Patents

Literature

249results about How to "Improve combing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hair conditioner capable of nourishing hair and repairing damage

ActiveCN104095792AFast actingGood responsivenessCosmetic preparationsHair cosmeticsHair conditionerHumectant

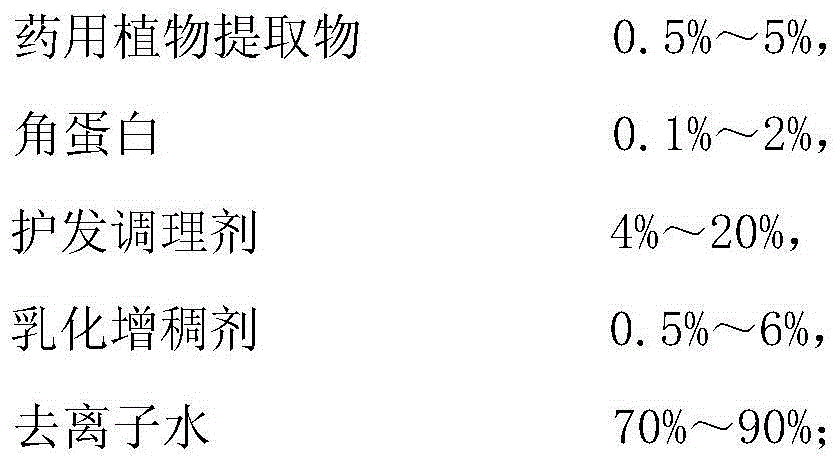

The invention relates to a hair conditioner capable of nourishing hair and repairing damage. The hair conditioner comprises three categories, namely rinsing type, washing-free type and foam type, wherein the rinsing type hair conditioner comprises the following components in percentage by mass: 0.5-5% of a medicinal plant extract, 0.1-2% of keratin, 4-20% of a hair care conditioner, 0.5-6% of an emulsification thickener and 70-90% of deionized water; the washing-free type hair conditioner comprises the following components in percentage by mass: 0.5-5% of a medicinal plant extract, 0.1-2% of keratin, 1-15% of a hair care conditioner, 0.5-2% of an emulsification thickener, 0.05-5% of a humectant and 75-95% of deionized water; the foam type hair conditioner comprises the following components in percentage by mass: 0.5-5% of a medicinal plant extract, 0.1-2% of keratin, 0.5-3% of a foaming agent, 0.5-5% of a hair care conditioner, 0.2-3% of a solubilizer and 83-94% of deionized water. The hair conditioner can more rapidly and efficiently repair damaged hair and nourish hair.

Owner:广州好迪集团有限公司

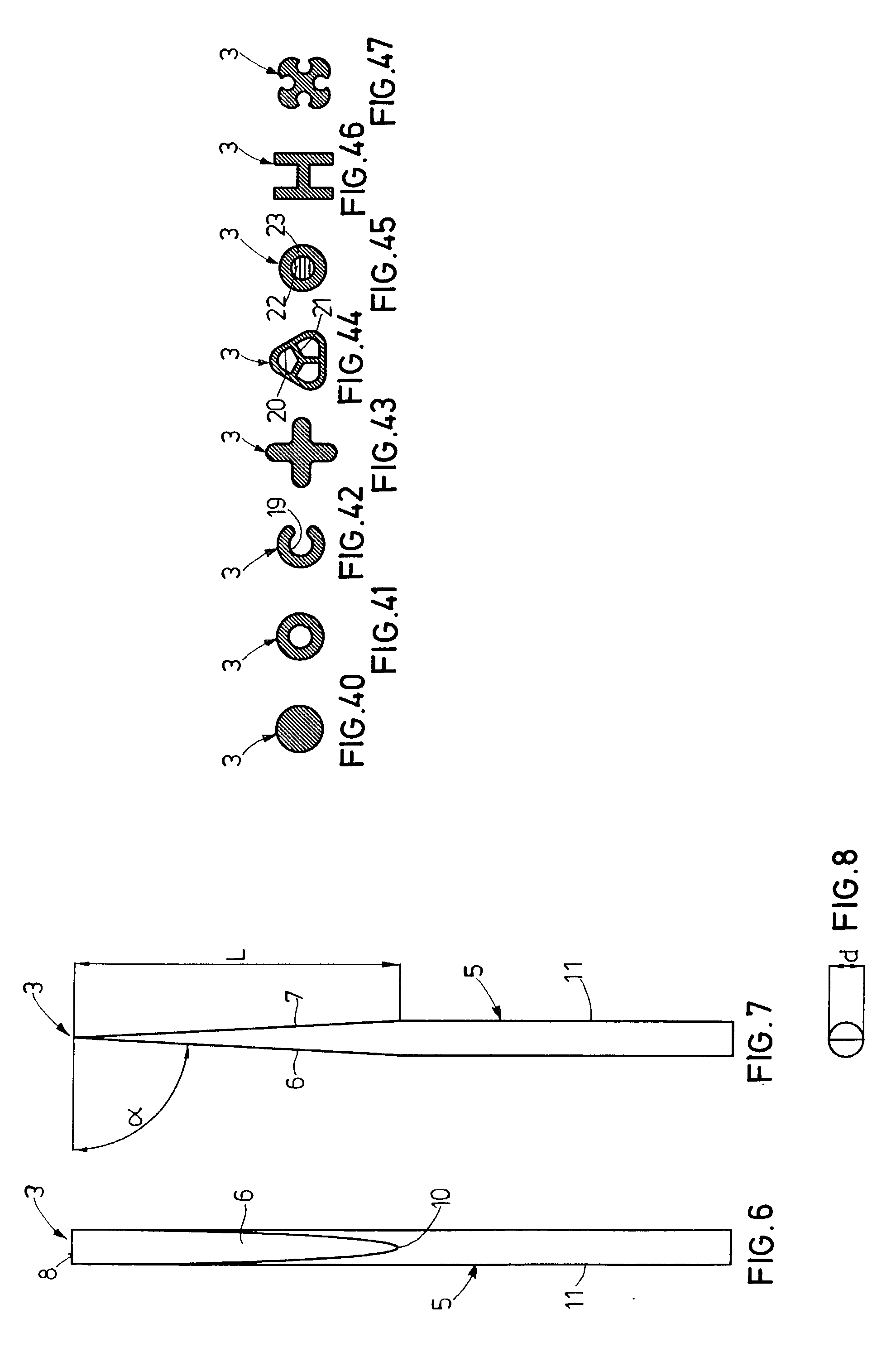

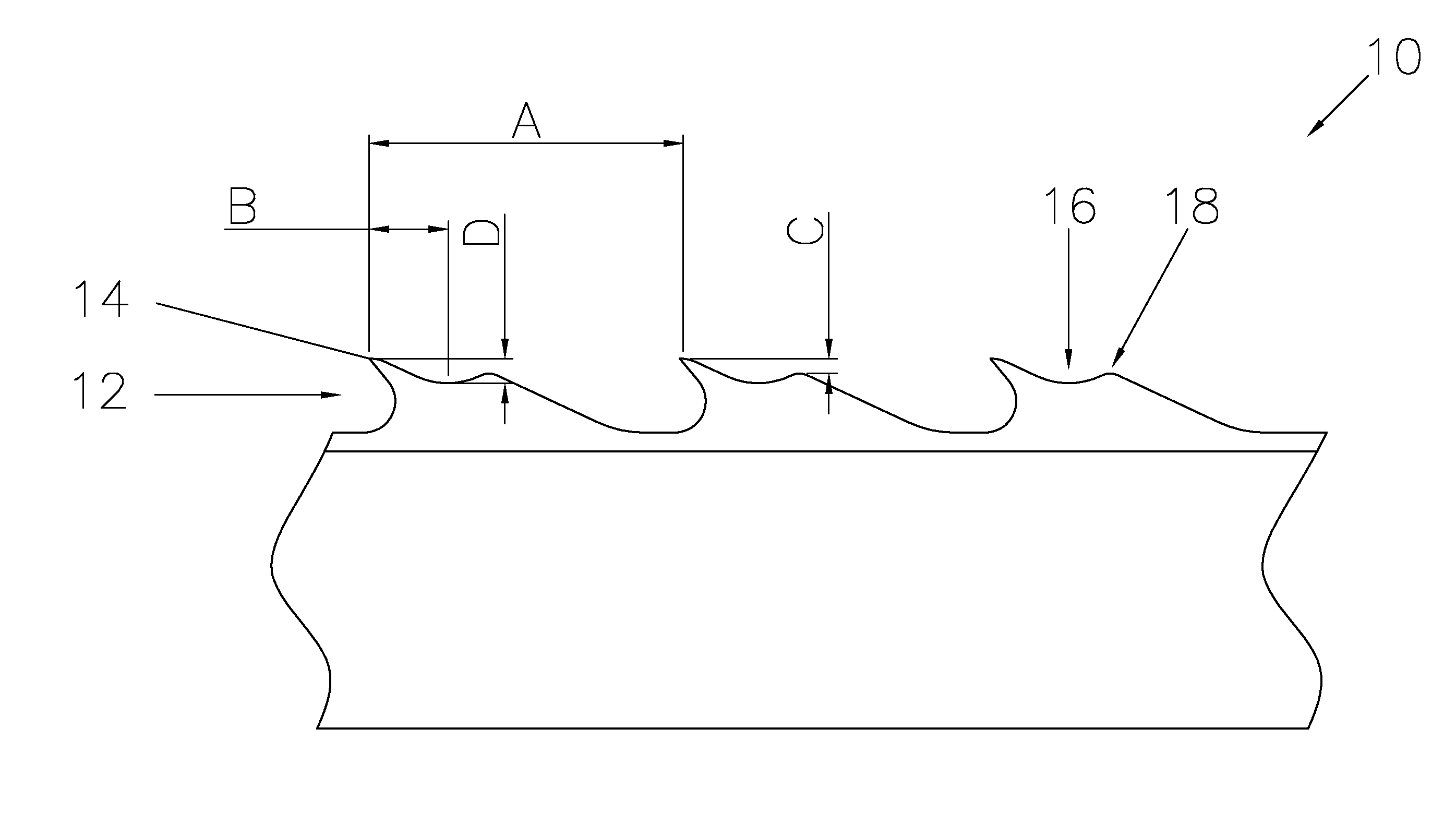

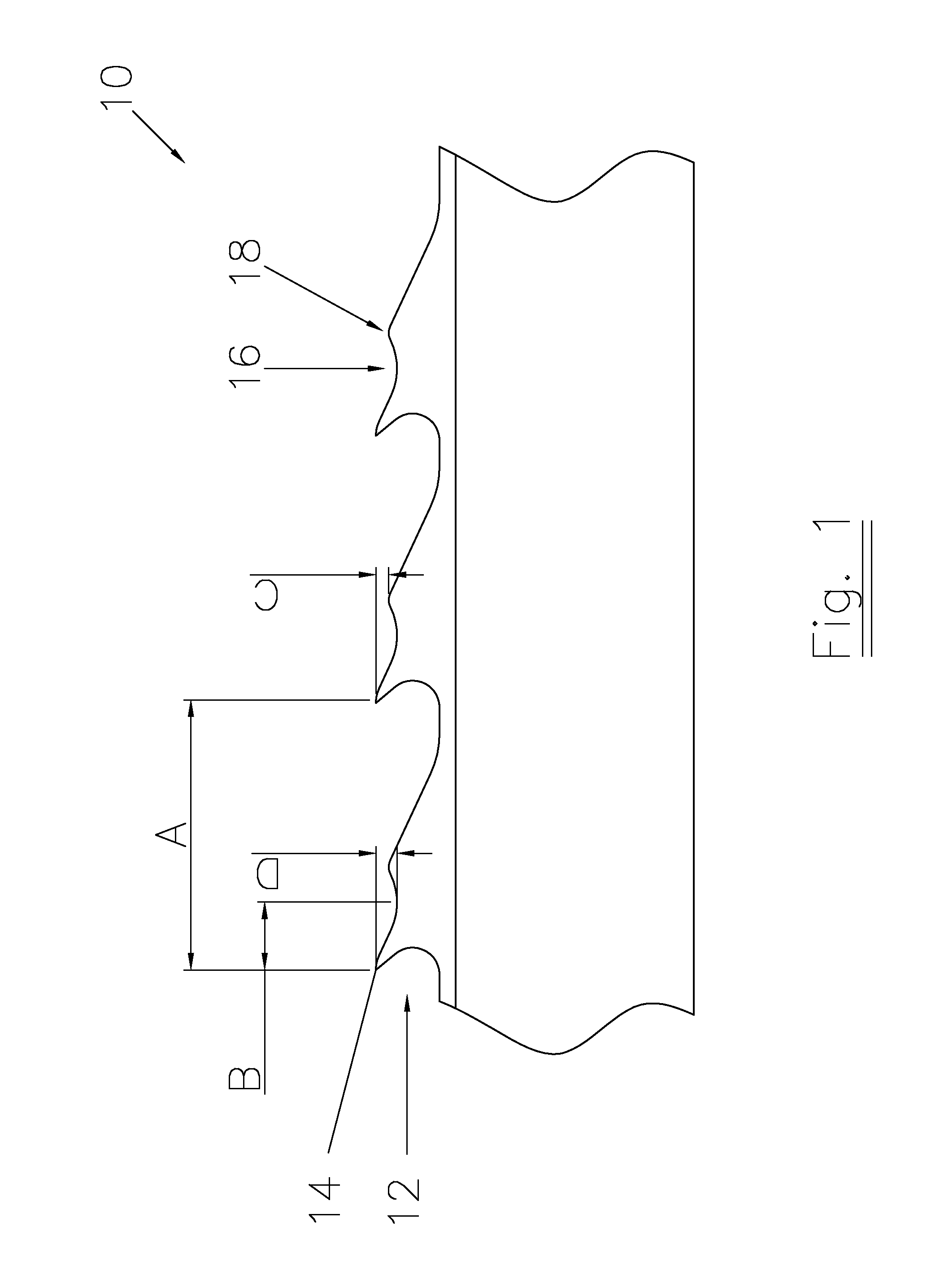

Mascara brush

InactiveUS20040011375A1Improve combing effectEasy and inexpensive to produceBristlePackaging toiletriesBristleEyelash

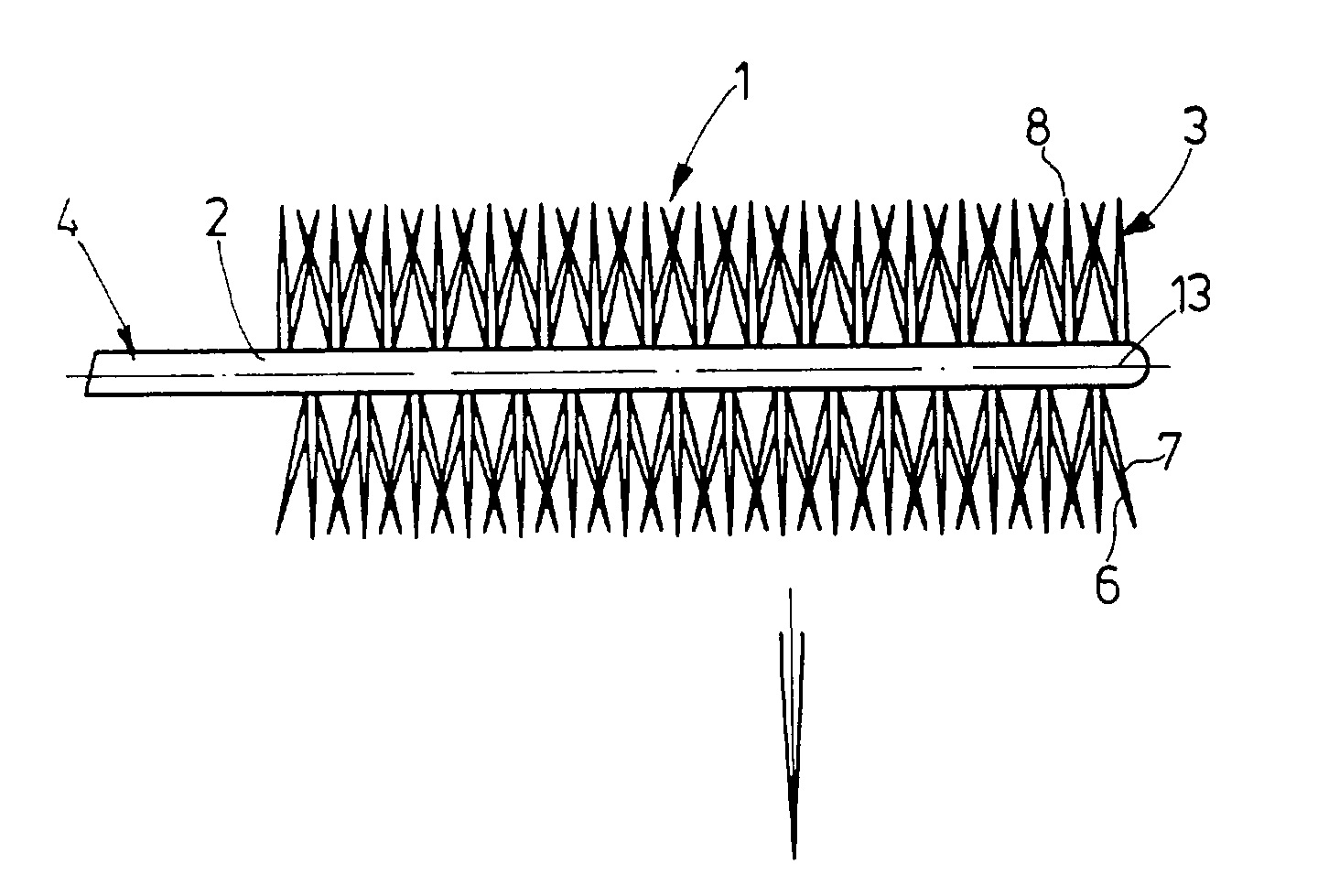

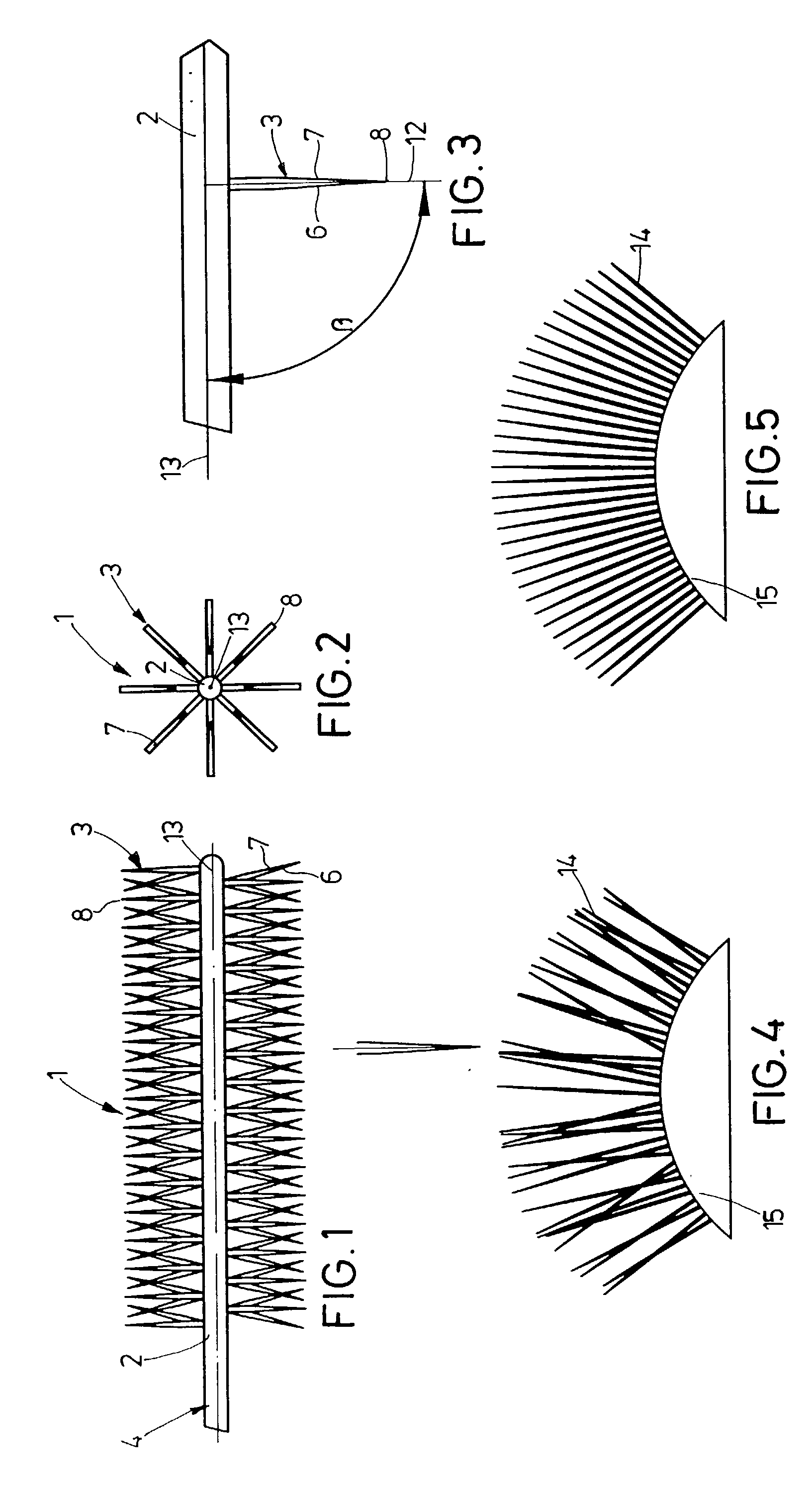

A mascara brush serves to apply a mascara mass onto the eyelashes. It comprises a plurality of bristles that are secured between two twisted wire segments and extend out from the wire segments. The free ends of the bristles are tapered wedge-shaped in cross section. This serves to improve the combing result of the mascara brush.

