Patents

Literature

65results about "Hackling machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

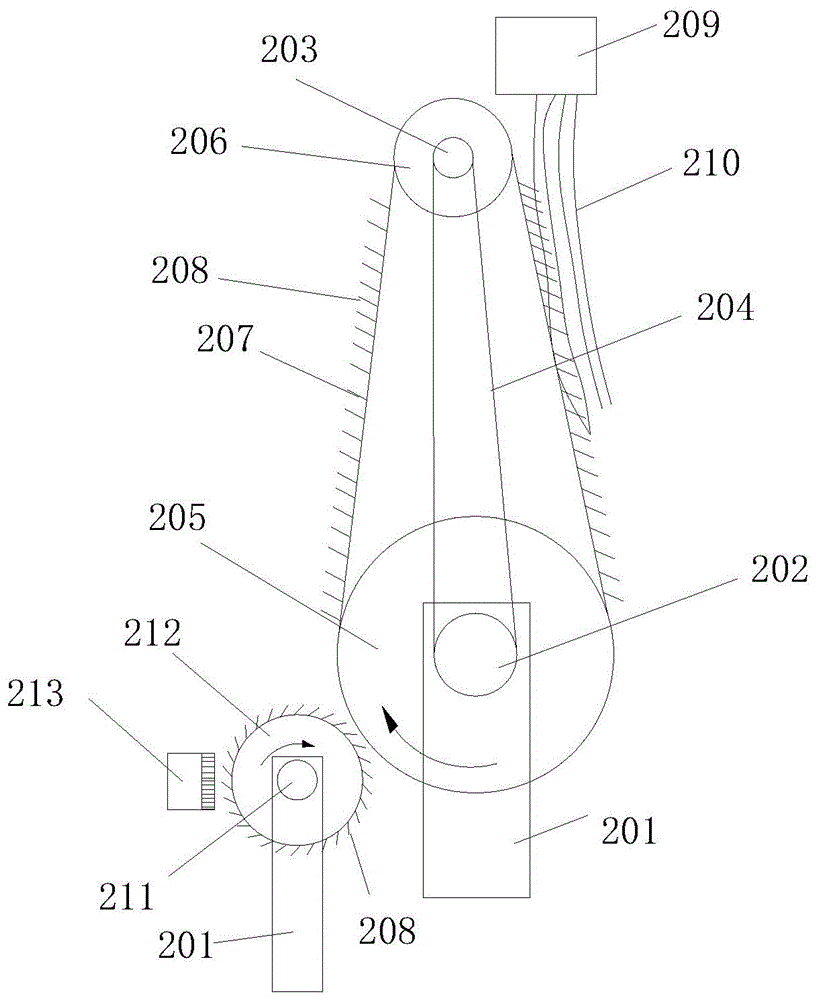

Hackling mechanism of flax hackling machine

The invention discloses a hackling mechanism of a flax hackling machine. The hackling mechanism is characterized in that a brushing shaft (211) which is erected on a framework (201) is arranged on a side surface of a main hackling drum (205), a brushing drum (212) is arranged on the brushing shaft (211), and steel brushes (208) are fully distributed on the surface of the brushing drum (212) and can intersect with steel brushes of a hackling track (207) at contact positions of the brushing drum (212) and the hacking track (207); a brush strip (213) is further arranged on a side surface of the brushing drum (212) and is in contact with the steel brushes of the brushing drum (212). The hackling mechanism has the advantages of simple structure, low failure rate and high efficiency. Besides, the problem of degradation of hackling effects due to the fact that flax fibers are easy to adhere on an existing main hackling drum can be solved by the aid of the hackling mechanism.

Owner:吴江市辰龙骏纺织有限公司

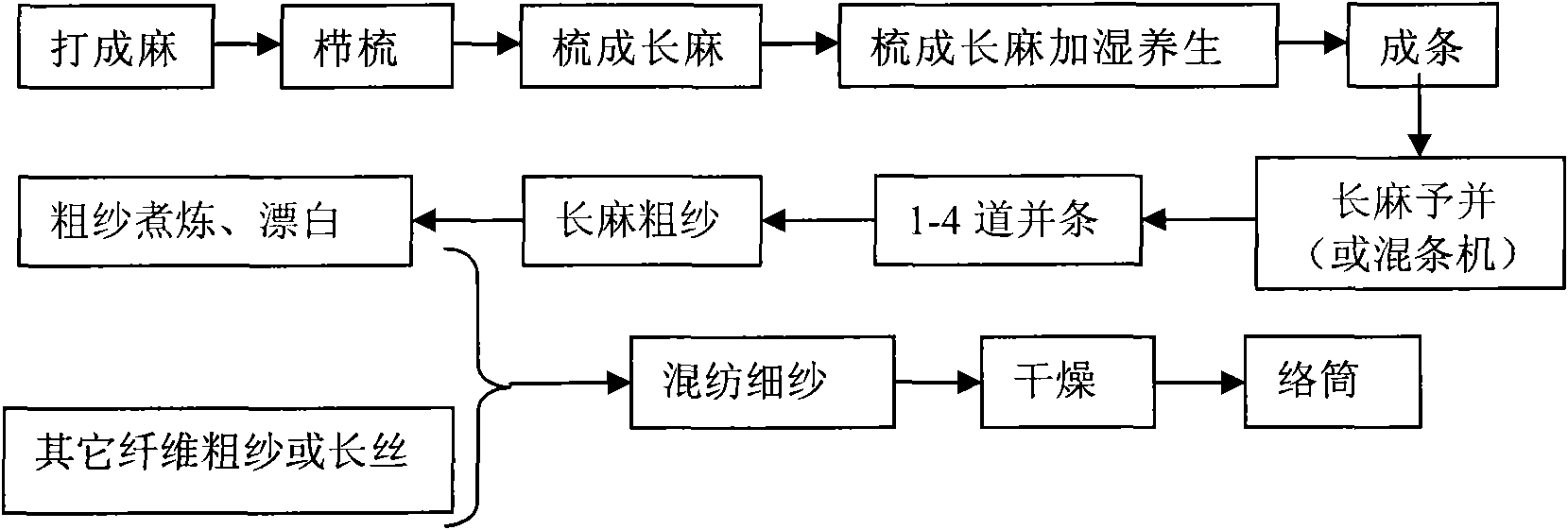

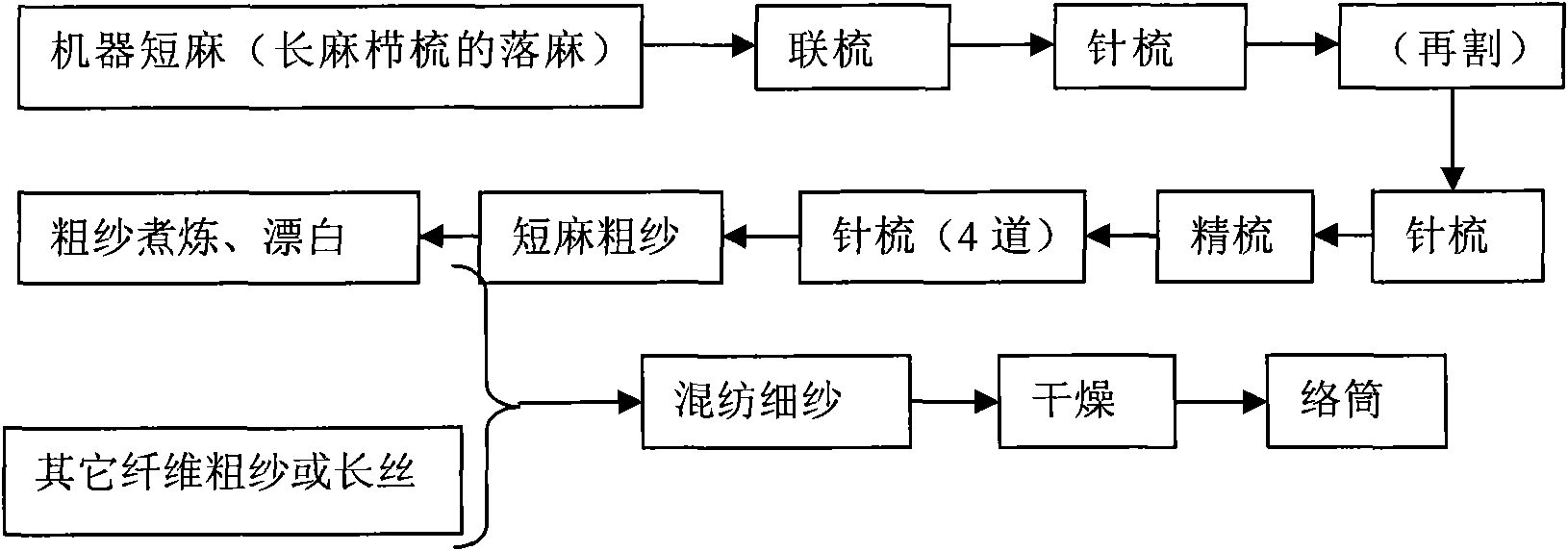

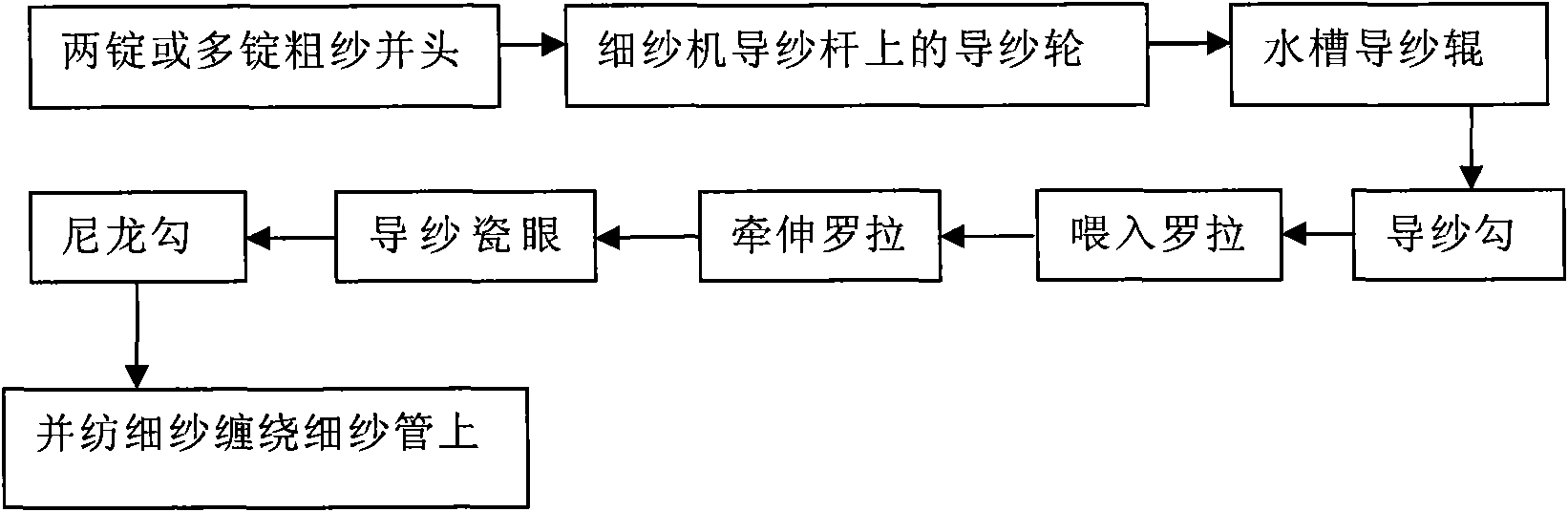

Blending method using hemp fiber as main material

InactiveCN101871147AIncrease the degree of splittingImprove impurity removalHackling machinesBleaching apparatusImpurityMaterials science

The invention relates to a blending method using a hemp fiber as a main material. The method comprises the following steps of: firstly, processing the hemp fiber into rovings; secondly, mixing the roving yarns of the hemp fiber with the rovings or filaments of other fibers in proportion to form bunch yarns; and finally, spinning the mixed bunch yarns in the second step into spun yarns. The blending method has the advantages of improving the disintegration degree of the hemp fiber and removing impurity without damaging the performance of the blended fibers, ensuring a high spinning yam count and quality of the blended yarns and greatly improving the quality of the blended yarns of the hemp fiber along with simple process.

