Patents

Literature

33 results about "Flax textile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation and application of flax adsorbent

InactiveCN103464115AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionFiberEpoxy

The invention discloses a preparation method and application technology of an epoxy chloropropane modified flax adsorbent. The preparation method is characterized by washing waste short fiber flax of a flax textile factory by using water, drying and crushing; processing by using NaOH and OP water solution and drying to obtain degummed flax; adding the following components in percentage by mass in a reactor: 22-40% of epoxy chloropropane, 12-25% of degummed flax, 4-8% of NaOH, 5-10% of isopropyl alcohol and 32-55% of water, wherein the sum of all the components is 100%; stirring at the constant temperature of 55-65 DEG C, carrying out backflow reaction for 1.0-4h, cooling, washing by using de-ionized water, carrying out suction extracting and filtering until the filtrate is neutral, washing by using a small amount of ethanol, drying in a 50-55 DEG C vacuum drying box, so as to obtain the epoxy chloropropane modified flax. The adsorbent has very high adsorbing capacity to basic dye, has high regeneration property, can be used repeatedly for several times, and is low in cost and environment-friendly.

Owner:UNIV OF JINAN

Preparing method for anti-wrinkle flax fabric and method for preparing flax anti-wrinkle textile

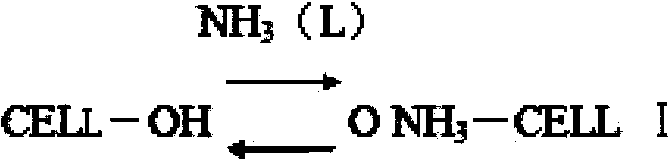

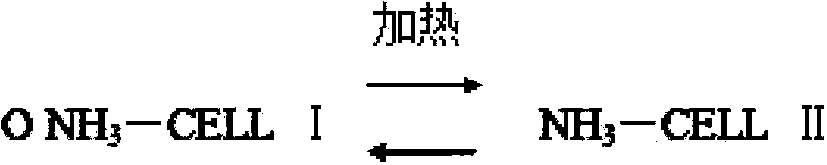

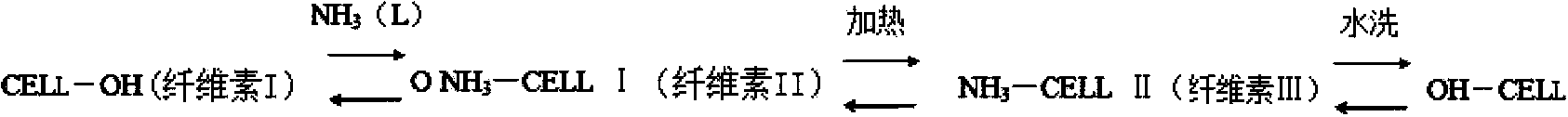

InactiveCN103437157AAchieve washable and wearable effectGood synergyBleaching apparatusDyeing processCelluloseAmmonia gas

The invention discloses a preparing method for anti-wrinkle flax fabric, which comprises the following steps: 1), enabling liquid ammonia to react with cellulose I of flax fabric to obtain cellulose II; 2), heating the cellulose II obtained in the step 1) to obtain cellulose III; 3), removing ammonia gas and cleaning the residual ammonia gas on the surface of the fabric; 4), adjusting the pH value of the fabric to the range from faintly acid to alkalescence, so as to obtain the anti-wrinkle flax fabric. Further, the invention discloses a method for preparing the fabric into a textile. According to the fabric provided by the invention, the uniform reflection of the flax textile to light rays is strengthened, the elasticity and strength are improved, and the hand feeling and dimensional stability are improved, so that the purpose that the flax textile can be washed and worn is achieved finally.