Owner:GEKA

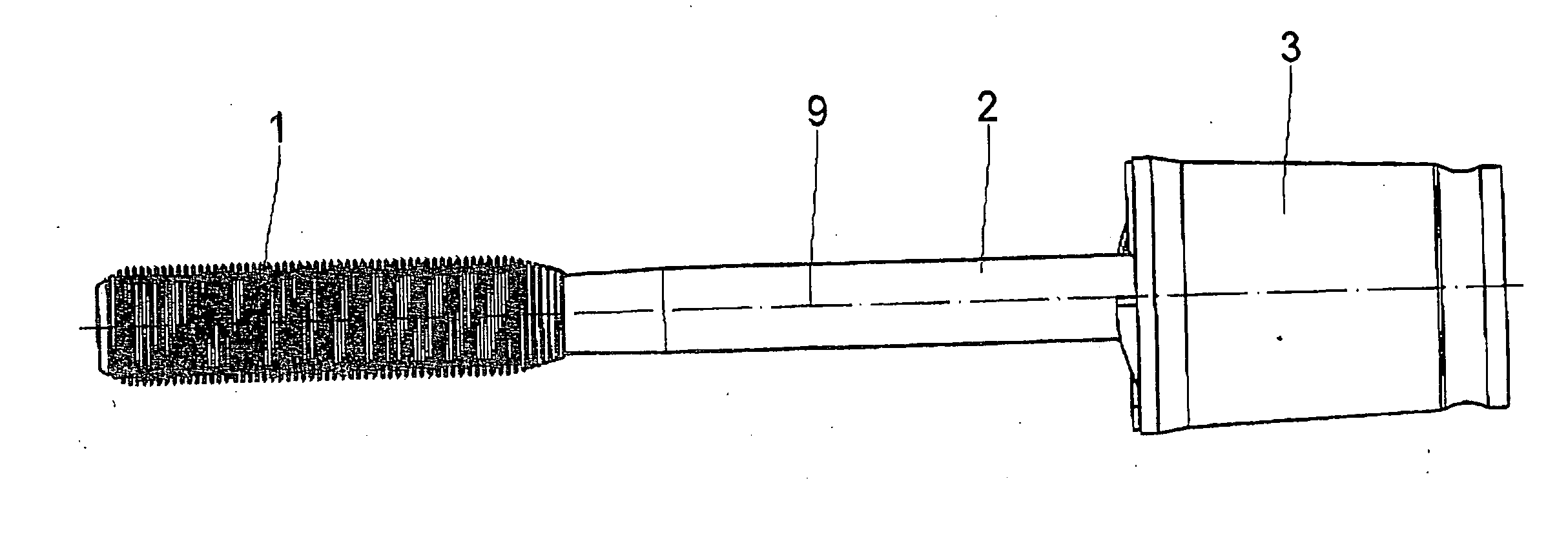

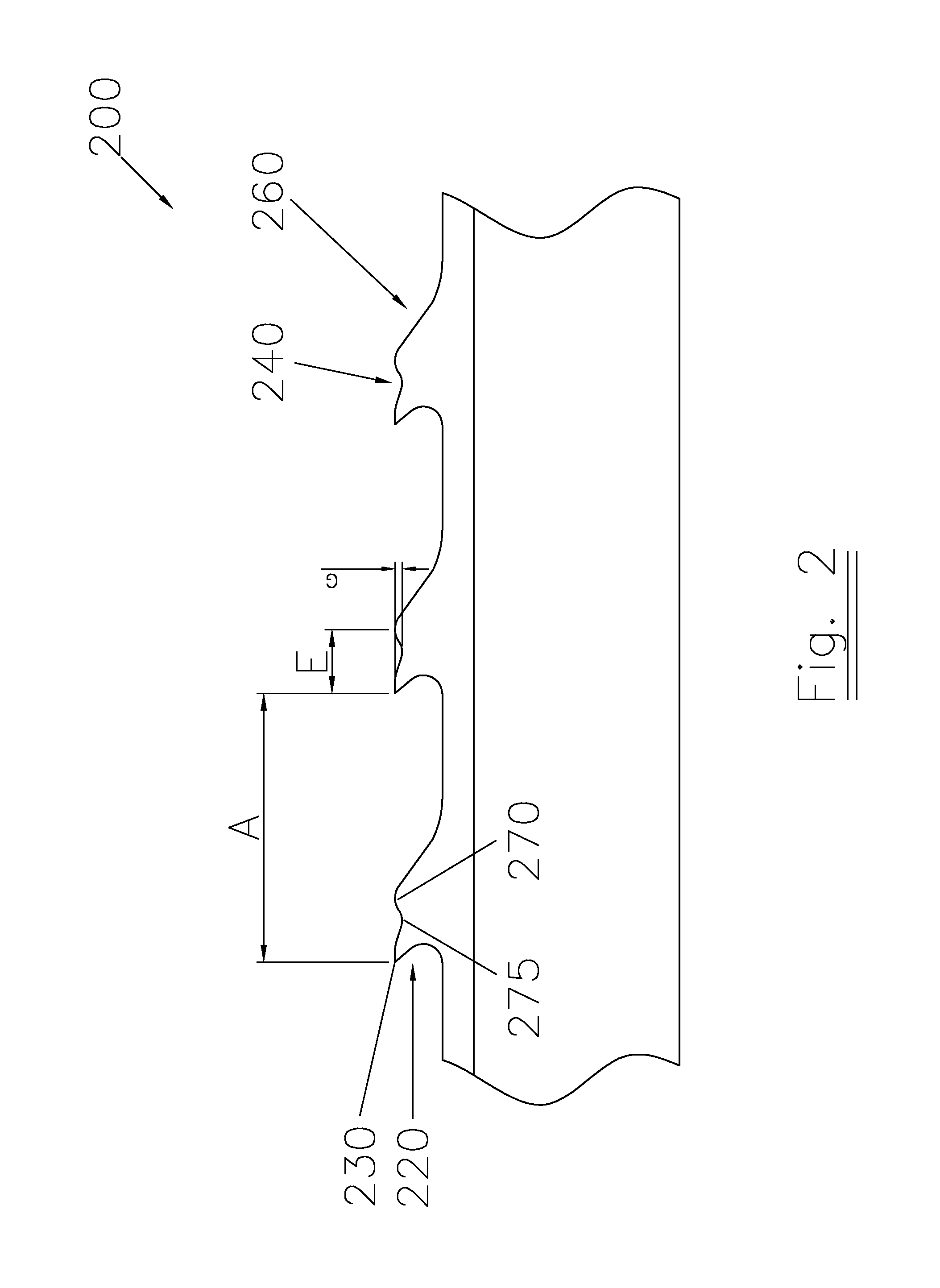

Applicator, in particular for mascara

InactiveUS20070034224A1Increase typeBroaden applicationBrushesPackaging toiletriesHair ColorantsEngineering

In an applicator for mascara, hair colorants or similar cosmetic products comprising a main body of a relatively hard material, such as metal or hard plastic, said main body being connectable to a rod and having a plurality of circumferential grooves, provision is made, in order to improve the combing action and transfer properties, for the grooves to extend parallel to each other and substantially perpendicular to the longitudinal axis.

Owner:GEKA

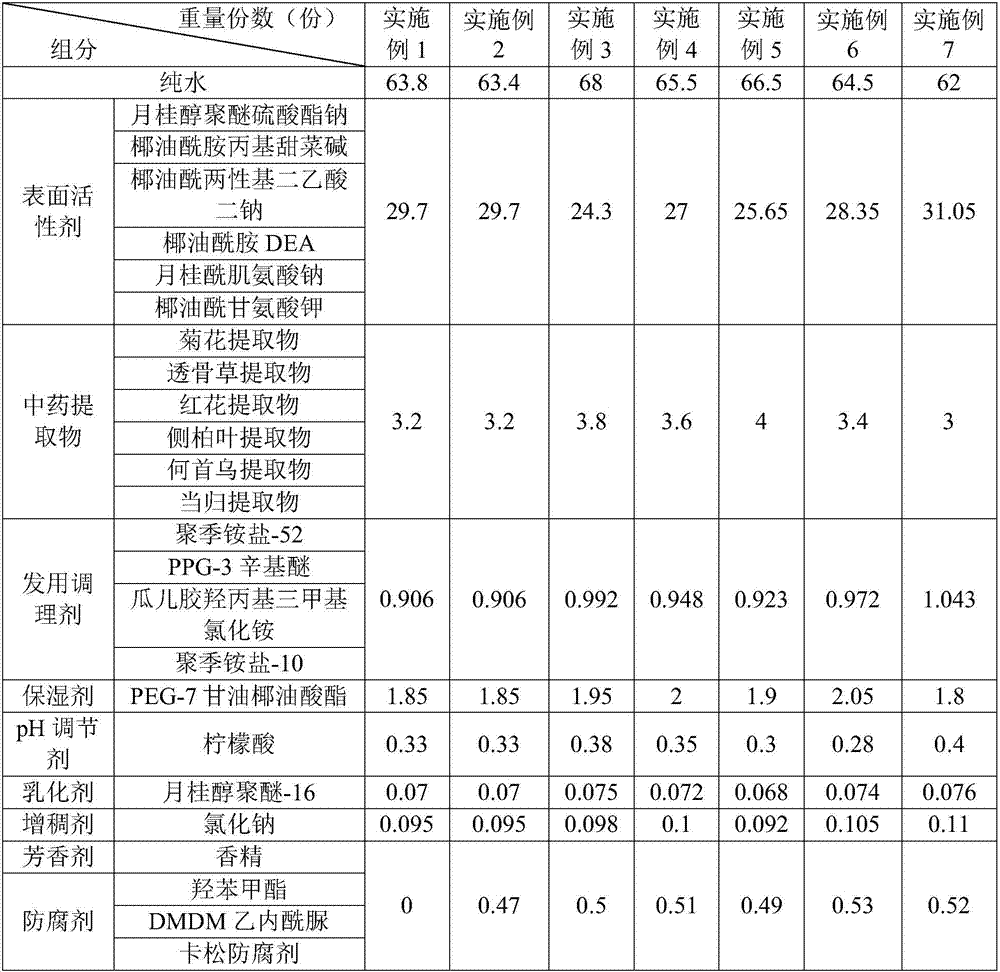

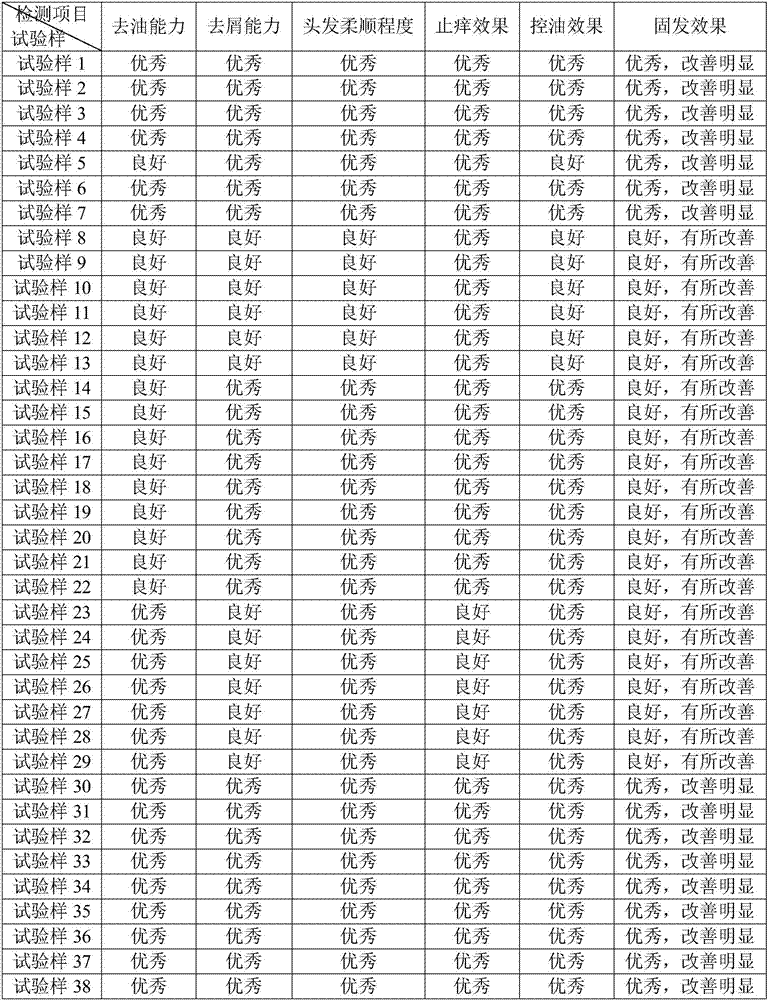

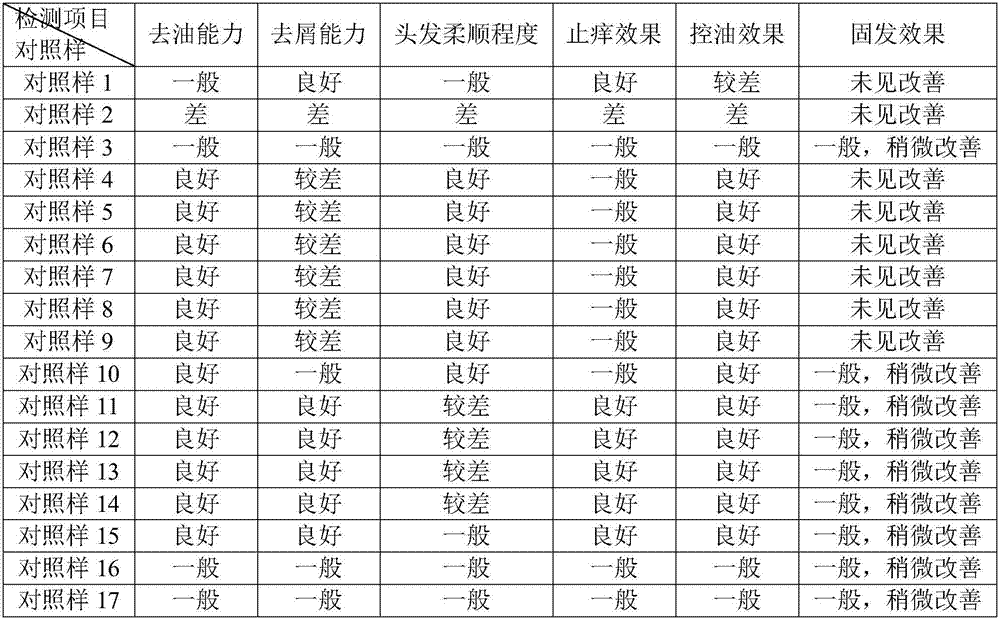

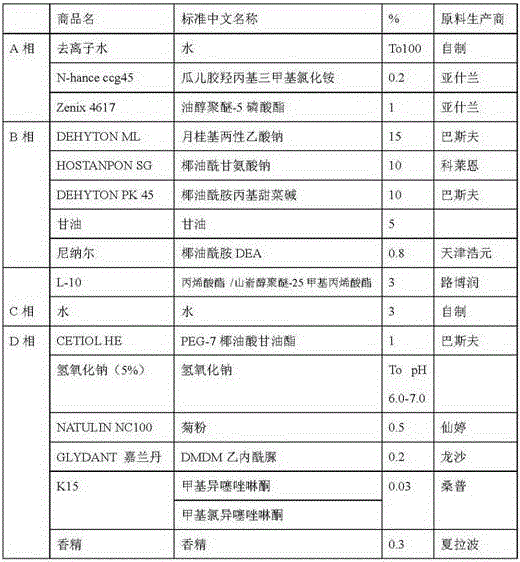

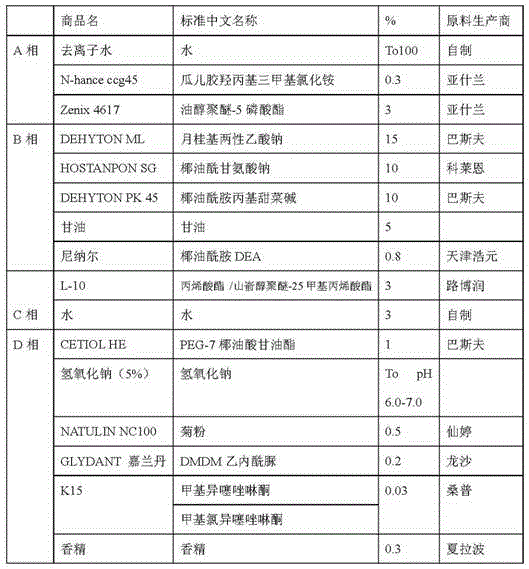

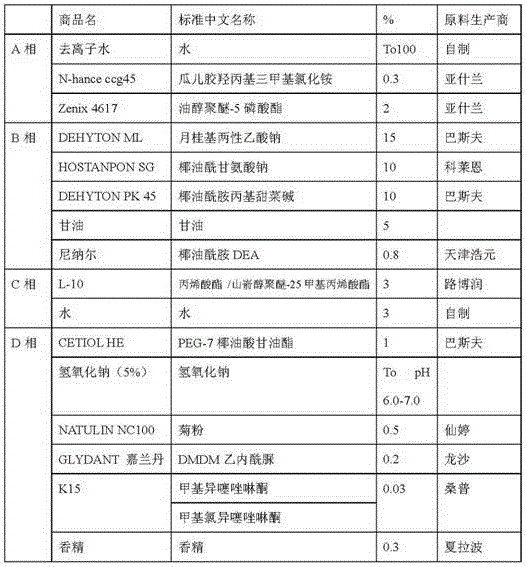

Chinese herb shampoo and preparation process thereof

ActiveCN107536749AImprove combing effectImprove solid hairCosmetic preparationsHair cosmeticsGuar hydroxypropyltrimonium chlorideBetaine

The invention discloses a Chinese herb shampoo and a preparation process thereof. The traditional shampoo is prepared from, by weight, pure water, a surfactant, mixtures of Chinese herb extracts, a conditioner for hair, a humectant, a pH modifier, an emulgator, a thickener and other components; the surfactant at least includes five of laurinol polyether sodium sulfovinate, cocoamidopropyl betaine,amphoteric disodium cocoyl oxalate, cocamide DEA, sodium lauroyl sarcosine and potassium cocoyl glycinate; the mixtures of the Chinese herb extracts include chrysanthemum extracts, garden balsam stemextracts, safflower extracts, cacumen biotae extracts, polygonum multiflorum extracts and angelica sinensis extracts; the conditioner for the hair comprises poly-quaternary ammonium salt-52, PPG-3 octyl ether, guar hydroxypropyltrimonium chloride and poly-quaternary ammonium salt-10; the other components at least include one of preservative and aromatic. The Chinese herb shampoo has excellent effects of hair fixation, itch relief, dandruff and oil removal, oil control, prevention and the like.

