Ramie banding and splitting device and method

A ribbon forming and ramie technology, which is applied in the field of ramie ribbon forming and fiber opening devices, can solve the problems of high labor intensity, high noise, and low production rate of long fibers in the subsequent process, and achieve the effects of saving labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

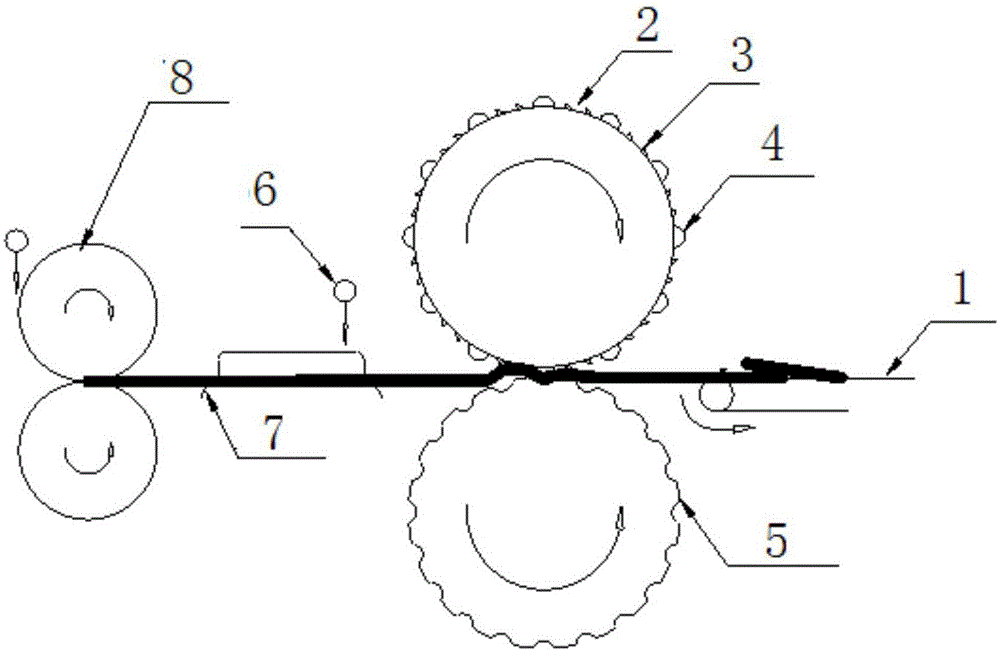

[0030] Example 1 - Lean Feed of Ramie

[0031] Taking thinly fed ramie as an example, the above-mentioned ramie belt forming and fiber opening device and method are used to realize the belt forming and fiber opening of ramie. The specific implementation method is: in the described ramie belt fiber opening device, the tooth ends of the ratchets 3 are indented by 2mm compared with the peeling bar 4, the circumferential ratchet distance is 20mm, and the axial ratchet distance is 15mm; the groove roller 5 The diameter of the groove is 10mm, the diameter of the groove roller 5 and the ratchet roller 2 is 400mm, and the gap between the groove roller 5 and the ratchet roller 2 is 0mm. The traction roller group 8 is provided with 3 pairs, and the gap between the pairs is 300 mm; the draft ratio of 1-2 pairs is 3 times, and the draft ratio of 2-3 pairs is 1.1 times.

[0032] The specific implementation process is: put the degummed ramie on the conveyor belt 1 step by step in a stacked...

Embodiment 2

[0033] Example 2 - Mass feed of ramie

[0034] Taking heavy-feeding ramie as an example, the belt forming and fiber opening of ramie are realized by using the above-mentioned ramie belt forming and fiber opening device and method. The specific implementation method is: in the described ramie belt fiber opening device, the tooth ends of the ratchets 3 are indented by 20mm compared with the peeling bar 4, the circumferential ratchet distance is 50mm, and the axial ratchet distance is 50mm; the groove roller 5 The diameter of the groove is 30mm, the diameter of the groove roller 5 and the ratchet roller 2 is 600mm, and the gap between the groove roller 5 and the ratchet roller 2 is 15mm. The traction roller group 8 is provided with 7 pairs, and the gap between the pairs is 600 mm; the draft ratio of 1-2 pairs is 6 times, and the draft ratio of 2-7 pairs is 1.5 times.

[0035] The specific implementation process is: put the degummed ramie on the conveyor belt 1 step by step in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com