes a pipe inlet stand 1, a conveying roller table 2, a bedside box, a steel pipe clamp 5, a pipe outlet stand 6, a pipe inlet stand 1, a conveying roller table 2, a bedside The box and the pipe outlet frame 3 are installed in sequence; the steel pipe fixture 5 is adjacent to the bedside box, and the bedside box includes two symmetrically arranged punchers 4 and a slide table 7 installed at the bottom of the puncher 4 , slideway 8, lead screw 9, screw nut 11, drive motor 10; two punchers 4 are respectively fixedly connected with two slide tables 7 by bolts, two slide tables 7 are slidingly connected with slideway 8, and lead screw 9 It is connected with the driving motor 10 in transmission, and the screw nut 11 is screwed on the lead screw 9, and the nut 11 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com