Owner:浙江高妍科技有限公司

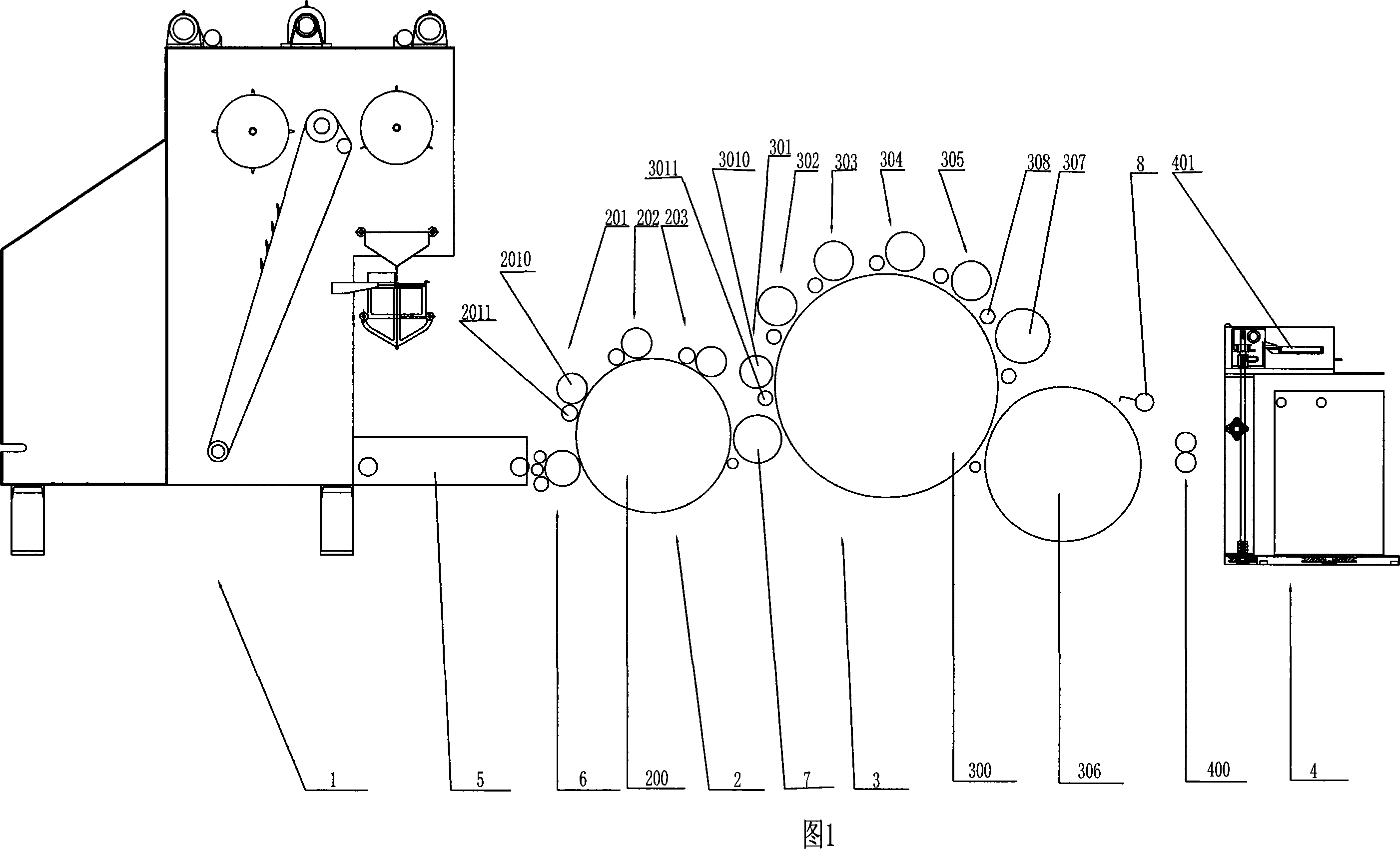

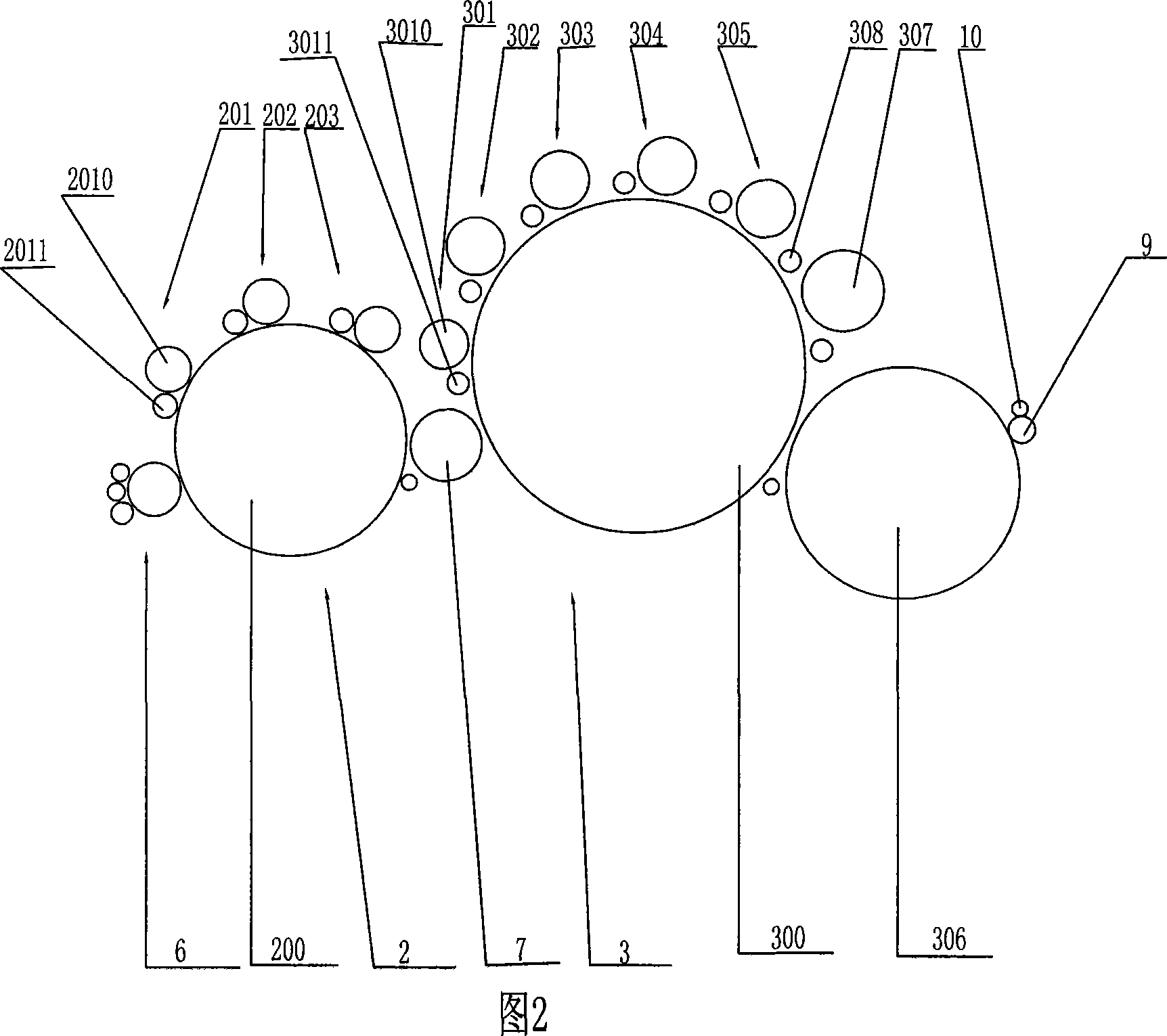

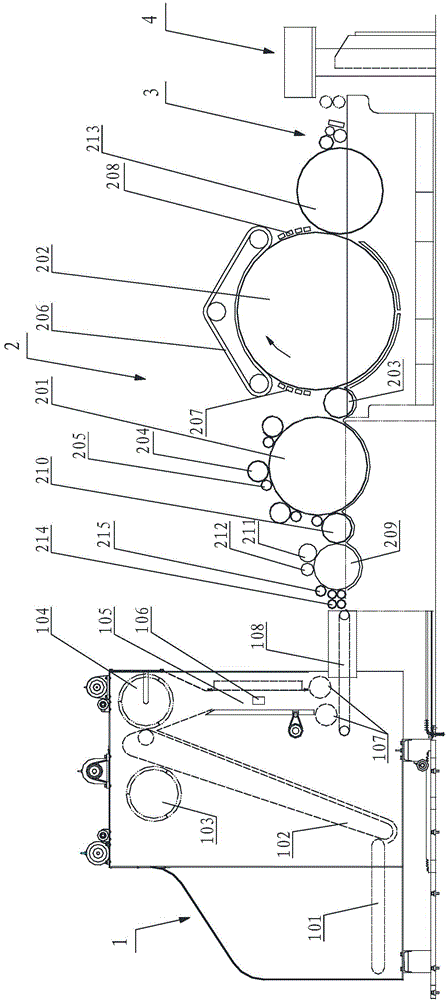

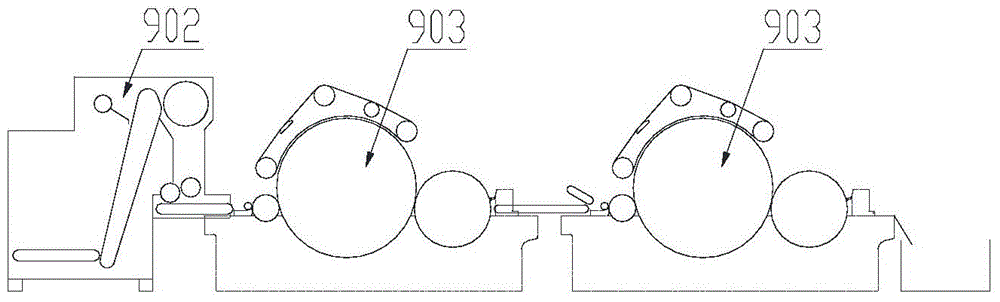

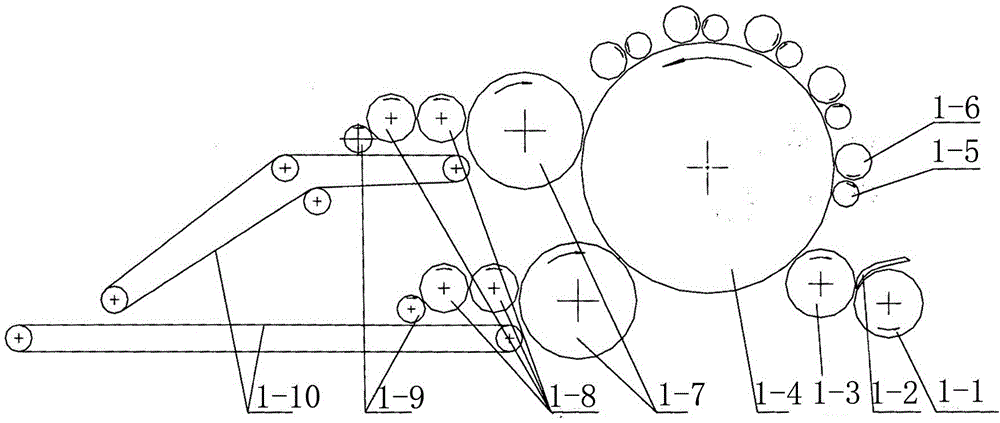

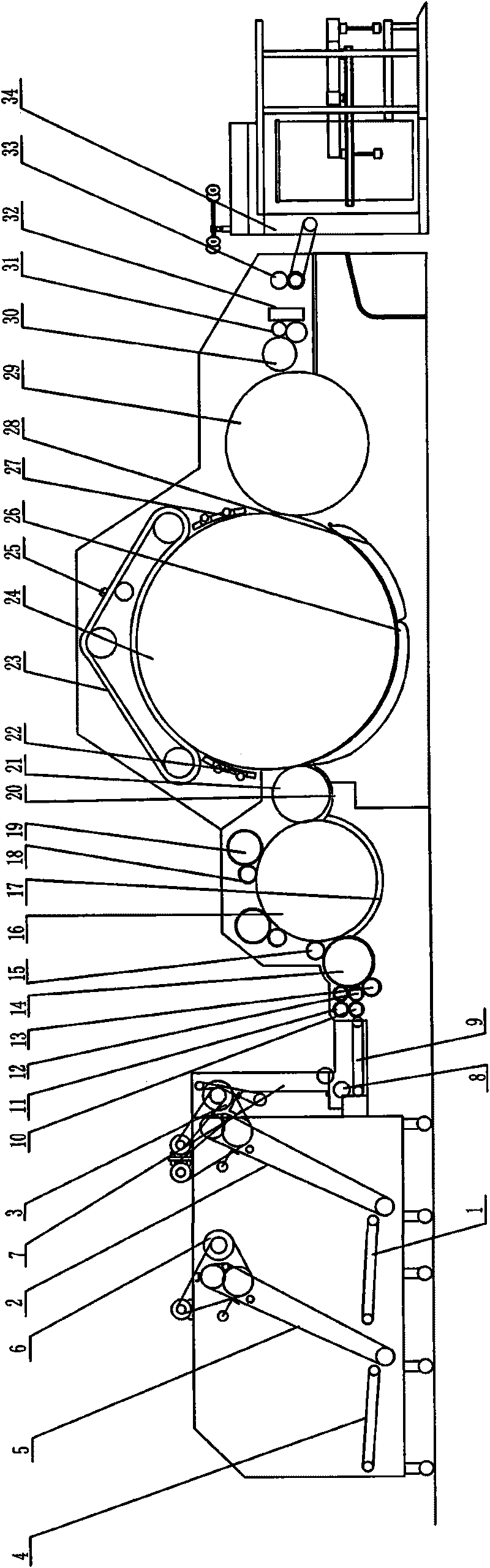

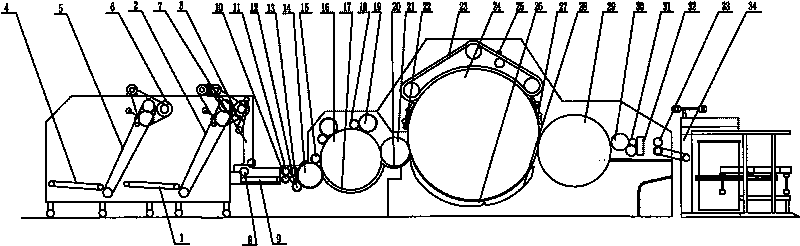

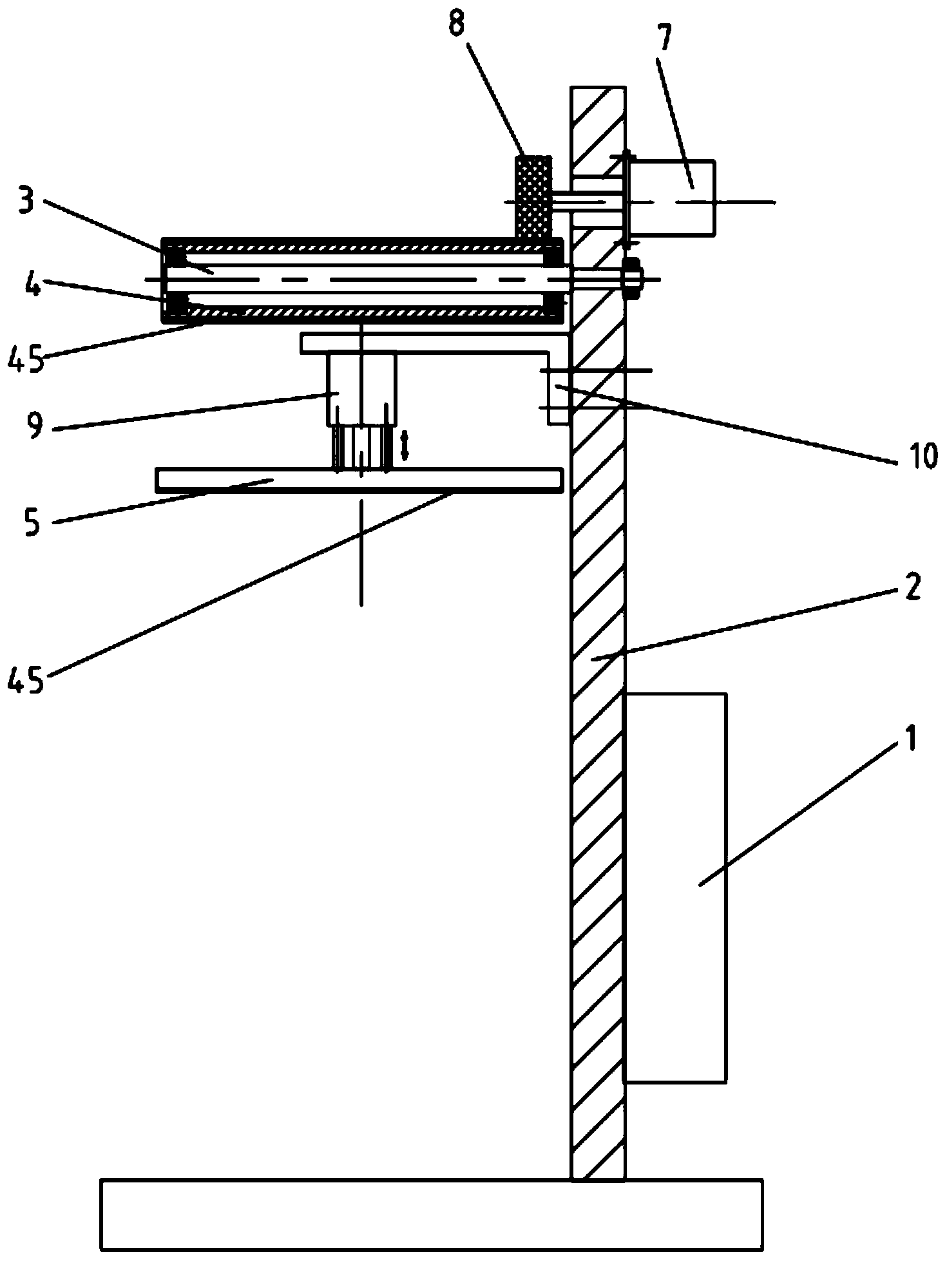

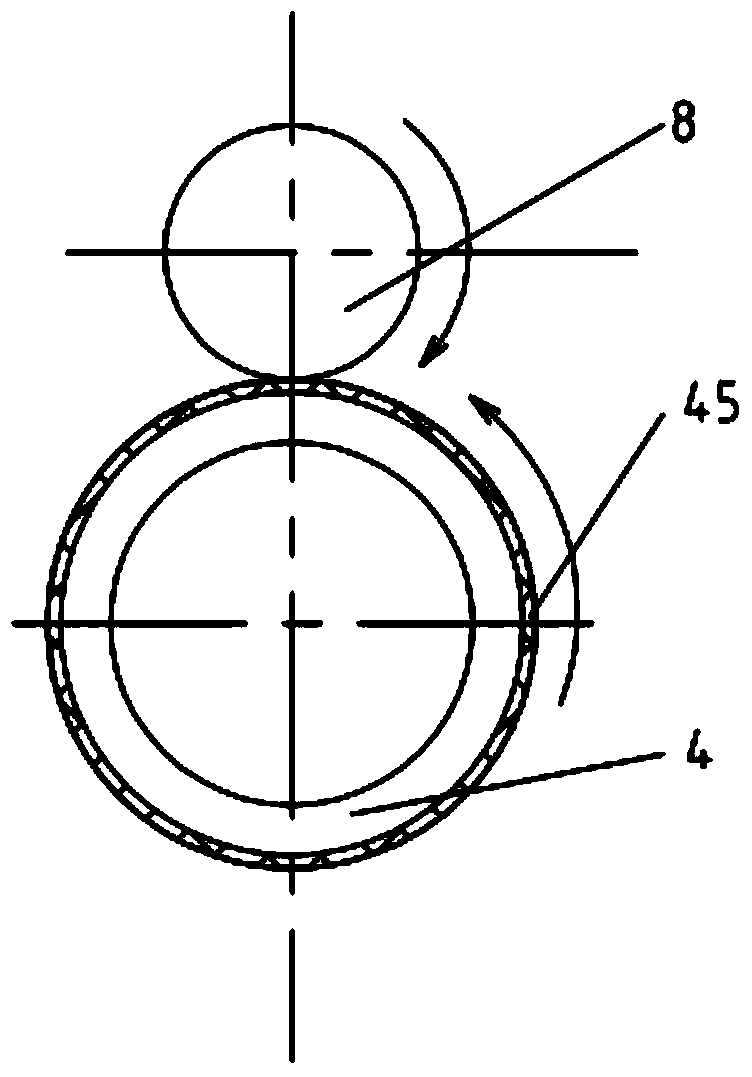

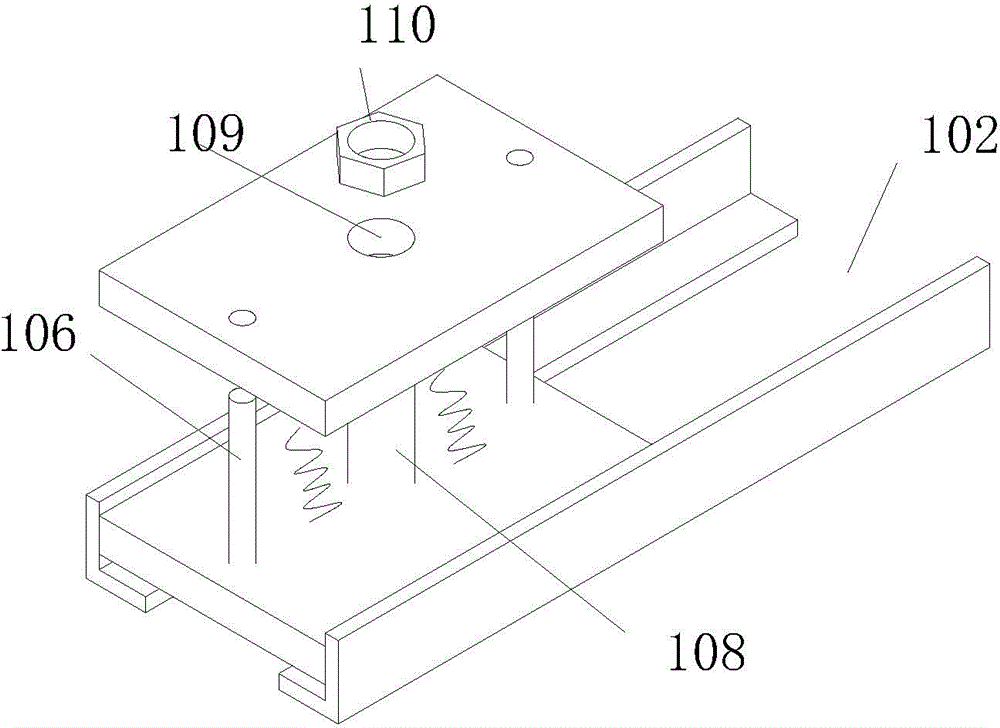

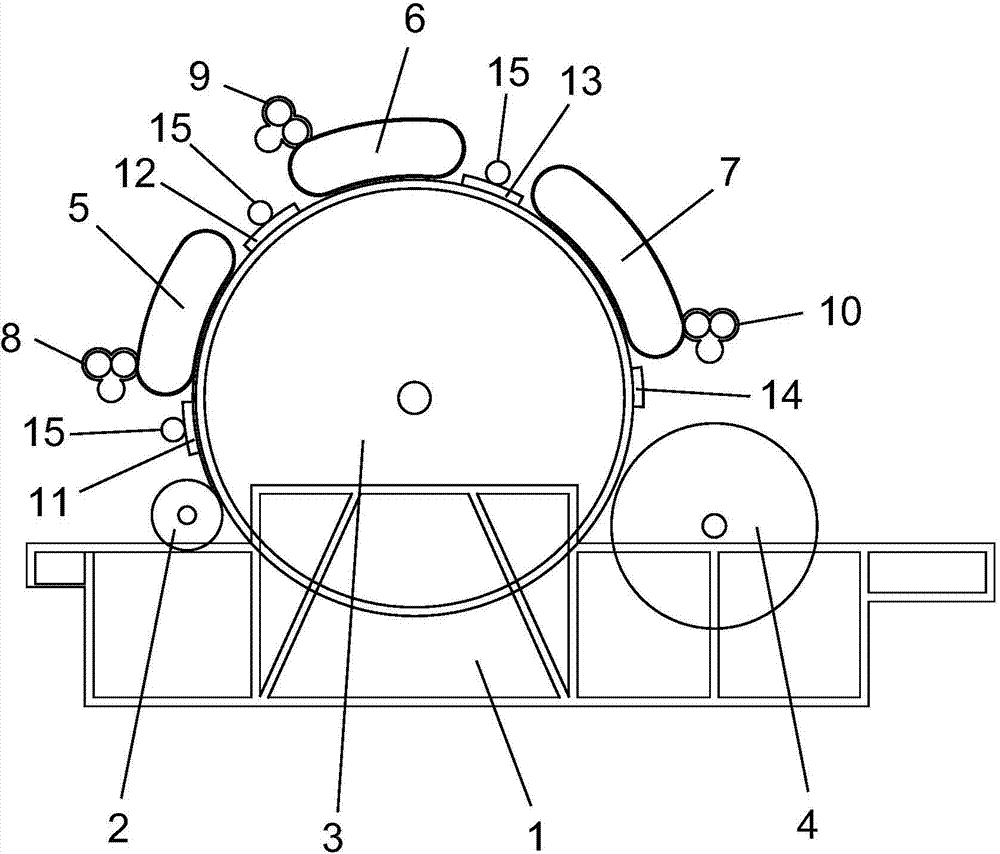

Semi-refined spinning slivering machine

The invention discloses a semi-worsted set frame, which comprises a feeding mechanism, a pre-carding mechanism, a carding mechanism, and a , wherein the pre-carding mechanism is has a breast cylinder on which at least one pair of working roller assemblies are arranged and each working roller assembly comprises a working roller and a stripping roller. The invention is characterized in that the carding mechanism has a large cylinder and a doffer, wherein the large cylinder is provided with at least one pair of working roller assemblies each comprising a working roller and a stripping roller; the breast cylinder is coated with a metal wire clothing; and the large cylinder and doffer are respectively coated with flexible wire clothing. It is proven that the invention can greatly improve the carding effect of special fibers such as wool fibers and reduce the fiber damage rate below 6 percent.

Owner:青岛东佳纺机(集团)有限公司

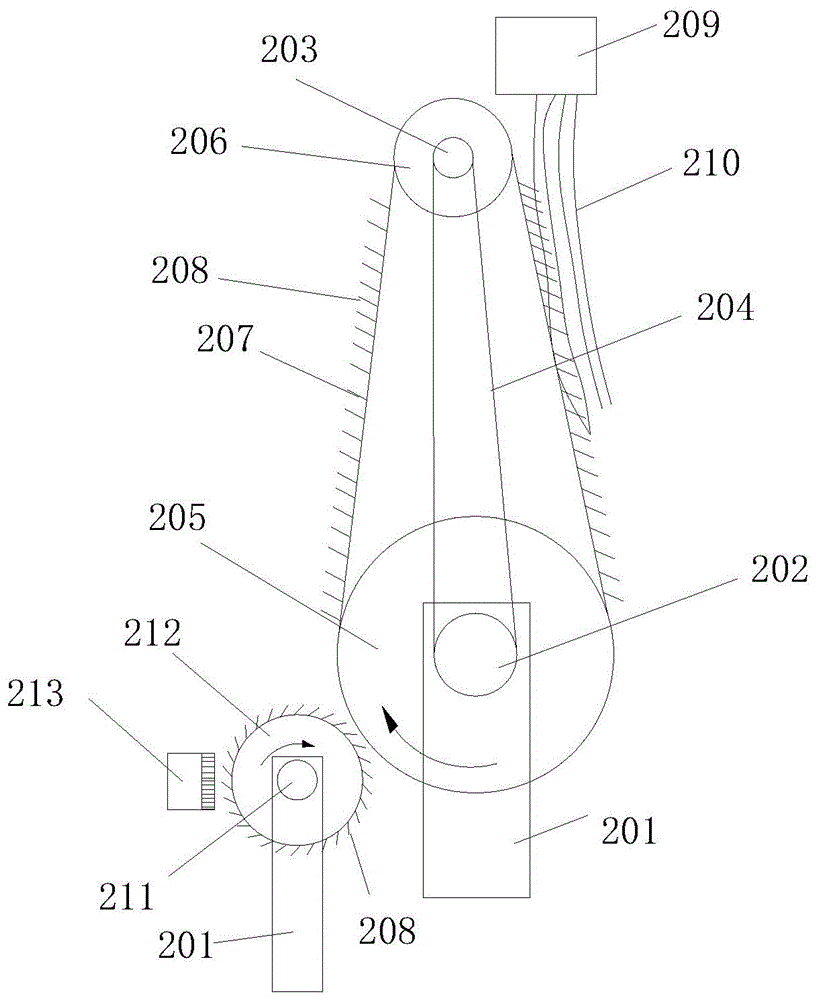

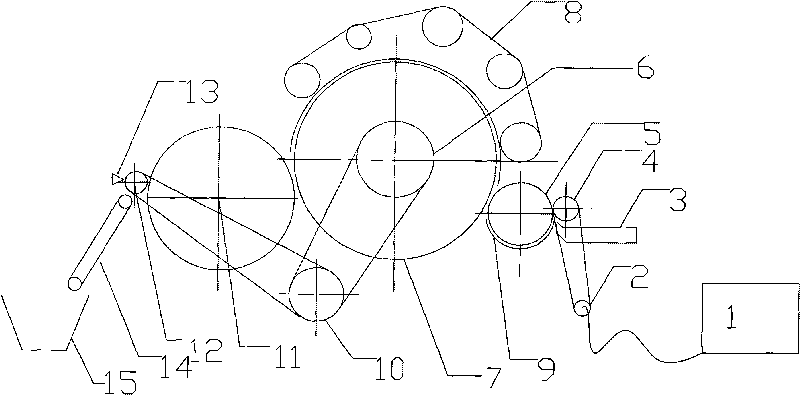

Hackling mechanism of flax hackling machine

The invention discloses a hackling mechanism of a flax hackling machine. The hackling mechanism is characterized in that a brushing shaft (211) which is erected on a framework (201) is arranged on a side surface of a main hackling drum (205), a brushing drum (212) is arranged on the brushing shaft (211), and steel brushes (208) are fully distributed on the surface of the brushing drum (212) and can intersect with steel brushes of a hackling track (207) at contact positions of the brushing drum (212) and the hacking track (207); a brush strip (213) is further arranged on a side surface of the brushing drum (212) and is in contact with the steel brushes of the brushing drum (212). The hackling mechanism has the advantages of simple structure, low failure rate and high efficiency. Besides, the problem of degradation of hackling effects due to the fact that flax fibers are easy to adhere on an existing main hackling drum can be solved by the aid of the hackling mechanism.

Owner:吴江市辰龙骏纺织有限公司

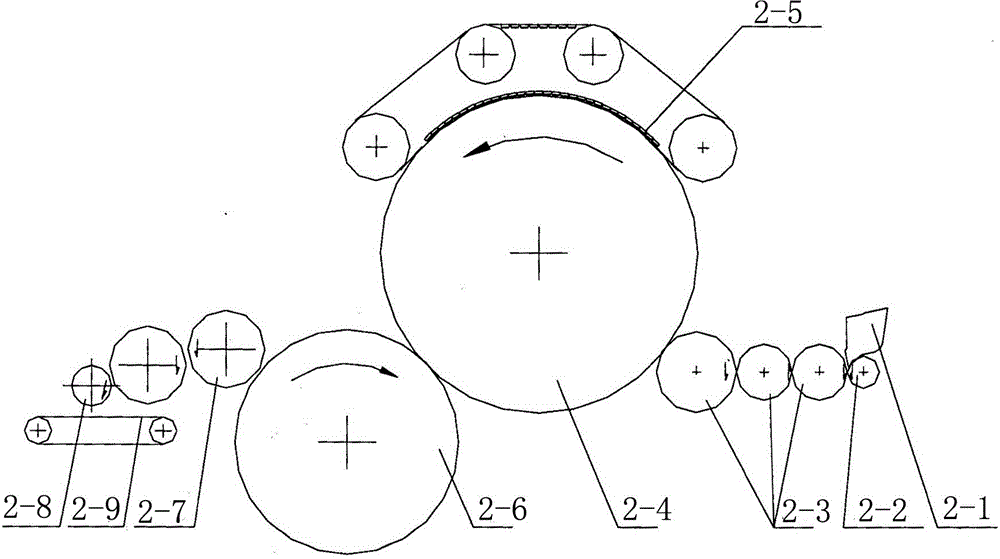

Novel carding machine

The invention discloses a novel carding machine which comprises a feeding mechanism, a carding mechanism, a stripping mechanism and a strip forming mechanism. The carding mechanism comprises a breast cylinder and a main cylinder. At least three breast cylinder working and fur stripping roller sets are arranged above the breast cylinder. Each breast cylinder working and fur stripping roller set comprises a breast cylinder working roller and a breast cylinder fur stripping roller. A movable cover board carding region is arranged over the main cylinder. A rear fixed cover board carding region is arranged above the rear portion of the main cylinder. A front fixed cover board carding region is arranged above the front portion of the main cylinder. A doffer is adjacently arranged in front of the main cylinder. A pre-opening cylinder is arranged behind the breast cylinder. A transfer roller is arranged between the pre-opening cylinder and the breast cylinder. A pre-opening working and fur stripping roller set is arranged above the pre-opening cylinder and comprises a pre-opening working roller and a pre-opening fur stripping roller. According to the novel carding machine, the damage degree of fibers is remarkably reduced.

Owner:青岛东佳纺机(集团)有限公司

Crimped polyester fiber and fibrous structure comprising the same

InactiveCN1343271AHas curl numberHas curl rateFilament/thread formingNon-woven fabricsFiber structurePolyethylene terephtalate

A crimped polyester fiber which is made of a polytrimethylene terephthalate polyester, is three-dimensionally crimped so as to have a number of crimps of 9 to 30 per 25 mm and a percentage crimp of 20 to 50%, and has a crimp elasticity of 80% or higher; and a fibrous structure which comprises short fibers of the crimped polyester fiber and short heat-bondable composite fibers in a weight ratio of from 30 / 70 to 95 / 5 and in which at least part of the points where the two kinds of short fibers are in contact with each other and / or the points where the short heat-bondable composite fibers are in contact with each other have been thermally fixed.

Owner:TEIJIN FRONTIER CO LTD

Silicon-free hair washing and bathing composition suitably used by children and preparation method thereof

InactiveCN106176285AGood hydrophobicityImproved carding performanceCosmetic preparationsHair cosmeticsHair washingChemistry

