Full fixed cover plate-type carding machine suitable for non-woven production line

A technology for fixing cover plates and non-woven fabrics, which is applied in the direction of non-woven fabrics, textiles, papermaking, fiber processing, etc. It can solve the problems of inability to transfer fibers and low output, and achieve reduced on-site flying, increased output, and good carding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with example (accompanying drawing):

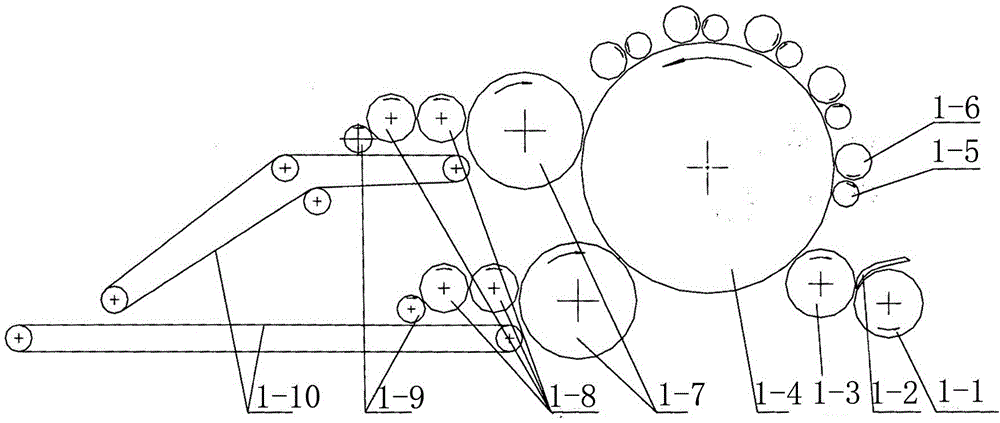

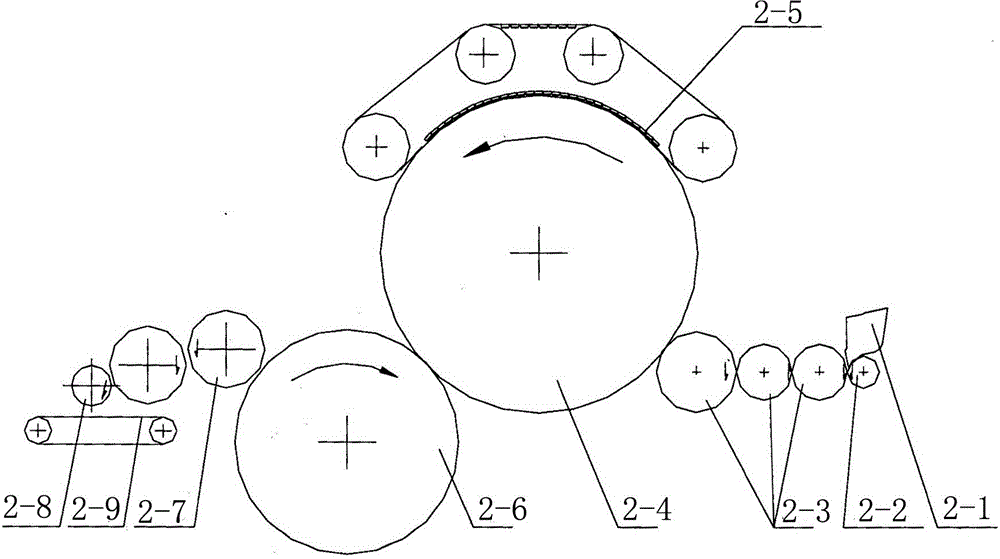

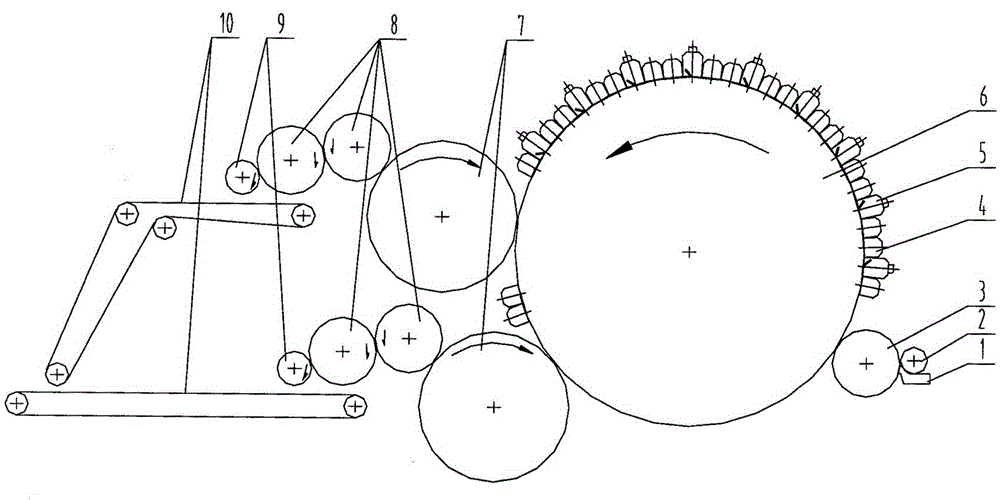

[0026] Such as image 3 As described above, the fully fixed flat carding machine suitable for fiber carding in the nonwoven production line of the present invention includes a cylinder 6, which is located below the feed end side of the cylinder 6 and performs preliminary opening and pre-carding of the fibers. The licker-in roller 3 is arranged on the discharge end of the cylinder 6, which is used to strip the carded single fiber on the cylinder 6 and forms the upper and lower doffers 7; 1 and the feeding mechanism composed of feeding roller 2; the upper and lower agglomeration rollers 8 for strengthening the transverse strength of the fiber web are respectively arranged at the discharge ends of the upper and lower doffers 7, and the fiber web is separated from the upper and lower agglomeration rollers 8 The upper and lower stripping rollers 9 for peeling off and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com