Jute processing system

A processing system, jute technology, applied in textiles and papermaking, mechanical processing, fiber processing, etc., can solve problems such as unaffordable and large investment, and achieve high cost performance and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

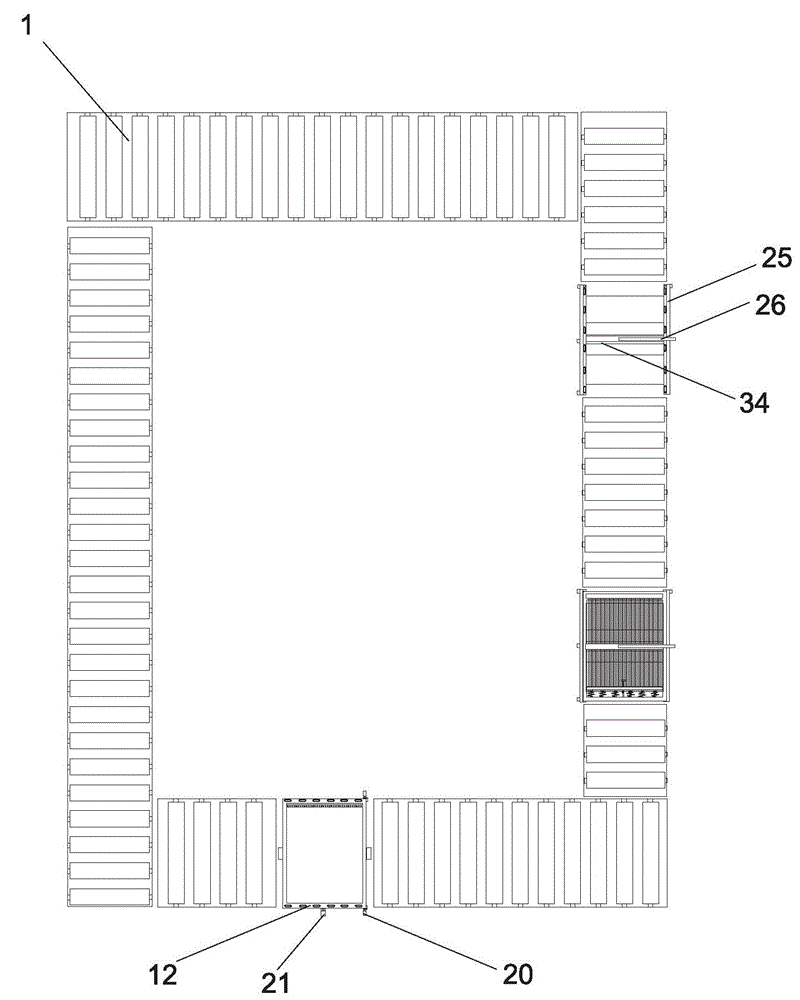

[0030] Such as Figure 1 to Figure 6 As shown, the jute processing system includes a jute carrier, an inlet and outlet station, a carding device and a conveying device. The carding device includes a rough carding device and a fine carding device. The jute carrier is provided with a jute leather clamping mechanism and a tensioning mechanism, and the conveying The device includes a closed conveying rail 1. The conveying rail 1 is a roller table formed by a sprocket-driven conveying roller for conveying jute carriers. The width of the conveying rail 1 is adapted to the size of the jute carriers. The baffle plate of the height of the jute carrier can be limited when the jute carrier travels on the conveying rail 1, so as not to deflect. The conveying rail 1 is surrounded by a rectangle, and each corner of the rectangular conveying rail 1 is provided with a reversing booster cylinder. The jute carrier is placed on the conveying rail 1 and transported counterclockwise along the con...