The invention provides a silicon-free hair washing and bathing composition suitably used by children and a preparation method thereof. Raw materials of the hair washing and bathing composition comprises a silicon-free conditioning component, a mild surfactant, a thickening agent, an anticorrosive agent, an esterifying agent, an acid-base regulator and water. The hair washing and bathing composition does not contain silicone oil, and is suitably used by the children; the silicon-free conditioning component added in the silicon-free hair washing and bathing composition can be adsorbed on the surface of hair with negative charges through a synergistic effect of a cationic polymer; a structural hydrophobic carbon chain (octadecyl) can exogenously supplement natural 18-MEA (18-Methyl Eicosanoic Acid) that the outermost layer of a hair scale of the hair loses; the better hydrophobicity is provided for the hair; therefore, the combing performance is improved.

Owner:TIANJIN YU MEI JING GRP

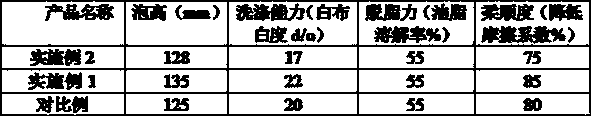

Washing and protecting combination low in excitation and good in flexibility

InactiveCN103349621AImproves wet flushing and dry combing performanceExcellent antistatic and conditioning effectCosmetic preparationsHair cosmeticsGlycerolDegreasing

The invention belongs to the field of daily cosmetics and particularly relates to a washing and protecting combination. The combination comprises the components in percentage by weight as follows: 5.0-40 percent of surfactant, 0.1-0.8 percent of hydroxypropyl guar gum trimethyl ammonium chloride, 0.5-2 percent of glycerine, 0.05-0.1 percent of EDTA-2Na, 0.05-0.1 percent of bisabolol, 0.1-0.5 percent of antiseptic, 0.2-0.8 percent of thickener, 0.1-1 percent of essence and the balance of 100 percent of water, wherein the surfactant is formed by compounding cocoamidopropyl betaine, alkyl polyglucoside, sodium lauroylsarcosinate and PEG-80 sorbitan laurate. The washing and protecting combination is prepared by a natural amino-acid surfactant and an amphoteric surfactant which are low in excitation and good in foaming performance, can provide formula foaming power and lower formula degreasing power, prevents dryness of hair, meanwhile, can improve performance of wet rinse and dry carding on account of the added hydroxypropyl guar gum trimethyl ammonium chloride, can be absorbed by the hair and then plays excellent roles of preventing static electricity and conditioning, and can greatly buffer the excitation of the surfactant.

Owner:OPAL COSMETICS HUIZHOU

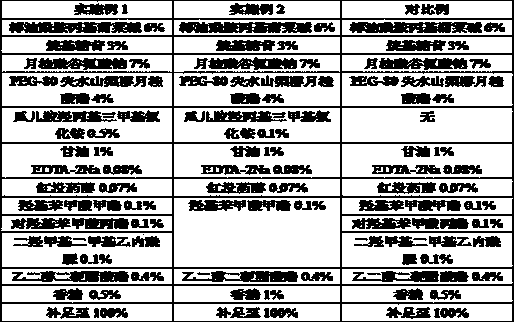

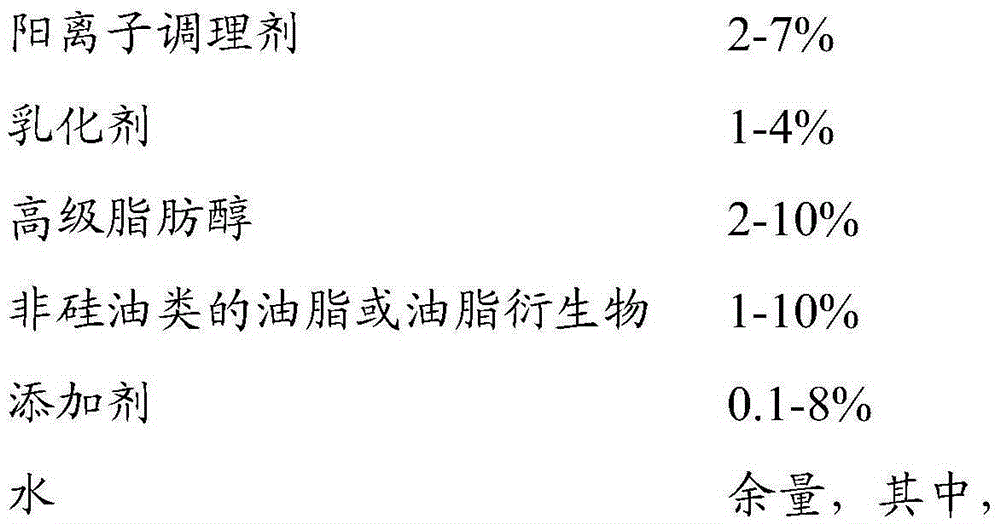

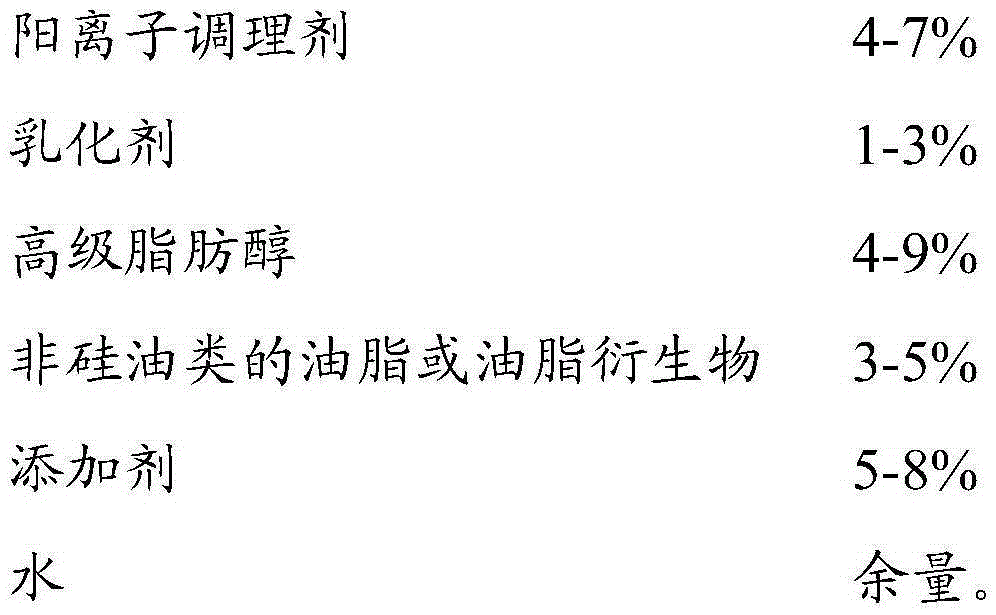

Mild nursing hair oil treatment and care composition containing no silicone oil and preparation method of mild nursing hair oil treatment and care composition

InactiveCN105380831AImprove toughnessIncrease elasticityCosmetic preparationsHair cosmeticsPolyesterMedicine

The invention relates to a mild nursing hair oil treatment and care composition containing no silicone oil and a preparation method of the mild nursing hair oil treatment and care composition. The hair care composition is prepared from the following components in percentage by weight: 2-7% of a cation conditioner, 1-4% of an emulsifier, 2-10% of higher aliphatic alcohol, 1-10% of non-silicone oil-type oil or a derivative thereof, 0.1-8% of an additive, and the balance of water, wherein the cation conditioner is composed of behentrimonium chloride, oilseed rape oleamidopropyl dimethylamine, aspartic acid and polyester-11. According to the hair care composition, no silicone oil is added, so that the defects that after silicone oil products are used for a long term, the conditioning property and the smoothness of hair are reduced, and the hair is dry, bifurcate, broken and free of luster are overcome, the hair care composition achieves the effects of moistening and caring hair in the real sense, preserves moisture and provides nutrition from the deep position of the hair, obviously improves the combing property of the wet hair, the combing property of the dry hair, the limpness of the wet hair, and the limpness of the dry hair, and obviously improves the tenacity, the elasticity and the luster of the hair.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

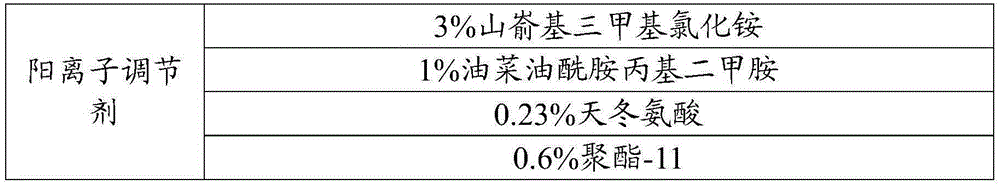

Sheep wool opening and carding complete equipment

ActiveCN105088427AOpen smoothlyInto the uniformFibre cleaning/opening by toothed membersContinuous processingEngineeringSheep wool

The invention belongs to the field of textile machines and particularly discloses sheep wool opening and carding complete equipment. The sheep wool opening and carding complete equipment comprises a first feeding mechanism, a first opening mechanism, a first coarse wood and impurity removal mechanism and a first carding mechanism which are sequentially connected from front to rear. A second feeding mechanism, a second opening mechanism, a third opening mechanism, a wool combination mechanism, a second carding mechanism and a wool bin are sequentially arranged in front of the first feeding mechanism in succession. By means of the design, primary opening, coarse wood and impurity removal and carding processes are conducted on sheep wool before sheep wool enters the first feeding mechanism, it is further guaranteed that sheep wool is evener when entering the first carding mechanism, and follow-up opening, coarse wood and impurity removal and carding effects are improved beneficially.

