Flax primary processing and long hemp carding machine

A technology of carding machine and long hemp, applied in the direction of combing machine, mechanical processing, fiber processing, etc., can solve the problems of reducing the reproduction rate, physical injury of workers, poor working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

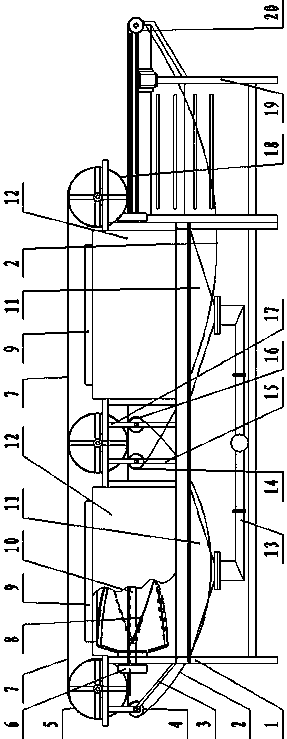

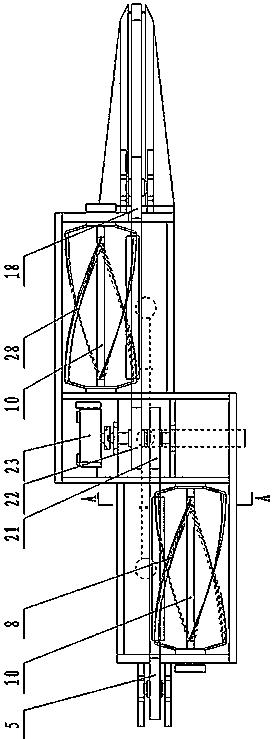

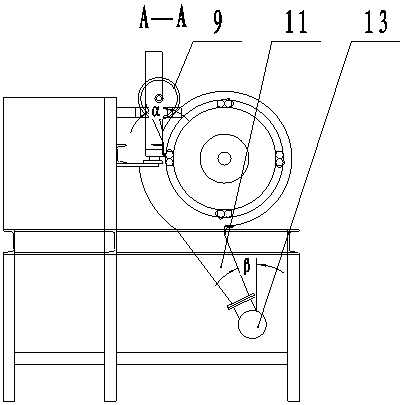

[0015] As shown in the attached figure, the long flax carding machine for primary processing of flax includes a support frame 1, a flax feeding wheel 5, a small clamping belt 2, guide wheels (4, 14, 16, 20), comb tooth roller I 8, and a cross-flow fan 9 , large clamping belt 7, miscellaneous suction bucket 11, air delivery pipe 13, reversing wheel (21, 22), comb roller II 28, hemp discharge wheel 18, hemp discharge table 19, protective cover 12; The bearing seat is set at the front upper end of the support frame 1, and a guide wheel I4 is set at the front and bottom of the hemp feeding wheel 5, and the guide wheel I4 is fixed on the support frame 3 connected to the support frame 1 with bolts, and the upper middle of the support frame 1 is coaxially arranged through the bearing seat. Direction wheel I21 and reversing wheel II22, one end of the shaft is connected with the reducer 23 installed on the support frame 1, and the V-belt is used to complete the connection between the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com