Hemp-type hackling machine shifting fork mechanism

A combing machine and hemp technology, which is applied in the field of the fork mechanism of the hemp combing machine, can solve the problems of instability and falling of the hemp gripper in the chain track conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

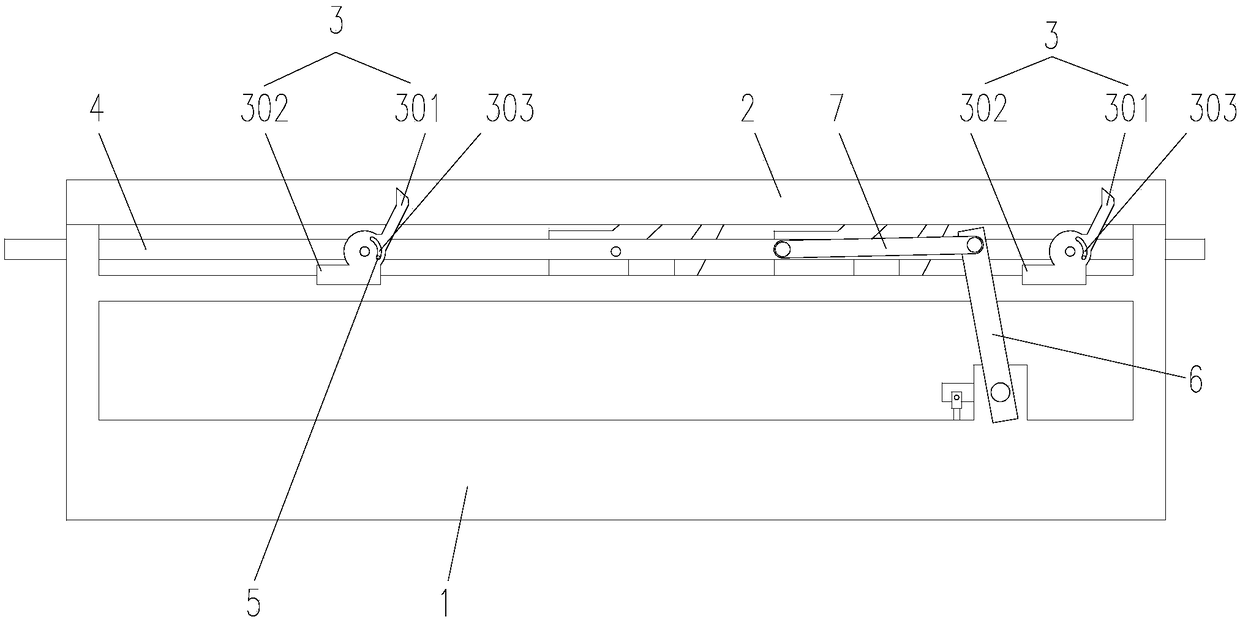

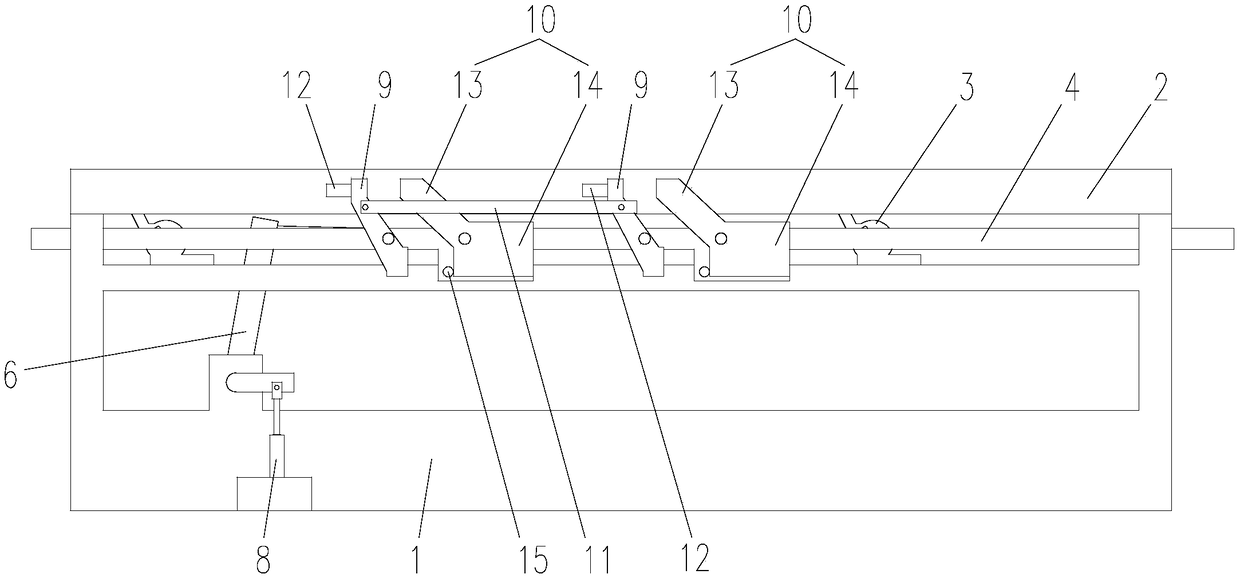

[0014] Such as Figure 1-2 As shown, a fork mechanism of a hemp combing machine includes a frame 1 provided with a linear guide rail 2, and also includes a driving rod 3, a sliding rod 4 and a limit pin 5, and the sliding rod 4 is slidably arranged on the On the frame 1, the slide bar 4 and the linear guide rail 2 are arranged parallel to each other; 3. There is a guide groove 303 on the driving rod 3, the central axis of the guiding groove 303 coincides with the rotation axis of the driving rod 3, and one end of the limit pin 5 is set on the sliding rod 4 , the other end of the limit pin 5 is set in the guide groove 303, the lever 3 has a first leg 301 and a first counterweight 302 extending outward, the first leg 301 is located close to the One side of the linear guide rail 2, the first counterweight 302 is located on the side away from the linear guide rail 2, and the frame 1 is provided with a reciprocating mechanism that drives the slide bar 4 to reciprocate. The limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com