Owner:青岛东佳纺机(集团)有限公司 +1

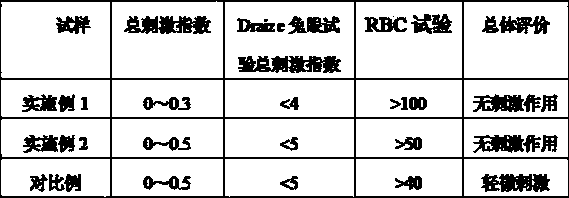

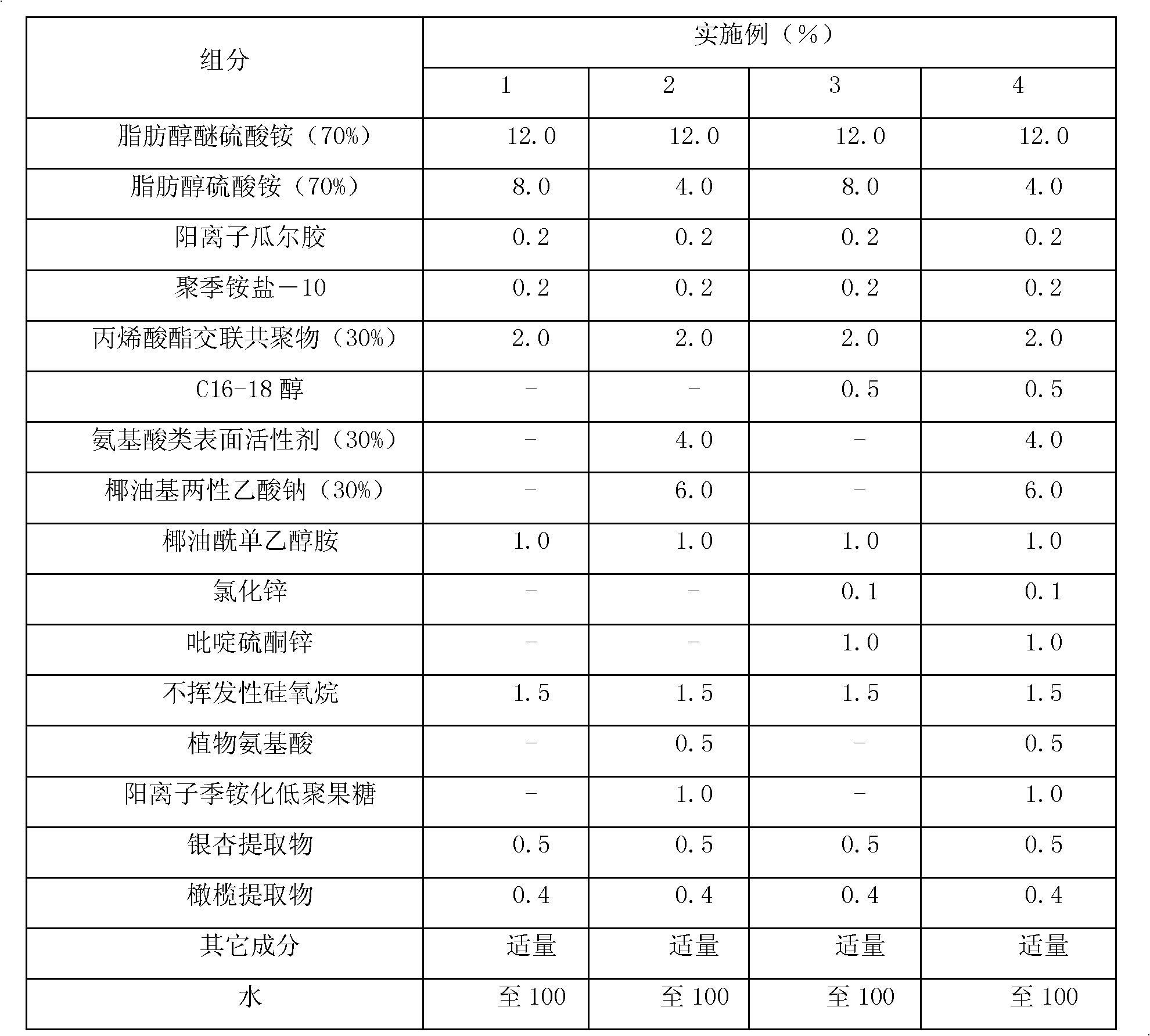

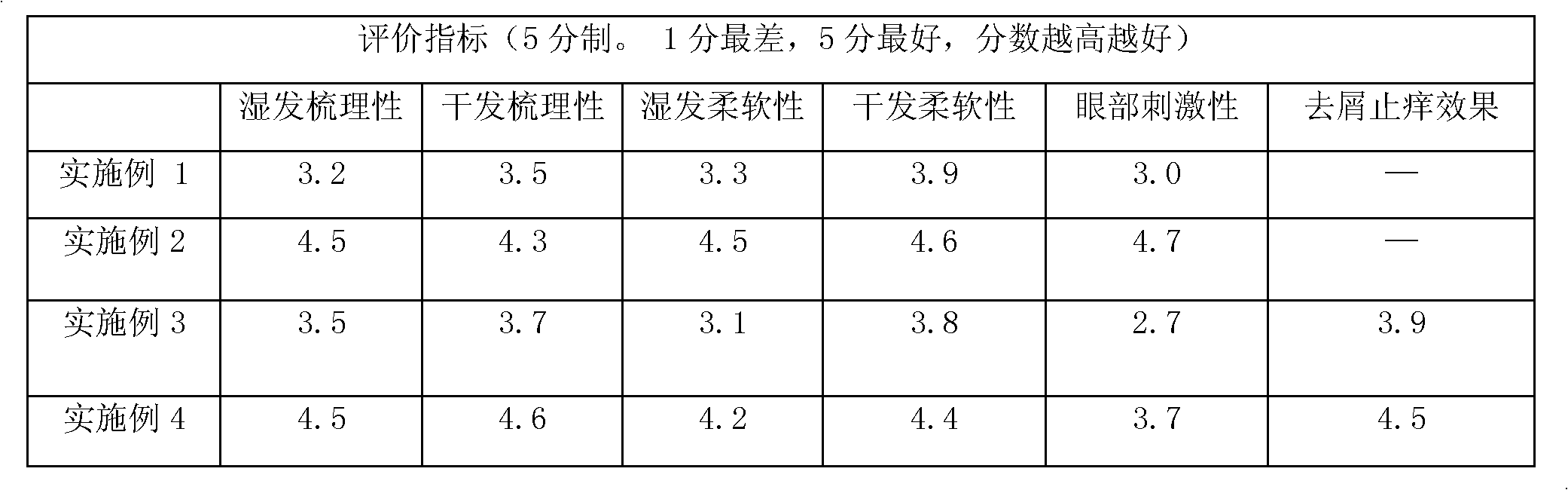

Shampoo composition

ActiveCN102552056AReduce stimulationGood conditioning effectCosmetic preparationsHair cosmeticsAntipruritic agentsIrritation

The invention relates to the field of daily chemicals and in particular relates to a shampoo composition. The shampoo composition comprises the following components: imidazoline surfactants, amino acid surfactants, cation quaternary fructooligosaccharides, plant amino acids and water. The weight of the imidazoline surfactants accounts for 0.01% to 10% of the total weight of the shampoo composition, the weight of the amino acid surfactants accounts for 0.01% to 10% of the total weight of the shampoo composition, the weight of the cation quaternary fructooligosaccharides accounts for 0.01% to 5% of the total weight of the shampoo composition, and the weight of the plant amino acids accounts for 0.01% to 5% of the total weight of the shampoo composition. The shampoo composition further comprises surfactants, non-volatile siloxane, cation polymers, suspension stabilizers, additives and optionally anti-dandruff and antipruritic agents. The shampoo composition causes less irritation to the scalp and enhances conditioning property of the scalp.

Owner:纳爱斯丽水日化有限公司

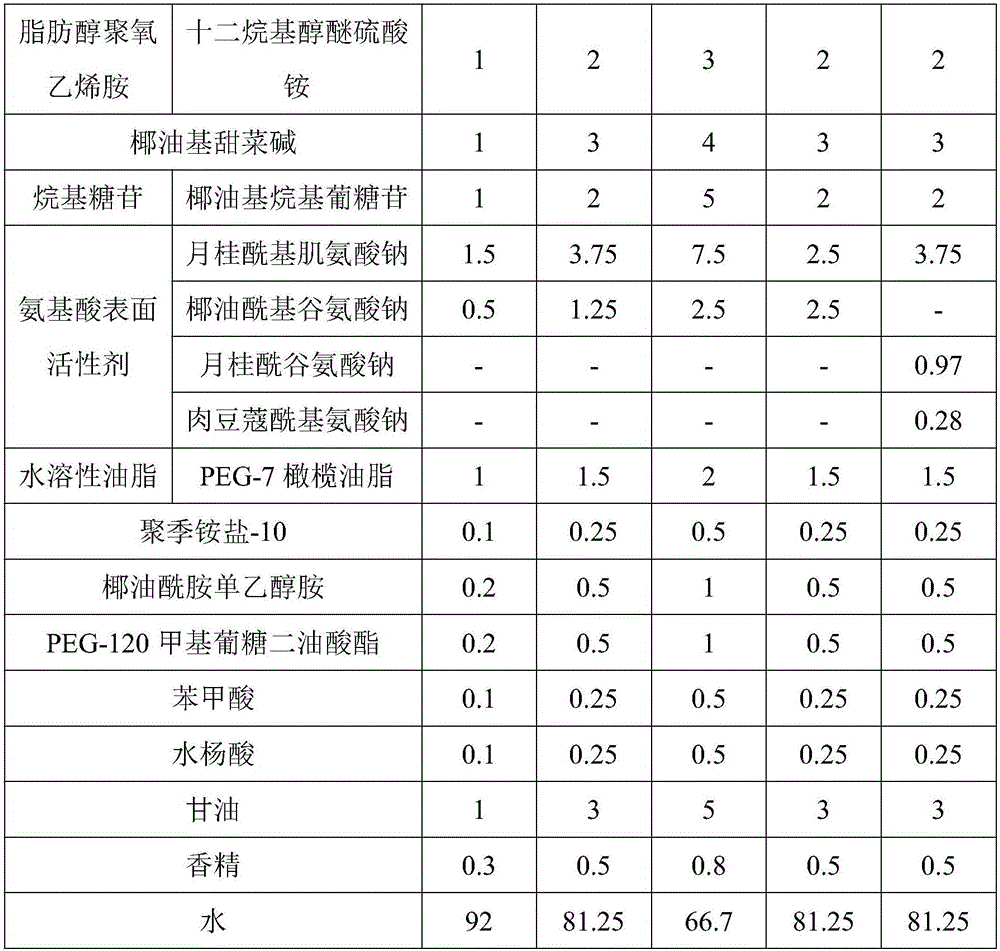

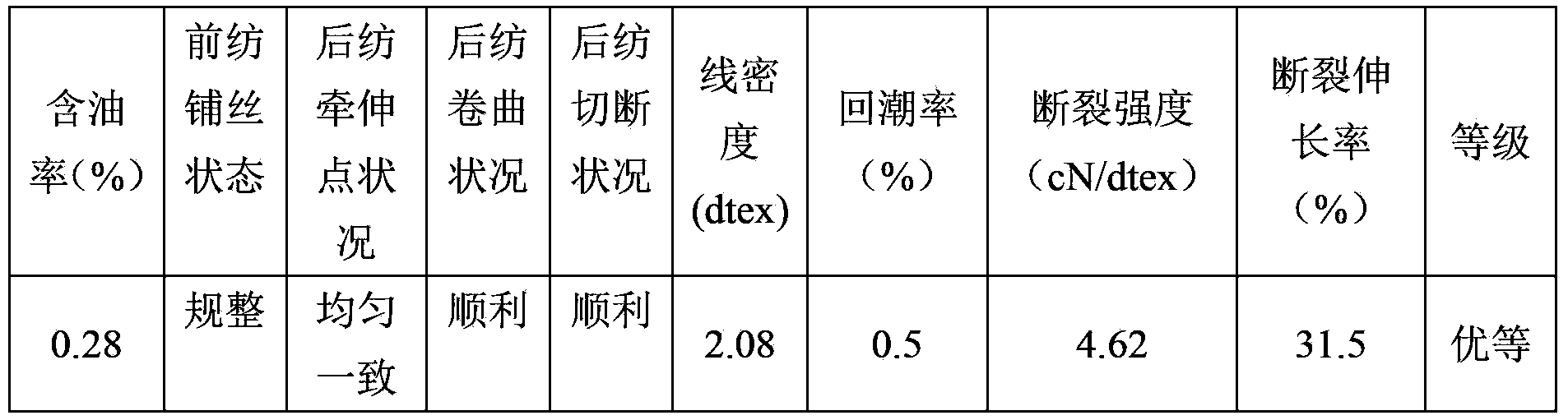

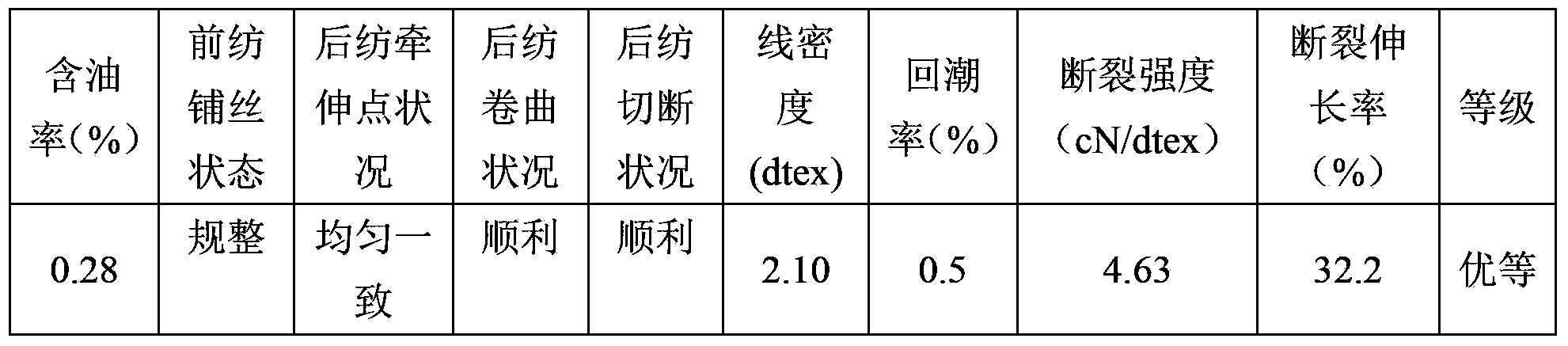

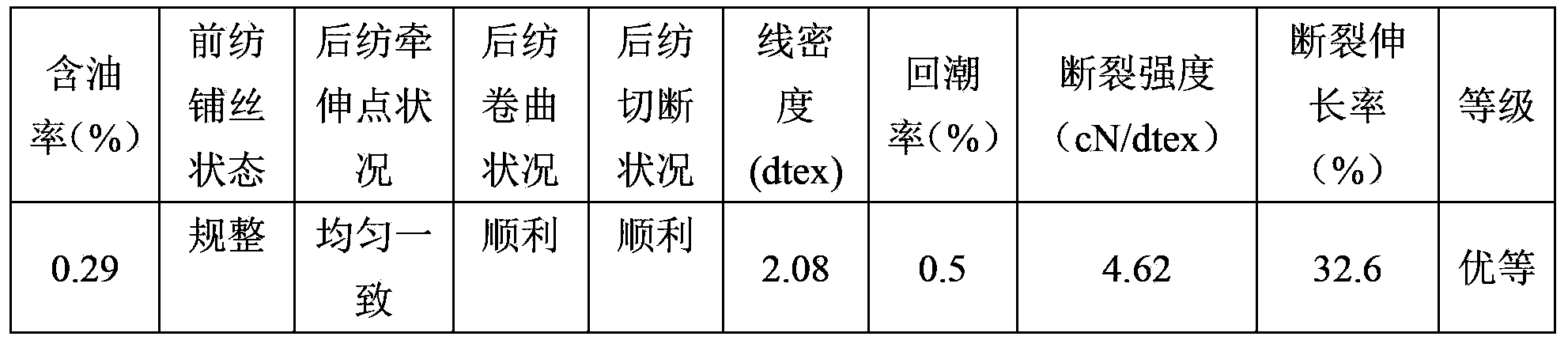

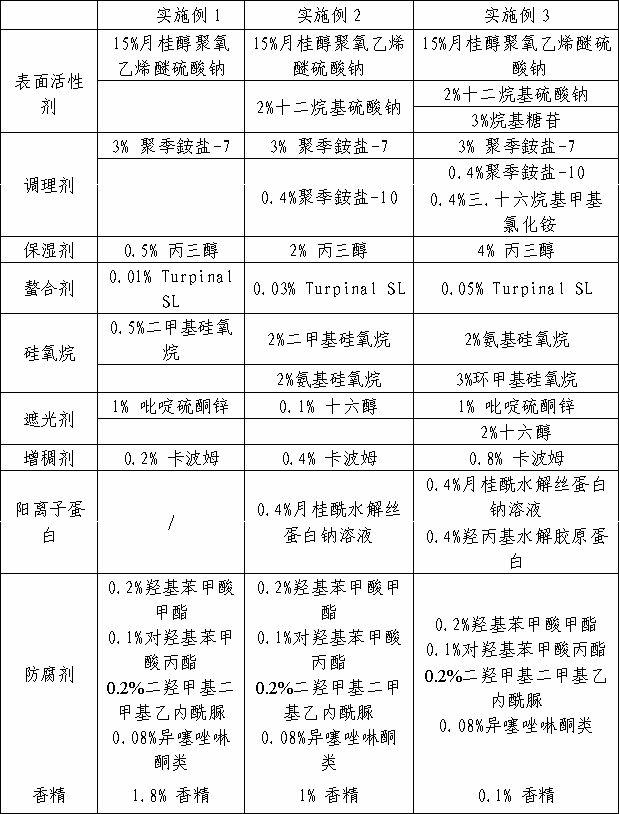

Moderate amino acid shampoo and preparation method thereof

The invention belongs to the field of daily chemical products, and particularly relates to moderate amino acid shampoo and a preparation method thereof. The amino acid shampoo comprises the following components: fatty alcohol polyoxyethylene amine, coco-betaine, alkyl polyglycoside, an amino acid surfactant, water-soluble grease, polyquaternium-10, cocamidopropyl monoethanolamine, PEG-120 methyl glucose dioleate, benzoic acid, salicylic acid, glycerin, essence and water. The amino acid shampoo has high foaming and foam stabilizing performance, moderate cleaning and washing capability and good moisturizing effects; washed hair is bright, smooth, elastic and high in combability; the amino acid shampoo is moderate, nontoxic and non-irritating to skin, comfortable, soft and moist.