Owner:肇融亚麻纺织有限公司

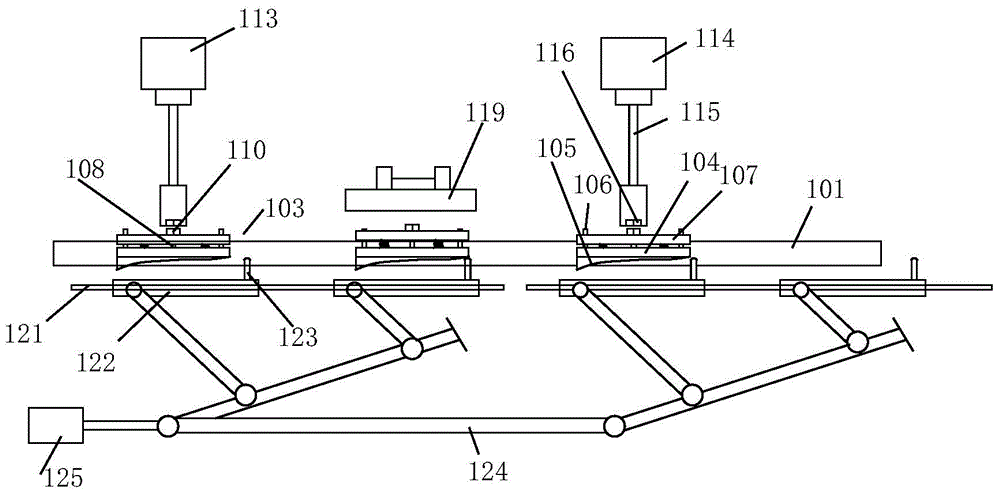

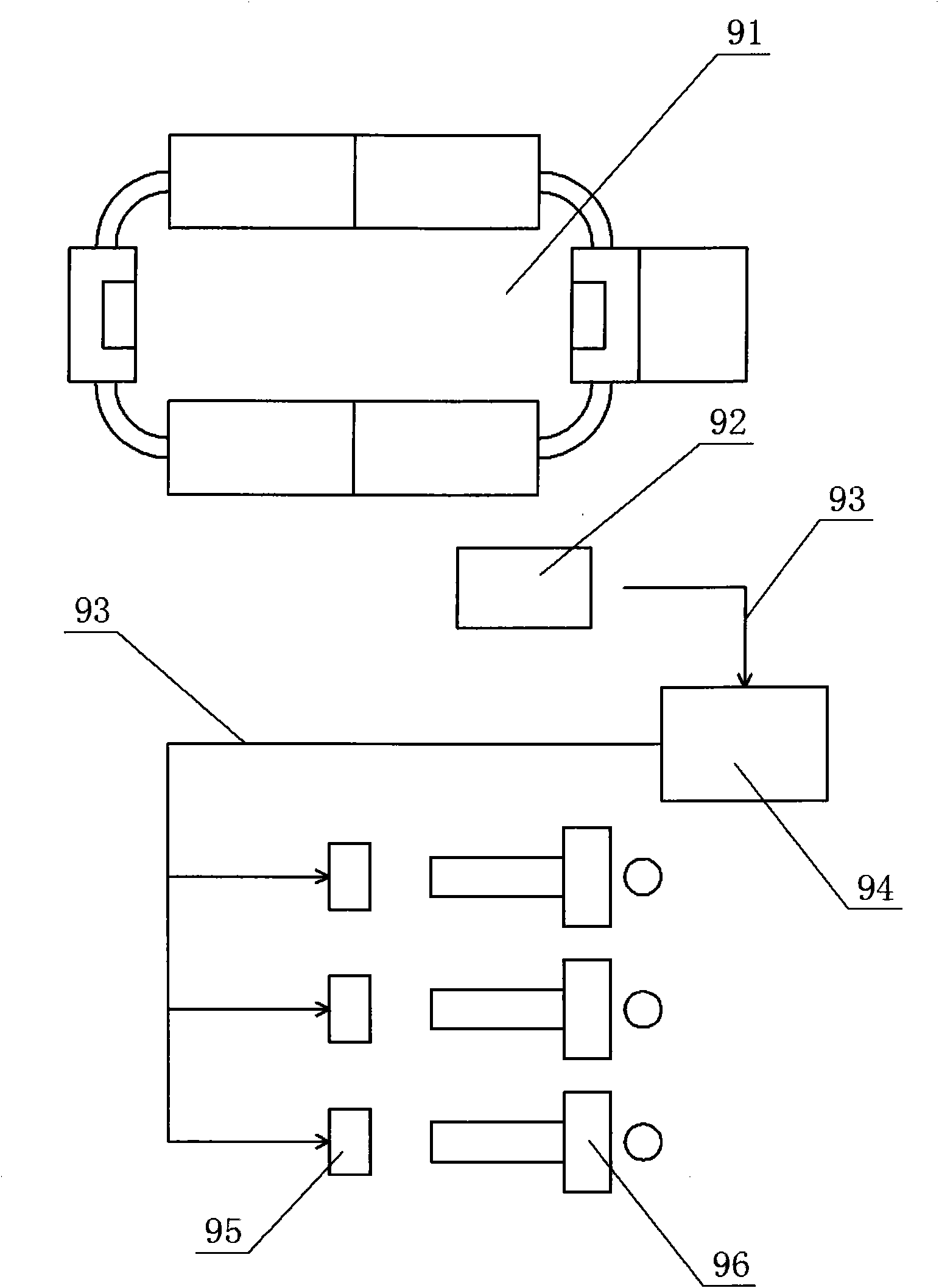

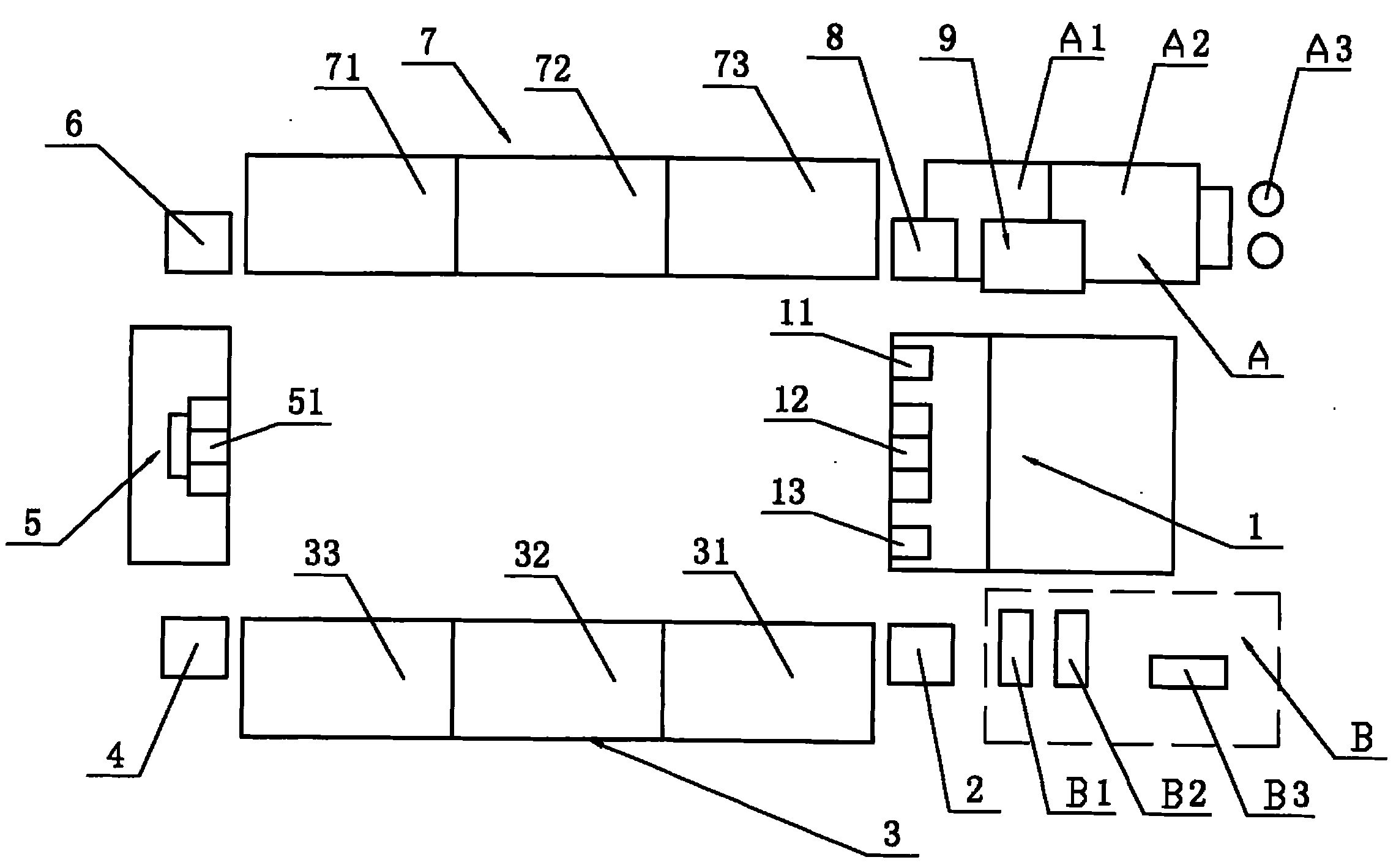

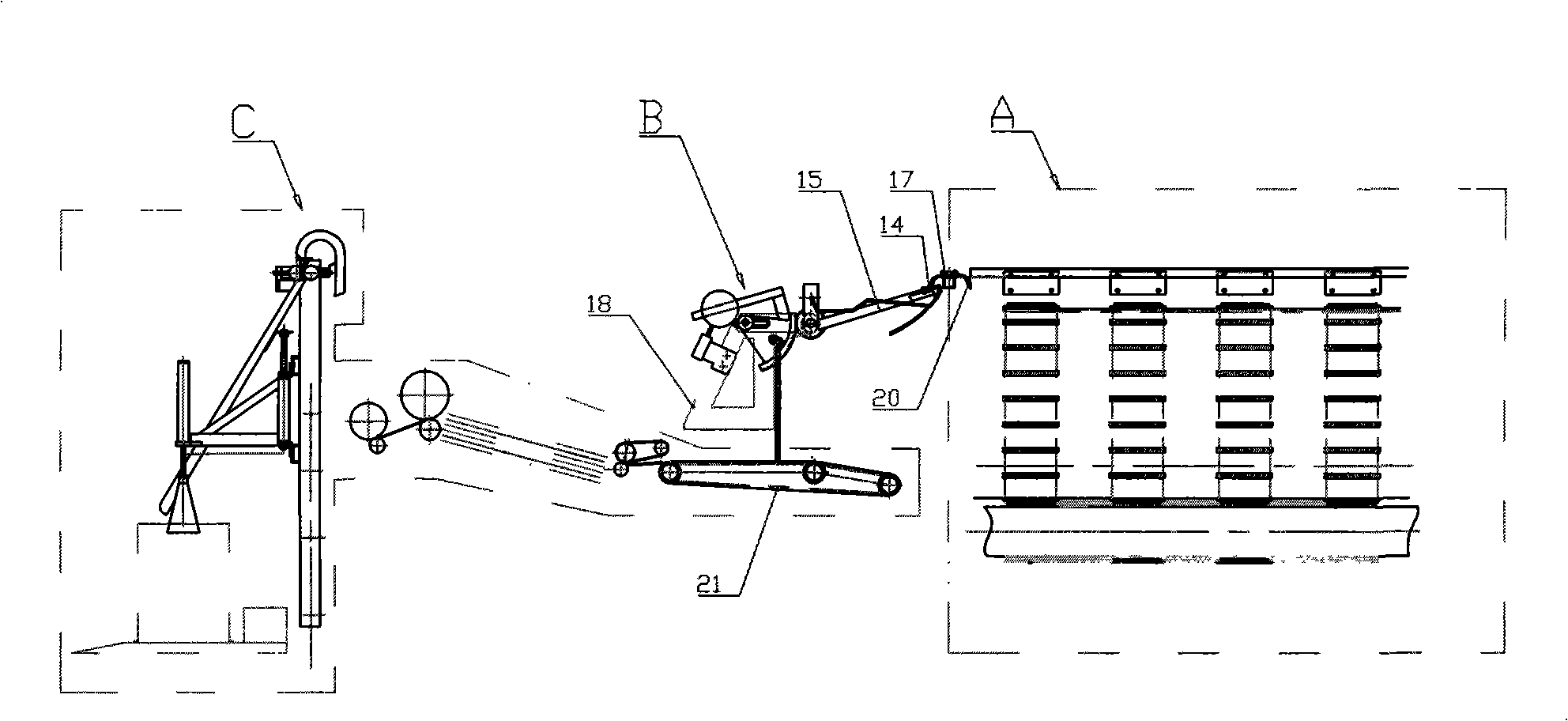

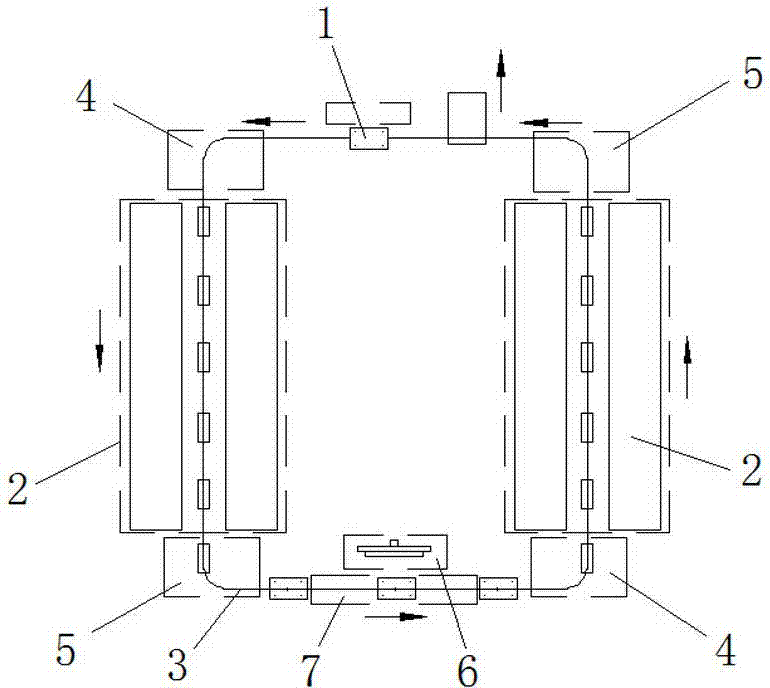

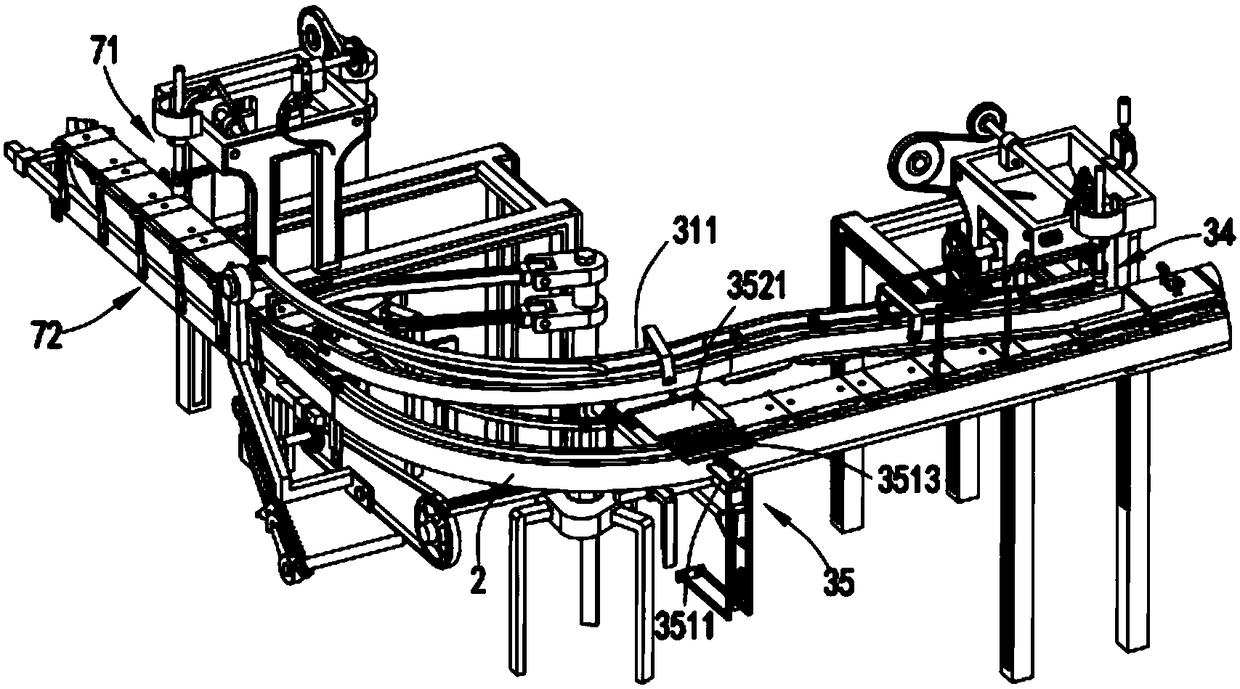

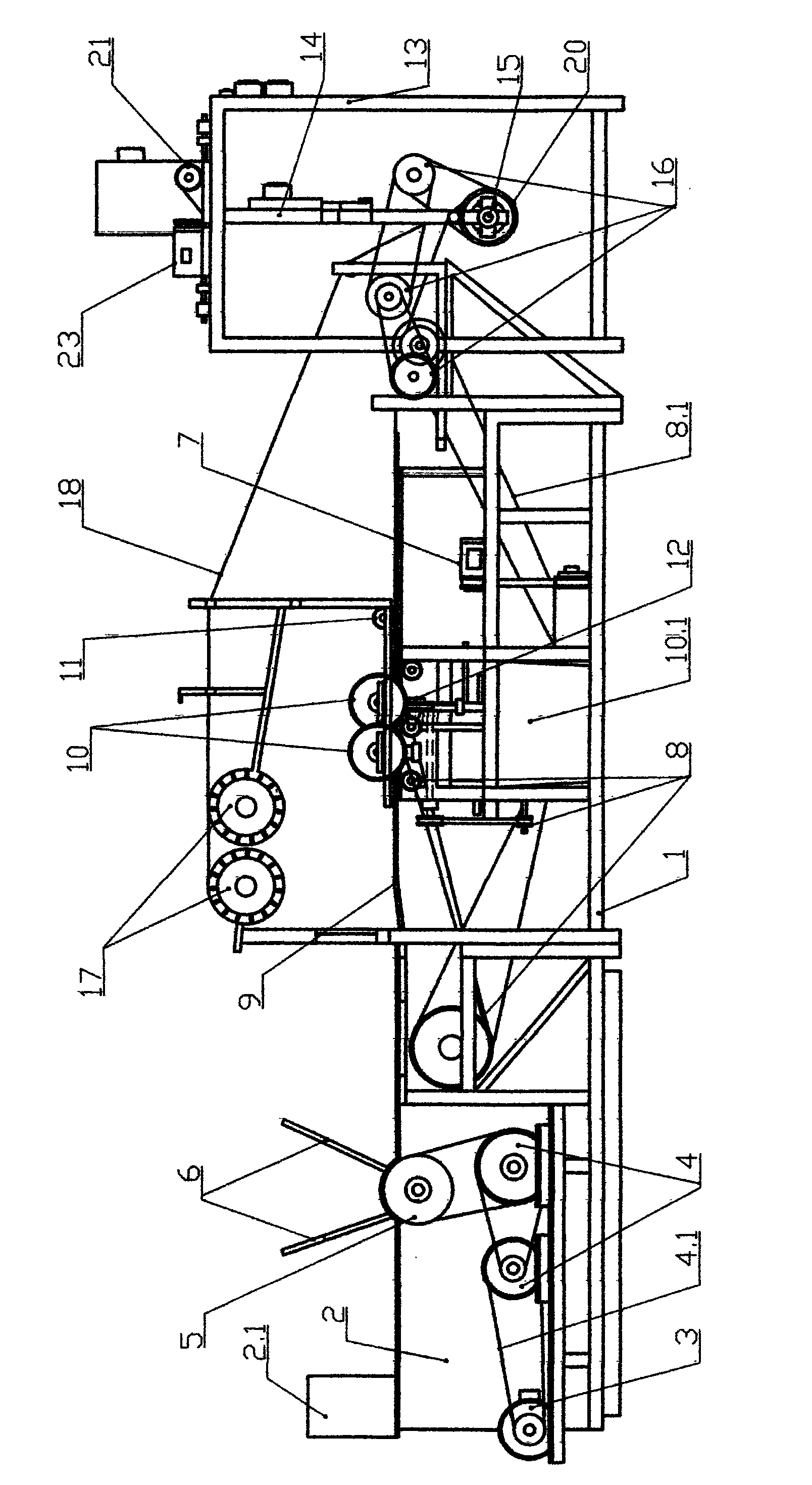

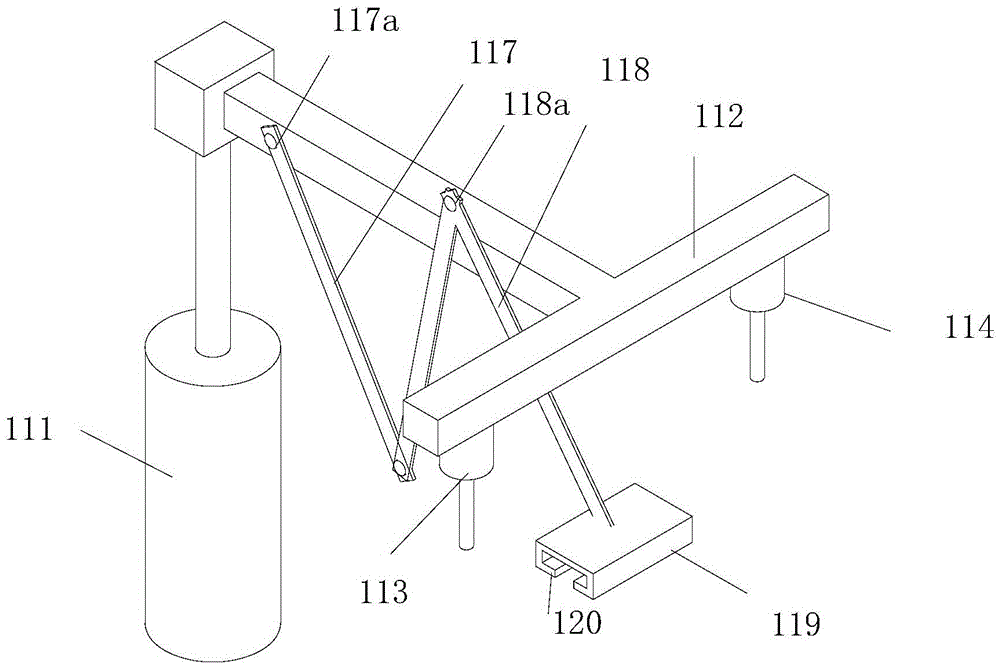

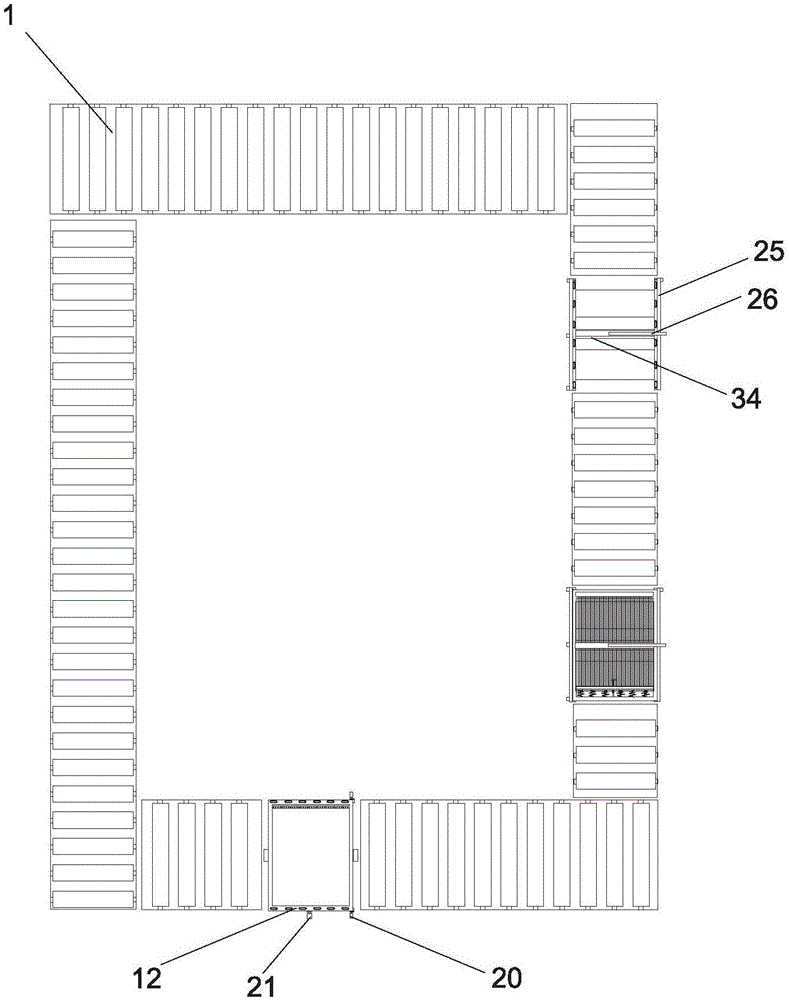

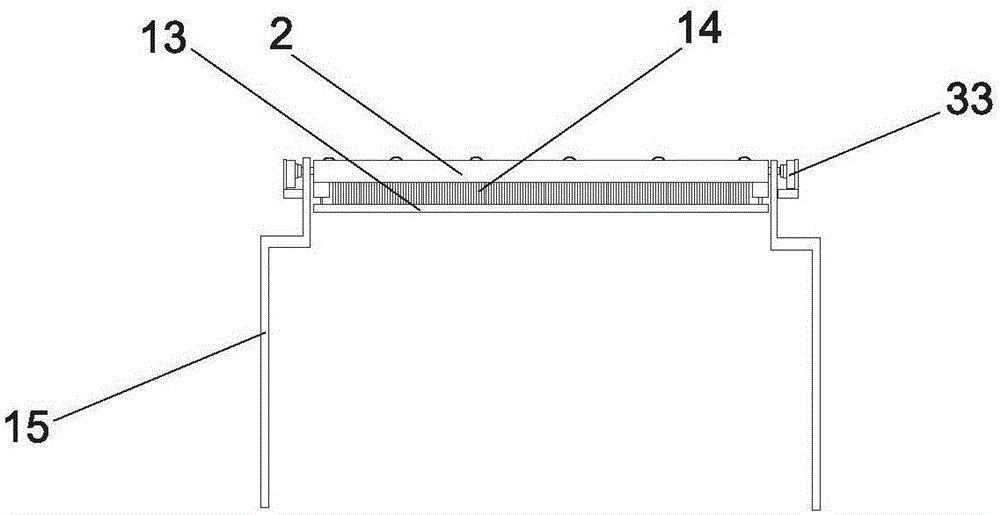

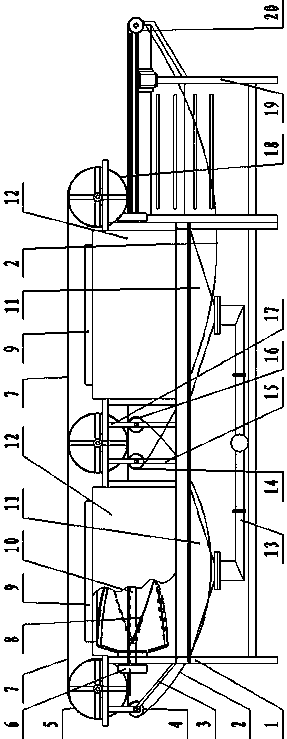

Automatic circular combined hackling machine for hackling and forming strip for flax and combined hackling method thereof

ActiveCN101845689AShort processReduce the number of employeesContinuous processingCarding machinesProduction lineCarding

The invention provides an automatic circular combined hackling machine for hackling and for forming strip for flax and a combined hackling method thereof. The combined hackling machine comprises an annular carding production line, a striping forming production line and a connecting device, wherein the annular carding production line is used for processing scutched flax into carded flax, the strip forming production line is used for making the carded flax into flax strips, and the connecting device is arranged between the annular carding production line and the strip forming production line to connect the annular carding production line and the strip forming production line. An advanced control technology adopted in the invention can combine a flax-hackling step with a strip forming step at present, thereby shortening the process flow, cancelling a non-value-added intermediate link, reducing number of employees greatly, reducing the labor intensity, improving the production efficiency, reducing the production cost and solving problems of large number of employee, high labor intensity, low production efficiency, high production cost and the like of equipment in China flax spinning industry.

