Bamboo short fiber extraction technology

A technology of bamboo short fiber and technology, which is applied in the directions of fiber treatment, fiber mechanical separation, and chemical method to produce bast fiber, can solve the problems of high cost, environmental pollution, difficult treatment, etc., achieves short extraction time, and improves degumming effect. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1, first extract bamboo fiber according to step a and step b in above-mentioned step 1, step 2, explore the impact of processing parameters on lignin, hemicellulose and pectin decomposition, wherein, the consumption of Cizhu is 1kg, fiber bundle The cut length is 10mm. The main chemical components in Cizhu are shown in Table 1 below (the components in the bamboo flesh layer were detected), and the processing parameters of each step are shown in Table 2 below.

[0044] Table 1 Main chemical constituents of Cizhu

[0045]

Hemicellulose / %

Cellulose / %

Lignin / %

Pectin / %

the remaining / %

Cizhu

22.21

50.15

23.45

1.10

3.09

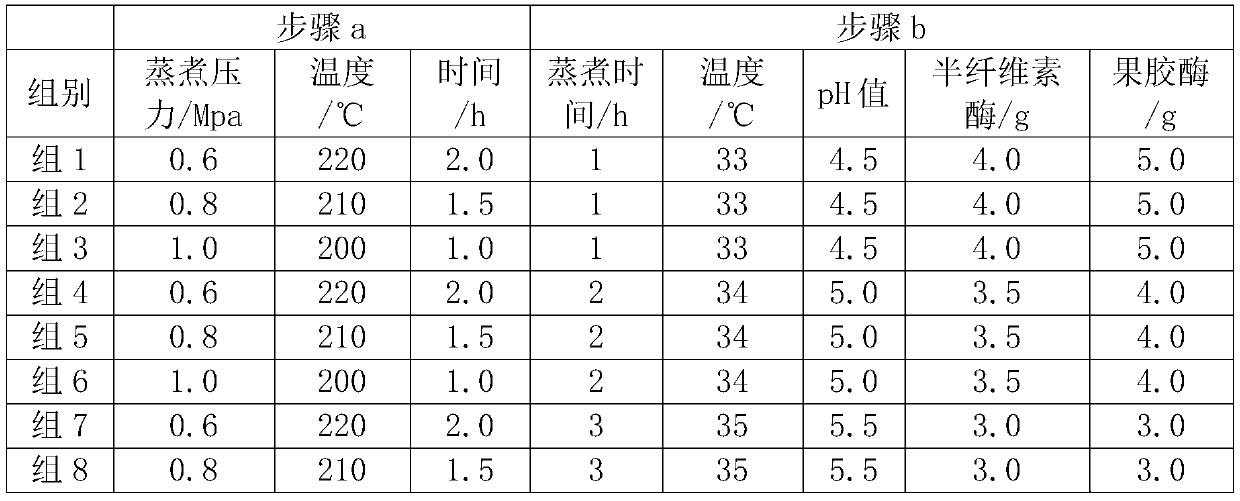

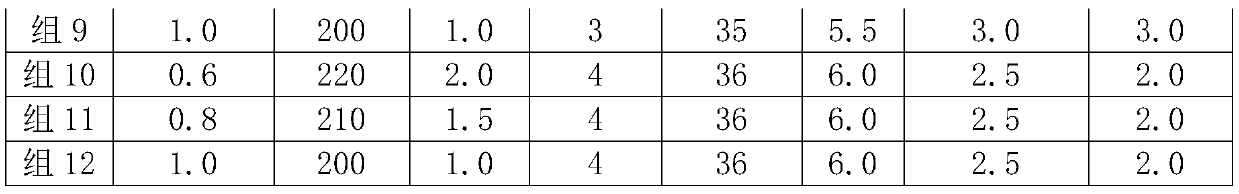

[0046] Table 2 Processing parameters of each step

[0047]

[0048]

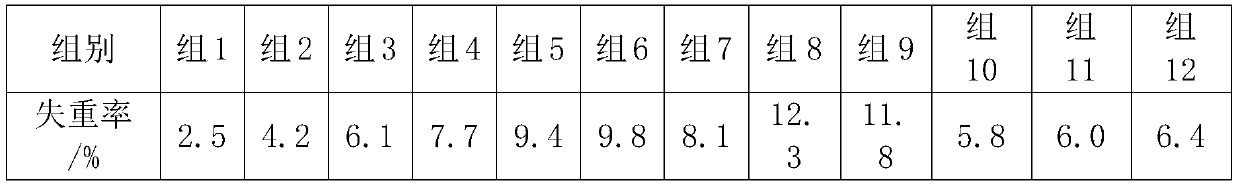

[0049] The bamboo strips after the above-mentioned groups of treatments are carried out to calculate the weight loss rate, so as to intuitively reflect the degumming effect. When calculating the weight loss rate, the bamboo strip...

Embodiment 2

[0063] The short bamboo fibers extracted in Example 1 are thinned, and undried bamboo short fibers are used when thinning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com