Owner:壹田(广州)生活健康用品有限公司

Polyphenylene sulfide short fiber spinning oil and preparation method thereof

ActiveCN103409855ASuitable for antistaticSuitable smoothnessSynthetic polymer filament chemical after-treatmentSpin effectAntistatic agent

The invention discloses a polyphenylene sulfide short fiber spinning oil and a preparation method thereof. The polyphenylene sulfide short fiber spinning oil comprises the following compound raw materials by weight percentage: 25-50 percent of antistat, 15-25 percent of smoothing agent, 18-35 percent of saturant, 5-20 percent of emulsifier and 2-8 percent of modifier. According to the weight percentage of each raw material component, the accurately metered antistat, smoothing agent, saturant, and emulsifier are pumped into a reaction pot, heated to 50-80 DEG C, and uniformly mixed; the modifier is pumped into the reaction pot, agitated for 1-3 h, cooled, filtered, unloaded and packaged. The polyphenylene sulfide short fiber spinning oil has good anti-static electricity performance, smoothness, saturation and the like, is uniform and stable in oil loading, can ensure smooth operation of spinning production and postprocessing working procedure, and satisfies production requirements on spinning effect and the mechanical performance of the fiber.

Owner:天津工大纺织助剂有限公司

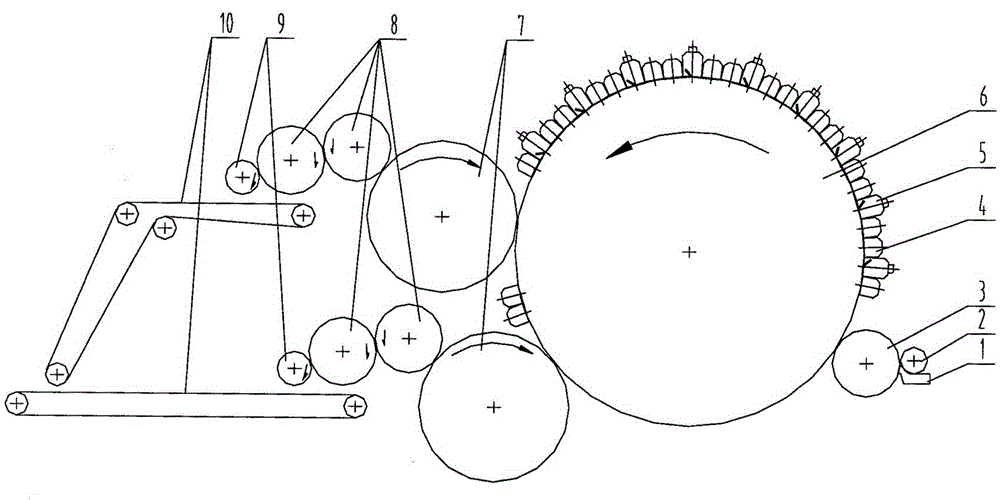

Full fixed cover plate-type carding machine suitable for non-woven production line

InactiveCN104911817AImprove combing effectDelicate cloth styleCarding machinesNon-woven fabricsProduction lineSingle fiber

The invention discloses a full fixed cover plate-type carding machine suitable for non-woven production lines, which comprises a cylinder, a pin roll located below a feeding end side of the cylinder, and an upper and a lower doffers that are set at a discharged end of the cylinder and that are used for stripping single fiber and web carded on the cylinder, wherein a feeding side of the pin roll is provided with a feeding mechanism constituted of a cotton-supplying plate and a cotton-supplying roller; discharged ends of the upper and the lower doffers are sequentially respectively provided with an upper and a lower condensing rollers used for strengthening the fiber web strength at the horizontal direction, an upper and a lower stripping rollers used for stripping the fiber web from the upper and the lower condensing rollers, and an upper and a lower web curtains used for delivering the fiber web to next devices; carding units that are staggered around the cylinder and are constituted of a fixed cover plate and a cotton web cleaner with a dust removal cutter and that are used for mainly carding the fiber are set between the upper doffer and the pin roll; a fixed cover plate is set on the roll surface surrounding the cylinder between the upper and the lower doffers; and the cotton-supplying plate is located below between the pin roll and the cotton-supplying roller.

Owner:CHTC HEAVY IND

Production device of fiber color points and spinning method of color point yarns

The invention provides a production device of fiber color points and a spinning method of color point yarns, and improves the common cotton spinning machinery, i.e. adding a cotton feeding system on various carding machines, simultaneously being dispensed with a cotton stripping device, installing a stripping and conveying device, configuring all the technological parameters (e.g. transmission rate, cutting die, doffer space and the like) of the carding machines, and being reformed into a device capable of producing various fiber color points. The spinning method utilizes the production device, selects the kind and the dosage of an adhesive suitable for the fiber to produce color points with different size specifications, different tightness and extensive color change according to different fiber types during the production process of the color points.

Owner:广东广纺检测技术股份有限公司

Novel semi-spinning specialized equipment

InactiveCN101709521AEasy to changeImprove the initial opening effectCarding machinesWorstedEngineering

The invention discloses novel semi-spinning specialized equipment, comprising a feeding mechanism, a carding mechanism, a stripping and taking mechanism and a strip forming and coiling mechanism; the rear part of the feeding mechanism is provided with a second flat-bottom lattice and a second inclined-spike lattice in sequence; the rear side of the upper part of the second inclined-spike lattice is provided with a second hair uniformizing roller and a second hair uniformizing rake; the front side of the upper part of the second inclined spike lattice is provided with a second hair stripping roller, the lower part of which is provided with a first flat-bottom lattice; the carding mechanism comprises a big cylinder; a rotary cover plate is arranged above the big cylinder, the front part of which is provided with a front fixed cover plate; four fixed cover plate bars are arranged on the front fixed cover plate; the rear part of the big cylinder is provided with a rear fixed cover plate; two fixed cover plate bars are arranged on the rear fixed cover plate; a front fixed cover plate carding region, an upper rotary cover plate carding region and a rear fixed cover plate carding region are formed on the big cylinder; and a card wire type structure is adopted to the fixed cover plate bars. The novel semi-spinning specialized equipment of the invention is beneficial to uniform feeding and further improves the carding effect.

Owner:青岛东佳纺机(集团)有限公司

Non cotton cellulose fiber opening oiling agent

ActiveCN101624781AExcellent opening before spinningImprove combing effectVegetal fibresAntistatic agentFoaming agent

The invention discloses a non cotton cellulose fiber opening oiling agent which is characterized in that: the opening oiling agent contains a soft smoothness agent which can lead the surface of the non cotton cellulose fiber to form a layer of extremely soft smooth film and an antistatic agent which can prevent fiber from generating static electricity owning to friction. The opening oiling agent adopts the soft smoothness agent, the antistatic agent and water with a certain proportion, which are stirred for a certain time under the normal temperature, and a PH value conditioning crosslinker is added to form the opening oiling agent. By adopting the opening oiling agent, a layer of the smooth and soft and antistatic film can be formed on the surface of the non cotton cellulose fiber with a small quantity of the opening oiling agent, so as to greatly reduce doubling and adhesion in the opening procedure of the fiber, and lead the fiber to be smooth, soft and fluffy, and cause the opening and carding procedures to be carried out easily; the operation is easy and the rate of finished products for silk making is improved.

Owner:SICHUAN RES INST OF SILK SCI

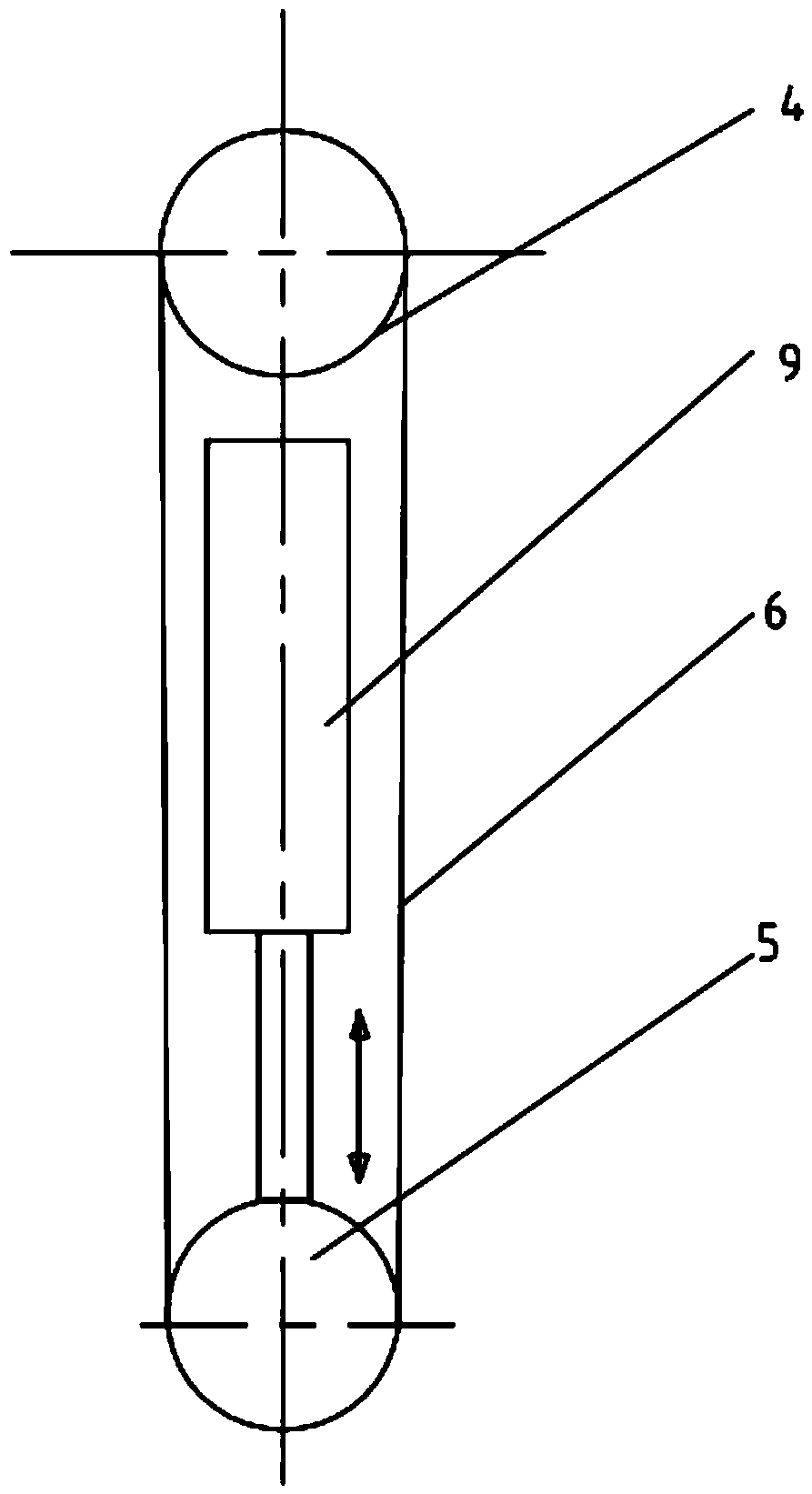

Double-roller frame yarn fluffing device

The invention discloses a double-roller frame yarn fluffing device, comprising a control box, a machine frame, a supporting shaft, an upper roller, a lower roller, a driving mechanism and a reciprocating transmission mechanism, wherein the supporting shaft is arranged on the machine frame; the upper roller is rotatably supported on the supporting shaft; the driving mechanism is movably connected with the upper roller so as to drive the upper roller to rotate relative to the supporting shaft; the upper roller and the lower roller are matched for sleeving two ends of frame yarns; the reciprocating transmission mechanism is movably connected with the lower roller so as to drive the lower roller to perform reciprocating movement relative to the upper roller; the control box is respectively connected with the driving mechanism and the reciprocating transmission mechanism in a controlling manner. The double-roller frame yarn fluffing device can achieve the effect of well combing the frame yarns.

Owner:CHANGZHOU TEXTILE GARMENT INST

Hair conditioner

Disclosed is a hair conditioner comprising aliphatic alcohol, octadecanamide propyl dimethyl tertiary amine, propylene glycol, dimethyl silicon oil, polyoxyethylene ether 45, organic acid, mixture of dimethylol dimethyl hydantoin and 3-iodo-2-propynyl-butyl-carbamate, perfume compound, disodium ethylenediamine tetraacetate and deionized water. The invention realizes fine moisture keeping property and combing characteristics.