Owner:常州金德纺机科技有限公司

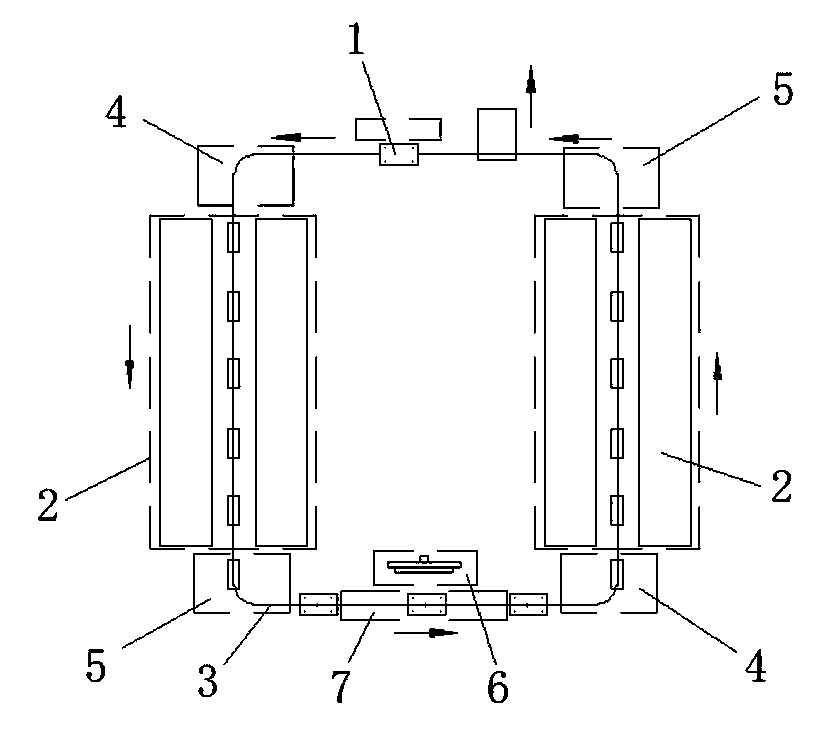

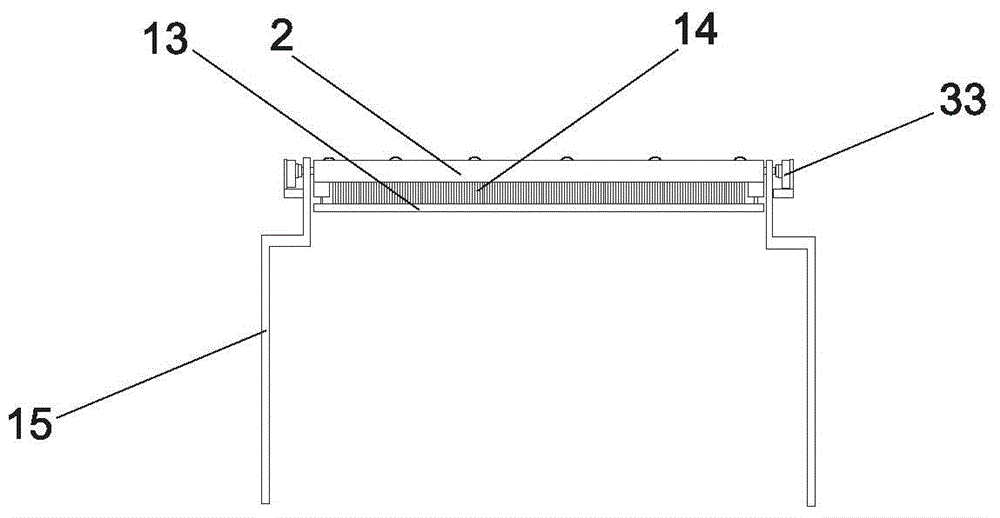

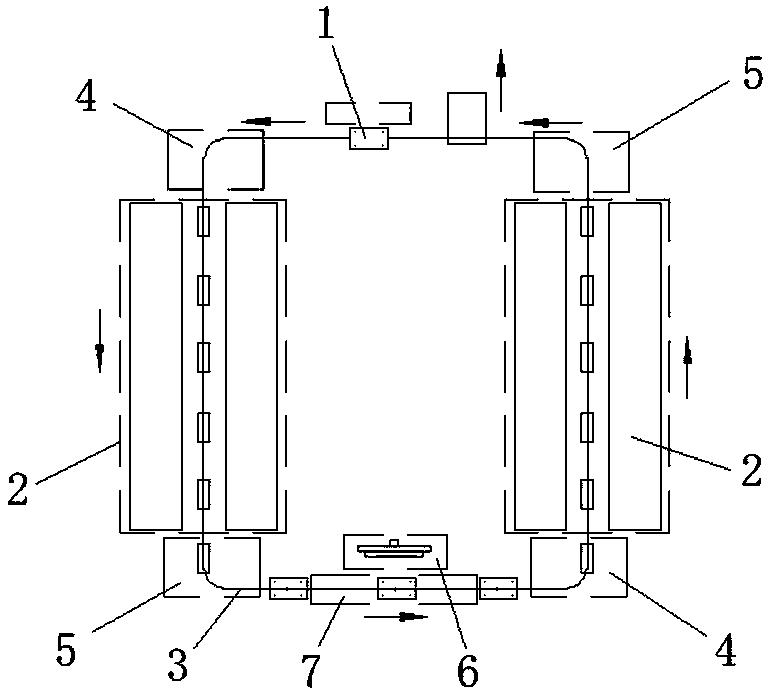

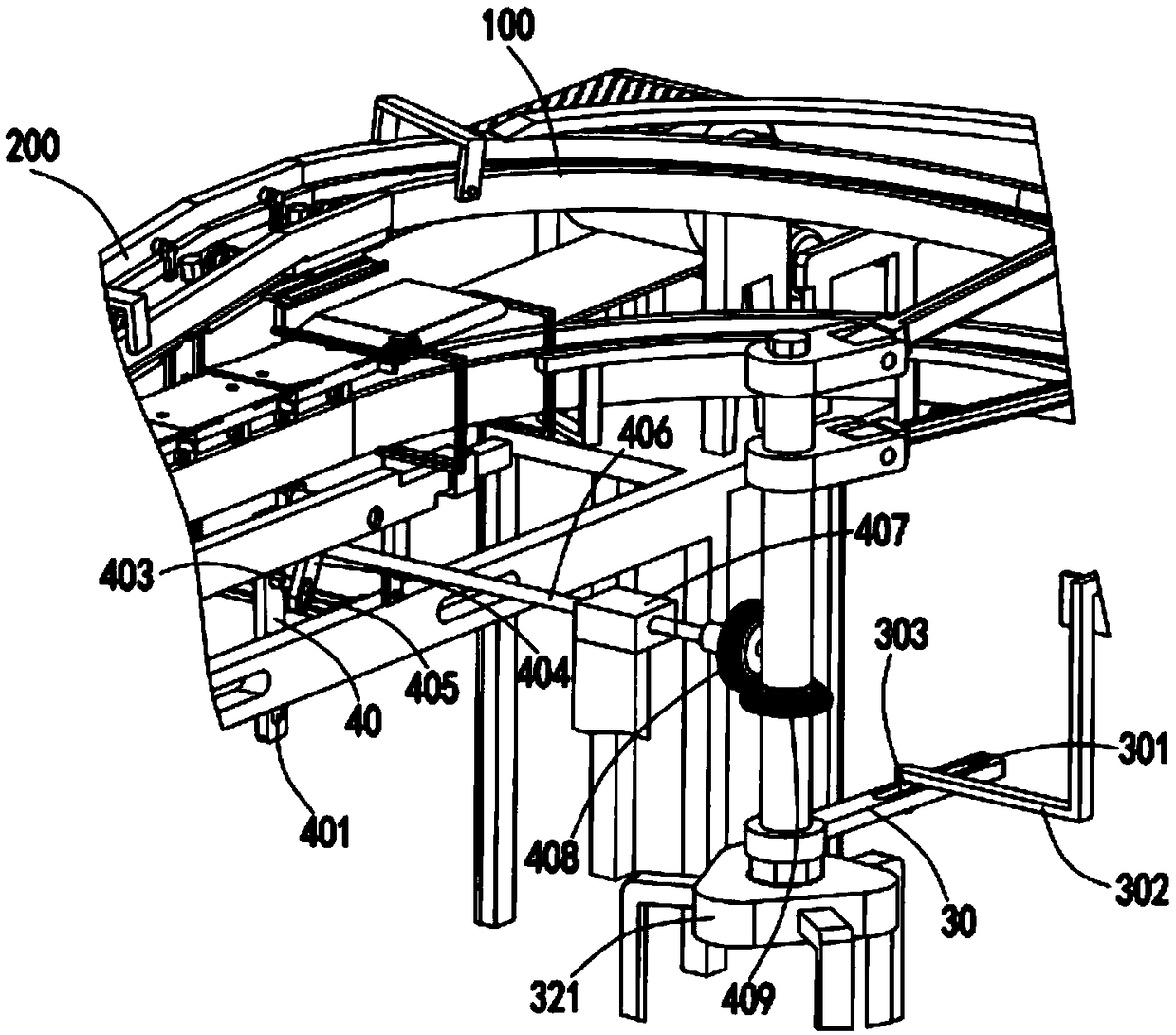

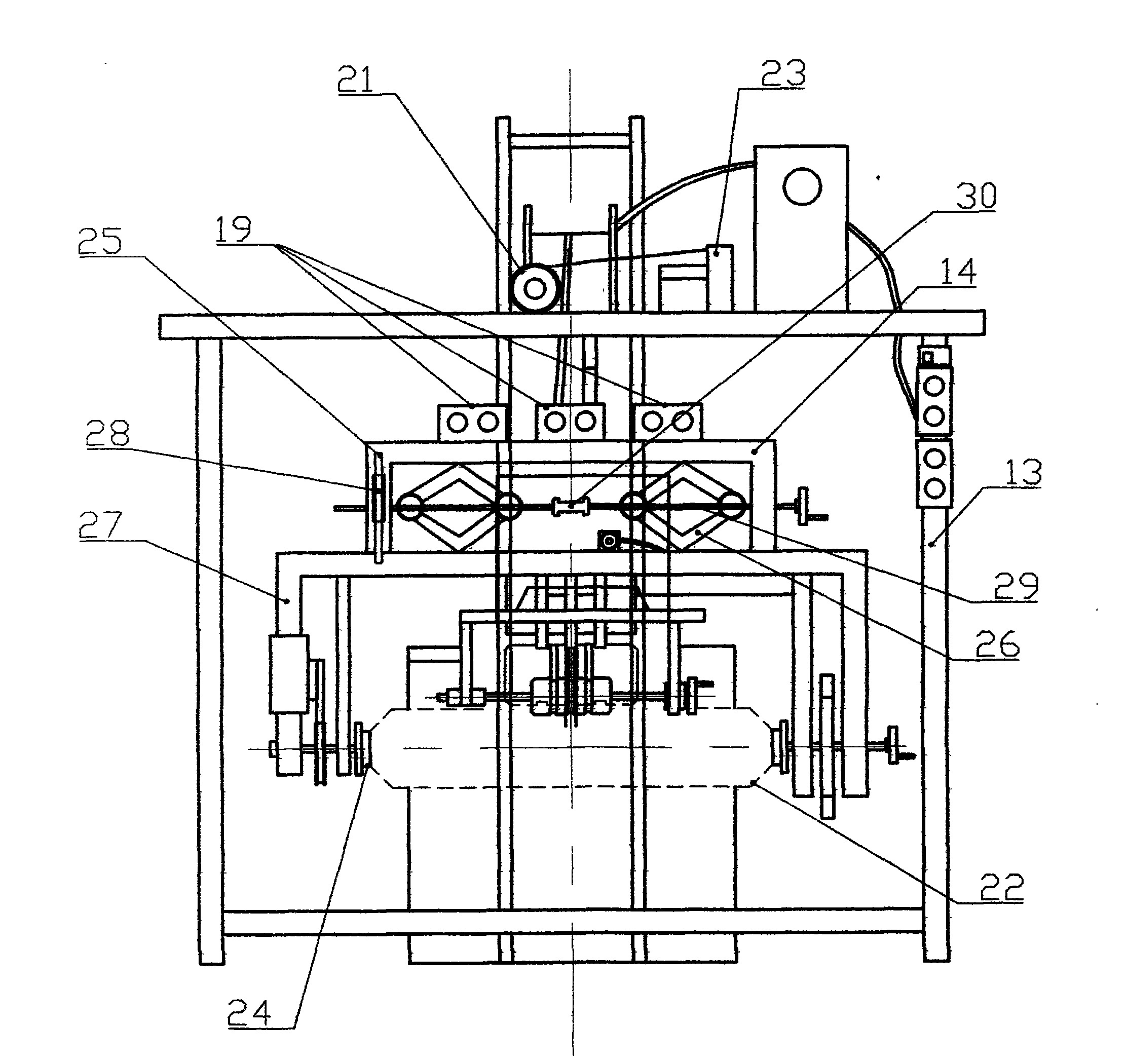

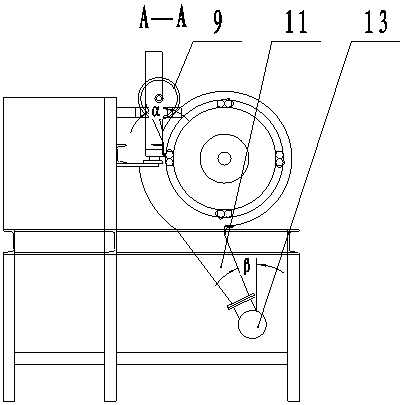

Bidirectional annular hackling machine

ActiveCN104294373AAutomatically achieve reversing operationImprove work efficiencyHackling machinesEngineeringHemp fiber

Disclosed is a bidirectional annular hackling machine. The bidirectional annular hackling machine comprises jute clamping devices, two heckling devices, a conveying passage, a bend push-in device, a bend push-out device, a turning device and a pushing device. By combination of the annular conveying passage and the two heckling devices, one heckling device heckles one sides of jute fibers firstly, and then the other heckling device heckles the other sides of the jute fibers. The entire jute fibers are heckled totally by only one process without multiple heckling steps, and working efficiency is increased greatly. The hackling machine can realize turning operation of the jute fibers automatically, the positions of the jute fibers in the jute clamping devices are changed, manual operation is omitted, working efficiency is improved, heckling precision is guaranteed as well, and labor cost is saved.

Owner:ZHEJIANG AXIANG LINEN TEXTILE

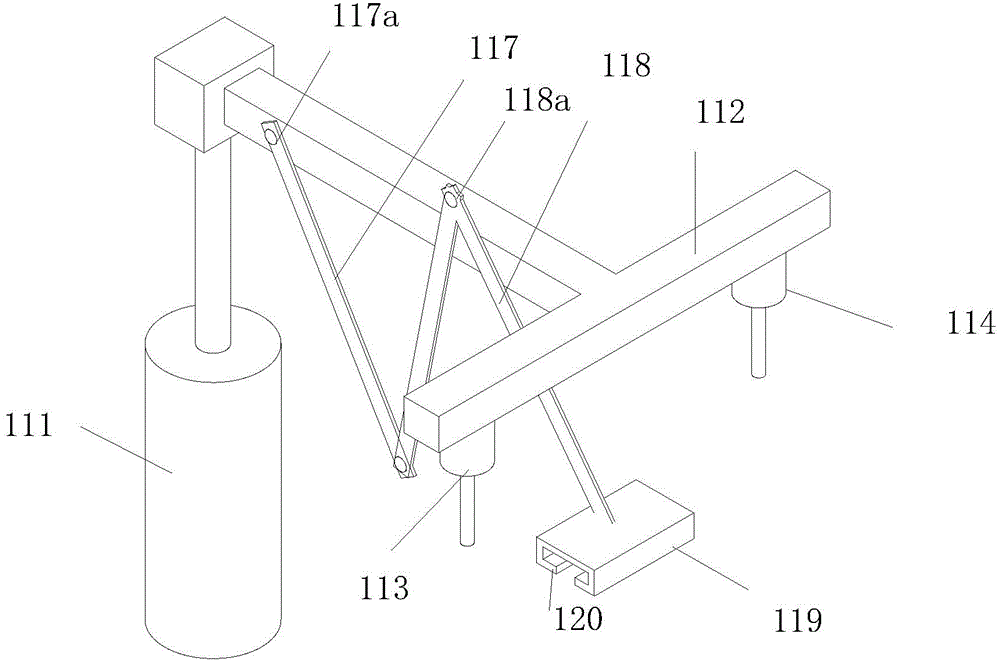

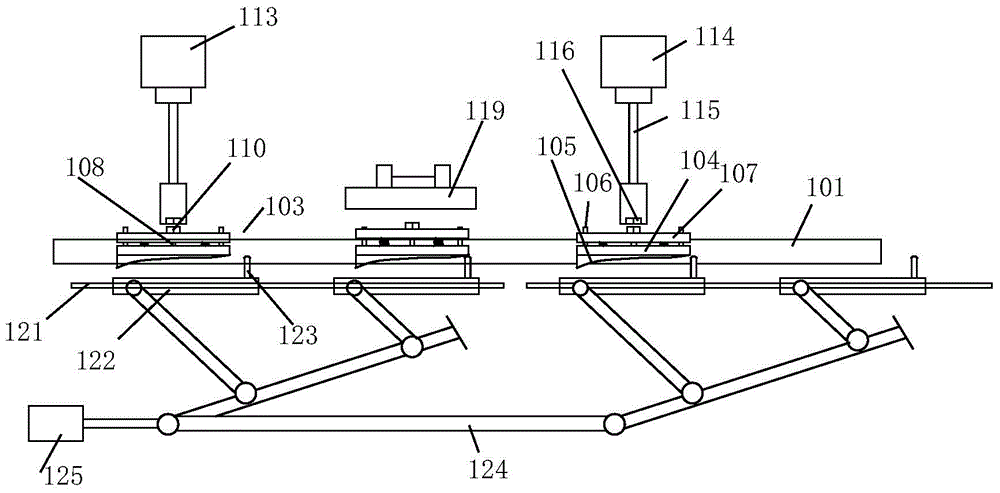

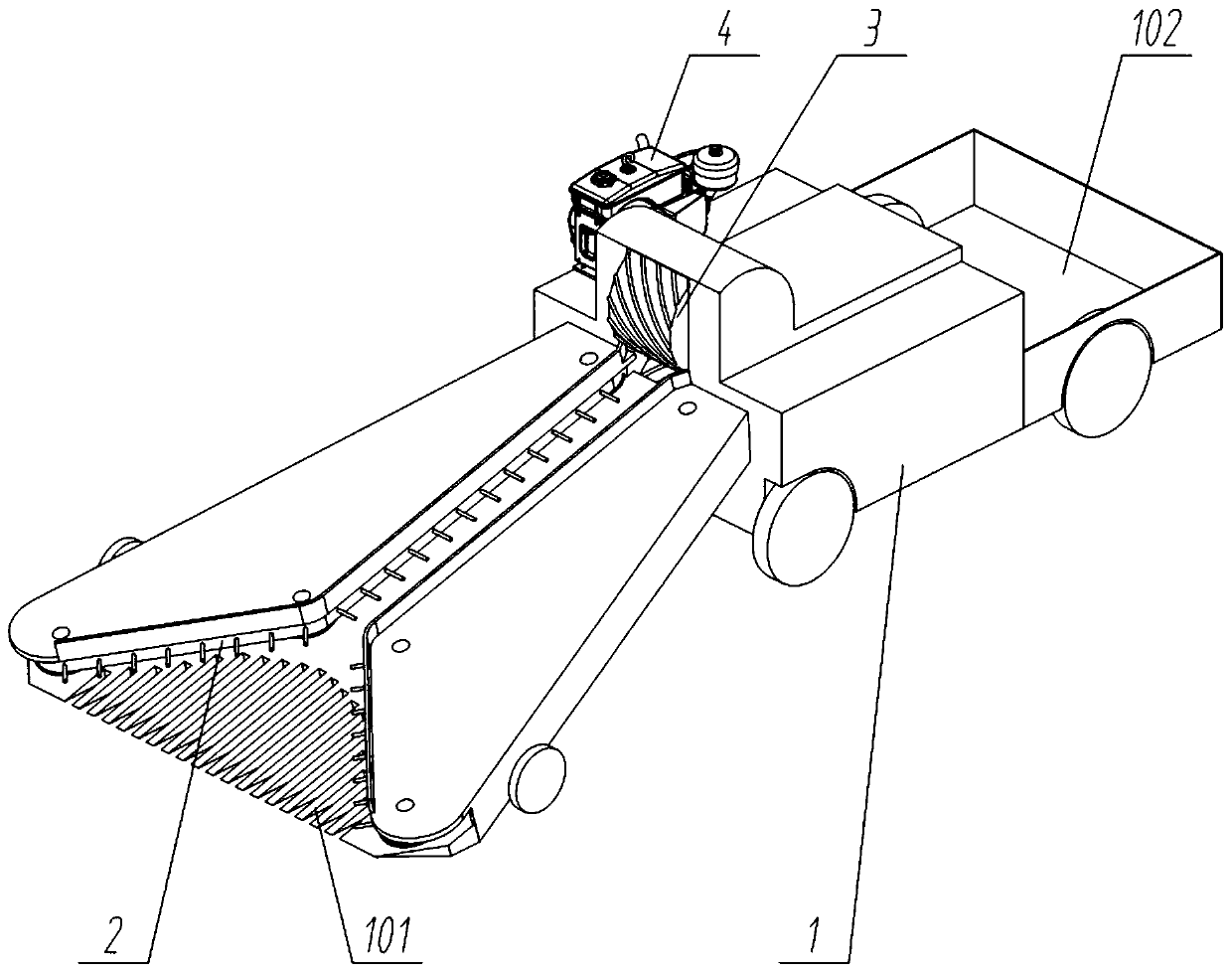

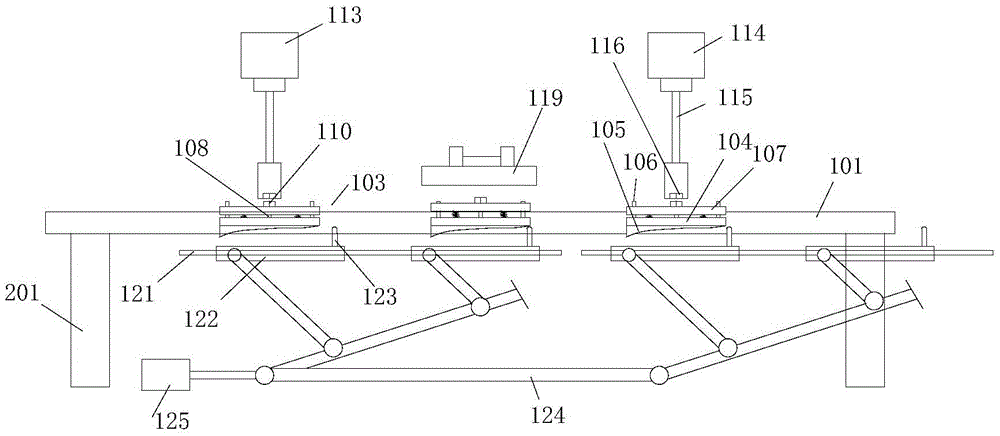

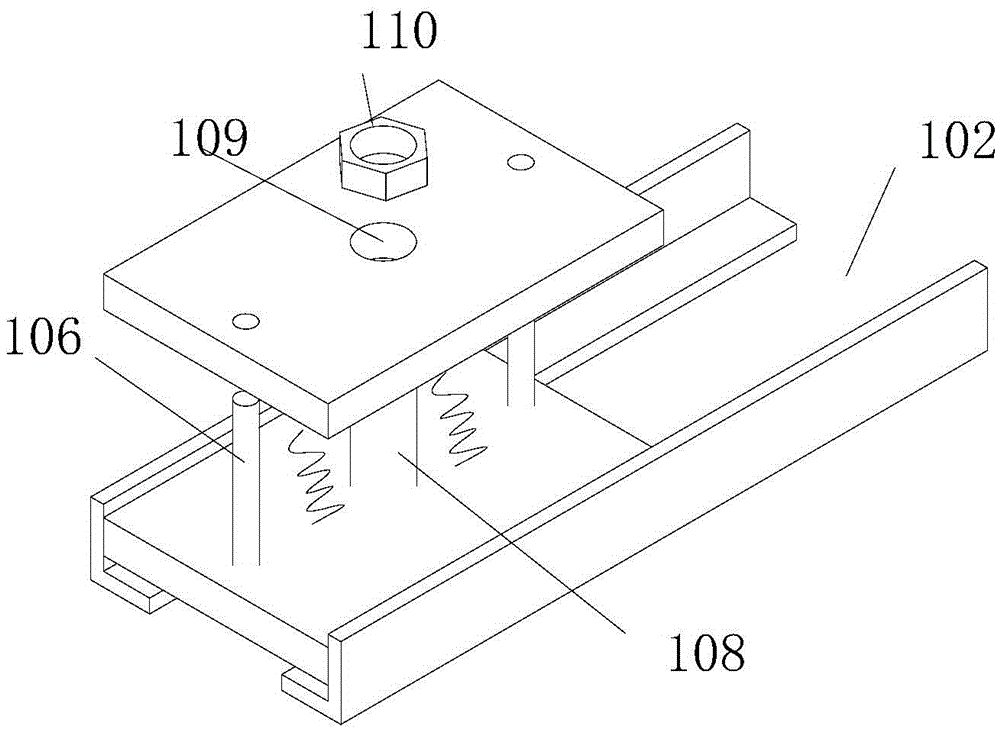

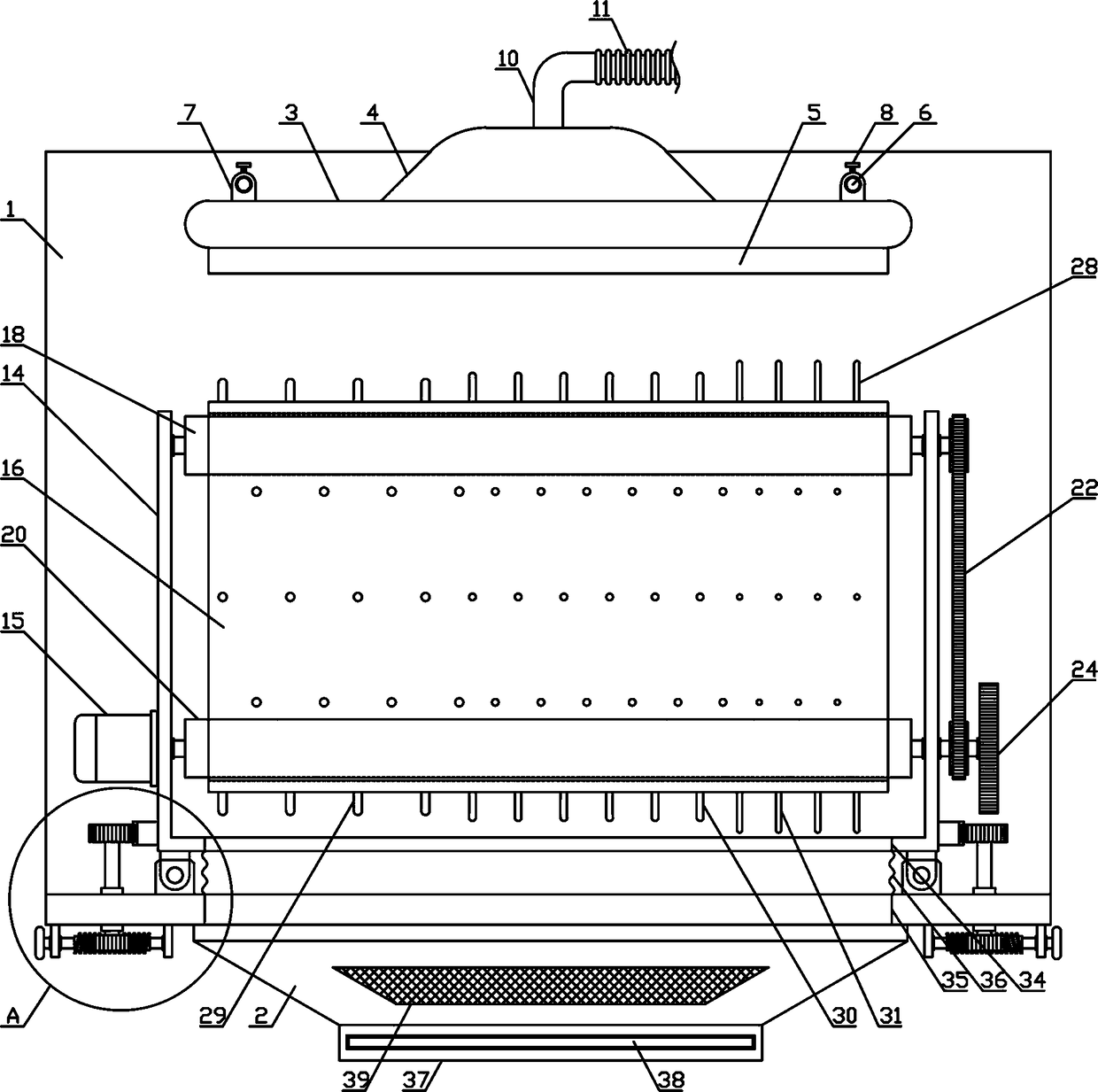

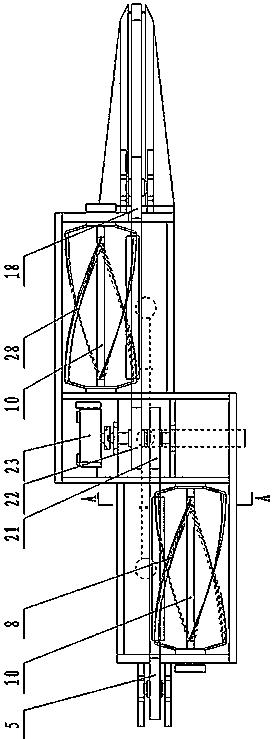

Full-automatic flax hackling machine

InactiveCN104099667AImprove combing effectEasy to cleanHackling machinesElectric machineryEngineering

