Automatic flax bundle splitting device with uniform and accurate control of flax bundles

A uniform and precise technology, applied in textiles and papermaking, mechanical processing, fiber processing, etc., can solve problems such as high labor costs, low efficiency, uneven bundles, etc., to reduce impact, ensure reliability, and avoid slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

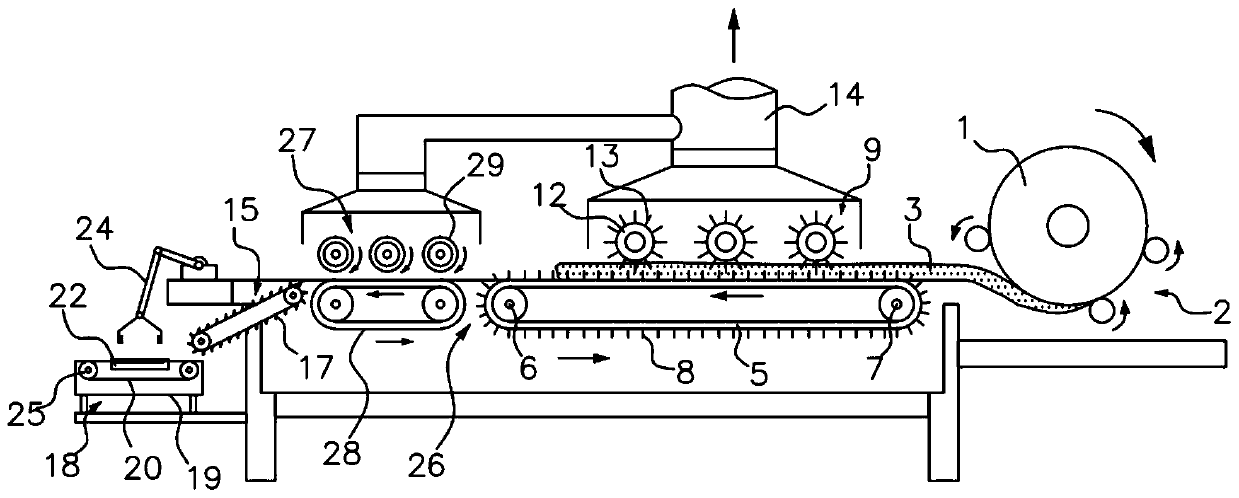

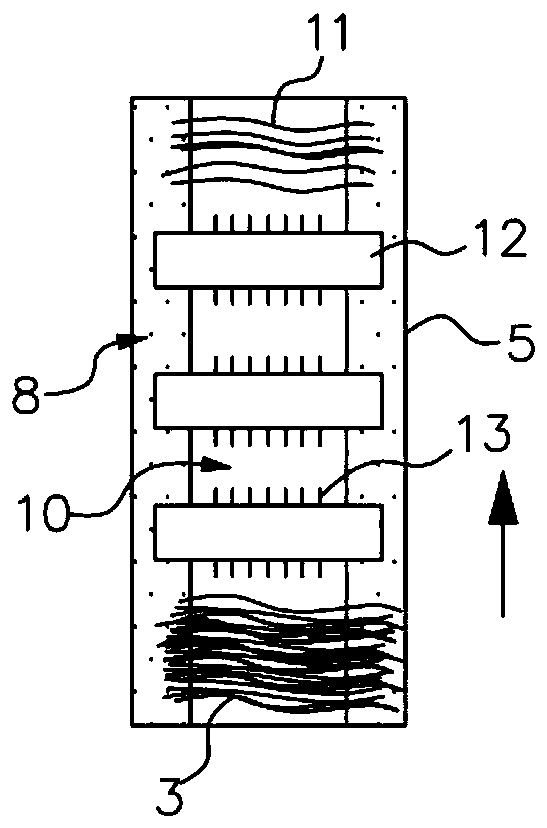

[0030] Such as figure 1 , 2 , 3, 4, 5, and 6, a flax automatic splitting device with uniform, precise and controllable flax bundles, including an uncoiling mechanism 2 for automatically launching the flax round bales 1, and a flax round bale The feeding mechanism 4 for transporting the rolled hemp 3 after the package 1 is expanded also includes a beam splitting mechanism 9 for automatically splitting the expanded hemp 3 .

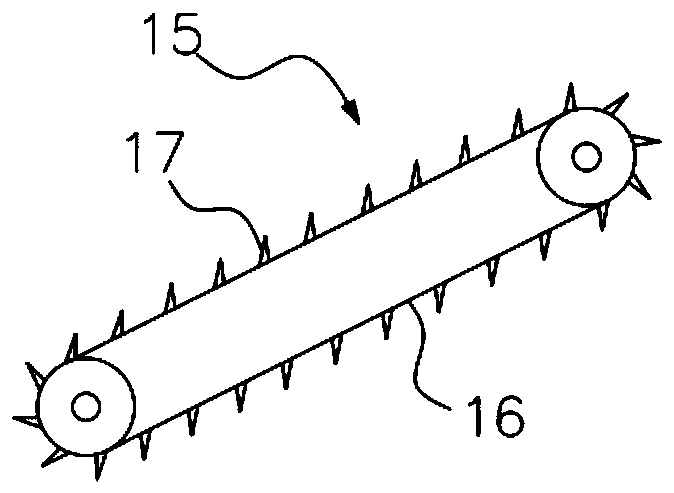

[0031]The feeding mechanism 4 includes a continuously moving conveying crawler belt 5, which is driven by the installed driving roller 6 and driven roller 7 to perform continuous and uniform circular motion. Along the moving direction of the conveyor belt 5, needle belts 8 for applying a quasi-constraining force to the unfolded hemp 3 and fixing them on the surface of the conveyor belt 5 are continuously arranged on both sides of the conveyor belt 5. A continuous tearing partition 10 cooperating with the beam splitting mechanism 9 is formed on the conveyi...

Embodiment 2

[0038] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that: figure 1 As shown, at the discharge port 26 of the beam splitting mechanism 9, a crushing mechanism 27 for secondary tearing and splitting of the continuous and uniform loose tow 11 formed by tearing and splitting is provided. Roll-off mechanism 27 comprises the second conveying crawler belt 28 that is arranged along the conveying direction of making hemp, and along the conveying direction of the second conveying crawler-belt 28, a plurality of rolling-off rollers 29 are arranged successively above the second conveying crawler belt 28, in each A tearing and grinding zone for performing secondary tearing and splitting of the continuous and uniform loose hemp bundle 11 is formed between the rolling roller 29 and the second conveying crawler belt 28 .

[0039] Due to the different thicknesses and densities of the beating hemp bundles 1, the density of the continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com