Owner:克劳丽化妆品股份有限公司

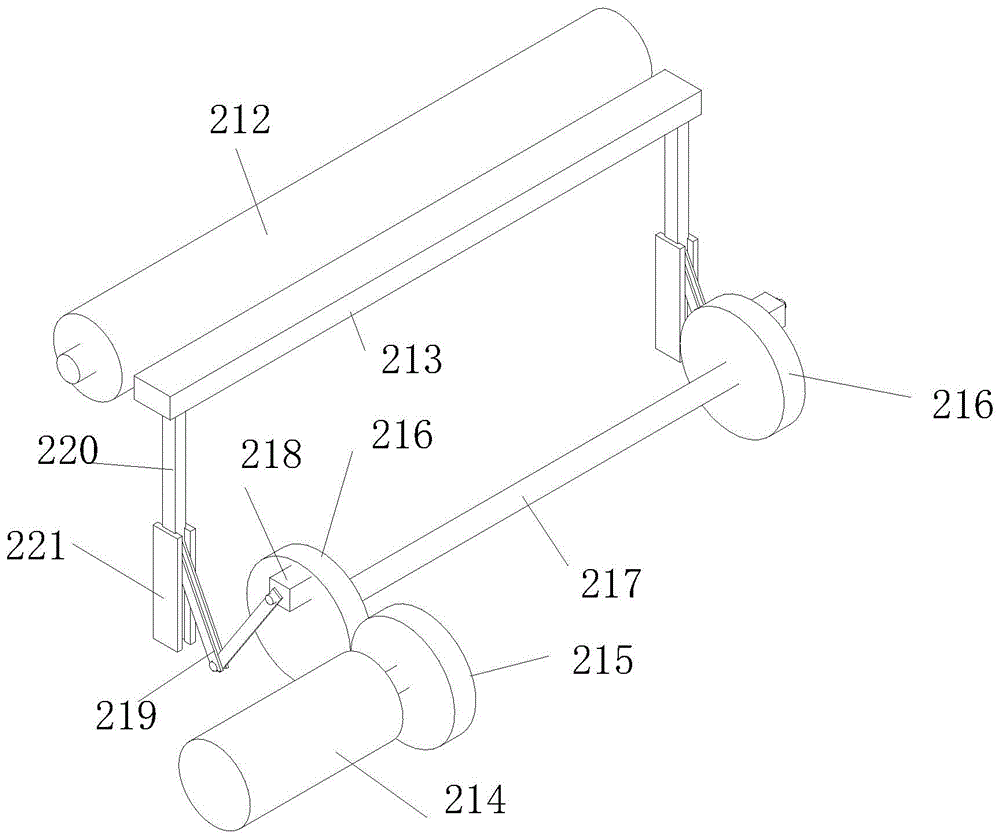

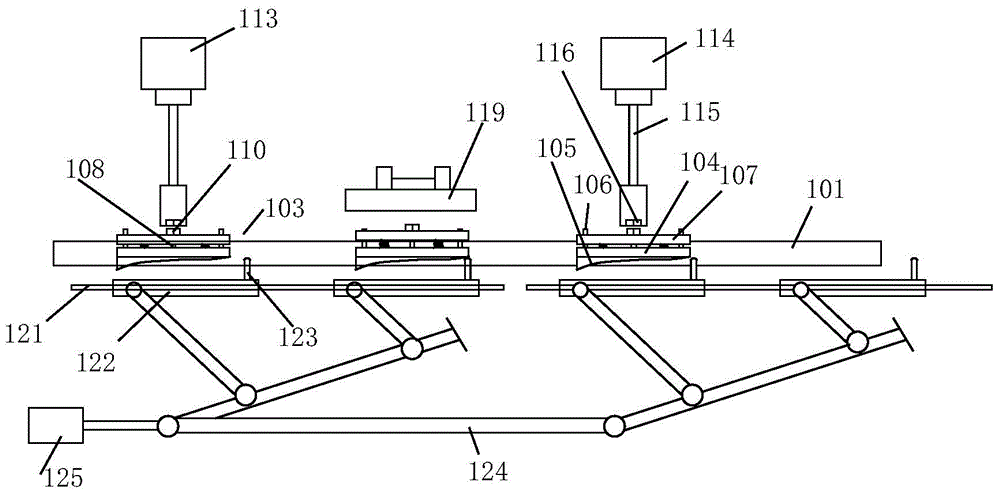

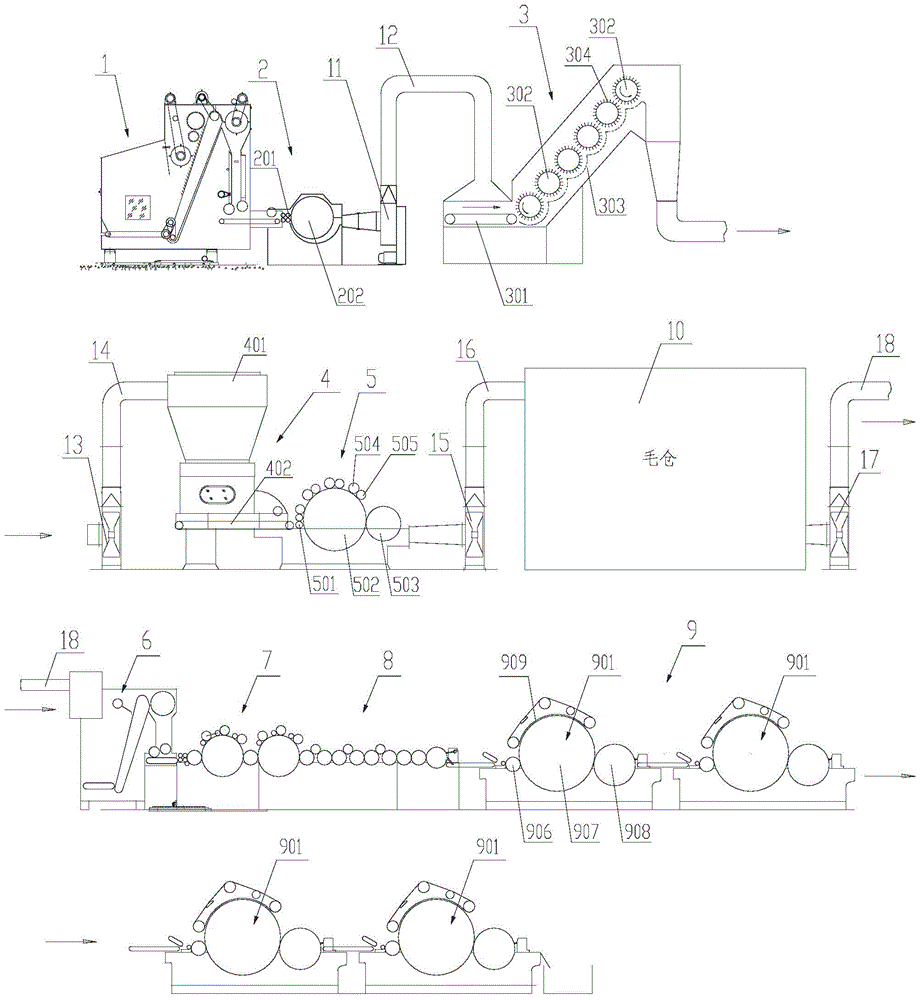

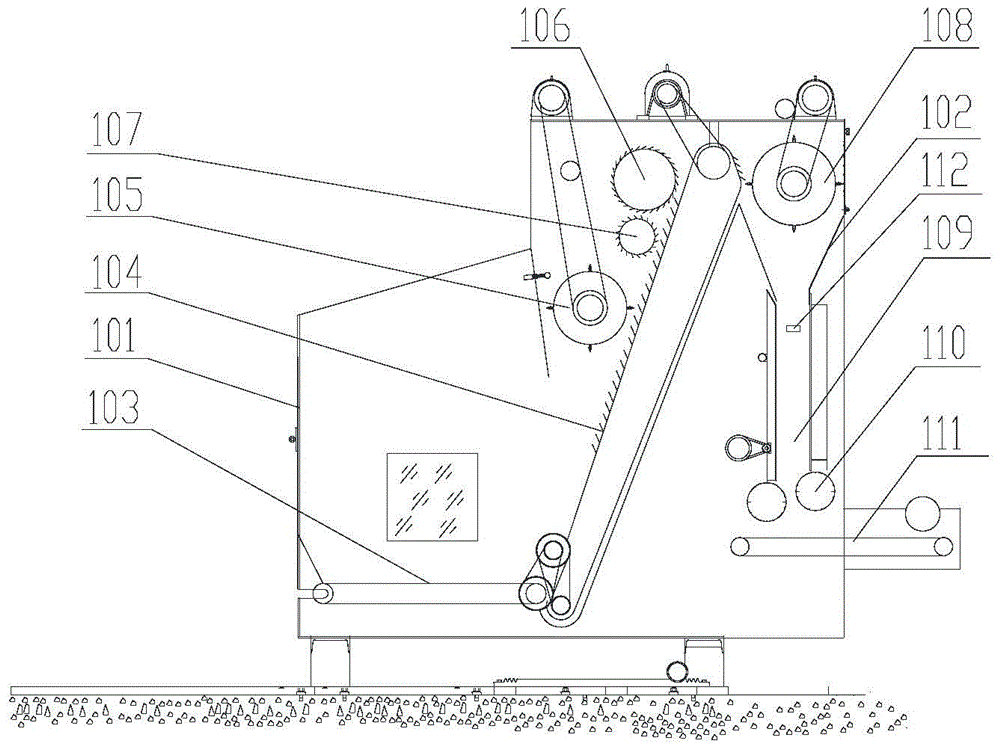

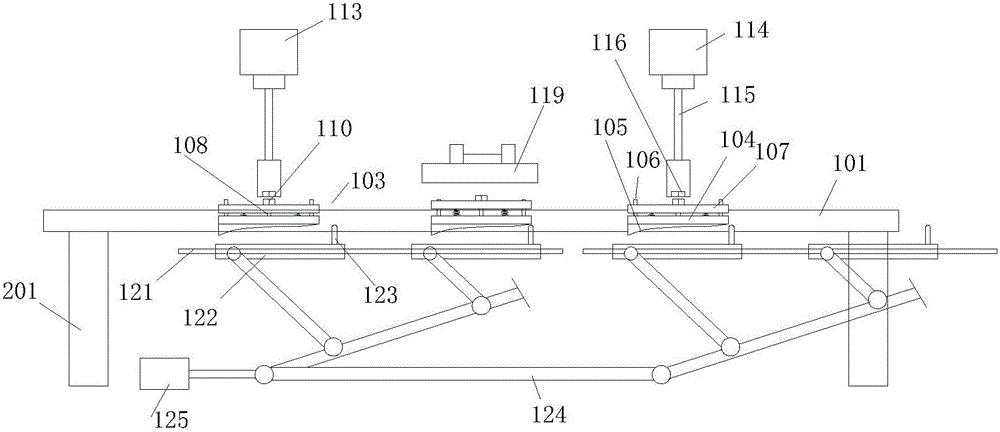

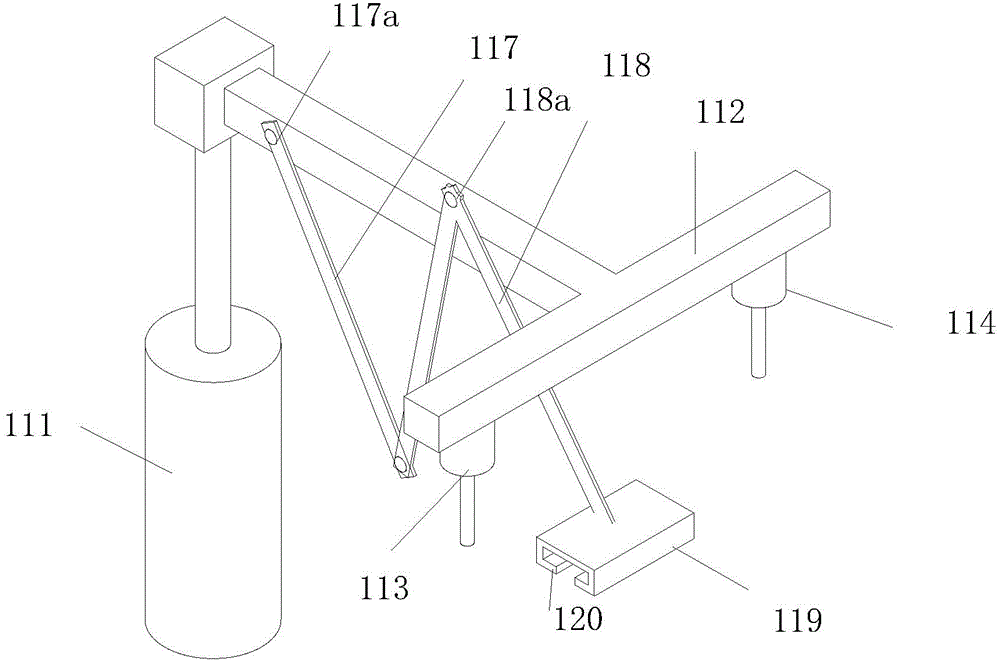

Full-automatic flax hackling machine

InactiveCN104099667AImprove combing effectEasy to cleanHackling machinesElectric machineryEngineering

The invention discloses a full-automatic flax hackling machine comprising a feeding mechanism fixed to a frame (201), and a hackling mechanism is arranged behind the feeding mechanism; the feeding mechanism comprises a sliding platform (101), the center of the sliding platform (101) is provided with a sliding groove (102), a sliding device (103) is erected on the sliding groove (102), a discharging motor (113), a grasping block (119) and a feeding motor (114) are arranged above the sliding device (103), and a pushing block (122) is arranged below the sliding groove. The hackling mechanism comprises a brush shaft (211) which is erected on the frame (201) and which is arranged on the side of a main hackling roller (205), the brush shaft (211) is provided with a brush roller (212), the surface of the brush roller (212) is provided with steel brushes (208) fully, and the steel brushes of the brush roller (212) are crossed with steel brushes of a hackling crawler (207) in the contacting position; the side of the brush roller (212) is provided with a brush stripe (213) contacting with the steel brushes of the brush roller (212).

Owner:吴江金怡纺织品有限公司

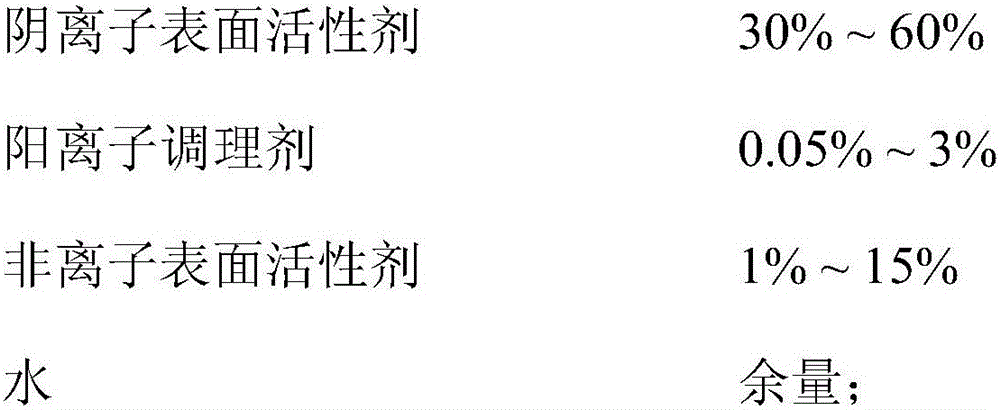

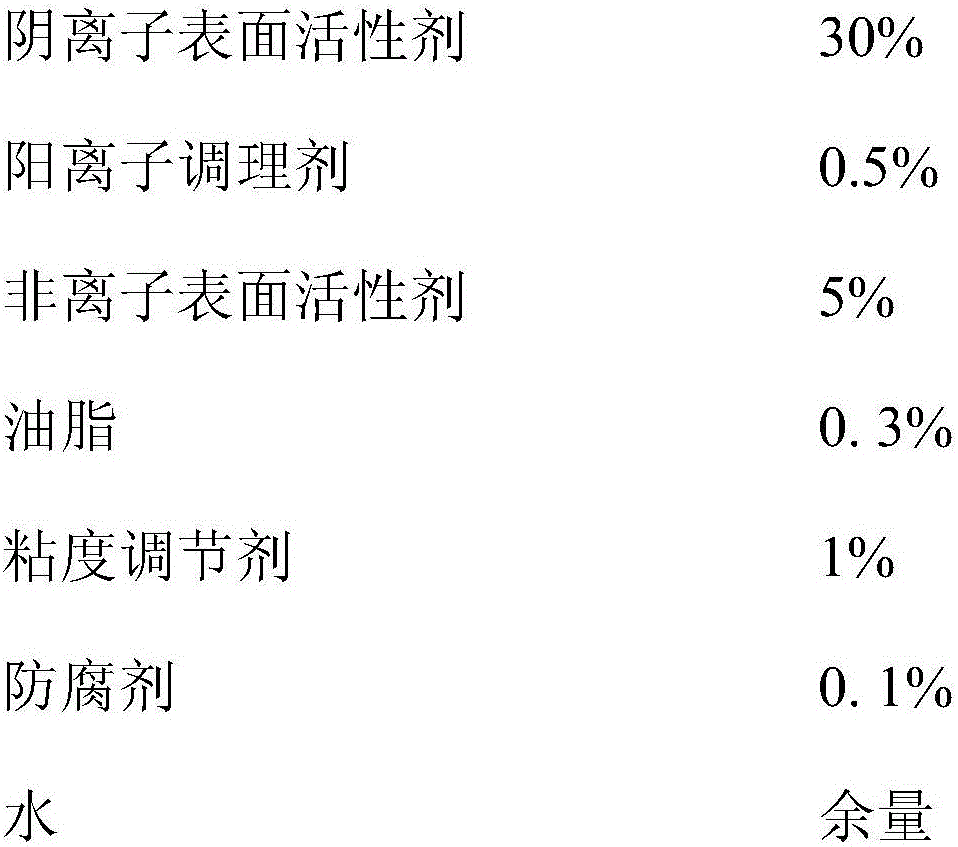

Liquid shampoo containing amino acid surfactant and preparation method thereof

InactiveCN105997553AImprove combing effectGood flexibilityCosmetic preparationsHair cosmeticsLipid formationSolubility

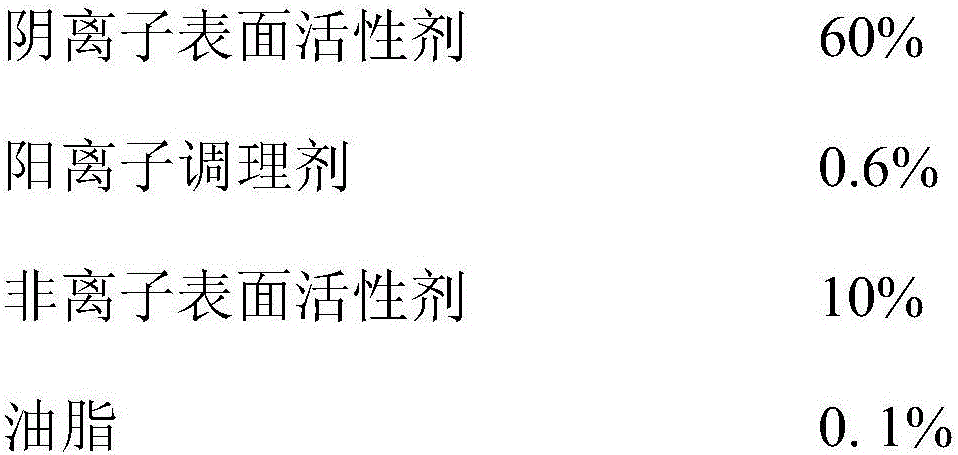

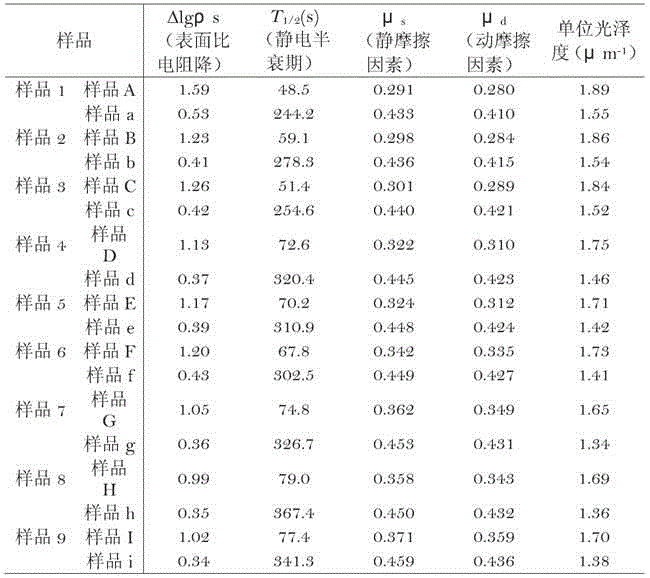

The invention discloses a shampoo containing an amino acid surfactant and a preparation method thereof. The shampoo comprises the following components in terms of mass percentage: 30%-60% of anionic surfactant; 0.05%-3% of cationic conditioning agent %; non-ionic surfactant 1% to 15%; the rest of the water. The amino acid surfactant is used as the main surfactant in the shampoo of the present invention, and one or more small molecule alcohols are added in the preparation process of the amino acid surfactant to increase the solubility of the lipid amino acid in the surfactant At the same time, the amino acid surfactant can reduce the overall degreasing power of the shampoo, improve the combability, softness, smoothness, and durability of the smoothness of the shampoo, and bring unique moisturizing power and softness to the hair. Feeling, oily feeling, enhanced anti-dandruff, oil control and other effects.

Owner:GUANGZHOU BAFEORII CHEM

Production process of pure-spined combed yak wool

The invention discloses a production process of pure-spined combed yak wool. The production process includes steps of (1), raw material pretreatment including precombing on an opening machine and controlling the wool fiber fineness within 17.5-20 micrometers and the fiber length within 17.5-20 millimeters; (2), blending on a blending machine, spraying wool oil and antistatic agents on yak wool fibers layer by layer and controlling the moisture regain; (3), carding on a wool type carding machine according to the process principle of soft carding; (4), gilling on a two-stage gilling machine to realize pre-gilling; (5), combing by a wool type combing machine according to a small-space, light-quantitive and low-speed process; and (6), gilling and balling by two gilling steps. The production process has the advantages that pure-spined combed yak wool can be produced by the production process and can be prepared for the next process of spinning pure yak wool high-count combed yarns, and accordingly a gap in production of high-grade combed yak wool fibers is filled.

Owner:张家港中孚达绒业科技有限公司

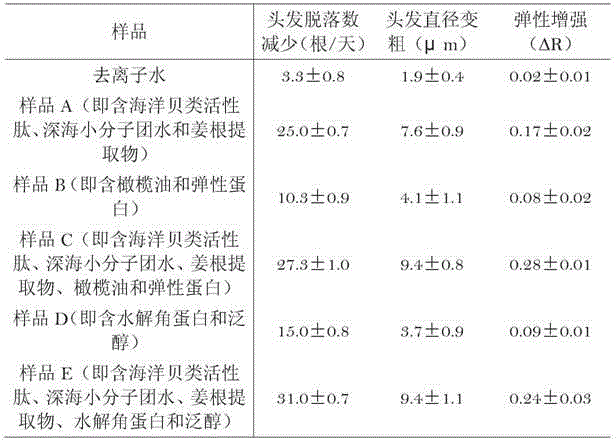

Hair-caring product containing marine biological protein peptide

ActiveCN104127327AVisible hair care effectEffective absorptionCosmetic preparationsHair cosmeticsKeratinHair loss

The invention discloses a hair-caring product containing a marine biological protein peptide. The hair-caring product contains a marine shellfish active peptide, assisted by deep sea small molecular group water and ginger root extract, and further may comprise olive oil and elastin, or hydrolyzed keratin and panthenol. The hair-caring product provided by the invention can be used as a wash-free health-care product such as wash-free spray, is in no need of washing with water, is not liable to be stained by dirt, and does not contaminate collar and bed clothes. The hairs become soft, elastic, anti-static and easy to comb and shape after the hair-caring product is used. The hair-caring product can repair damaged hairs and has hairdressing effects of moisturizing, moistening, decorating and fixing a hairstyle. Besides, the marine biological type wash-free spray has a significant function of preventing hair loss and achieves the effects of nourishing the hairs and protecting the hairs at the same time.

Owner:FOSHAN ANAN BEAUTY & HEALTH PRODS +2

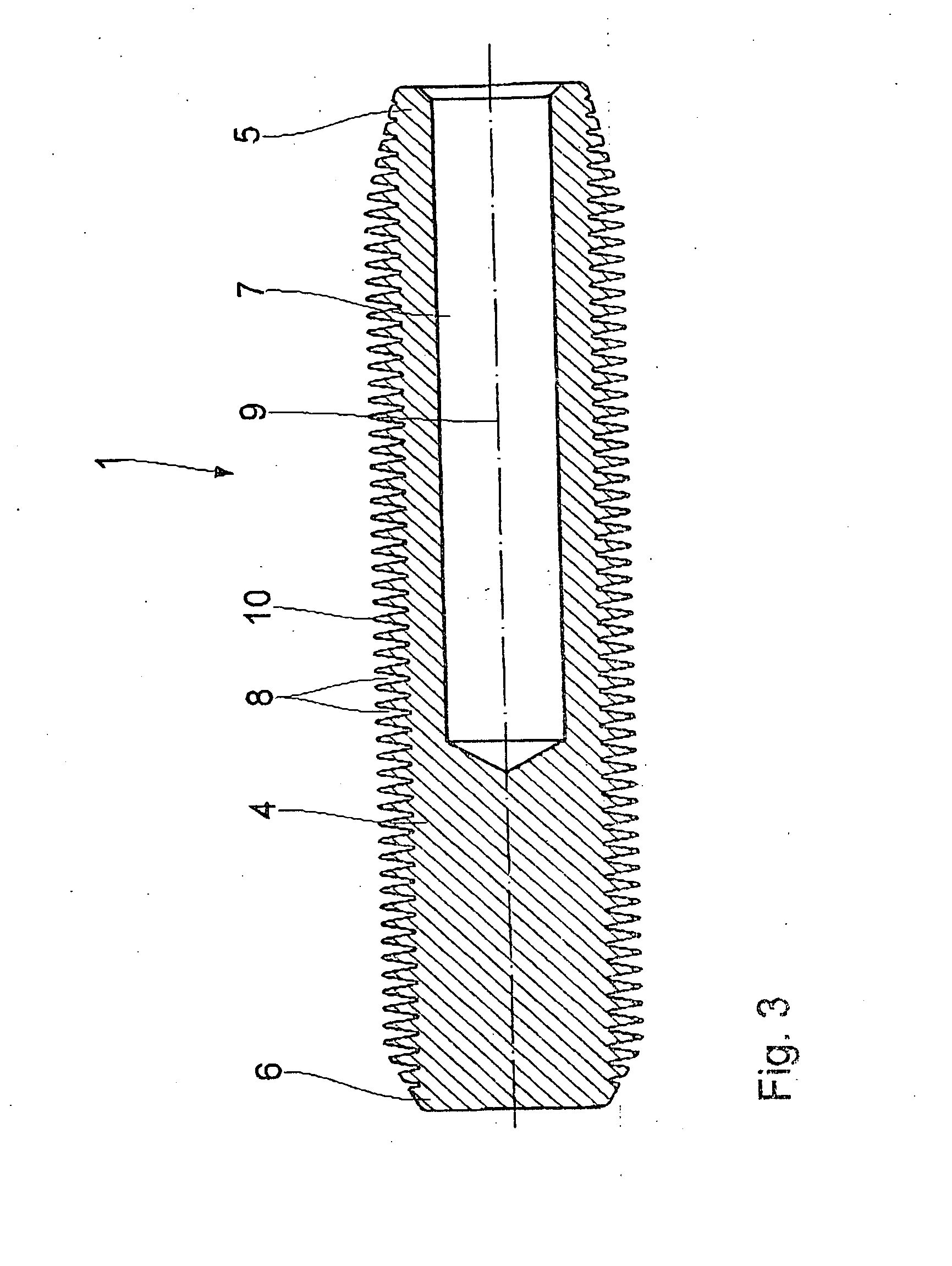

Metallic card wire

ActiveUS20140259537A1Improve performanceImprove abilitiesMetal sawing tool makingCarding machinesEngineeringFiber

A metallic card wire has an elongated rib portion and teeth. The teeth have a front segment, a top segment and a back segment. The front segment has the connection of the tooth from the elongated rib portion and the front segment including a tip which is actively taking fibres in carding. The top segment has at least one hunch after the tip in the direction of the back segment. If more than one hunch is present the first hunch is the hunch positioned closest to the tip; if only one hunch is present this hunch is the first hunch. The back segment forms the connection of the top segment towards the elongated rib portion and the front segment of the next tooth.