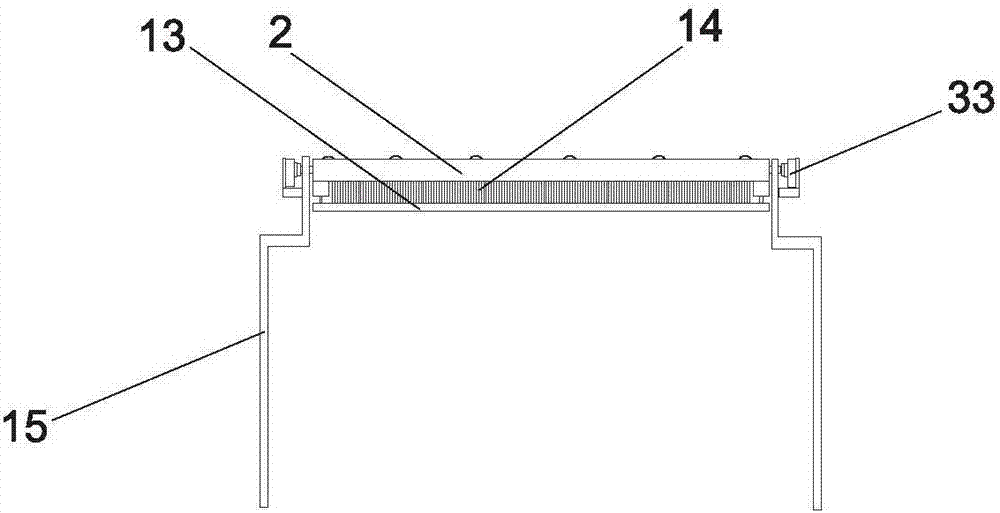

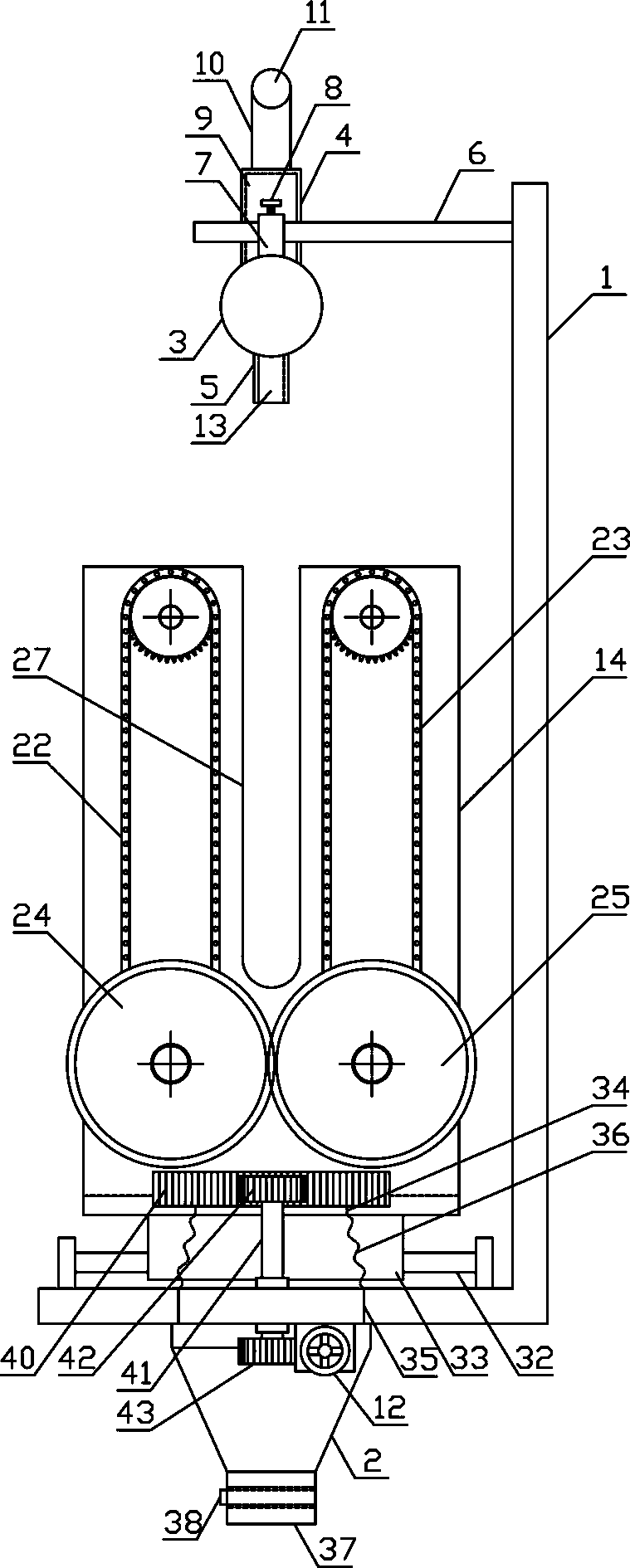

The invention discloses a full-automatic flax hackling machine comprising a feeding mechanism fixed to a frame (201), and a hackling mechanism is arranged behind the feeding mechanism; the feeding mechanism comprises a sliding platform (101), the center of the sliding platform (101) is provided with a sliding groove (102), a sliding device (103) is erected on the sliding groove (102), a discharging motor (113), a grasping block (119) and a feeding motor (114) are arranged above the sliding device (103), and a pushing block (122) is arranged below the sliding groove. The hackling mechanism comprises a brush shaft (211) which is erected on the frame (201) and which is arranged on the side of a main hackling roller (205), the brush shaft (211) is provided with a brush roller (212), the surface of the brush roller (212) is provided with steel brushes (208) fully, and the steel brushes of the brush roller (212) are crossed with steel brushes of a hackling crawler (207) in the contacting position; the side of the brush roller (212) is provided with a brush stripe (213) contacting with the steel brushes of the brush roller (212).

Owner:吴江金怡纺织品有限公司

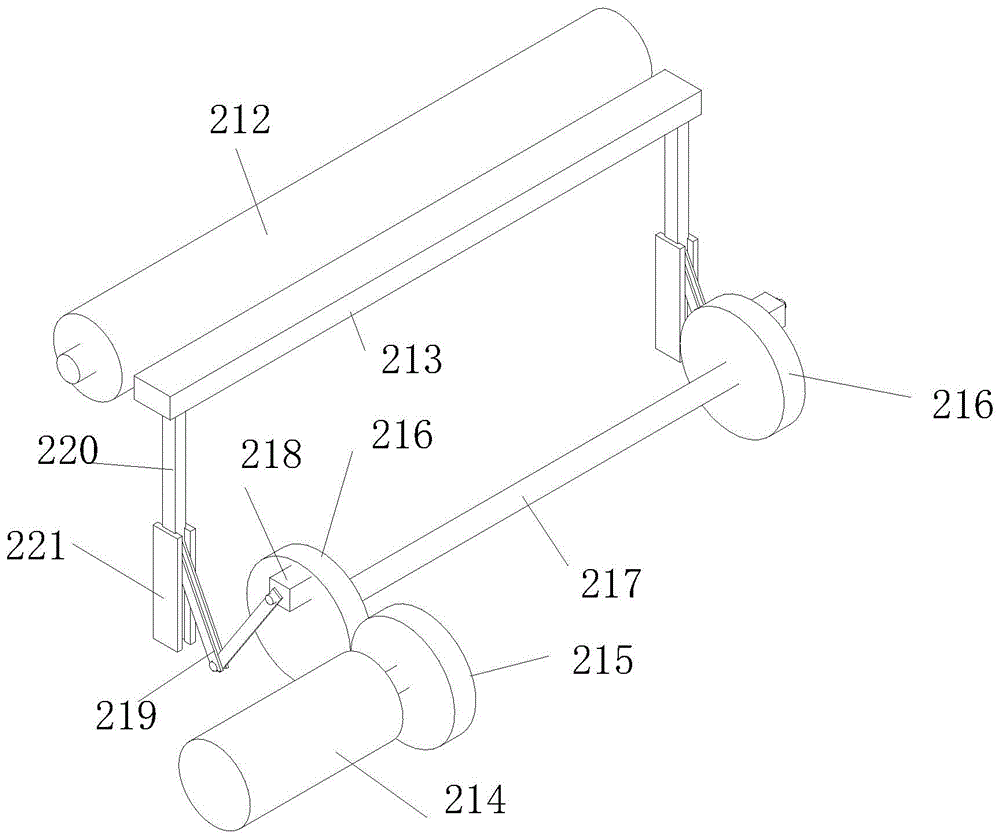

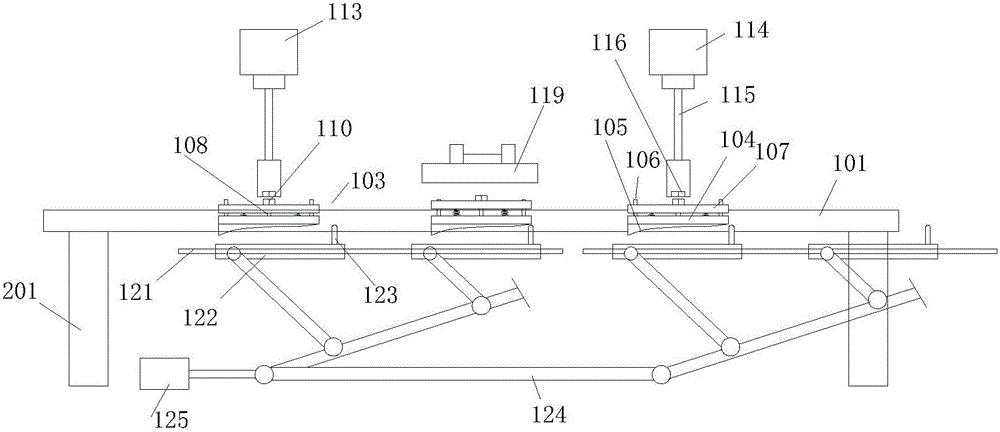

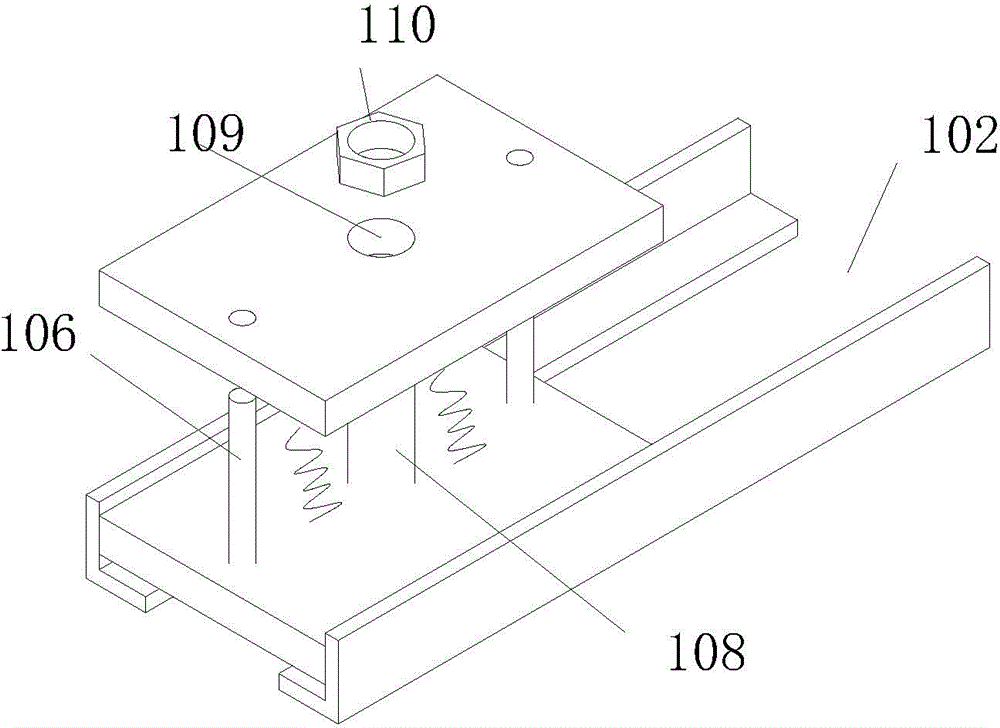

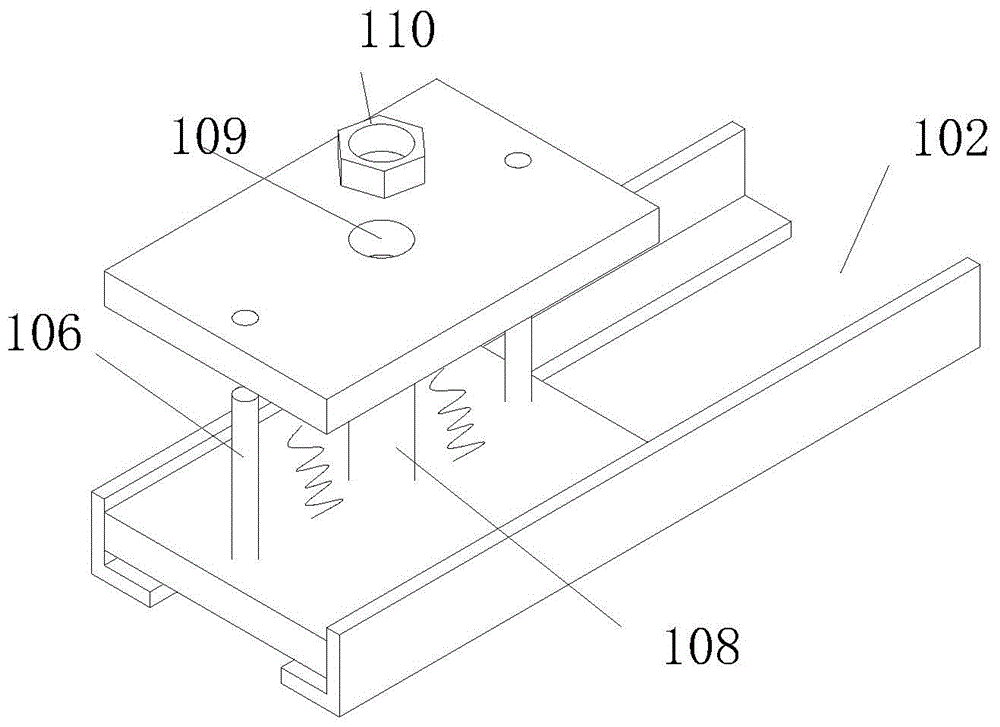

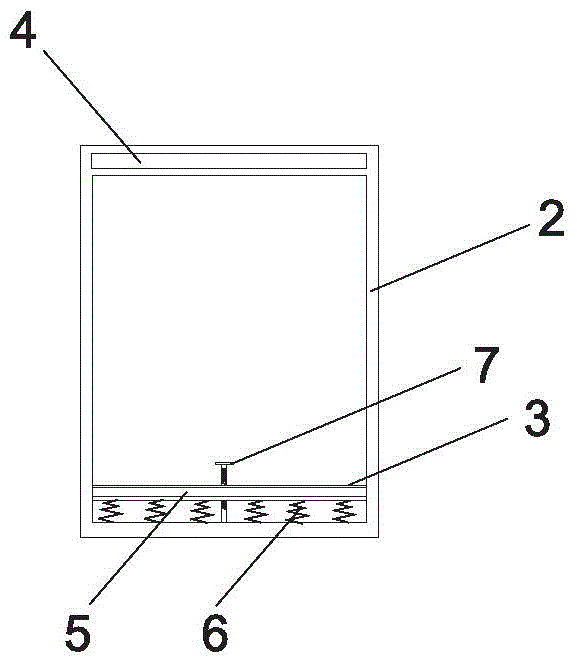

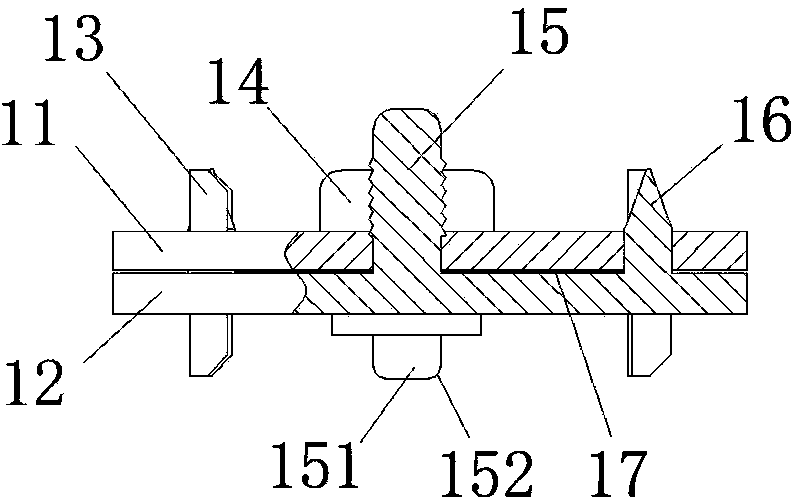

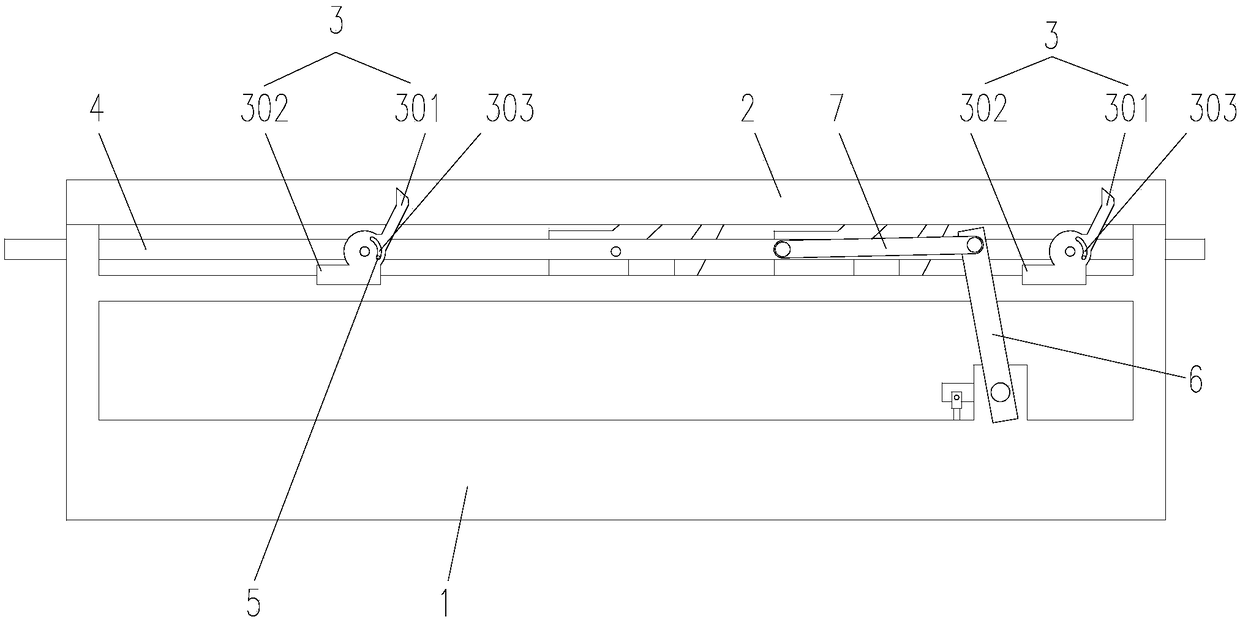

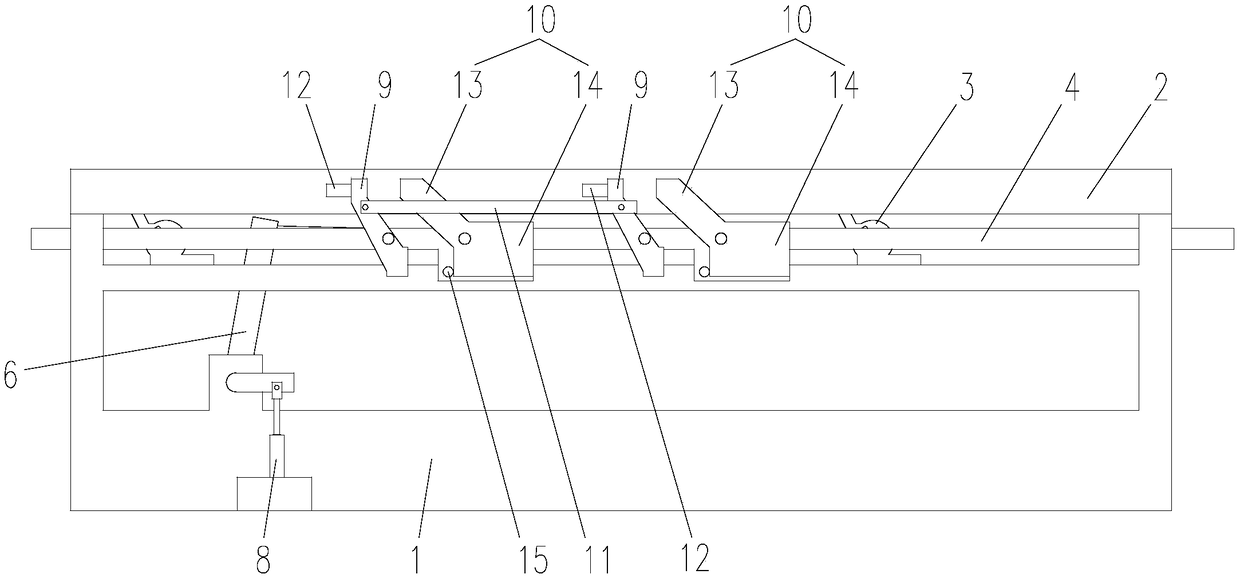

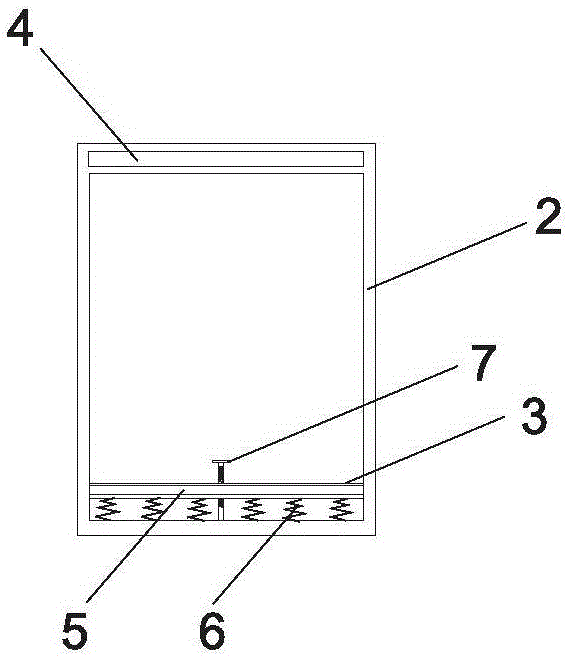

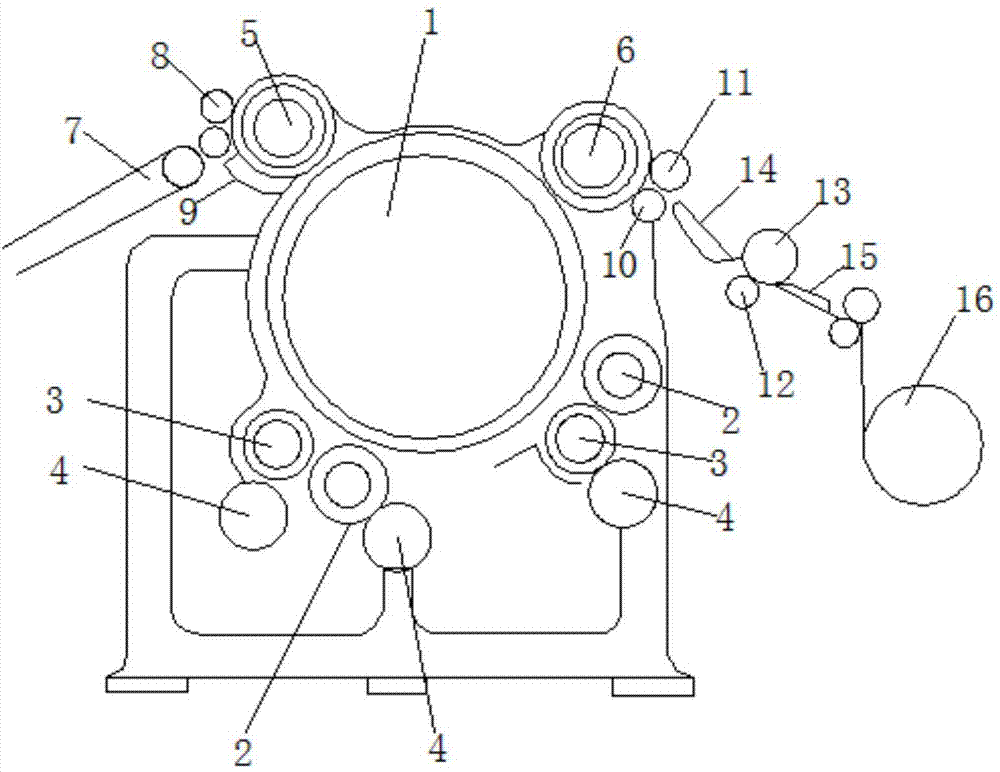

Feeding mechanism of flax hackling machine

InactiveCN104099668ASimple structureLow failure rateHackling machinesMechanical engineeringFailure rate

The invention discloses a feeding mechanism of a flax hackling machine. The feeding mechanism comprises a slide platform (101). A slide groove (102) is formed in the middle of the slide platform (101), a group of slide devices (103) is erected on the slide groove (102), a discharging motor (113), a grab block (119) and a feeding motor (114) are arranged above the slide devices (103), and push blocks (122) are arranged on the lower side of the slide groove. The feeding mechanism has the advantages of simple structure, low failure rate, high efficiency and applicability to industrial mass production.