Embodiment 2

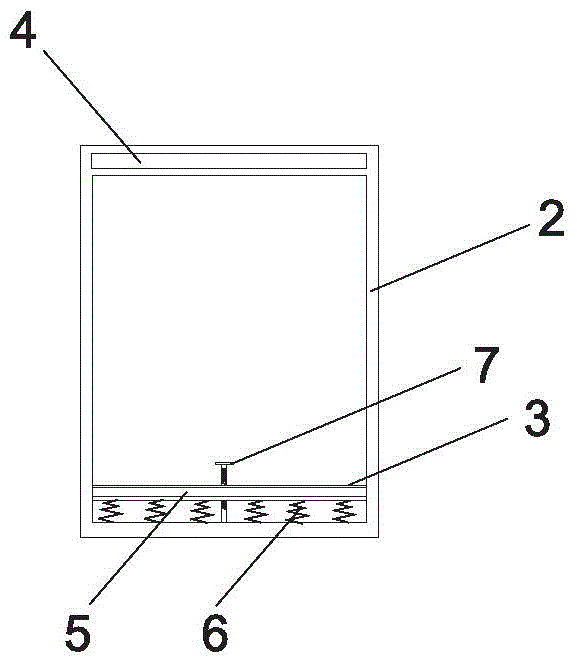

[0033] Such as Figure 7 to Figure 9Shown, described jute carrier comprises that described jute carrier comprises two winding rollers 8 and the rectangular frame body 2 that is made of two side frames and front and rear end frames, two winding rollers 8 two ends are rotatably connected on On the two side frames of the rectangular frame body 2, the jute skin clamping mechanism is a bead 9 arranged on the peripheral surface of the winding roller 8, and the tensioning mechanism includes an L-shaped stop bar 10 and can be connected with the winding roller. 8 The friction plate 11 in contact with the end surface, the stop rod 10 is hinged on the edge of one side frame of the rectangular frame body 2, the hinge part of the stop rod 10 and the rectangular frame body 2 is provided with a reset torsion spring, and the friction plate 11 is fixed on the stop The top of the moving rod 10, the two groups of the stop rod 10 and the friction plate 11 correspond to the two winding rollers 8 r...

Embodiment 3

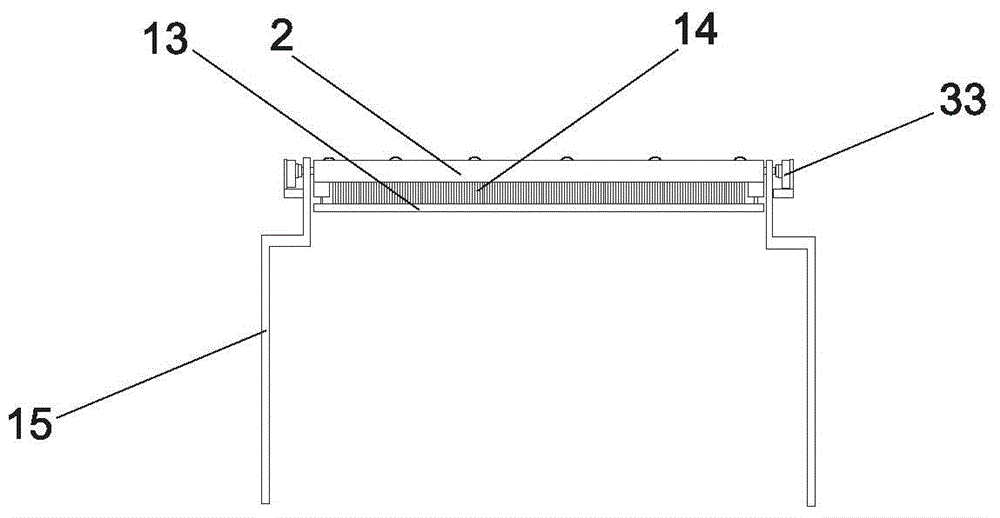

[0036] Such as Figure 10 As shown, the two support bars of the carrier bracket 25 and the connecting rod 34 form an H shape, the bottom of the connecting rod 34 is fixed with a protruding threaded seat 35, the bottom of the threaded seat 35 is provided with a slider, and the reciprocating platform 23 is correspondingly provided with a The chute, the slide block and the chute are matched and connected to form a sliding connection. The threaded seat is internally threaded to connect a screw, and the end of the screw is connected to the reciprocating platform 23 in rotation. The sliding direction of the screw is perpendicular to the reciprocating platform 23. Stepper motor drive connection. All the other are with embodiment 1.

[0037] In addition to the longitudinal combing effect of the carding head on the jute strips, the jute carrier can also change the lateral position under the control of the stepping motor and the screw, so that the comb needles will vertically split the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com