Owner:GROZ BECKERT KG

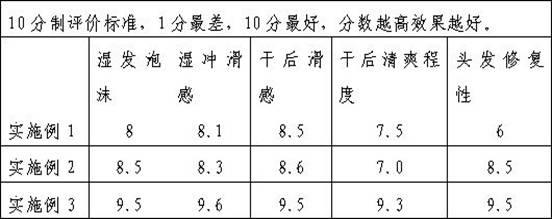

Cream shampoo

ActiveCN102670430AReduce coefficient of frictionDryness will notCosmetic preparationsHair cosmeticsSurface-active agentsBalance water

The invention belongs to the field of daily chemicals and particularly relates to a cream shampoo formula. A novel cream shampoo comprises, by weight, 5.0% to 25.0% of surface active agents, 0.5% to 5% of cationic conditioners, 0.5% to 4% of humectants, 0.01% to 0.05% of chelating agents, 0.5% to 5% of siloxane, 0.1% to 3% of sunscreens, 0.2% to 0.8% of thickening agents and the balance water. The novel cream shampoo further comprises, by weight, 0.1% to 5.0% of cationic protein. According to the novel cream shampoo, the foaming performance is good, the shampoo has a moderate cleaning capability, the excessive degreasing and hair dryness are absent, the resistance of combing wet hair is low, the carding effect after hair is dried is good, the deposition of various conditioners is moderate, visible or obvious residues can not be generated, the cream appearance is attractive, the repairability is high, and the cream shampoo can be safely used.

Owner:OPAL COSMETICS HUIZHOU

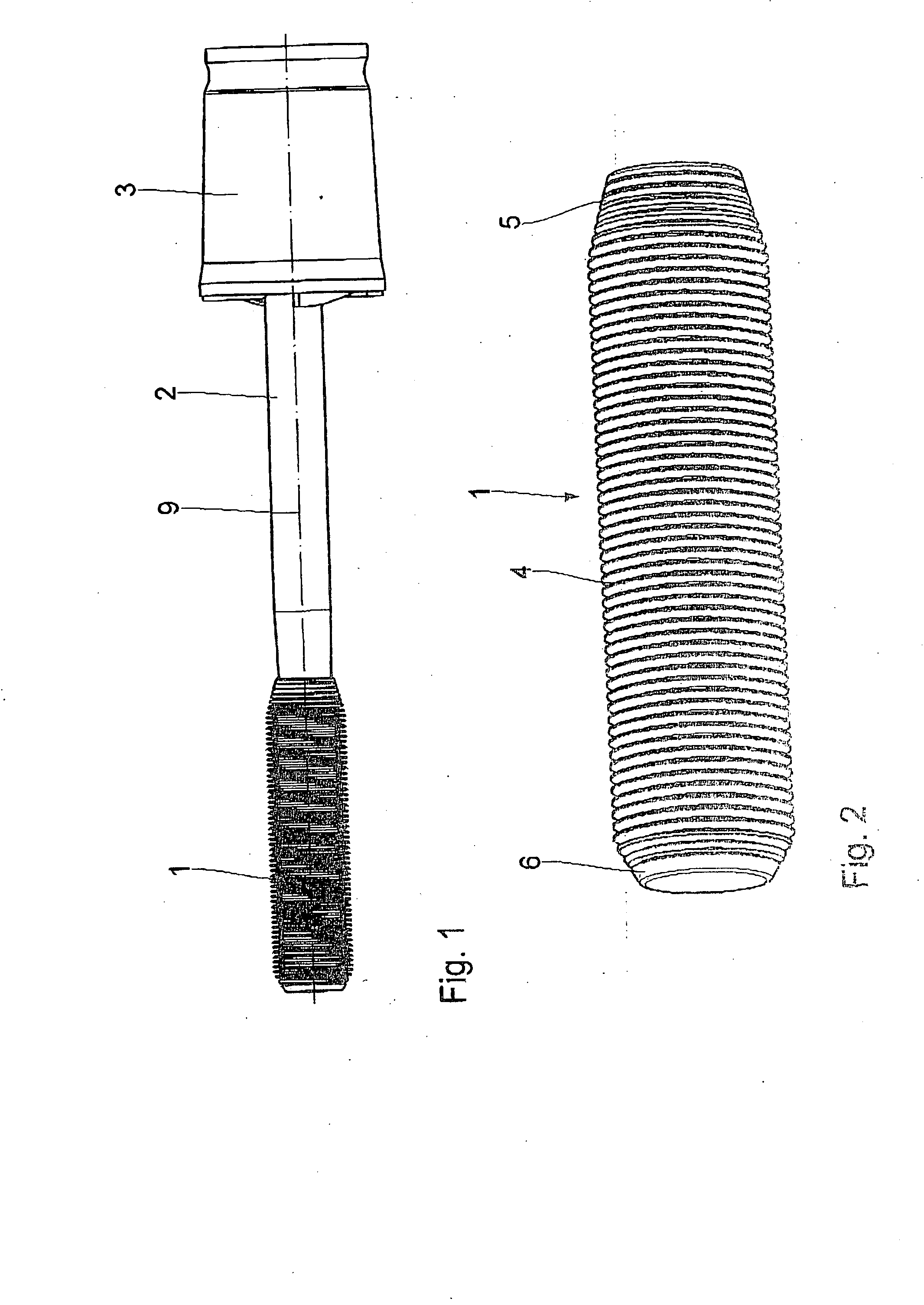

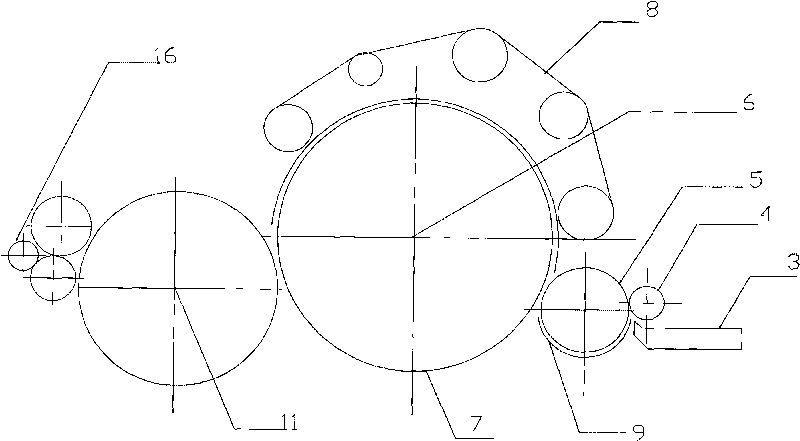

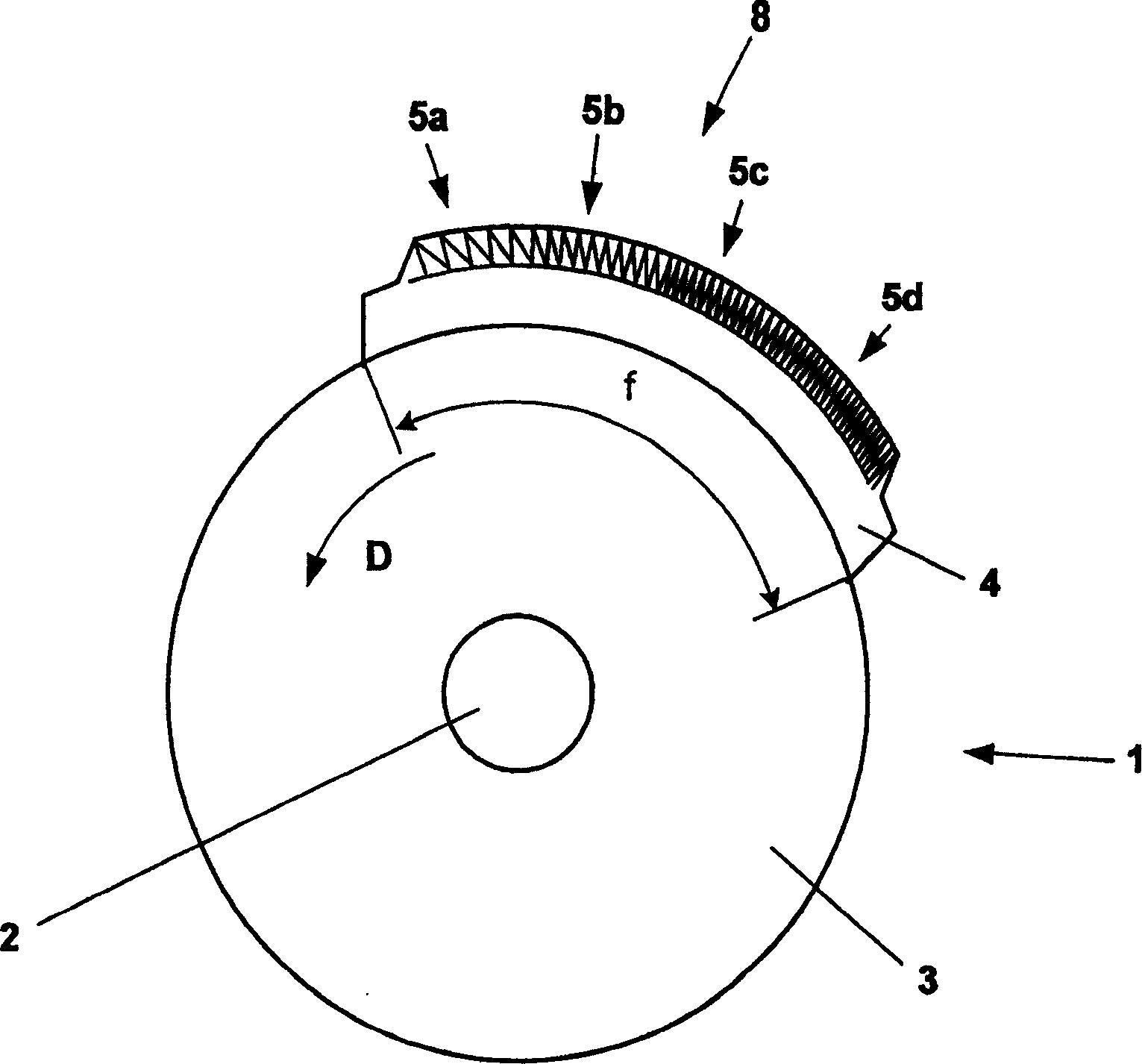

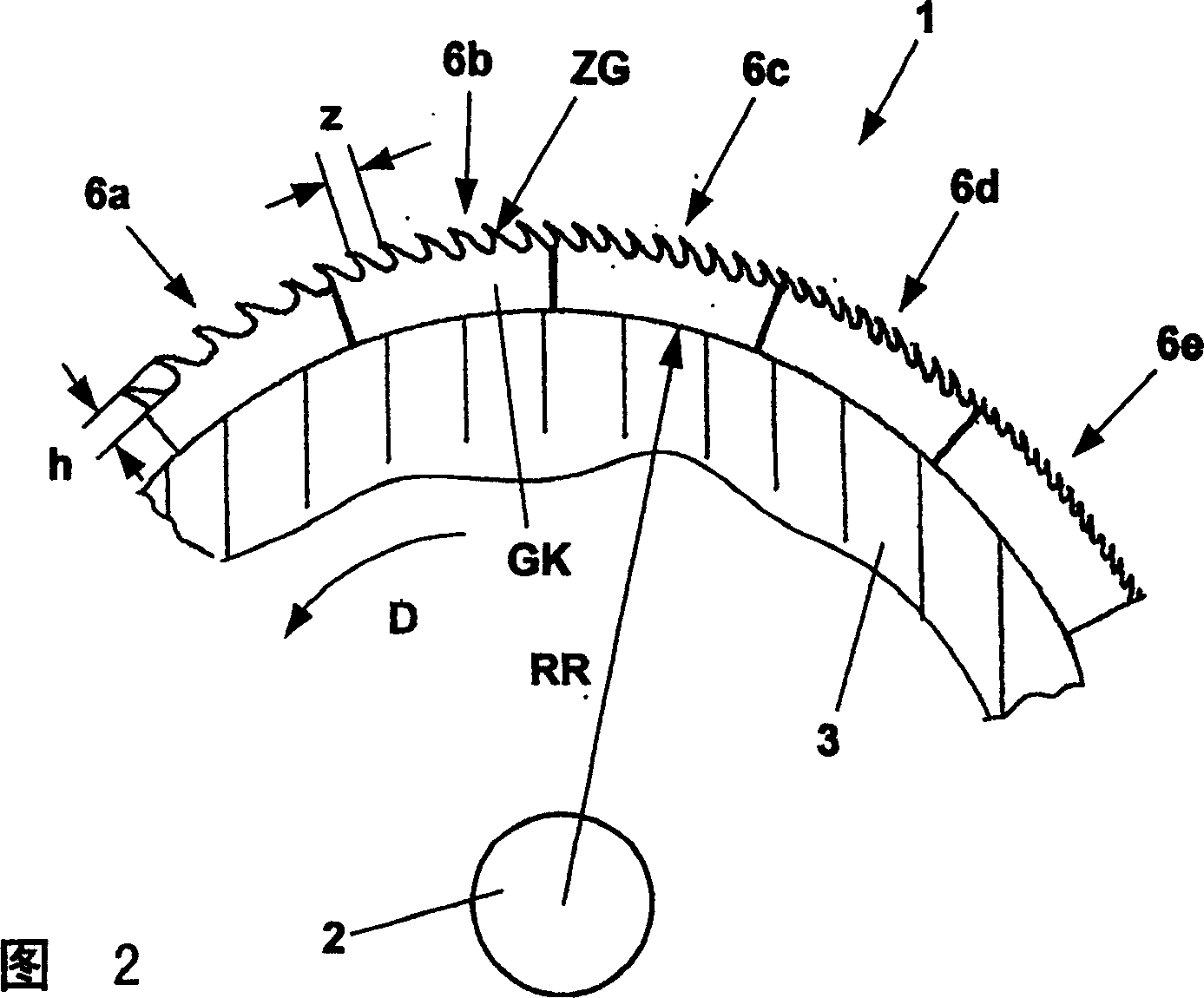

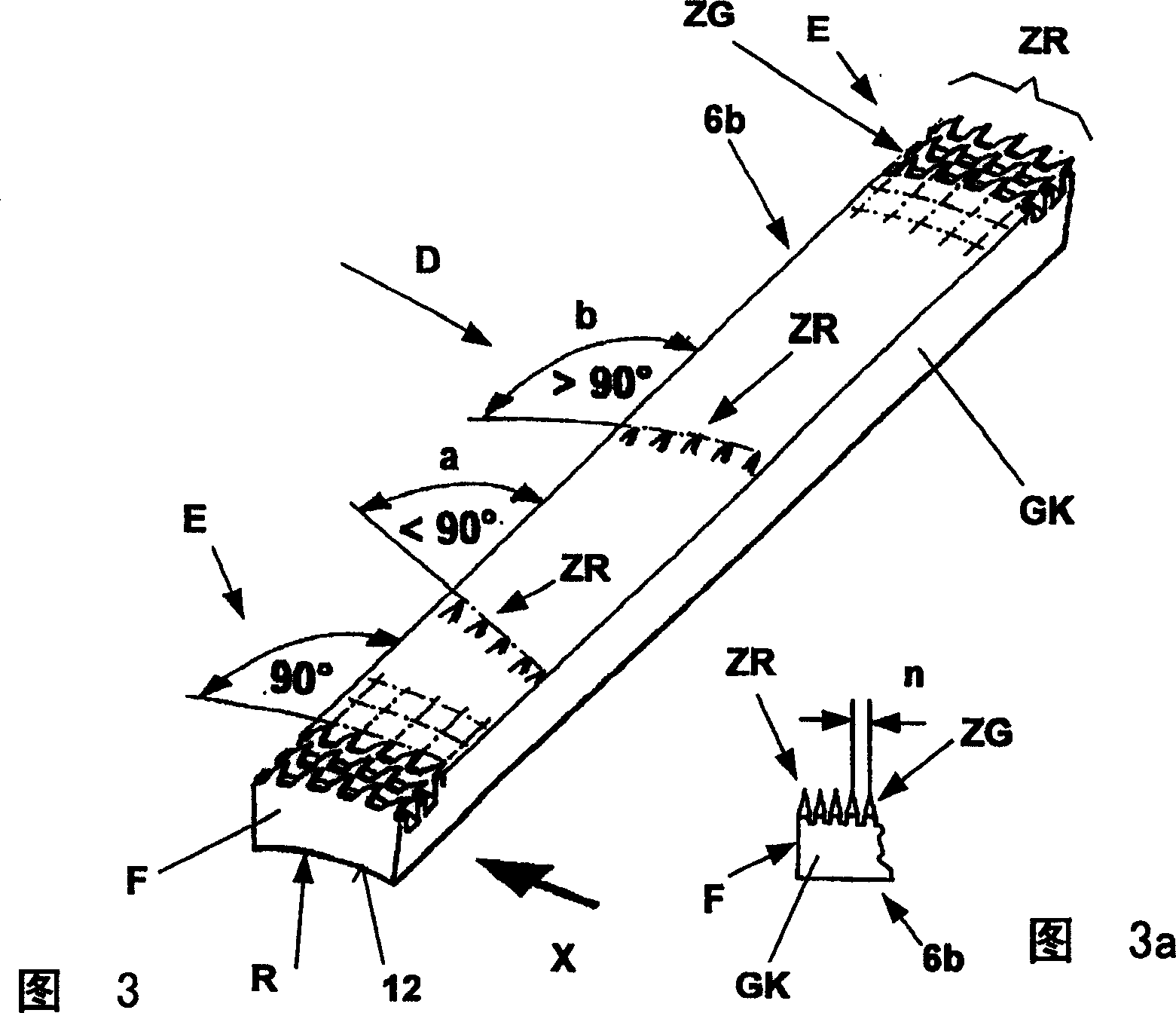

Combing cylinder with clothing elements

InactiveCN1616728AImprove combing effectCombing Effect ExpectationsCombing machinesCarding machinesEngineeringSerration

The invention relates to a circular comb (1) for a combing machine with a circular comb carrier (3), which is fastened on a shaft (2) in a torsion-proof manner and on a part of its circumference, the sawtooth fittings Or the clothings (5a-5d) are fastened to the base body (4, GK). In order to simplify the assembly and disassembly of such toothed wires, and to expand the variation possibilities of the toothed wires themselves, it is proposed that the base body (GK) and the toothed wires (ZR) be a single piece, and in the direction of rotation of the circular comb (1) As seen in (D), it consists of at least two consecutive clothing elements (6a-6e).

Owner:MASCHINENFABRIK RIETER AG

Oil-removal alopecia-preventing shampoo and preparation method thereof

ActiveCN105287338AEasy to cleanFunction increaseCosmetic preparationsHair cosmeticsBiotechnologyEleutherococcus gracilistylus

The invention discloses an oil-removal alopecia-preventing shampoo and a preparation method thereof, the oil-removal alopecia-preventing shampoo is prepared from deionized water, chitosan, sodium lauryl sulfate, ginger, acanthopanax, pelargonium, citric acid, stearic acid glycol diester, potassium sorbate, hydrolyzed corn starch, rose petal, essence, white vinegar, propolis and an oil-removal alopecia-preventing auxiliary agent. The shampoo of the present invention employs the traditional Chinese medicine components such as ginger and pelargonium, chitosan and potassium sorbate are combined together for usage, the alopecia-preventing effect is good, hair combing effect is good, cleaning is easy, the oil-removal alopecia-preventing auxiliary agent is helpful for enhancing oil-removal function and alopecia-preventing function of the shampoo, the shampoo has little damage to human body, the sterilization capability is strong, and shampoo is suitable for industrialization.

Owner:广州帝臣生物科技股份有限公司

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are sequentially arranged on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are sequentially arranged on the top of the cylinder from front to back and correspond to the rack; partitions are respectively arranged between the first carding region cover plate and the second carding region cover plate and between the second carding region cover plate and the third carding region cover plate; the carding machine is provided with the three carding cover plates, so that three carding regions are formed; the first carding region is mainly used for clearing up and combing fibers smoothly and initially discharging impurities and short fibers; the second carding region is further used for clearing up and combing the fibers smoothly and initially discharging the impurities and the short fibers; the third carding region is mainly used for precisely combing the fibers and discharging the impurities and the short fibers further; each carding region cover plate is provided with a cover plate cleaning device; the cover plate cleaning devices can clean independently; and the cleaned carding cover plates can be used for combing operation rapidly and efficiently. The carding machine is provided with the three carding cover plates, the radian of each carding cover plate is reduced, the carding cover plates can be cleaned as soon as possible, the cleaning efficiency of the cover plates is improved further, and the carding effect is guaranteed.

Owner:QINGDAO HUANUO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com