Owner:宋瑾 +1

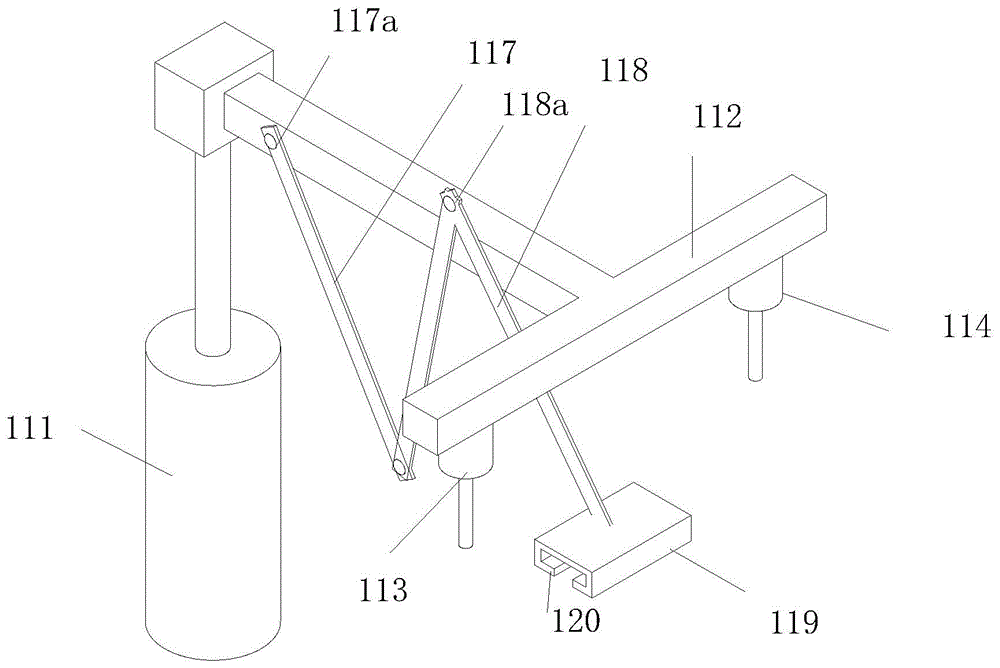

Linen spreading mechanism of mechanical arm

ActiveCN101314868AImplement automatic connectionReduce stepsCarding machinesHackling machinesManipulatorJaw opening

The invention relates to a fibre spreading mechanism by a manipulator, which comprises a plywood tilting mechanism, a plywood jaw opening and closing mechanism, and an air supplying mechanism. The top of the plywood tilting mechanism is connected with one end of the plywood jaw opening and closing mechanism in a transmission manner, and drives the plywood jaw opening and closing mechanism to swing around a shaft; a plywood jaw is arranged at the other end of the plywood jaw opening and closing mechanism, and is driven by the plywood jaw opening and closing mechanism to execute the opening and closing actions; the air supplying mechanism is arranged at the top of the plywood jaw. The fibre spreading mechanism has the advantages that the productivity effect is increased, and the production cost is saved; because a manipulator device is used for automatic fibre spreading, the rhythm is designed to lead one ramie beam to press another ramie beam, the spacing is accordant and equivalent, the stems of the formed ramie stripes are more uniform, and the product quality is increased.

Owner:常州金德纺机科技有限公司

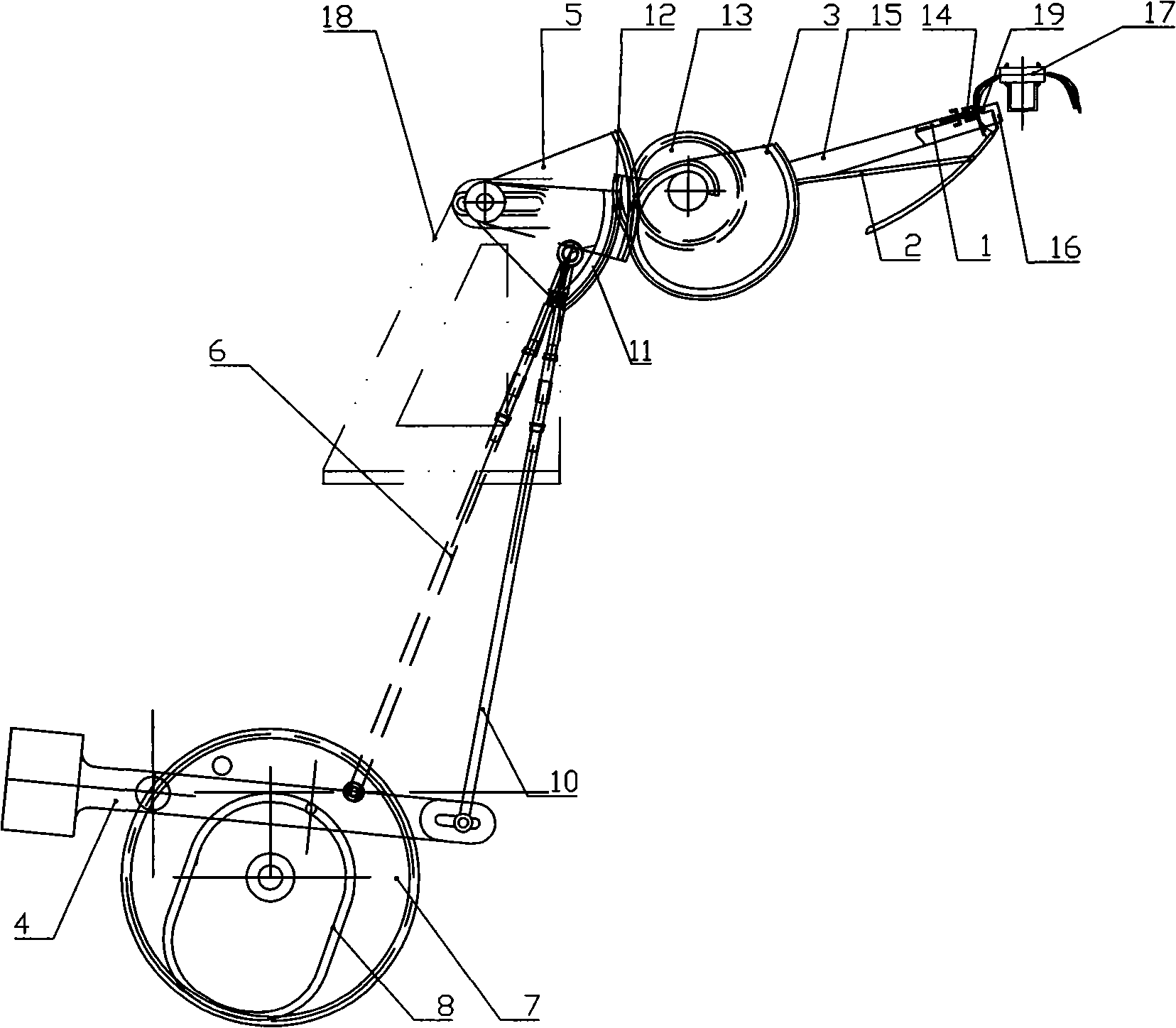

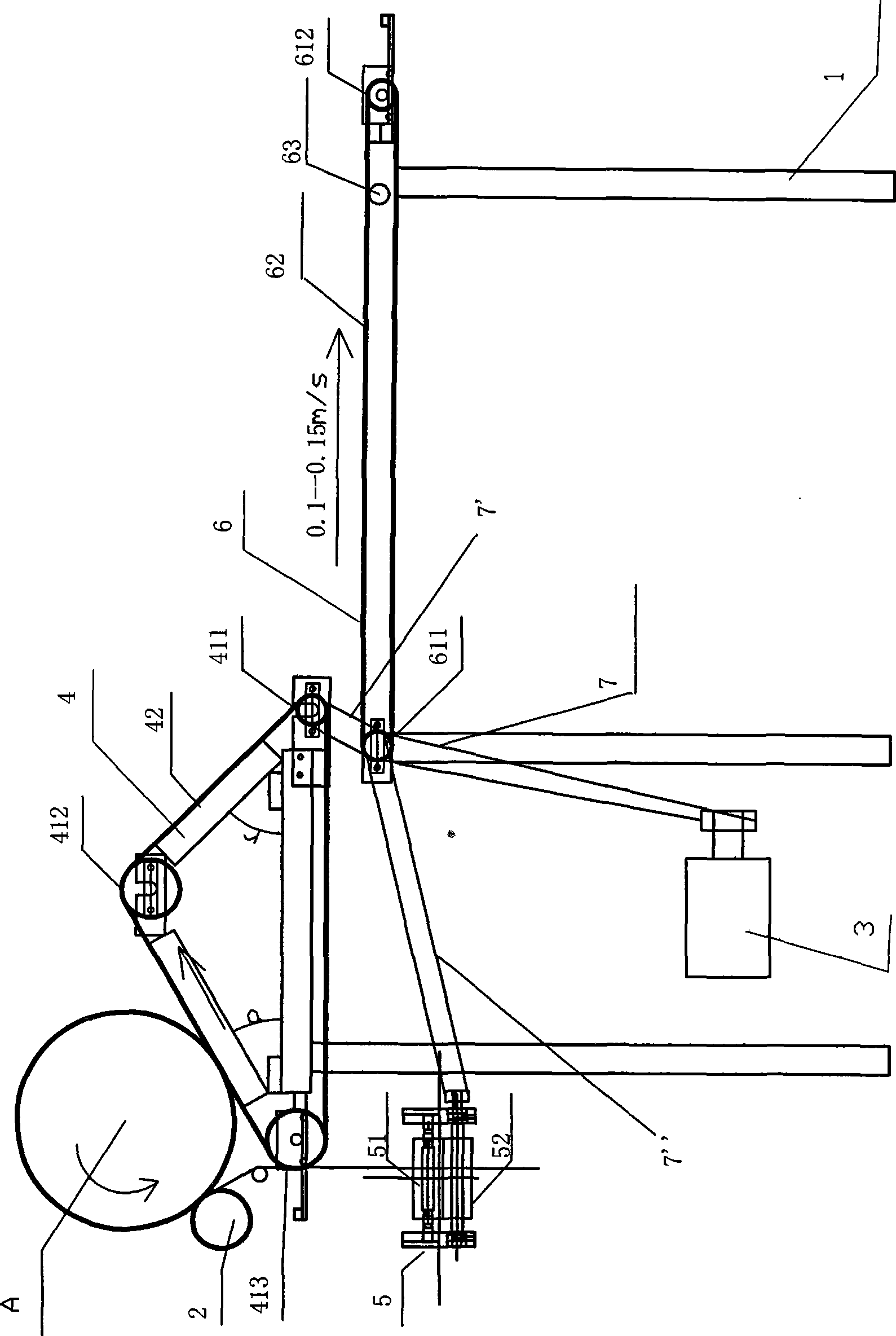

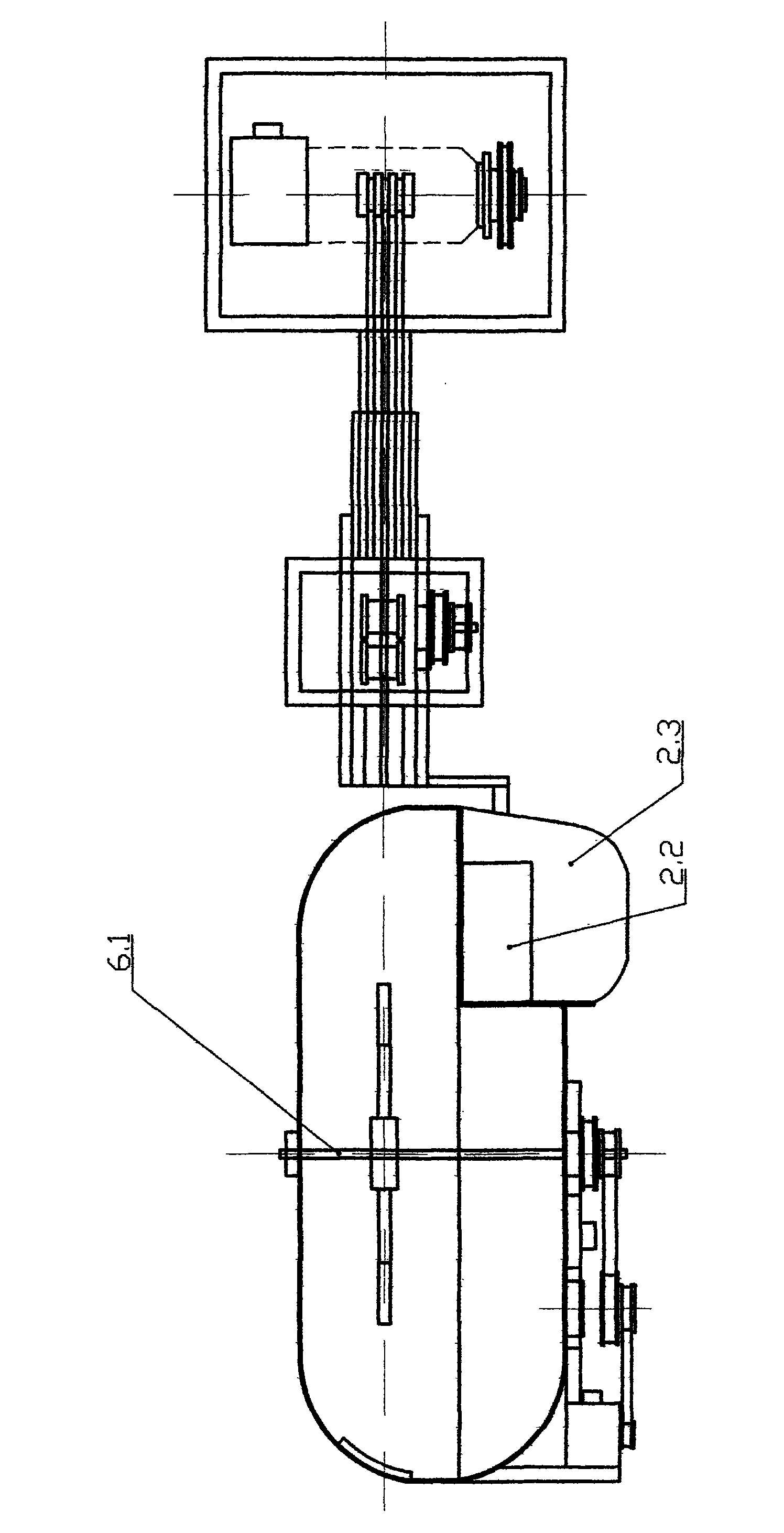

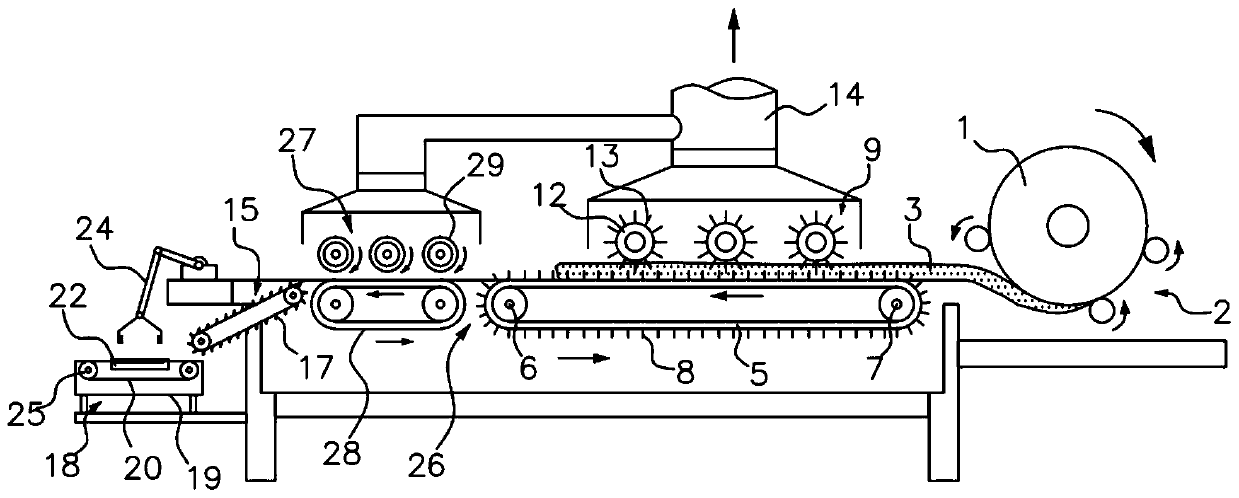

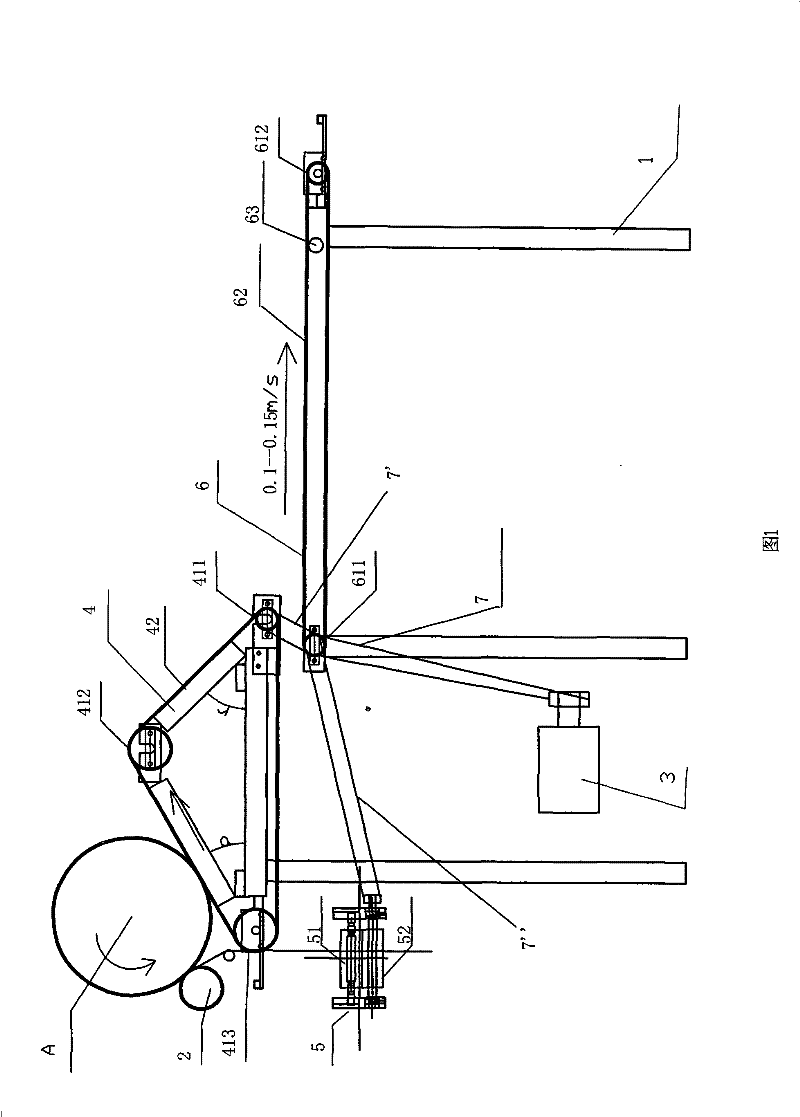

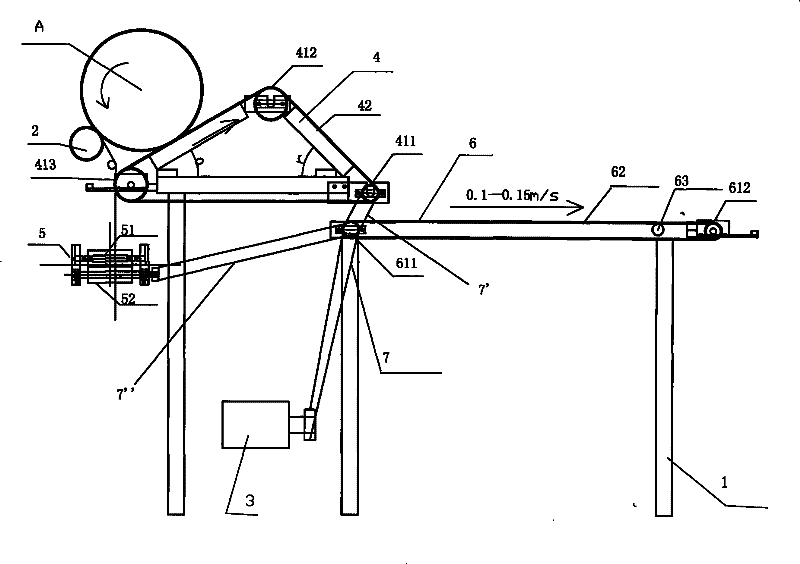

Mechanical device for automatically opening flax round packages from flax

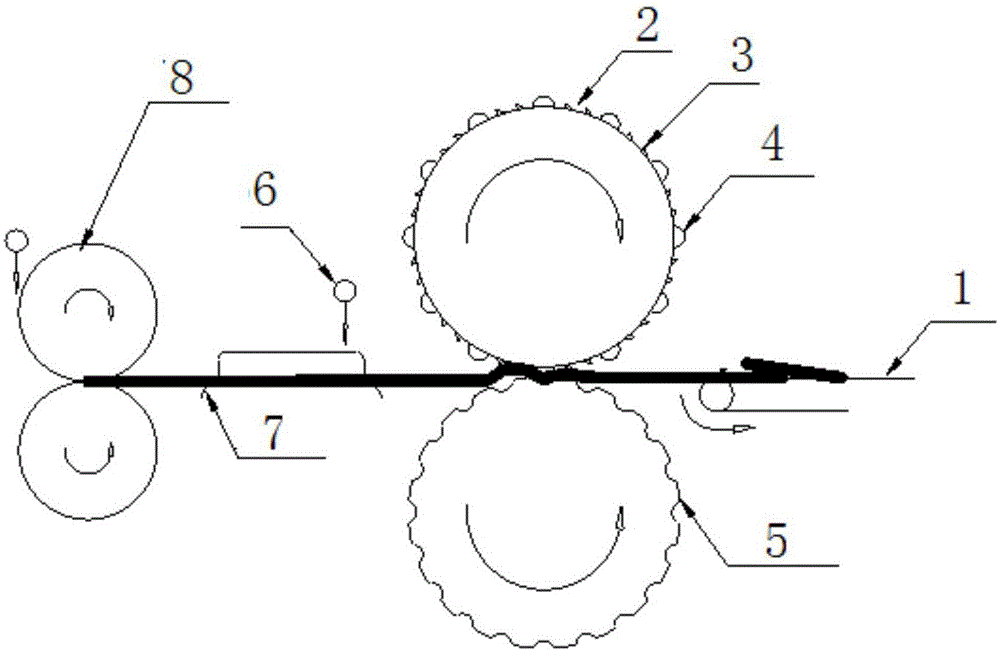

ActiveCN101532192AFlat tow sizeStable tensionHackling machinesFibre breakingTransmission beltEngineering

The invention discloses a mechanical device for automatically opening flax round packages from flax comprising a frame, a guide roller, an electrical motor, and is characterized in that the mechanical device is further provided with a round package uncoil-stand, a string-pulling device and a conveyer device, wherein the electrical motor is connected with the conveyer device via a transmission belt, the conveyer device respectively drives the round package uncoil-stand and the string-pulling device, the round package uncoil-stand is a triangle transmission device consisting of an uncoiling guide roller and an uncoiling belt, the string-pulling device comprises a belt roller and an iron roller, and the conveyer device is a plate-type conveyer device consisting of a conveyer guide roller and a conveyer belt. The invention has high labor efficiency and low labor intensity.