Owner:金光一

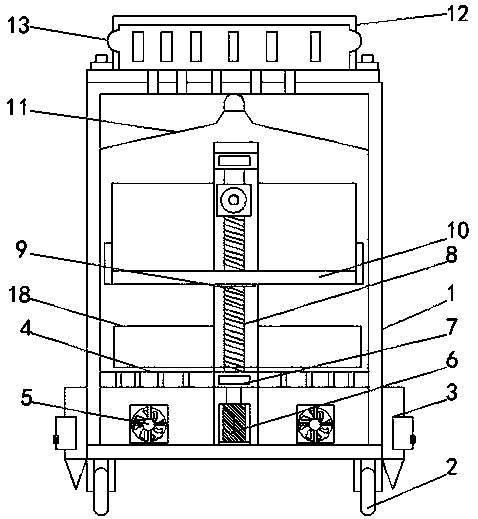

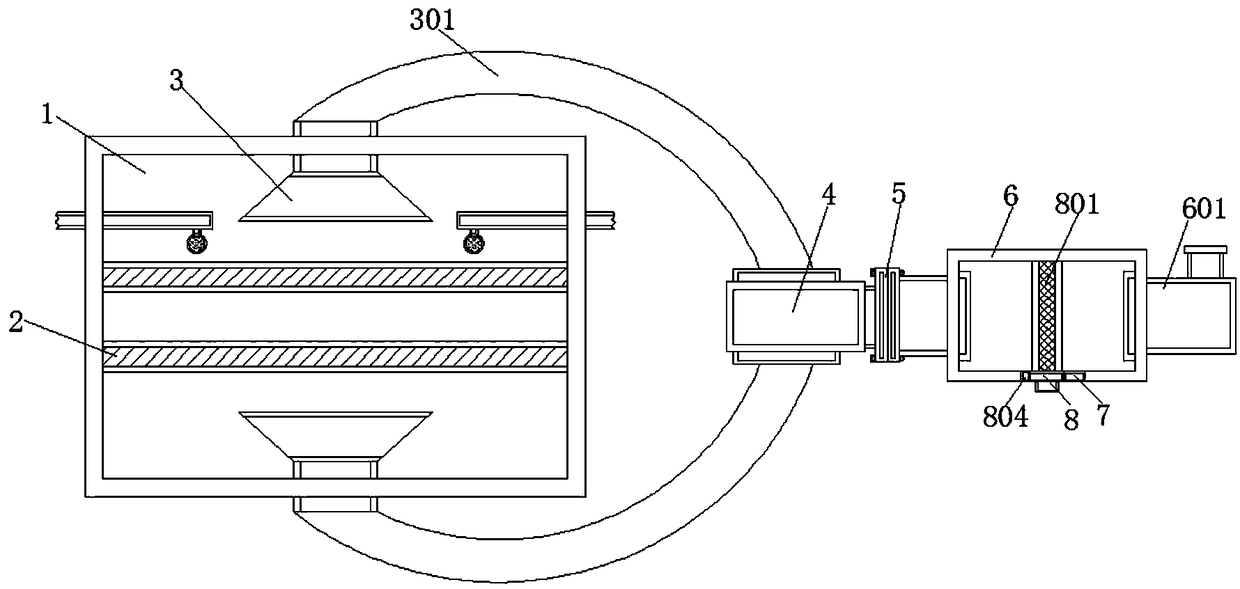

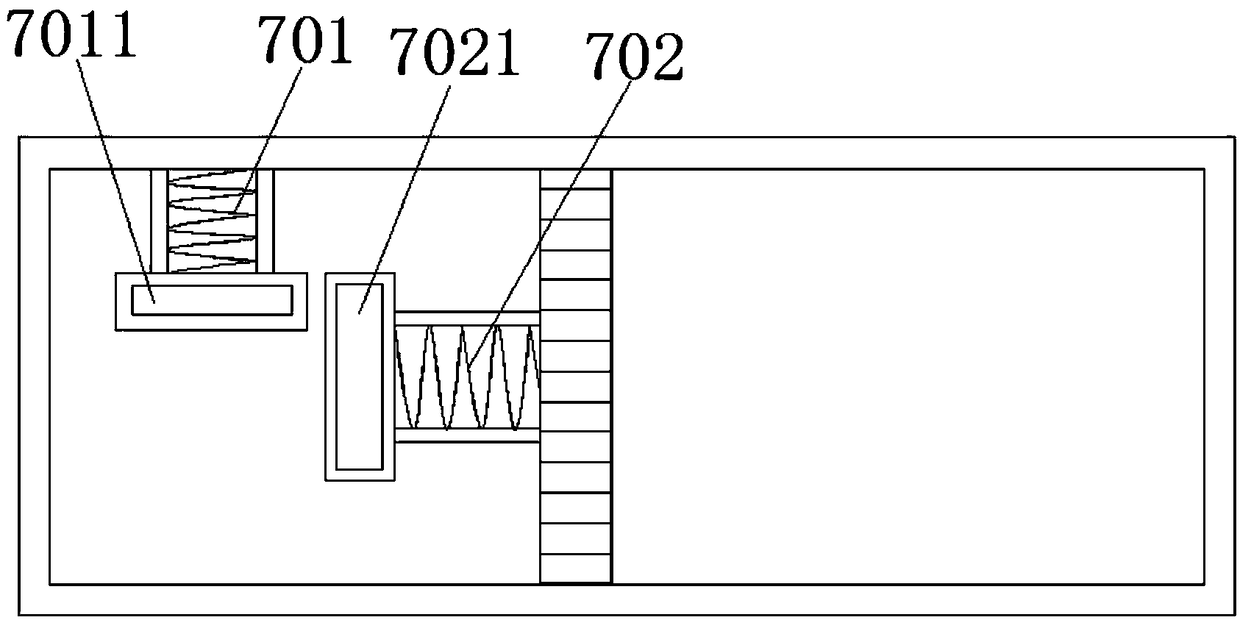

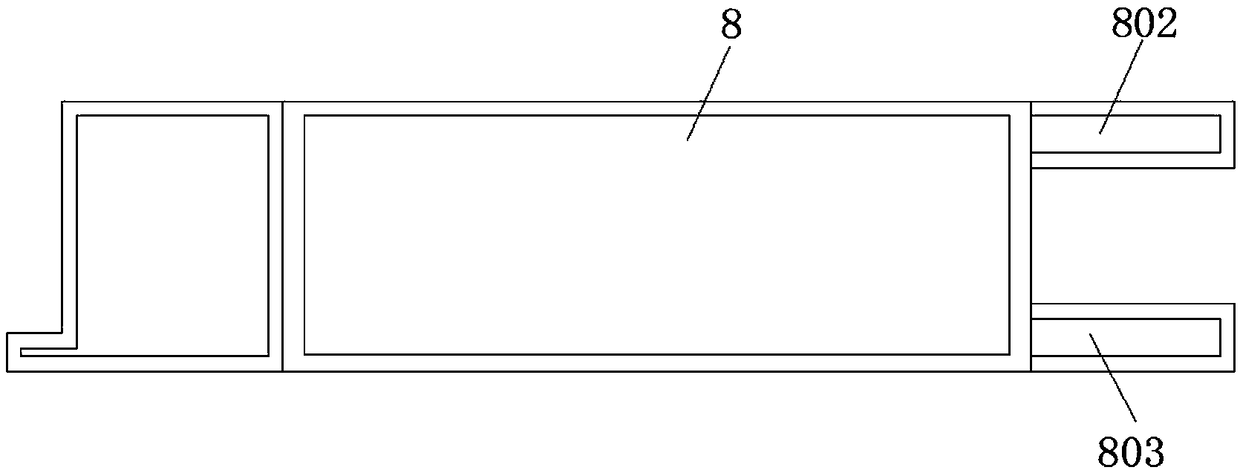

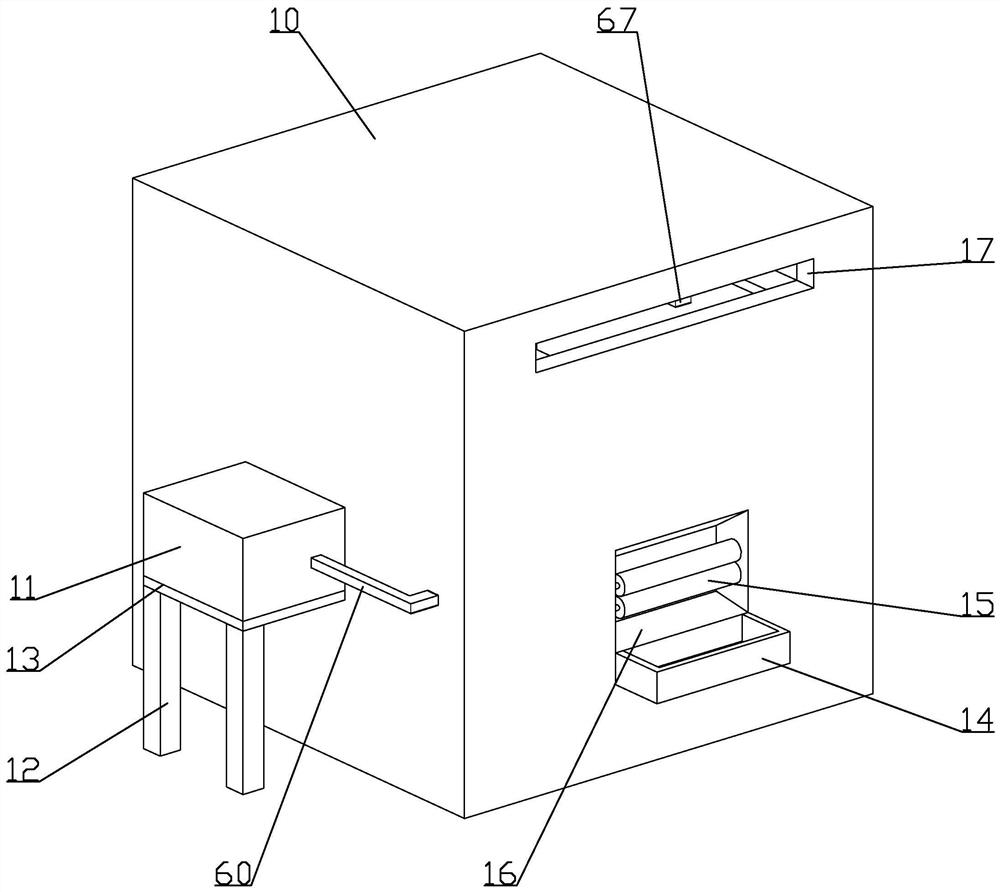

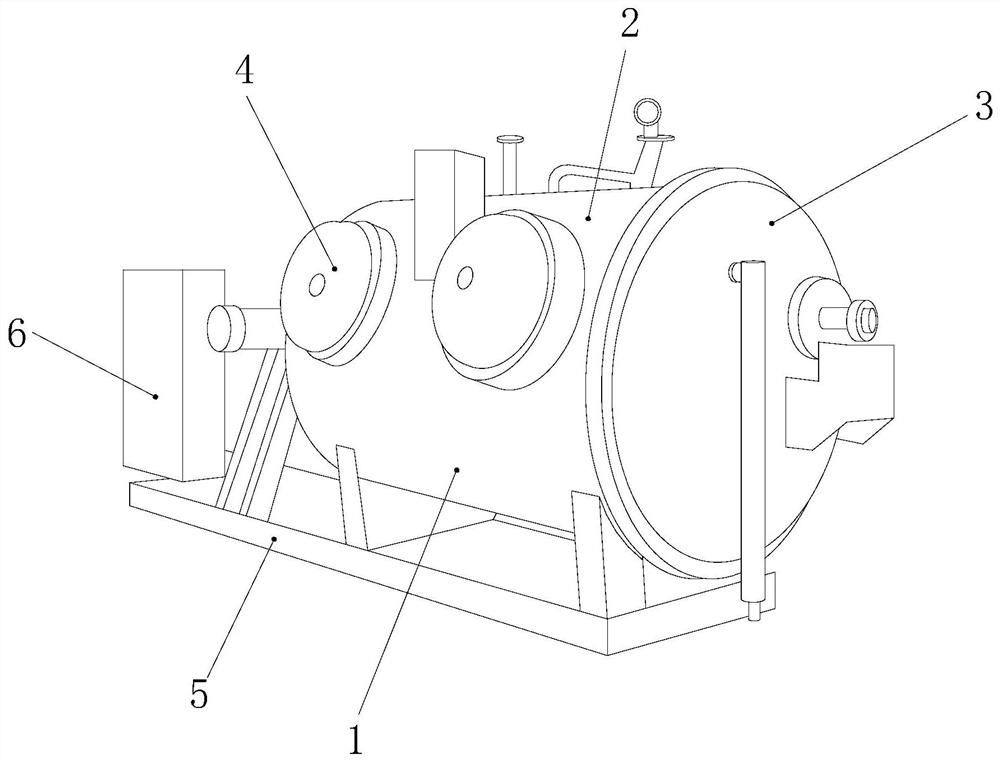

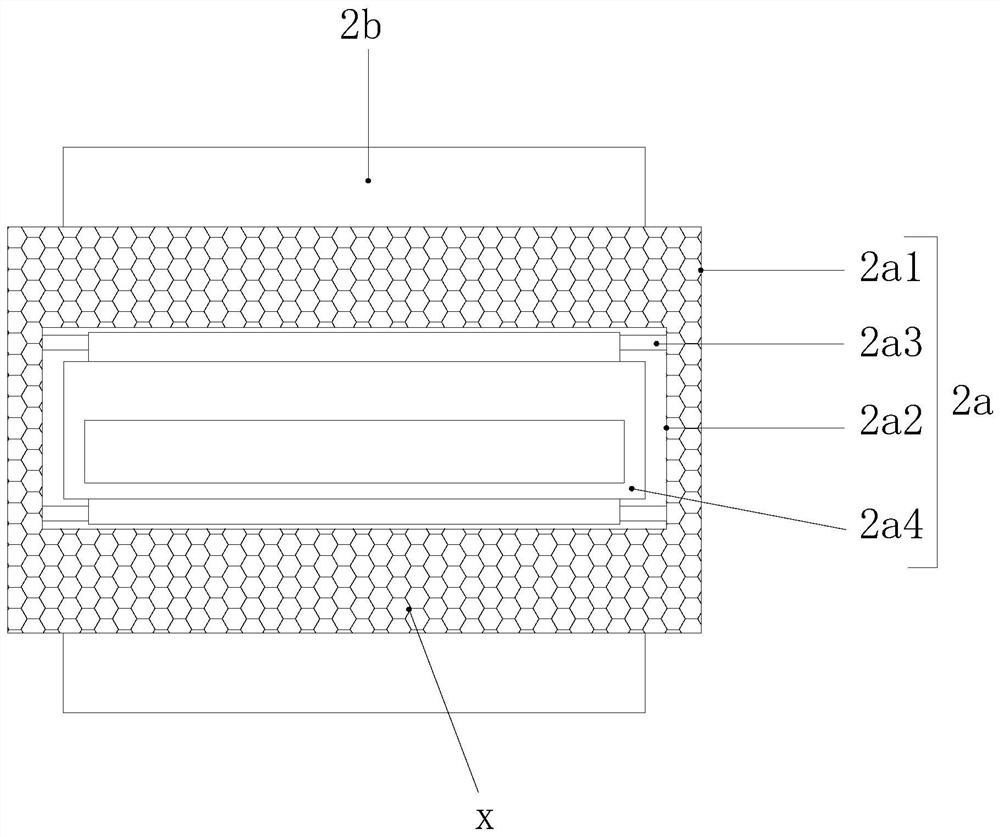

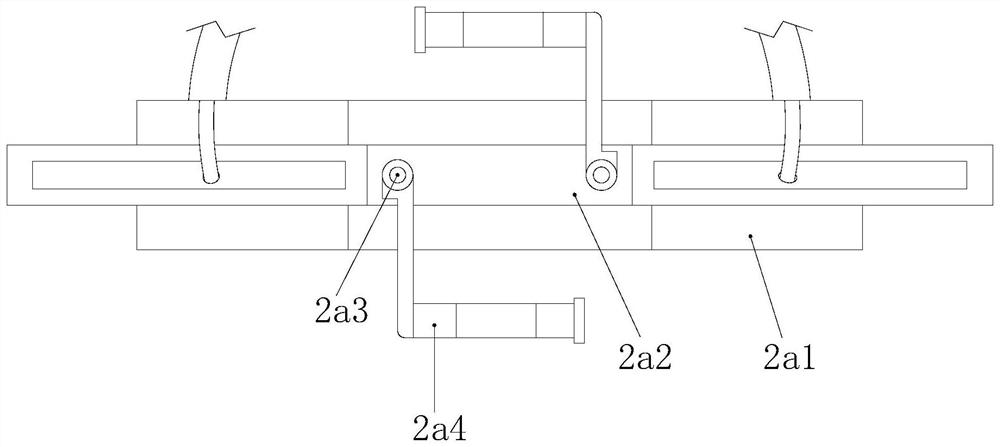

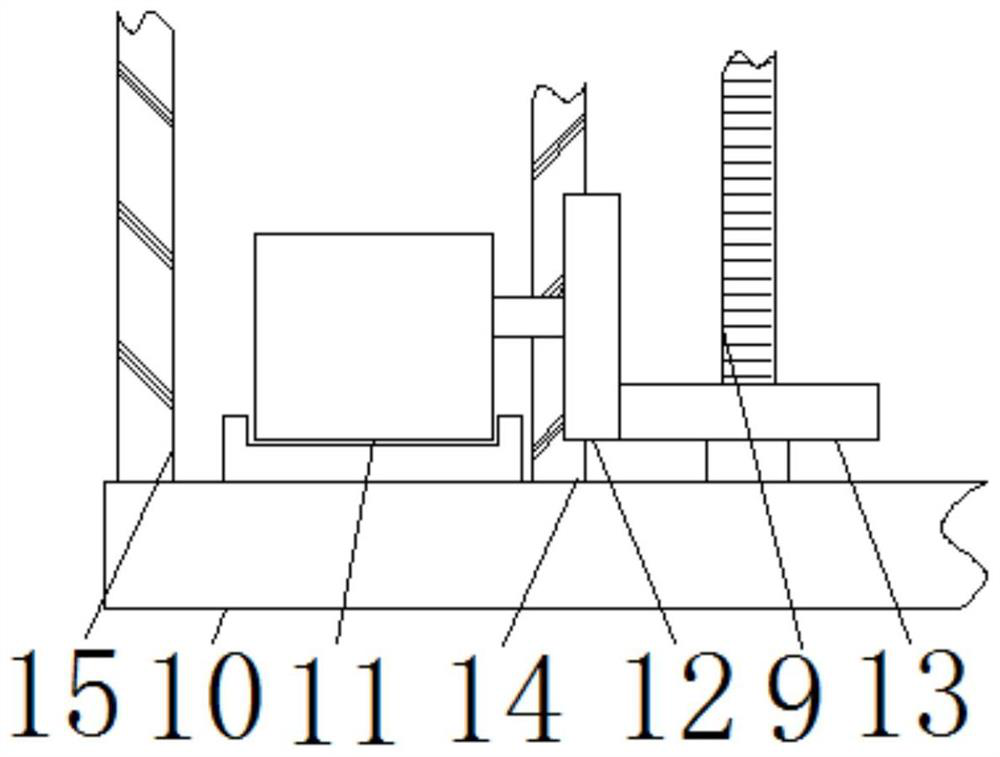

Flax textile dehumidification storage device

InactiveCN108045741AAvoid pollutionSimple structureClosuresContainers preventing decayElectric machineryEngineering

The invention relates to the technical field of dehumidification devices, and discloses a flax textile dehumidification storage device. The flax textile dehumidification storage device comprises a rack body; the rack body is rotationally connected with rolling wheels through rotary shafts, the two sides of the rack body are both fixedly connected with fixing devices, and partition plates are fixedly installed in the rack body; the inner wall of the rack body is fixedly connected with fans, and the rack body is internally and fixedly connected with a motor; and the output end of the motor is fixedly connected with a threaded rod, the surface of the threaded rod is provided with a bearing, and a threaded block is in threaded connection with the surface of the threaded rod. According to the flax textile dehumidification storage device, by arranging the fans, a dustproof cover and a bridge plate, the dustproof cover arranged at the top end of the rack body conducts dedusting on air entering the device, the device is prevented from being polluted by external pollution sources, ventilation drying is further conducted on the air through water absorption sponges and the fans, the structureis simple, using is convenient, and accordingly, the good dampproof effect is achieved.

