Novel semi-spinning specialized equipment

A special equipment and semi-worsted spinning technology, used in textiles and papermaking, deburring devices, fiber treatment, etc., can solve fiber damage and other problems, achieve uniform feeding, improve initial opening effect, quantity selection and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

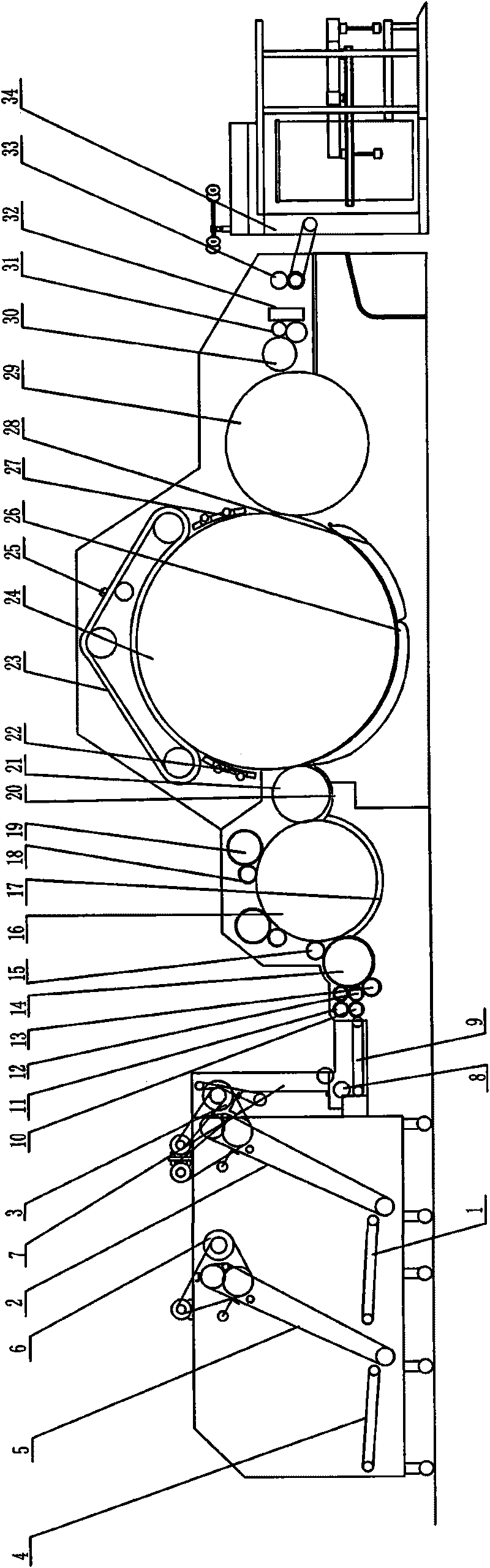

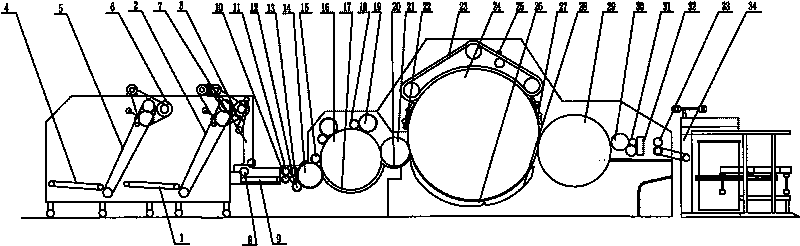

[0018] Referring to the accompanying drawings, a new special equipment for semi-worsted spinning includes a feeding mechanism, a feeding and opening mechanism, a carding mechanism, a stripping mechanism and a coiling mechanism. The technical contents not mentioned in the utility model can adopt corresponding or corresponding technical methods in the prior art.

[0019] The above-mentioned feeding mechanism includes a hair feeding box and a vibrating box. The first bottom flat curtain 1 and the first oblique nail curtain 2 are arranged in sequence in front of the inside of the feeding box, the first hair equalizing roller or the first hair equalizing rake are arranged on the upper rear side of the first oblique nail curtain 2, and the first oblique nail curtain The first stripping roller 3 is arranged on the front side of the upper part; the second bottom flat curtain 4 and the second oblique nail curtain 5 are arranged sequentially behind the inside of the hair feeding box, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com