Owner:ZHEJIANG JINYUAN FLAX

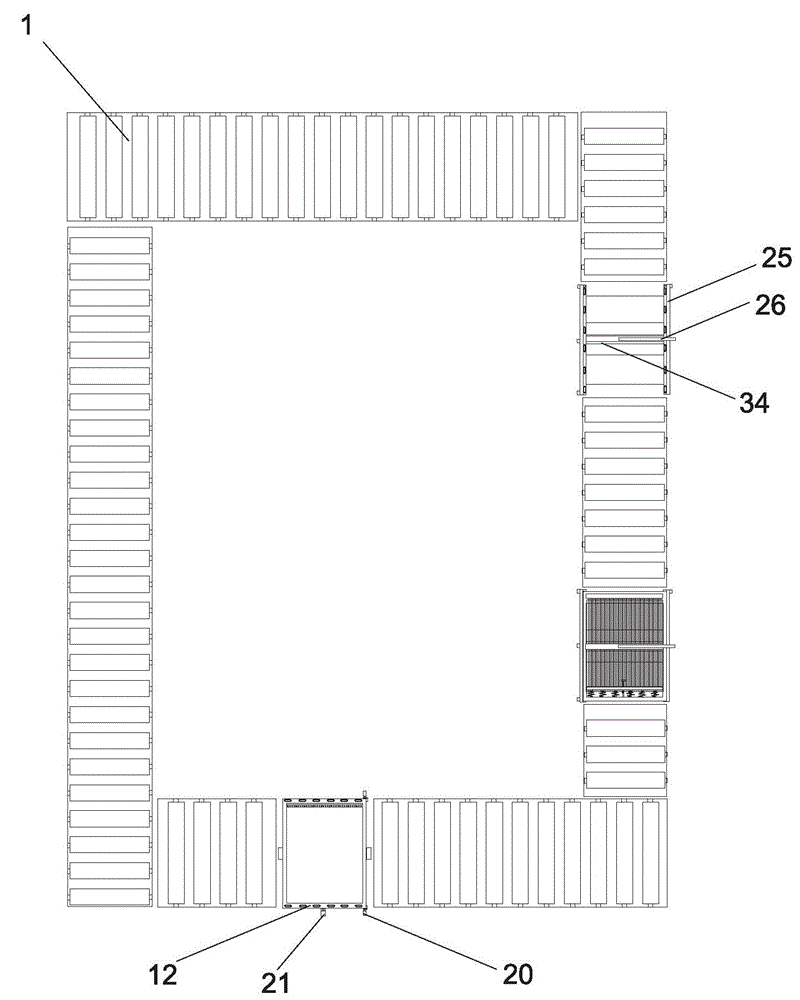

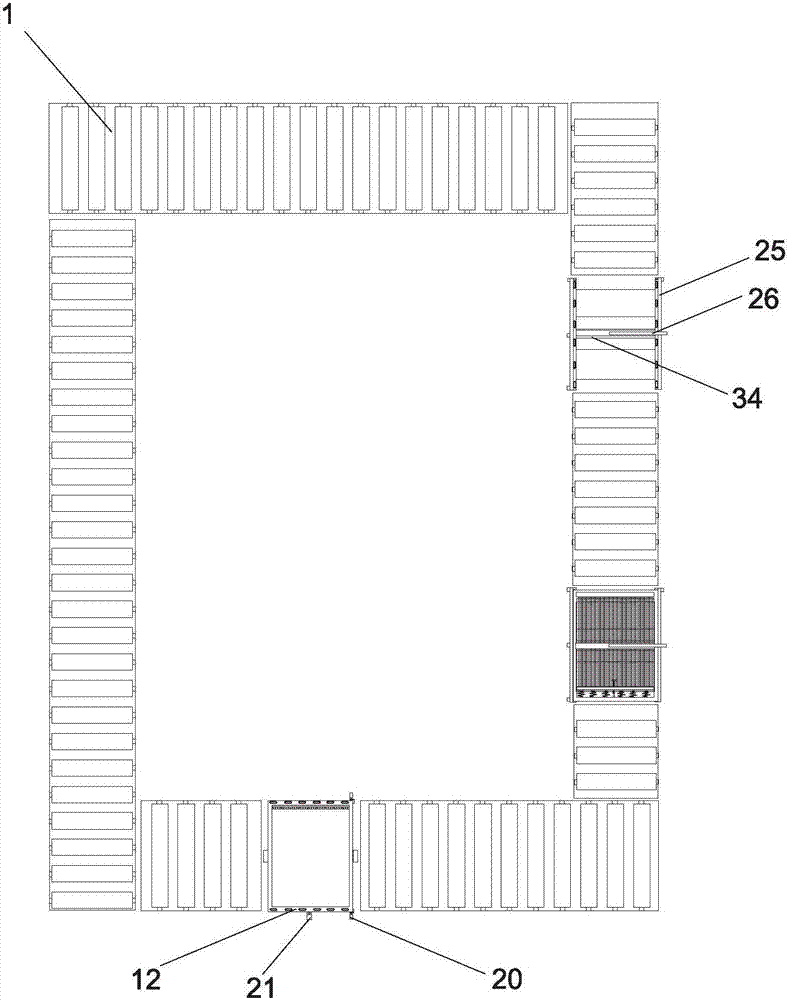

Jute processing system

InactiveCN105297148AGood value for moneyReduce use costHackling machinesMechanical fibre separationEngineeringAssembly structure

The invention discloses a jute processing system. The jute processing system comprises a jute carrier, a feeding and discharge station, carding devices and a conveying device. A jute leather clamping mechanism and a tensioning mechanism are arranged on the jute carrier. The conveying device comprises an enclosed conveying track. The jute carrier is arranged on the conveying track having multiple joints. The feeding and discharge station and the carding devices are arranged on the joints. The jute processing system has following beneficial effects: a simple processing device capable of replacing manual work is replaced by the jute processing system; parts and an assembly structure are designed easily; usage and maintenance are simple; purchase and usage cost are far lower than that of a full-automatic hemp fiber processing machine; machining efficiency and machining quality are obvious superior than those of manual work; and higher cost performance is obtained.

Owner:ZHEJIANG OCEAN UNIV

Direction-changing device for automatically changing position of flax fiber

ActiveCN104328509AAutomatically achieve reversing operationImprove work efficiencyHackling machinesEngineeringChange positions

The invention discloses a direction-changing device for automatically changing the position of flax fiber. The direction-changing device comprises a stretching device and a loosening device, wherein the stretching device is used for changing the position where the flax fiber is fixed by a flax clamp; the loosening device is used for eliminating the fastening force exerted on the flax fiber by the flax clamp. According to the direction-changing device, the direction-changing operation of the flax fiber is automatically realized, the position of the flax fiber in the flax clamp is changed, the manual operation is eliminated, the working efficiency is improved, the carding accuracy is guaranteed, and the manpower cost is reduced.

Owner:ZHEJIANG AXIANG LINEN TEXTILE

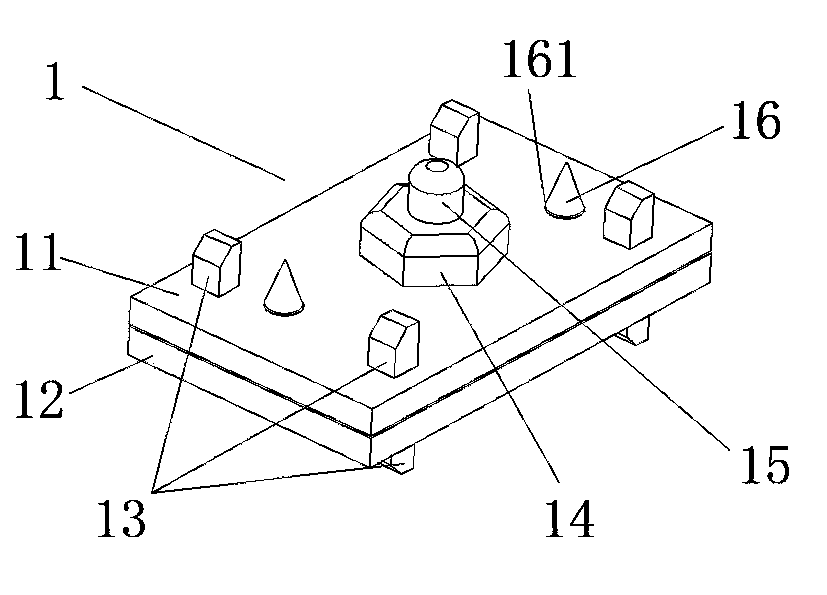

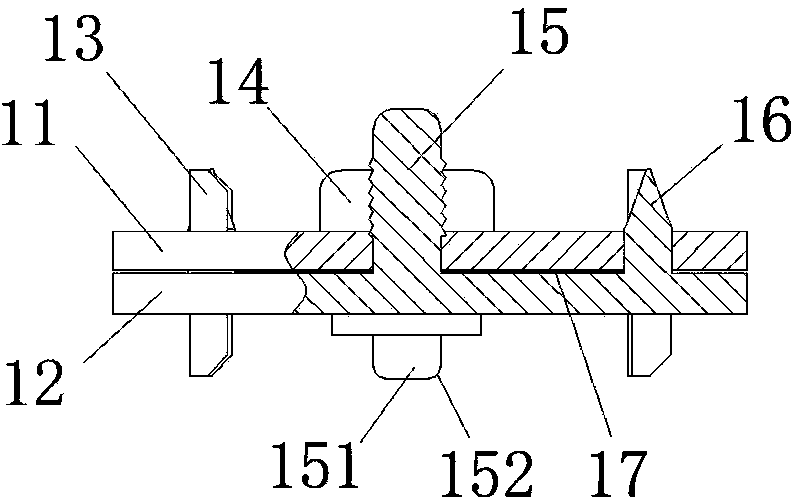

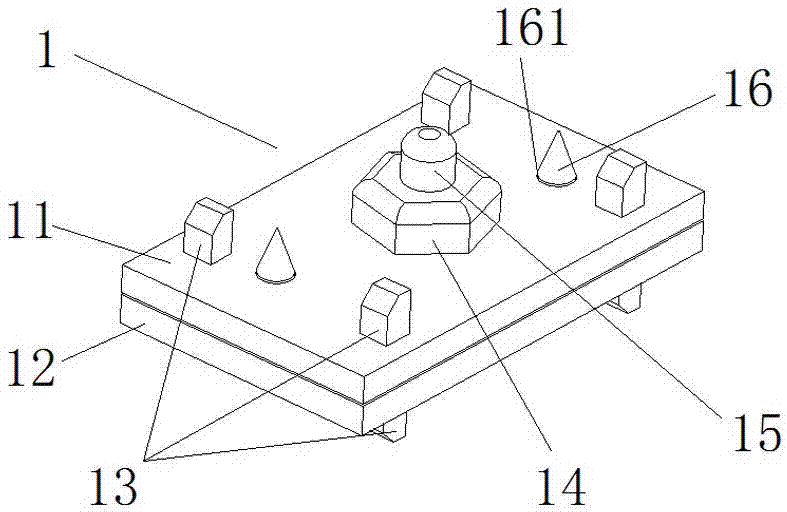

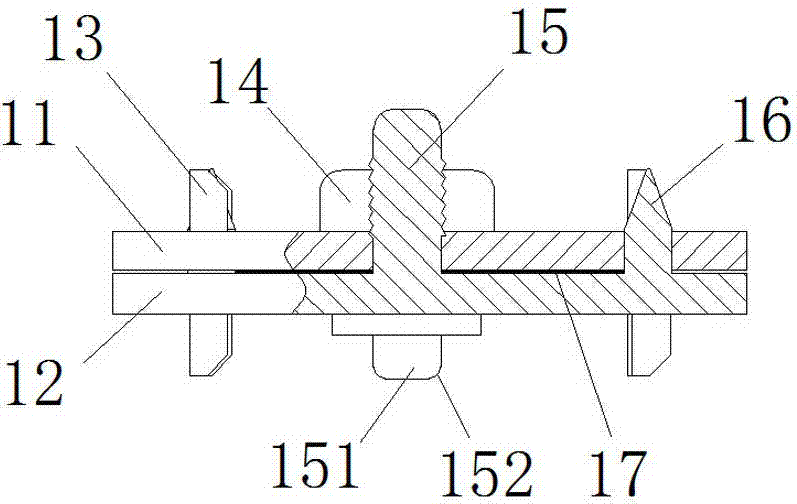

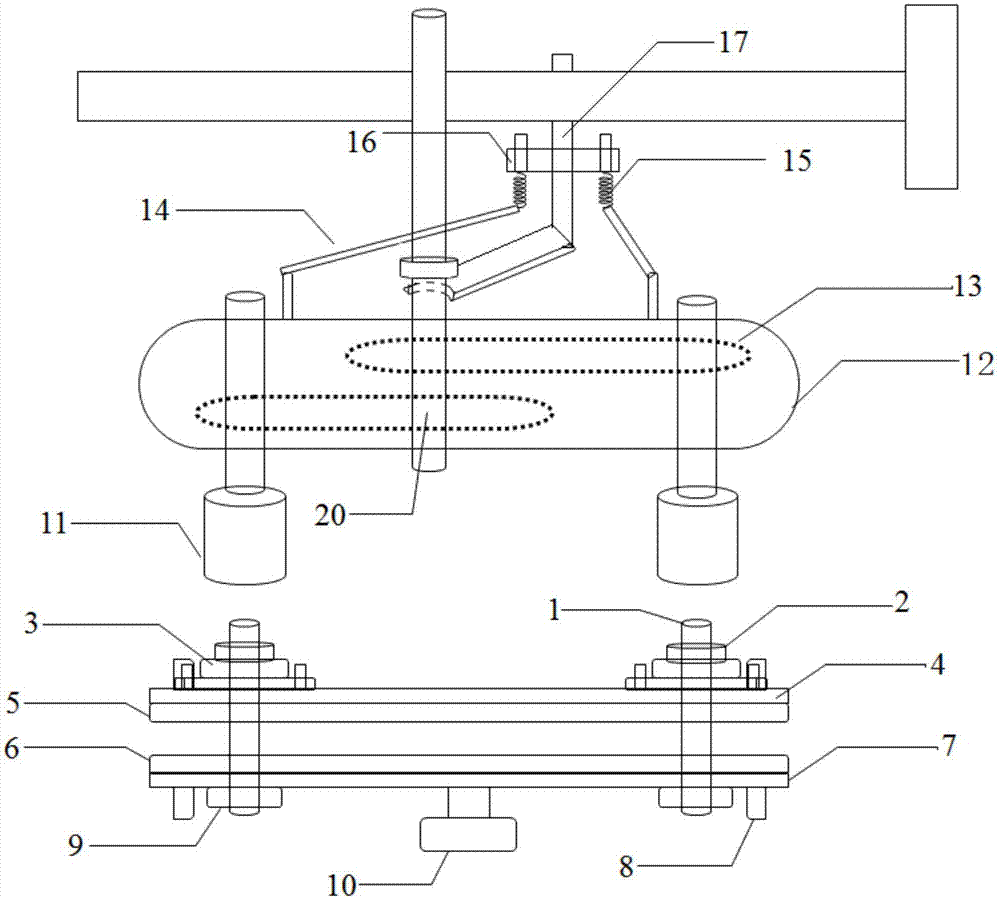

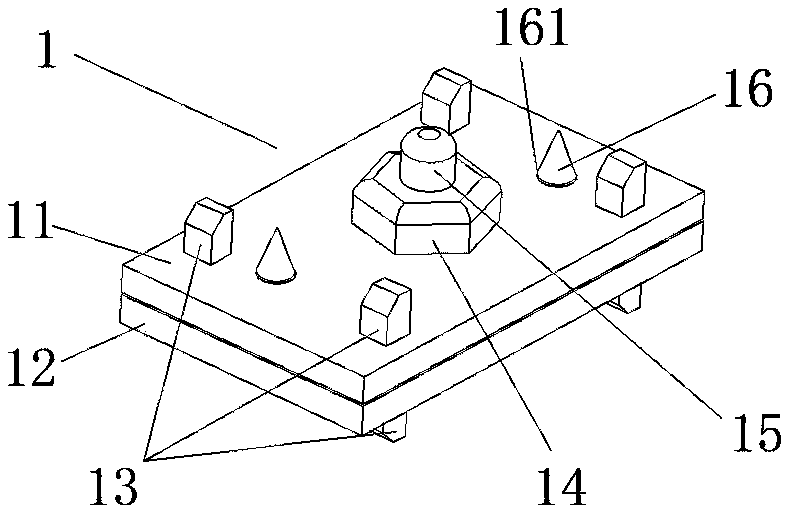

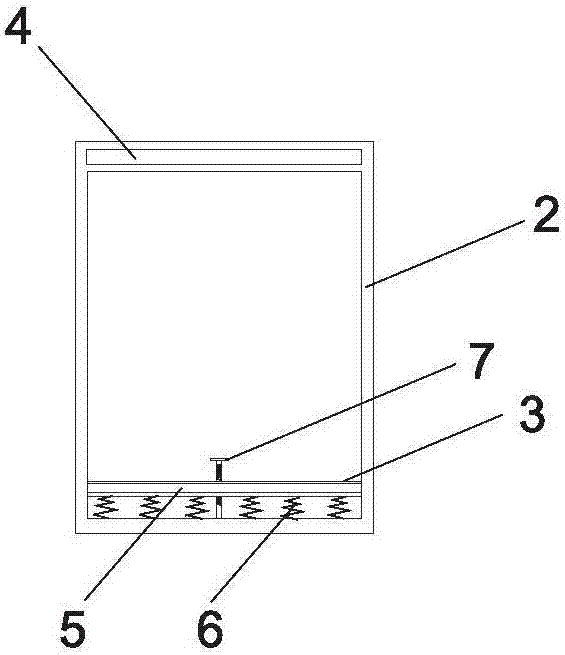

Novel hackle clamp device

InactiveCN107447259AEasy to operateAvoid entanglementHackling machinesEngineeringMechanical engineering

The invention relates to a novel hackle clamp device. The novel hackle clamp device comprises an upper clamp plate, a lower clamp plate, two screw assemblies and a drive assembly, wherein the upper clamp plate and the lower clamp plate are oppositely parallelly arranged at interval, the two screw assemblies penetrate the upper clamp plate and the lower clamp plate and are located at two opposite ends of the upper clamp plate and the lower clamp plate, the upper end of each screw assembly is provided with an adjusting end, and the drive assembly is arranged above the upper clamp plate and can move upwards and downwards. The novel hackle clamp device has the advantages that the two screw assemblies are arranged at two ends of the upper clamp plate and the lower clamp plate, hemp is fed through an area between the two screw assemblies, hemp bundle intertwining caused by the fact that hemp bundles are mistakenly placed on the screws, and carding quality and hackled line producing rate are increased; operation of a hemp feeding operator is facilitated, quality and yield can be increased favorably, and the work efficiency of bundle separation can be multiplied.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

Sisal fiber extraction device based on sisal textile processing

InactiveCN111172599AEasy to useSuitable for useHackling machinesMechanical fibre separationFiberSisal fiber

The invention discloses a sisal fiber extraction device based on sisal textile processing, relates to the technical field of sisal production, and solves the problems of troublesome use and operation,lower production efficiency and high labor intensity of the existing sisal harvesting. The device comprises a main machine body; a group of feeding devices is arranged on the left side of the main machine body; the rear part of an upper end surface of the main machine body is fixedly connected with a group of diesel engines; two groups of primary pressure devices are axially connected to the inner side of the middle part of the main machine body; two rows of squeezing devices are axially connected inside the right side of the main machine body; two groups of carding devices are axially connected inside the right side of the main machine body; and a group of intermediate transmission shafts are coaxially connected inside the front end face and the rear end face of the main machine body. The device is more convenient to use, free of artificial collection and processing, simplified in work procedure, and capable of improving production efficiency and saving manual operation, and the device is simple in structure, small in volume, low in cost and suitable for small-size peasant household at the same time.

Owner:向道英

Method for removing dust of dust filtering of FA201B carding machine

The invention relates to a FA201B carding machine dust collection method. The FA201B carding machine safe stripper area triangular space, flat strips, and licker-in degassing four absorption points are connected to concourse tube by spring tube. Three or four FA201B carding machines are formed one set. Droppings and dust are continuously absorbed to filter equipment. The droppings under the machine are intermittently absorbed into fiber compactor by uphill line pipeline. The invention is upper machine continuous absorption and under machine intermittent absorption method. It can reduce energy consumption, simplify structure, and economize material cost.

Owner:NANTONG DOUBLE GREAT TEXTILE

Carding device for hackling machine

InactiveCN104278332AAutomatically achieve reversing operationImprove work efficiencyHackling machinesFiberEngineering

The invention discloses a carding device for a hackling machine. The carding device comprises a jute clamping device and two hackling devices, wherein the jute clamping device is used for folding and fixing strip-shaped jute fibers into a flat shape and driving the jute fibers to move; the two hackling devices are used for carding the jute fibers and removing the impurities; each hackling device comprises two needle curtains which are symmetrically arranged; a lifting rack used for supporting the jute clamping device to move up and down is arranged above the needle curtains; the vertical motion of the lifting rack is driven by a lifting device; brush rollers used for cleaning the residual jute fibers on the needle curtains are arranged below the needle curtains; jute stripping rollers and hairbrushes used for cleaning the jute fibers on the jute stripping rollers are arranged on one sides of the brush rollers; and collection grooves are formed in the lower parts of the brush rollers, the jute stripping rollers and the hairbrushes. According to the carding device, multiple carding steps are not needed, and the working efficiency is greatly improved.

