Economical jute processing system

A processing system, economical technology, applied in textile and papermaking, mechanical processing, fiber mechanical separation, etc., can solve problems such as large investment and difficult to afford, and achieve high cost performance and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

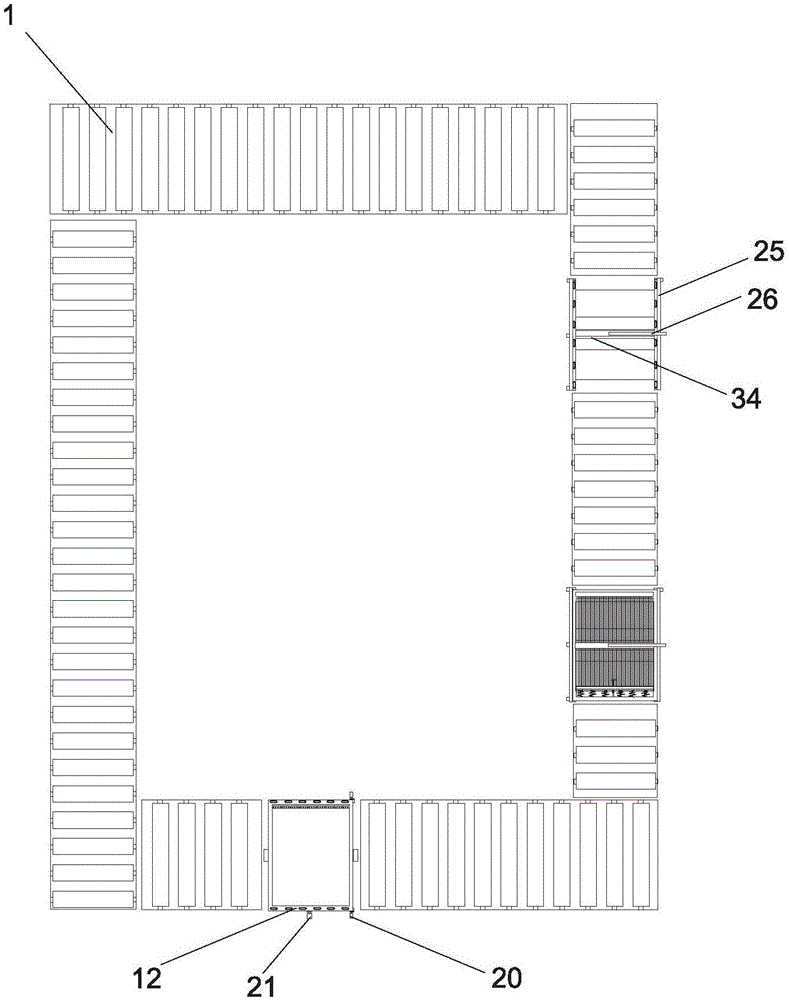

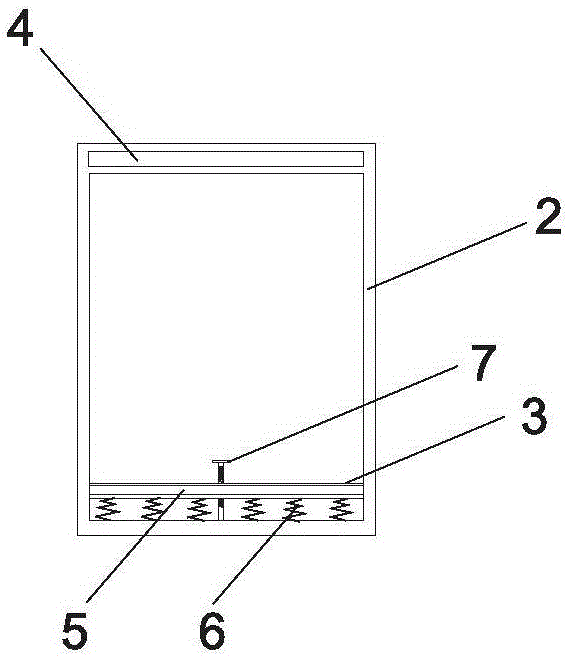

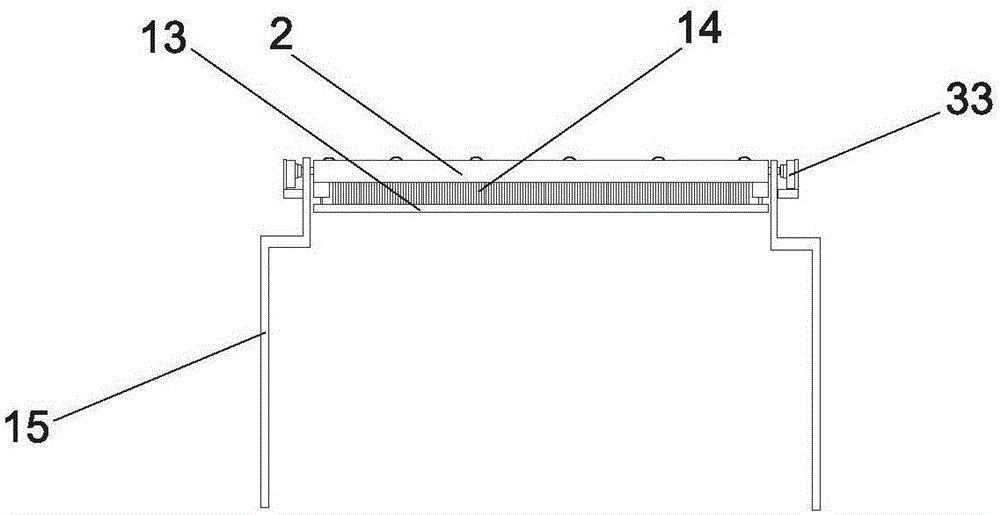

[0022] like Figure 1 to Figure 6Shown, a kind of economical jute processing system comprises jute carrier, feeding and discharging station, carding device and conveying device, and carding device comprises rough carding device and fine carding device, and jute carrier is provided with jute leather clamping mechanism and tensioning device. Tight mechanism, the conveying device includes a closed conveying rail 1, and the conveying rail 1 is a roller table composed of conveying rollers driven by a sprocket, which is used to convey jute carriers. The width of the conveying rail 1 is adapted to the size of the jute carriers. The conveying rail 1 is two The side is provided with a baffle plate greater than the height of the jute carrier, and the jute carrier can be limited when it travels on the conveying rail 1, so as not to deflect. The conveying rail 1 is surrounded by a rectangle, and each corner of the rectangular conveying rail 1 is provided with a reversing booster cylinder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com