A fully automatic flax combing machine

A combing machine and fully automatic technology, applied in the field of combing machines, can solve problems such as easy sticking of flax fibers, low failure rate, and reduced combing effect, so as to improve combing effect, processing efficiency, and cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

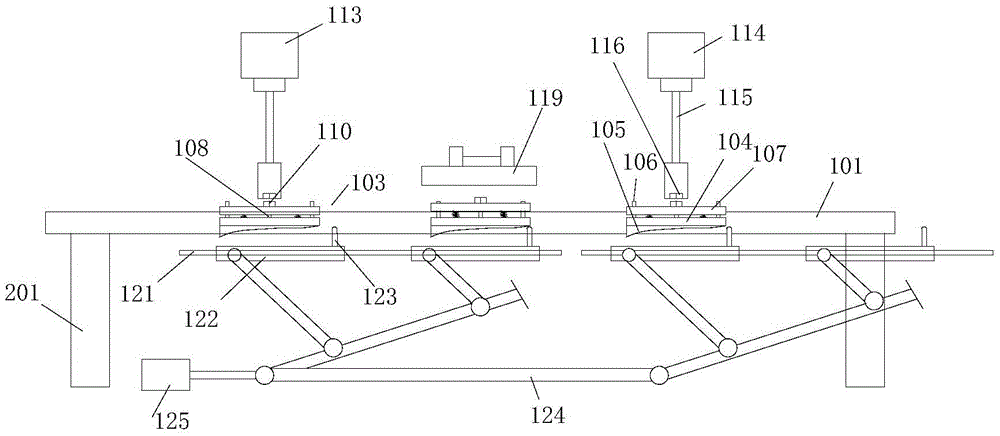

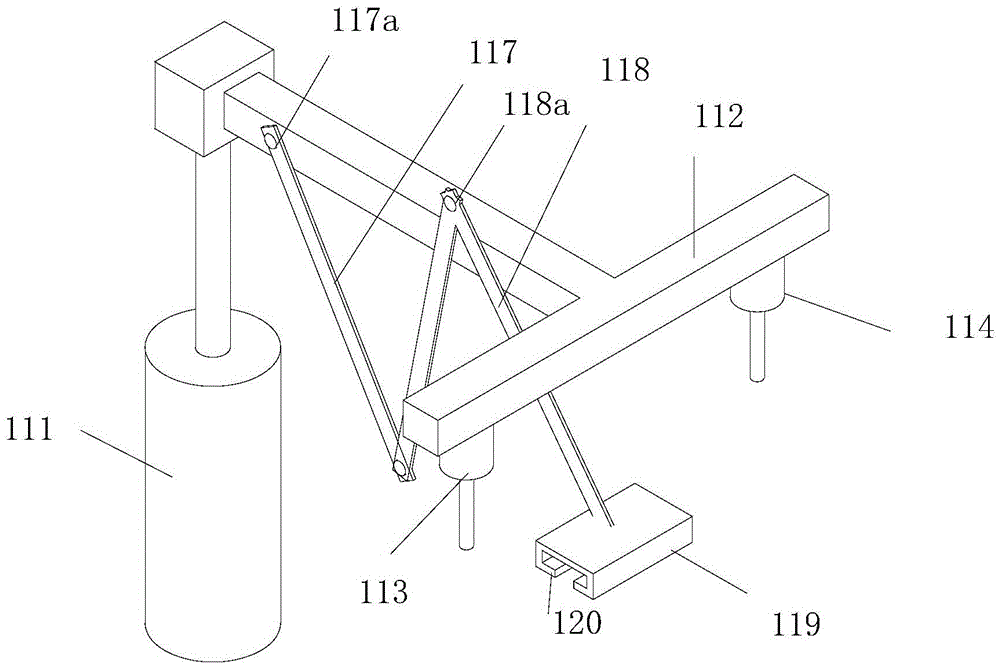

[0020] Embodiment: a kind of full-automatic flax combing machine, comprises the feeding mechanism that is fixed on the frame 201, is provided with combing mechanism after the feeding mechanism;

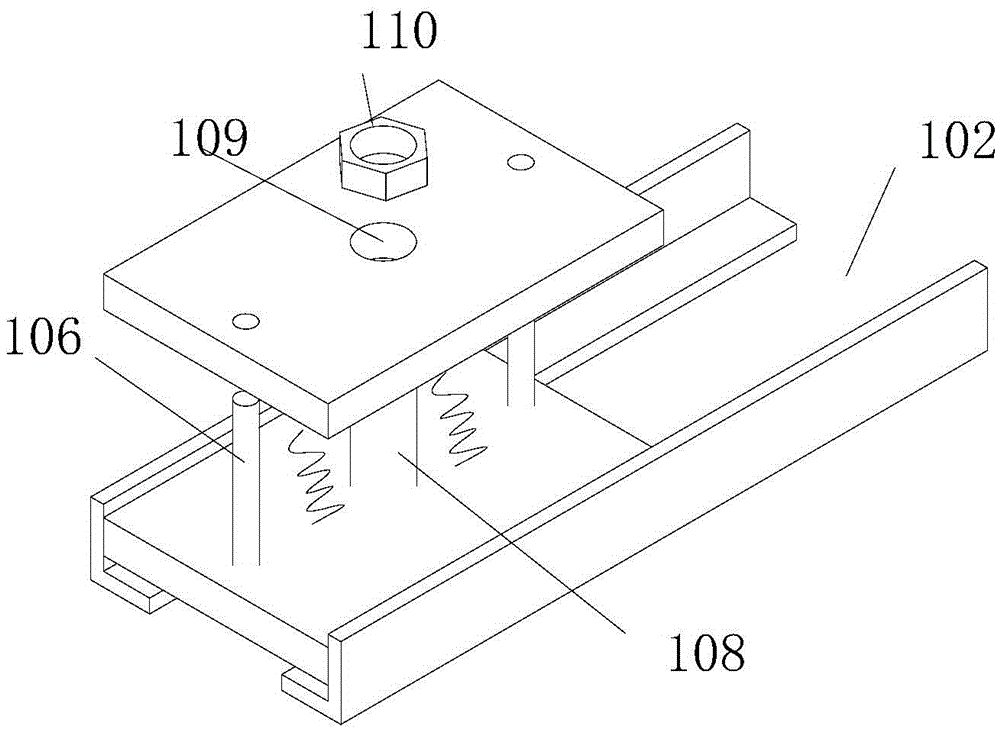

[0021] Described feed mechanism comprises the sliding platform 101 that is arranged on the frame, is provided with sliding groove 102 in the middle of sliding platform 101, and is provided with a group of sliding device 103 on sliding groove 102, and sliding device 103 comprises the sliding device that is erected on sliding groove 102. Block 104, the bottom surface of the slider 104 has a curved surface 105 that is high on the left and low on the right, fixed pins 106 are provided on both sides of the slider 104, and a pressing block 107 is arranged on the sliding block 104, and through holes are provided on both sides of the pressing block 107 And be inserted in the fixed pin 106, be provided with spring between slide block 104 and briquetting block 107; The center of described slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com