Owner:ZHEJIANG AXIANG LINEN TEXTILE

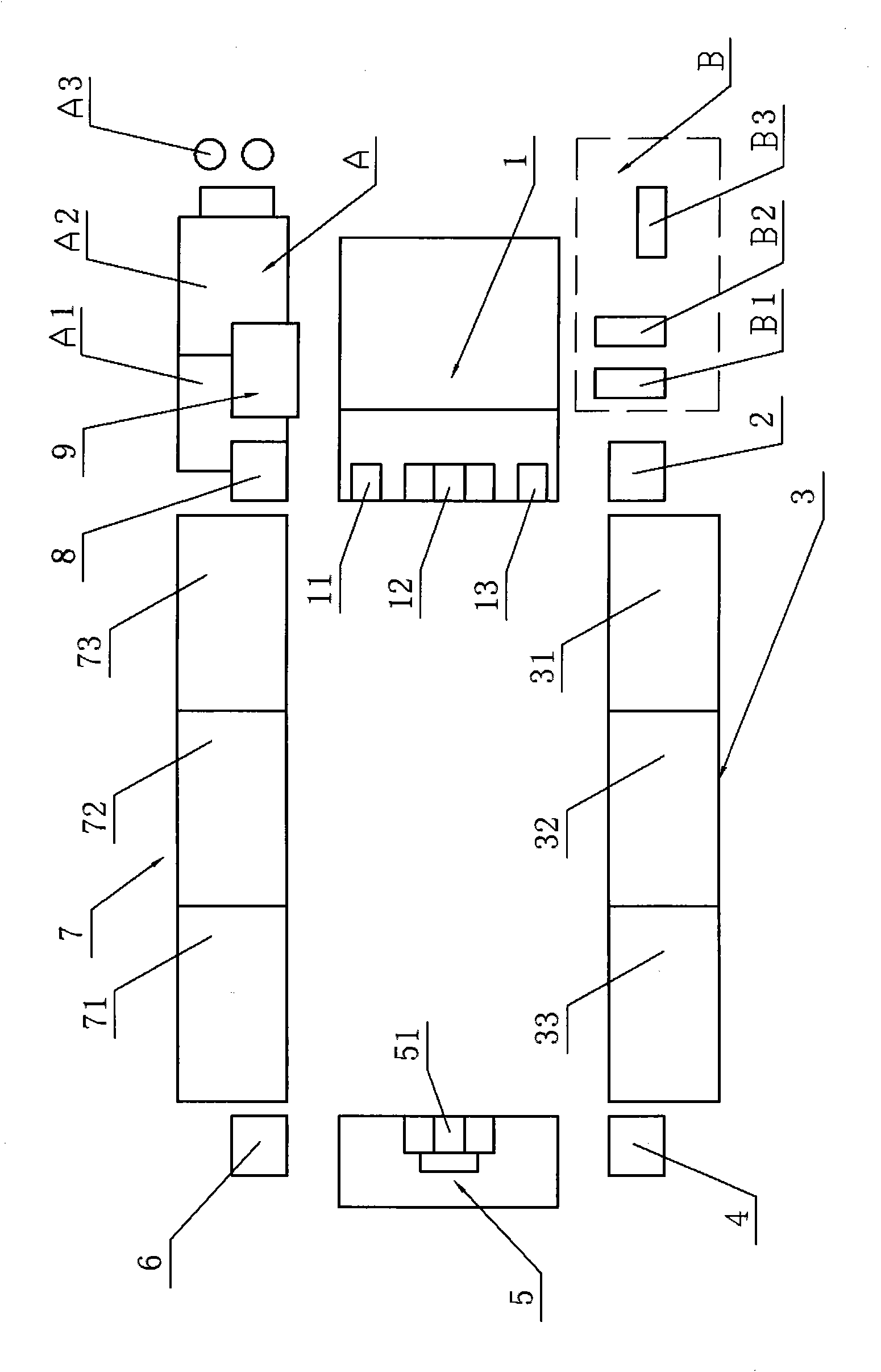

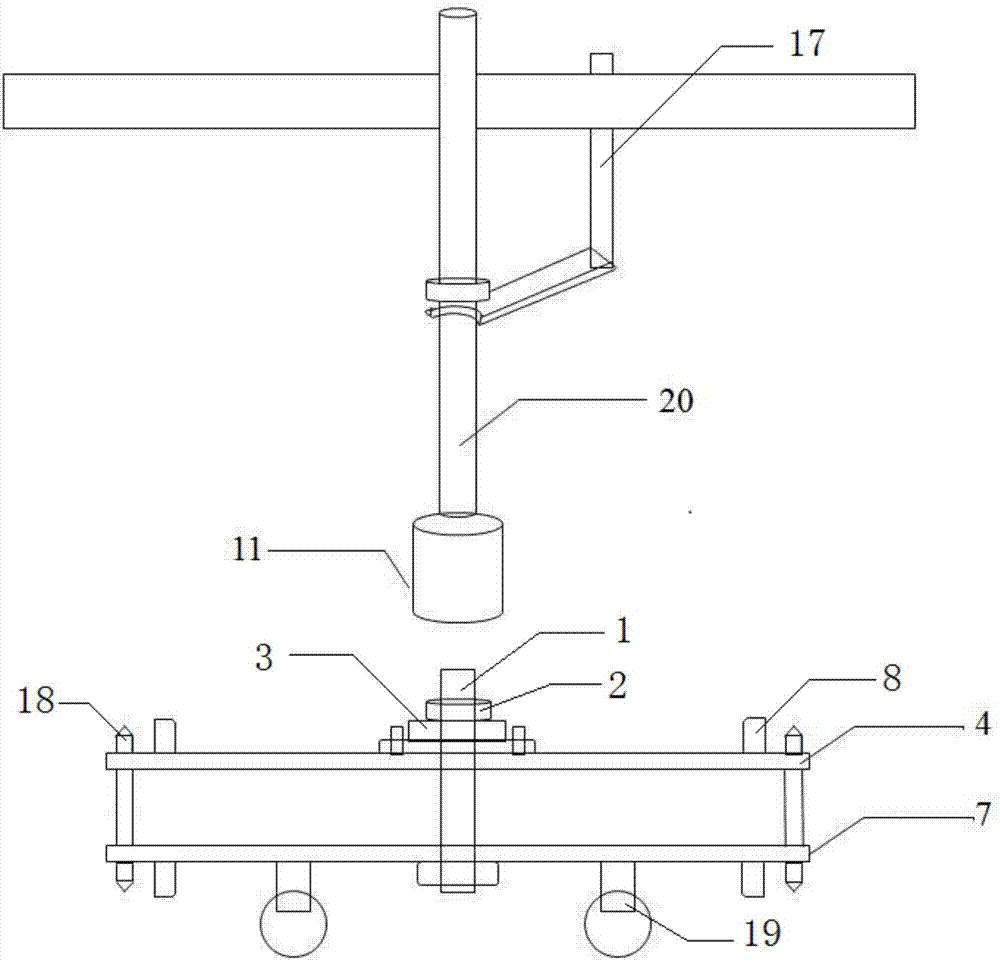

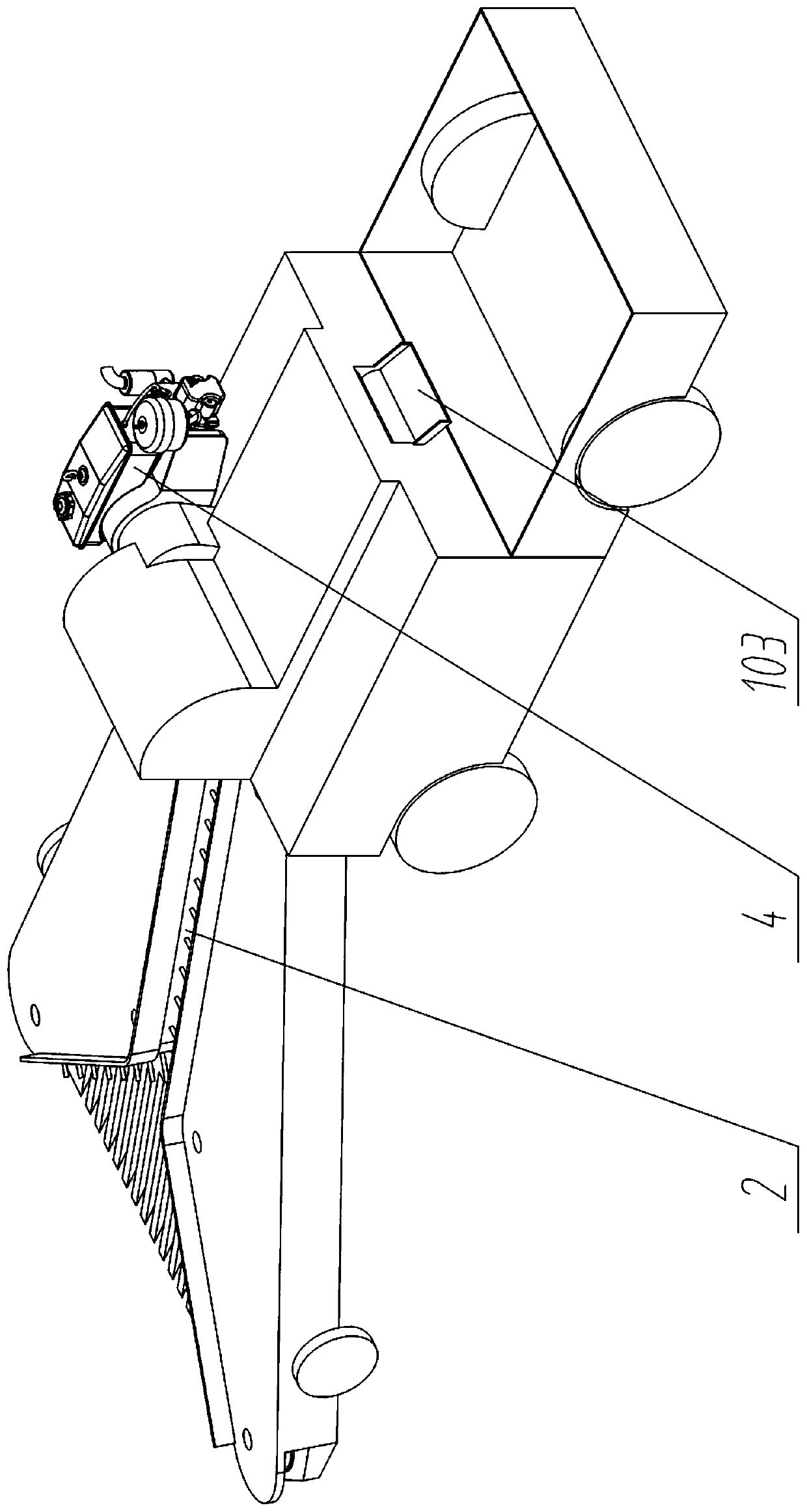

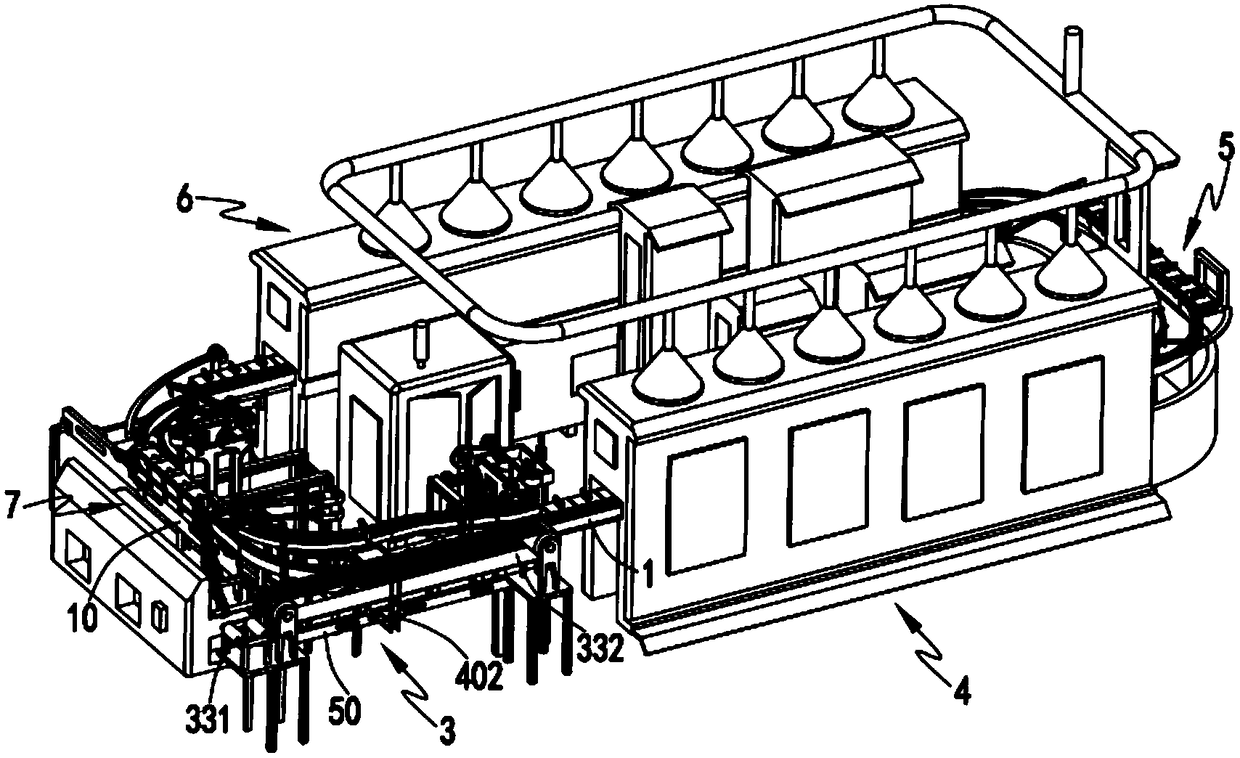

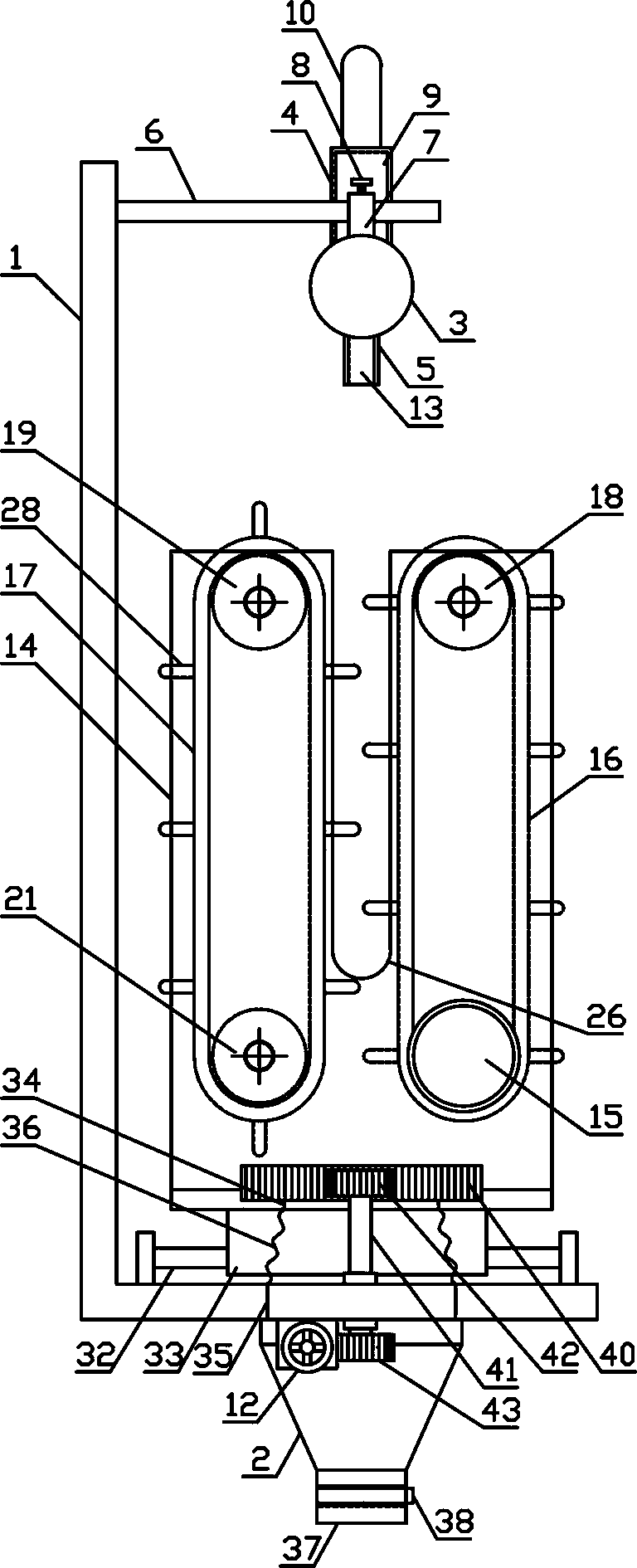

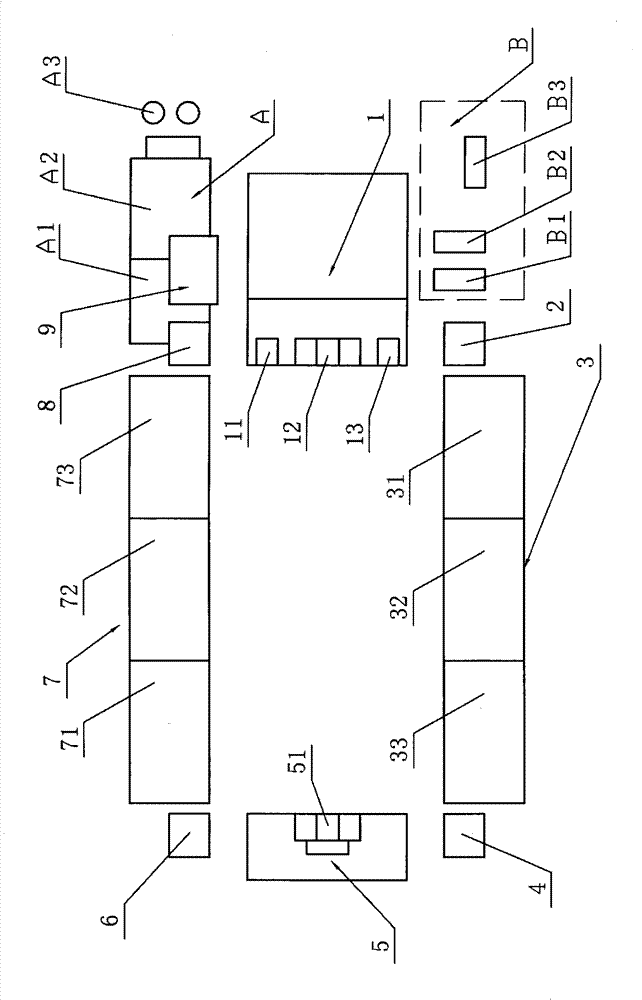

Flax fiber yarn automatic production line and production process thereof

ActiveCN109295502AAchieve clampingOvercoming the problem of low efficiency and manpower consumptionHackling machinesYarnProduction line

The invention relates to a flax fiber yarn automatic production line and a production process thereof. The production line comprises a rail and a clamping mechanism, a feeding part, a first heckling part, a rotary part, a second heckling part and a material taking part are sequentially arranged in the moving trajectory of the clamping mechanism, the clamping mechanism comprises an upper clamping assembly and a lower clamping assembly, the feeding part comprises a guiding separating mechanism, a stirring delivery mechanism, a conveying mechanism, a screwing mechanism and a transferring mechanism, the clamping mechanism is stirred and delivered by the stirring delivery mechanism to the direction of the screwing mechanism, the lower clamping assembly continues to move along the rail in the stirring delivery process, the upper and lower clamping assemblies are separated up and down, flax drops downwards towards one end of the rail on the conveying mechanism, the downward end of the flax istransferred to the lower clamping assembly by the transferring mechanism, the lower clamping assembly moves to the screwing mechanism to cooperate with the upper clamping assembly to clamp the flax under the action of the screwing mechanism. By means of the production line, the technical problems that flax needs to be sorted manually before heckling is conducted to put flax on the clamping mechanism, the labor cost is high, the efficiency is low, and the flax amount is nonuniform are solved.

Owner:湖州蓝硕亚麻纺织有限公司

Jute processing system

InactiveCN105442056AGood value for moneyReduce use costHackling machinesEngineeringAssembly structure

The invention discloses a jute processing system which comprises a jute carrier, a feeding and discharging station, a carding device and a conveying device. The jute carrier is provided with a jute skin clamping mechanism and a tensioning mechanism. The conveying device comprises a closed conveying rail, the jute carrier is placed on the conveying rail, the conveying rail is provided with a plurality of nodes, and the feeding and discharging station and the carding device are arranged at the position of the node. The jute processing system is a simple processing device capable of replacing pure manual work and is simple in part and assembly structure design and relatively simple to use and maintain. The purchase and use cost of the jute processing system is much lower than that of a full automatic bastose processing machine, the processing efficiency and processing quality are obviously better than those of manual work, and thus the jute processing system is high in cost performance.

Owner:ZHEJIANG OCEAN UNIV

Bamboo short fiber extraction technology

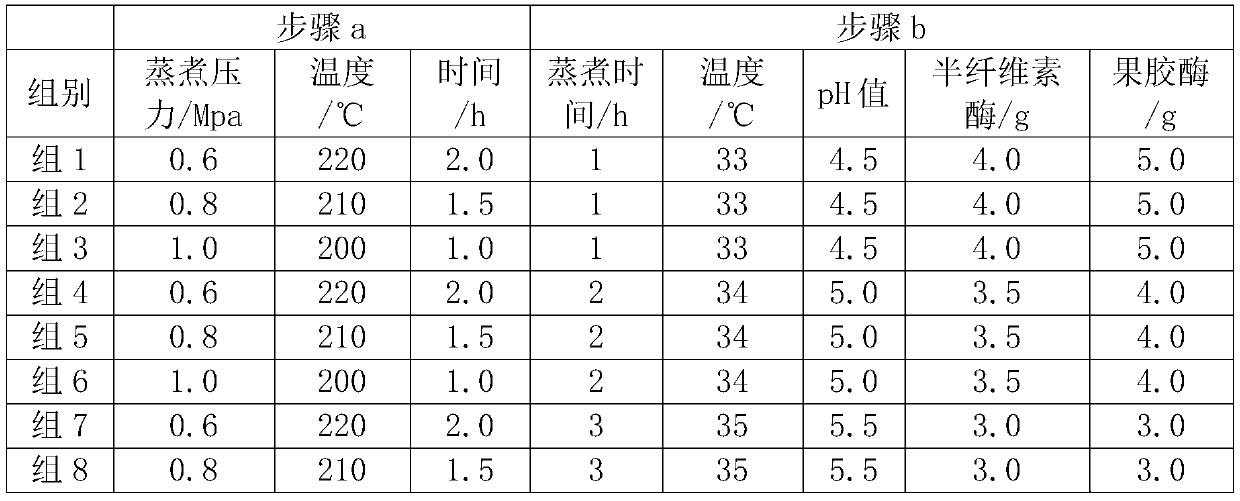

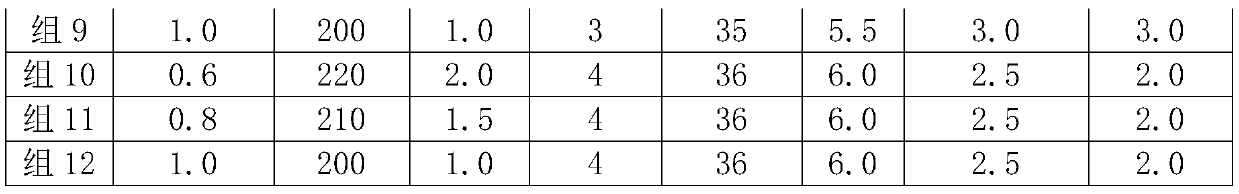

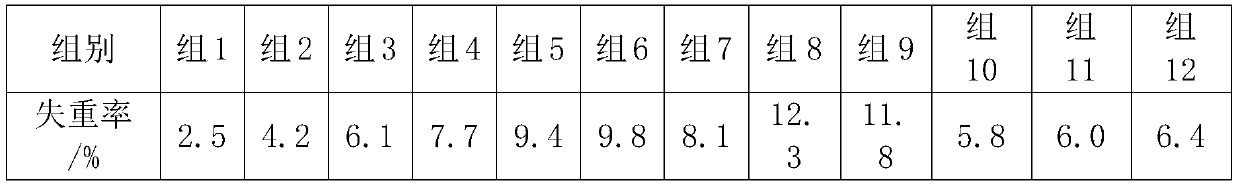

InactiveCN109853051AImprove degumming effectImprove qualityHackling machinesMechanical fibre separationFiber bundleWastewater

The invention relates to the technical field of bamboo processing, in particular to a bamboo short fiber extraction technology. According to the specific scheme, the bamboo short fiber extraction technology comprises the steps that 1, bamboo joints of bamboo are removed, the bamboo is processed into bamboo pieces, and the bamboo pieces are washed clean; 2, the bamboo pieces are crushed into bamboostrips, and high-temperature high-pressure processing is carried out; 3, the bamboo strips obtained in step 2 are rolled to obtain bamboo cakes; and the bamboo cakes are put into a fiber splitting machine for carding to obtain crude fiber; 4, the crude fiber is cleaned and cut into segments; 5, fiber bundles obtained in step 4 are ground, washed and dried to obtain bamboo fiber. According to thebamboo short fiber extraction technology, the degumming effect of the bamboo fiber is improved, the quality of the bamboo fiber is improved, and the utilization rate of the bamboo is improved; moreover, the technology is convenient to operate, the extraction time is short, and no wastewater polluting the environment is generated.

Owner:泸州锦兰科技有限公司

Automatic bristle plate binding machine

InactiveCN101649493AReduce labor intensityCompact structureWool fibre washing/scouringHackling machinesBristleElectric machinery

An automatic bristle plate binding machine comprises a cleaning and mixing device, a conveying and carding device and a binding and forming device, which are installed on a rack. The cleaning and mixing device comprises a cleaning pool, a mixing drive motor, a plurality of transmission wheels, a mixing rod driving wheel and a mixing rod. The conveying and carding device comprises a conveying and carding drive motor, a plurality of transmission wheels, a conveyer belt, a primary forming pulley, a secondary sizing pulley and a metal comb. The binding and forming device comprises a binding support, a secondary binding support frame, a forming support, a binding drive motor, a plurality of transmission wheels, a plate binding pulley, a plate binding rope, an upper-lower position regulation control device, a left-right position regulation control switch, a rotating pulley, a forming pulley and a binding and forming hollow shaft. The machine overcomes the disadvantage that the traditional handwork is heavy in labor intensity and low in efficiency. The machine replaces the traditional handwork, is convenient to be maintained and is stable and reliable, and the product is good in straightness, thus alleviating the labor intensity of workers and greatly improving the production efficiency.

Owner:湖南常德市超汉猪鬃厂

Hemp-type hackling machine shifting fork mechanism

The invention relates to the technical field of weaving equipment, and especially relates to a hemp-type hackling machine shifting fork mechanism. The shifting fork mechanism comprises a frame with alinear guide rail, and also comprises lifting levers, a sliding rod, and a limiting pin. The sliding rod is disposed on the frame in a manner of sliding in the axial direction of the linear guide rail, and the sliding rod is set to be parallel to the linear guide rail. The lifting levers are rotatingly disposed on the sliding rod, and two ends of the sliding rod are respectively provided with thelifting levers. The lifting levers are provided with guide grooves, and the central axis of each guide groove coincides with the rotating axis of the corresponding lifting lever. One end of the limiting pin is disposed on the sliding rod, and the other end of the sliding pin is disposed in the corresponding guide groove. When the shifting fork mechanism is in use, a reciprocating motion mechanismdrives the sliding rod to make reciprocating motion, thereby achieving a purpose that the lifting levers at two ends of the sliding rod convey a hemp clamp in a stepped manner from one end of the linear guide rail to the other end of the linear guide rail.

Owner:常州金德纺机科技有限公司

A fully automatic flax combing machine

InactiveCN104099667BImprove combing effectEasy to cleanHackling machinesElectric machineryEngineering

Owner:吴江金怡纺织品有限公司

Economical jute processing system

InactiveCN105297146AGood value for moneyReduce use costHackling machinesMechanical fibre separationEngineeringAssembly structure

The invention discloses an economical jute processing system. The economical jute processing system comprises a jute carrier, a feeding-discharge station, a carding device and a conveying device. A jute leather clamping mechanism and a tensioning mechanism are arranged on the jute carrier. The conveying device comprises a closed conveying track. The jute carrier is arranged on the conveying track, on which multiple joints are arranged. The feeding-discharge station and the carding device are arranged on the joints. The economical jute processing system has following beneficial effects: a simple processing device capable of replacing manual work is replaced by the economical jute processing system; parts and an assembly structure are designed easily; usage and maintenance are simple; purchase and usage cost are far lower than that of a full-automatic hemp fiber processing machine; machining efficiency and machining quality are obvious superior than those of manual work; and higher cost performance is obtained.

Owner:ZHEJIANG OCEAN UNIV

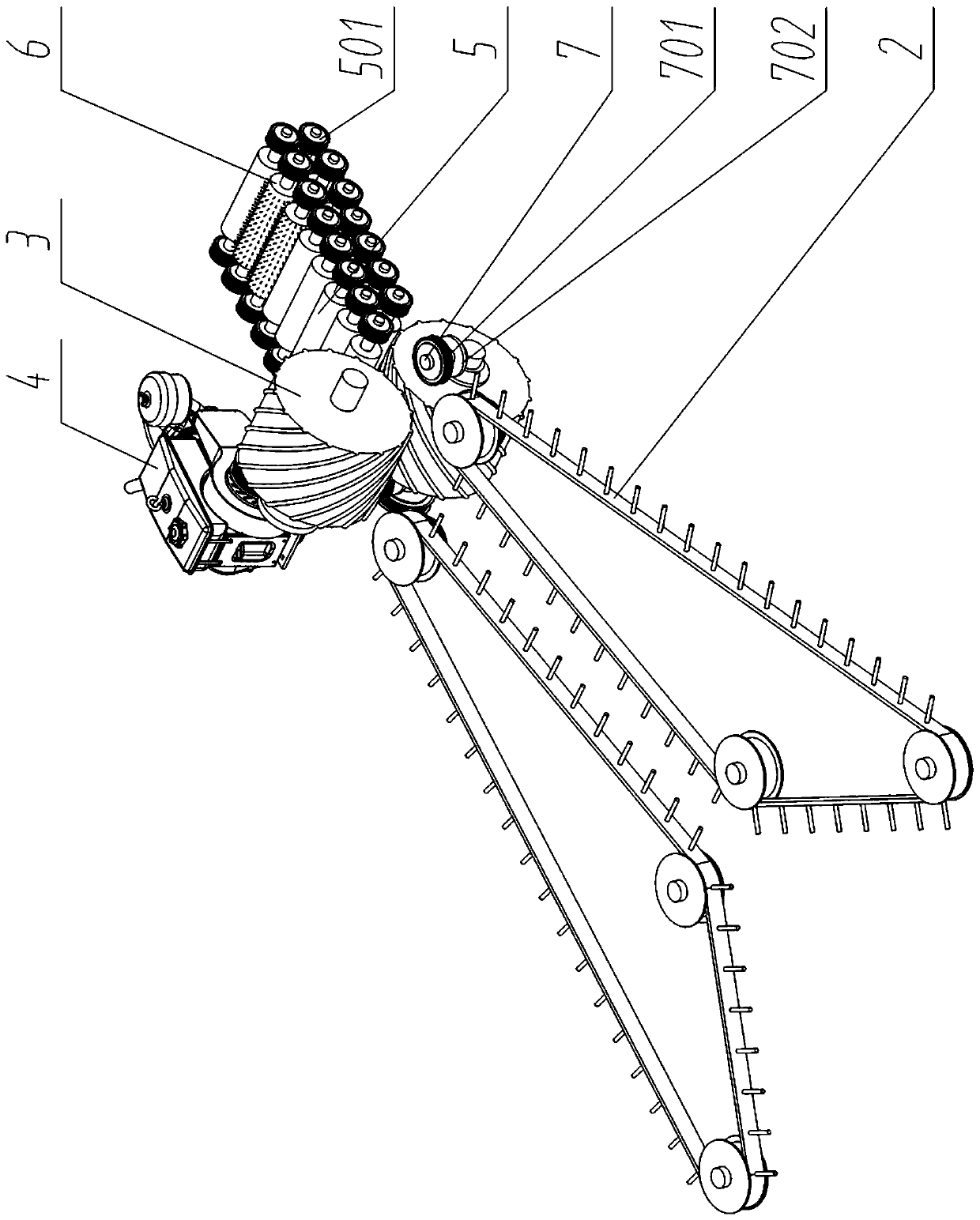

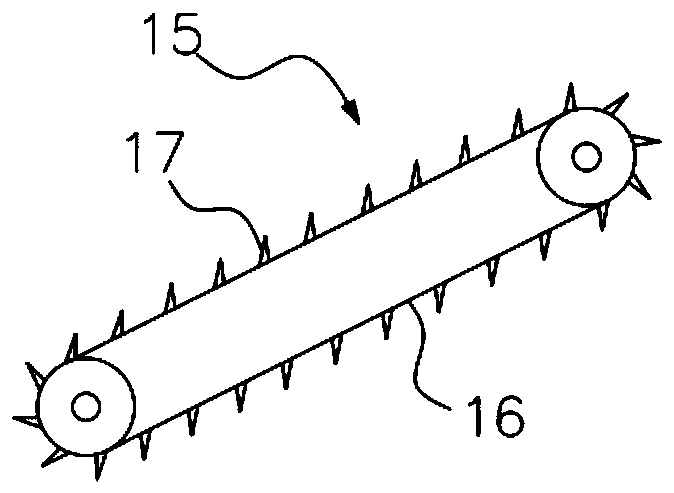

Automatic flax bundle splitting device with uniform and accurate control of flax bundles

PendingCN110257923AUniform, precise and controllable towRealize layer tear separationHackling machinesTextile disintegration and recoveryEngineeringMechanical engineering

The invention discloses an automatic flax bundle splitting device with uniform and accurate control of flax bundles. The automatic flax bundle splitting device comprises an unwinding mechanism, a feeding mechanism and a bundle splitting mechanism; the feeding mechanism includes a continuous moving conveyor track, needle belts are respectively arranged on both sides of the conveyor track continuously along the moving direction of the conveyor track, a continuous tear separation area matched with the bundle splitting mechanism is formed on the conveyor track between the two needle belts, the bundle splitting mechanism includes a plurality of bundle splitting rollers which are continuously arranged in the direction of movement of unrolled scutched flax to tear and split the unrolled scutched flax to form a number of continuous and uniformly loose flax bundles, multiple annular needle belts are uniformly distributed on the bundle splitting rollers, and a buffer mechanism and a weighing device connected with the buffer mechanism and used for quantitatively weighing the continuous and uniformly loose flax bunches are arranged at the output end of the bundle splitting mechanism. By the arrangement, the problem of uneven bundle splitting in traditional unit flax bundles is solved, working efficiency is improved, and labor intensity is reduced.

Owner:YUYUE HOME TEXTILE +1

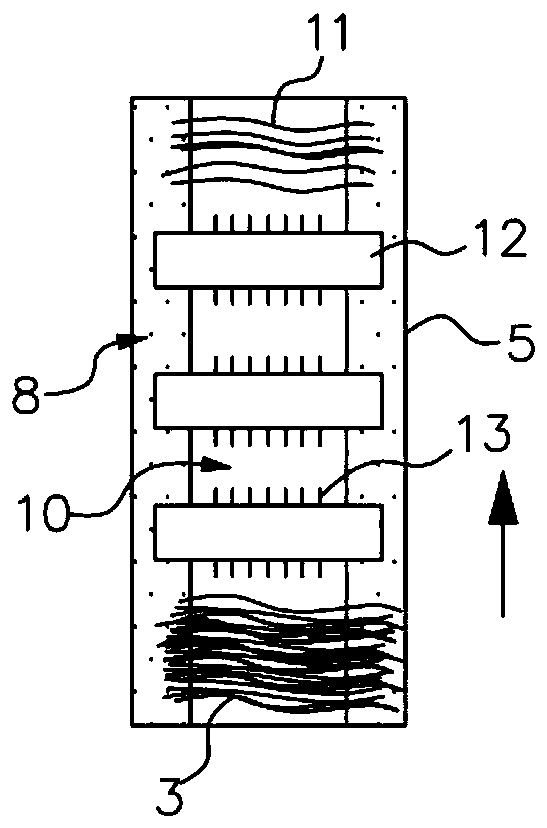

Continuous sectional flax carding mechanism

InactiveCN108977891AContinuous and efficient segmental cardingImprove efficiencyHackling machinesCardingEngineering

The invention discloses a continuous sectional flax carding mechanism, and belongs to the field of textile processing mechanical equipment. The continuous sectional flax carding mechanism comprises animpurity blowing mechanism and a carding mechanism, wherein the impurity blowing mechanism and the carding mechanism are sequentially and horizontally arranged at one side of a fixed bracket from topto bottom, an impurity collection hopper is horizontally arranged on the fixed mechanism at the lower side of the carding mechanism, an impurity blowing windpipe is horizontally arranged at one sideof the upper portion of the fixed bracket, the middles of the two sides of a carding bracket are vertically provided with a flax inlet guide groove and a flax outlet guide groove respectively, a maincombing conveyor belt and an auxiliary combing conveyor belt are vertically and symmetrically arranged on the carding bracket in sequence in the horizontal direction, the outer sides of the main combing conveyor belt and auxiliary combing conveyor belt are evenly provided with multiple flax carding needles respectively, and the carding bracket is slidably arranged on a translation guide rod in thehorizontal direction. The continuous sectional flax carding mechanism has the advantages that the structural design is reasonable, continuous sectional carding processing can be carried out on flax rapidly and efficiently, the automation degree of flax carding and processing is improved, and the needs of processing and use are met.

Owner:徐阳

Automatic circular combined hackling machine for hackling and forming strip for flax and combined hackling method thereof

ActiveCN101845689BShort processReduce the number of employeesContinuous processingCarding machinesProduction lineCarding

Owner:常州金德纺机科技有限公司

Ramie banding and splitting device and method

The invention discloses a ramie banding and splitting device and method. The device comprises a conveyer belt, a transition groove, flushing devices, traction roller sets and a banding device. The banding device comprises ratchet rollers and groove rollers. The circumferential surface of each ratchet roller is provided with ratchets and stripping strips. Axial grooves are formed in the circumferential surface of each groove roller. Each traction roller set is composed of two rubber rollers or the groove rollers with clean surfaces in the mode of being distributed symmetrically about the conveying face of the conveyer belt. The conveyer belt is sequentially provided with the banding device, the flushing devices, the transition groove and the traction roller sets in the ramie conveying direction. Under the combined action of the conveyer belt and traction rollers, degummed ramie fibers penetrate through the banding device formed by the ratchet rollers and the groove rollers, and the banding device produces the fast and slow fibers so that bands can be formed. The ramie banding and splitting device always keeps the fibers straight in the ramie banding and splitting processes, ramie is finished and dragged, manual smoothing is not needed, production efficiency is improved, a great deal of labor cost is saved, and the ramie can be produced continuously in a large-scale mode.

Owner:DAZHU GOLDEN BRIDGE RAMIE

Flax primary processing and long hemp carding machine

ActiveCN108301052APerfect primary processing production lineMeet the needs of agricultural modernizationTextile disintegration and recoveryHackling machinesCombingPulp and paper industry

The invention relates to a flax primary processing and long hemp carding machine. The machine comprises a supporting frame, a hemp feeding wheel, small clamping belts, guiding wheels, a comb tooth roller I, a cross-flow fan, large clamping belts, impurity suction hoppers, an air delivery pipe, two reversing wheels, a comb tooth roller II, a hemp discharging wheel and a hemp discharging table. Thehemp feeding wheel and the hemp discharging wheel are arranged at the upper ends of the front and rear sides of the supporting frame, the reversing wheels are arranged in the middle of the supportingframe, the large clamping belts are installed on the hemp feeding wheel, the hemp discharging wheel and the reversing wheels, the offset comb tooth roller I and the comb tooth roller II are arranged in the middle of the supporting frame, and the cross-flow fan is arranged above the comb tooth rollers. The impurity suction hoppers are arranged under the comb tooth rollers, the small clamping beltsare arranged on every two guiding wheels, and each comb tooth is composed of two steel pipes, wherein one steel pipe is smooth, and convex teeth are embedded onto the other steel pipe. Long hemp is clamped by the large and small clamping belts, enters the comb tooth roller I through which one end of the long hemp is combed, and then enters the comb tooth roller II for combing after being reversed.Combing workers are perfectly substituted, the quality of the long hemp is improved, the reproduction rate is decreased, and primary processing of flax is more intelligent and better in line with theneeds of agricultural modernization.

Owner:HEILONGJIANG PROV AGRI MACHINERY REPAIR INST

Novel hard waste ramie carding machine

The invention discloses a novel hard waste ramie carding machine which comprises an enclosure, a cylinder, working rollers, decortication rollers, galvanized iron rollers, a ramie feeding roller, a doffer, a ramie feeding curtain, a fluted roller, an iron supporting plate, a drafting roller, a pressing roller, a ramie outlet roller, a dead-weight pressure roller, a ramie guide hopper, a small guide hopper and an automatic lap former; the ramie feeding roller and the doffer are respectively arranged on the left side and the right side above the enclosure; the cylinder is arranged at the middle of the enclosure; the ramie feeding curtain is arranged on the left side of the enclosure in a connecting manner; the fluted roller is arranged at the top end of the ramie feeding curtain in a connecting manner; the ramie feeding curtain is connected with the ramie feeding roller through the fluted roller; the iron supporting plate is also arranged below the ramie feeding roller. The novel hard waste ramie carding machine disclosed by the invention is simple in structure and convenient for operation; overlong fibers are enabled to be pulled apart into fibers with proper length and are primarily loosened to obtain certain quantitative ramie stripes; the ramie stripes are wound to obtain ramie rolls, so that the feeding requirement of the ramie carding machine is met.

Owner:周盈裕

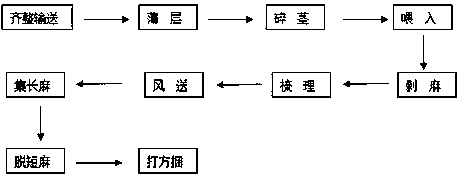

Preliminary processing method of flax stocks

InactiveCN108411376AImprove qualityReduce in quantityHackling machinesMechanical fibre separationFiberPulp and paper industry

The invention discloses a preliminary processing method of flax stocks. The preliminary processing method comprises the following steps of trimming conveying, wherein a trimming conveyor is utilized to trim and then convey the flax stocks; thinning, wherein trimmed spread flax is thinned, so that the spread flax is consistent in thickness; stem smashing, wherein the trimmed spread flax is subjected to stem smashing, and xylem is grinded; feeding, wherein the thinned spread flax stocks subjected to stem smashing are continuously fed into a flax breaker; flax breaking, wherein fed stock fiber isseparated from the xylem to form long flax; carding, wherein long flax is sorted, and impurities are carded; pneumatic conveying, wherein dust, the impurities and short flax generated in the processare absorbed away through a pneumatic conveying channel; long flax collecting, wherein the carded long flax is collected and bundled into small bundles; short flax separation, wherein the impurities and the short flax are subjected to pneumatic conveying to a flax separation machine through the pneumatic conveying channel, and the short flax is separated; square bundling, wherein the long flax andthe short flax are bundled into square bundles through a packing machine, so that a finished product is obtained. The whole process is mechanized, the long flax rate is high, the quality is good, theduplicating rate is low, the pollution is small, and the preliminary processing method is safe and reliable.

Owner:黑龙江省农业机械运用研究所

Mechanical device for automatically opening round packages of flax

ActiveCN101532192BFlat tow sizeStable tensionHackling machinesFibre breakingTransmission beltEngineering

The invention discloses a mechanical device for automatically opening flax round packages from flax comprising a frame, a guide roller, an electrical motor, and is characterized in that the mechanical device is further provided with a round package uncoil-stand, a string-pulling device and a conveyer device, wherein the electrical motor is connected with the conveyer device via a transmission belt, the conveyer device respectively drives the round package uncoil-stand and the string-pulling device, the round package uncoil-stand is a triangle transmission device consisting of an uncoiling guide roller and an uncoiling belt, the string-pulling device comprises a belt roller and an iron roller, and the conveyer device is a plate-type conveyer device consisting of a conveyer guide roller anda conveyer belt. The invention has high labor efficiency and low labor intensity.

Owner:ZHEJIANG JINYUAN FLAX

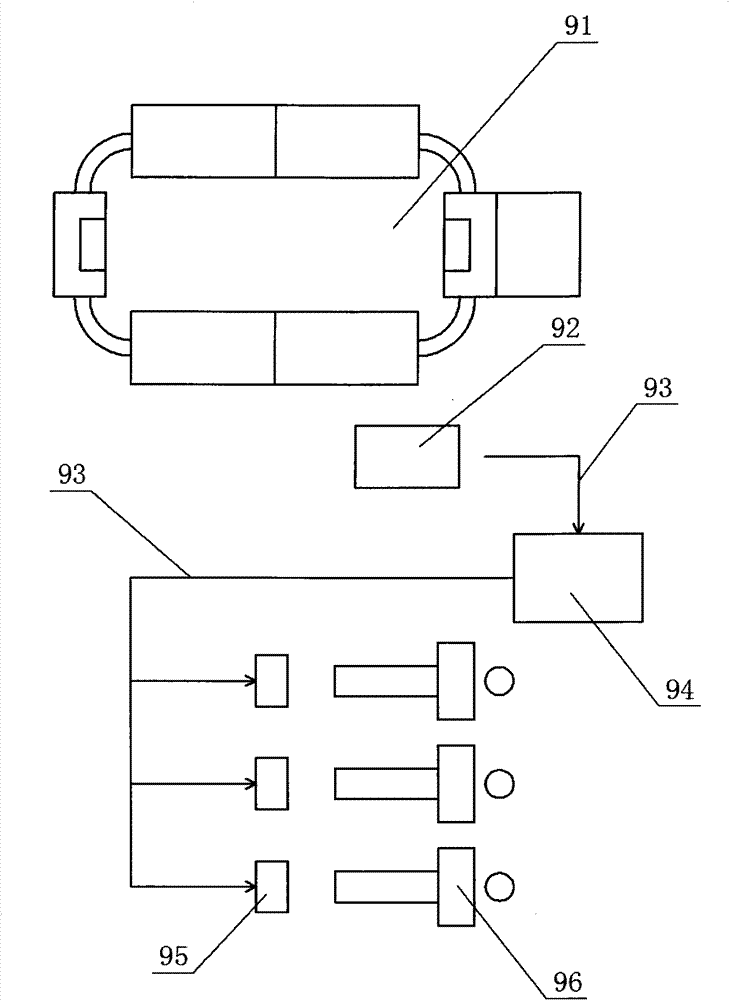

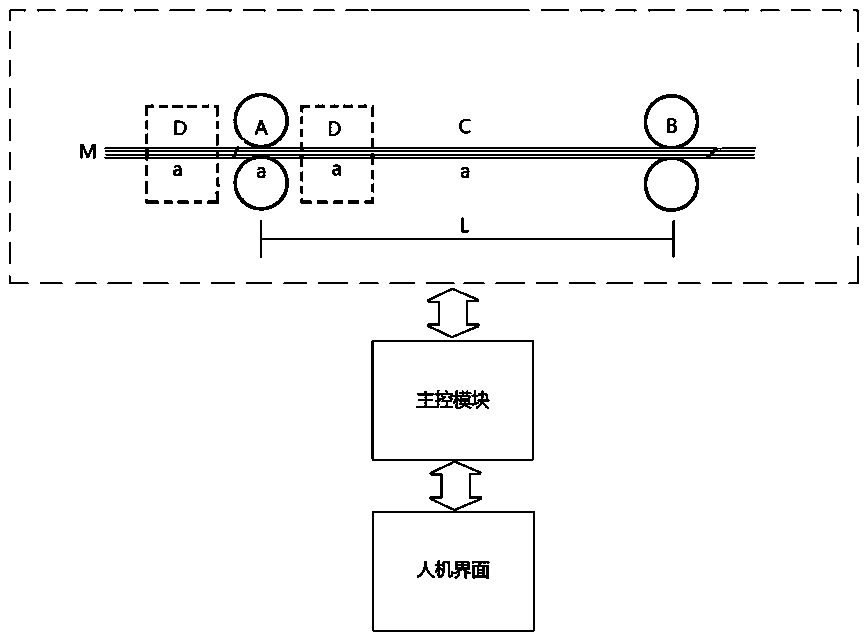

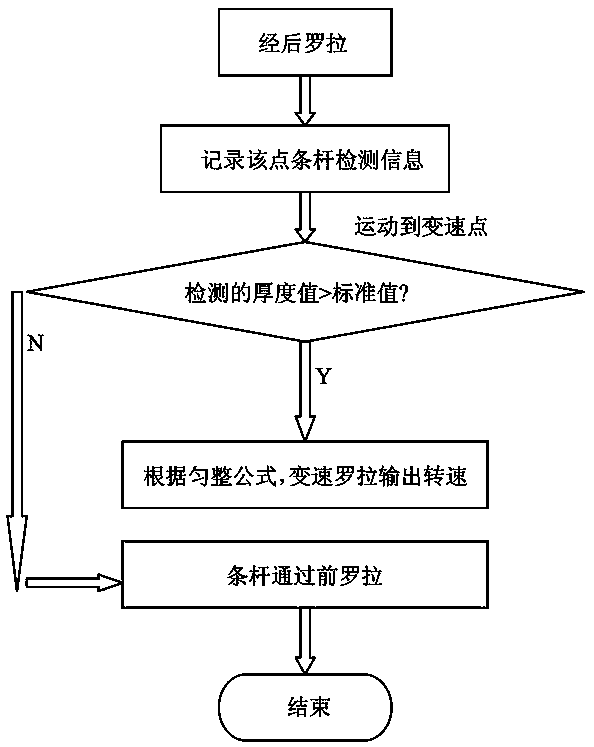

Hackling slivering machine control device and control method

The invention discloses a hackling slivering machine control device. The hackling slivering machine control device includes a control unit, and a back drafting unit and a front drafting unit which arearranged in the conveying direction of bars sequentially; a bar thickness detection member is arranged between the back drafting unit and the front drafting unit; the control unit compares the detected bar thickness and a preset standard thickness, and adjusts the speed of the back drafting unit or / and the front drafting unit according to the comparison result, so that the back drafting unit andthe front drafting unit pull the bar so as to control the bar thickness in the preset standard thickness. The invention also discloses a control method. The control method includes: S01, detecting thethickness of the bar in real time in the conveying process of the bar; and S02, comparing the detected bar thickness with the preset standard thickness, and adjusting the speed of the back drafting unit or / and the front drafting unit according to the comparison result so that the back drafting unit and the front drafting unit pull the bar to control the bar thickness in the preset standard thickness. The method and device can lower the unevenness of the bar.

Owner:李彬清 +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com