Owner:盐城金科亚麻纺织有限公司

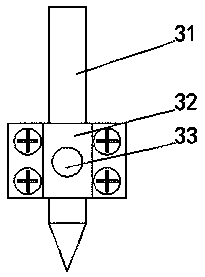

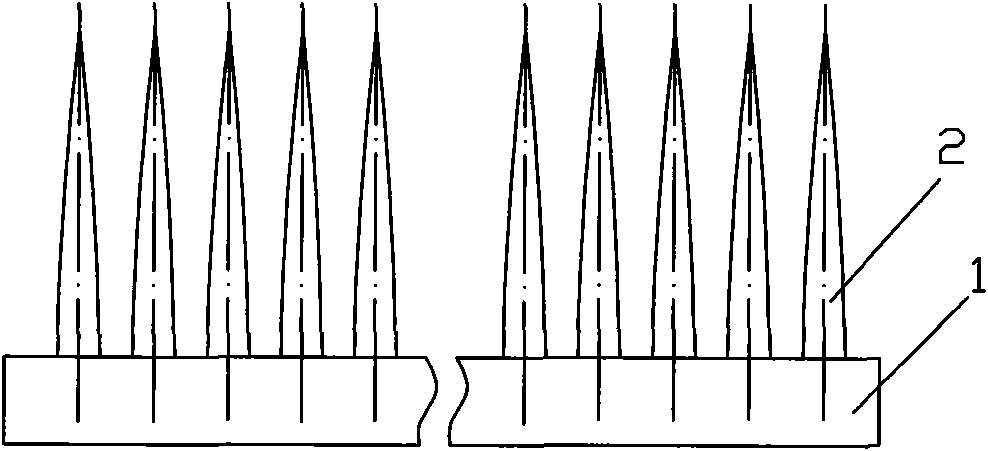

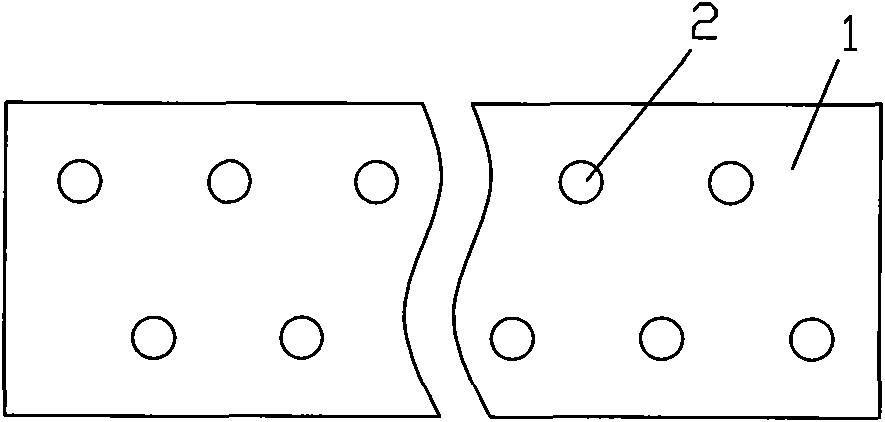

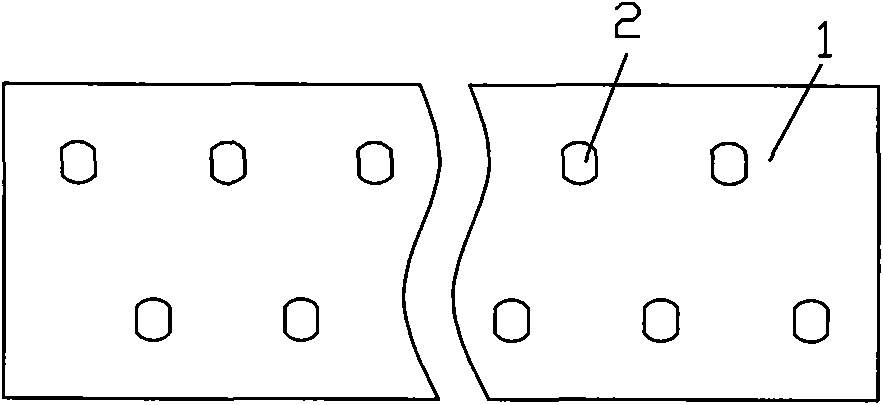

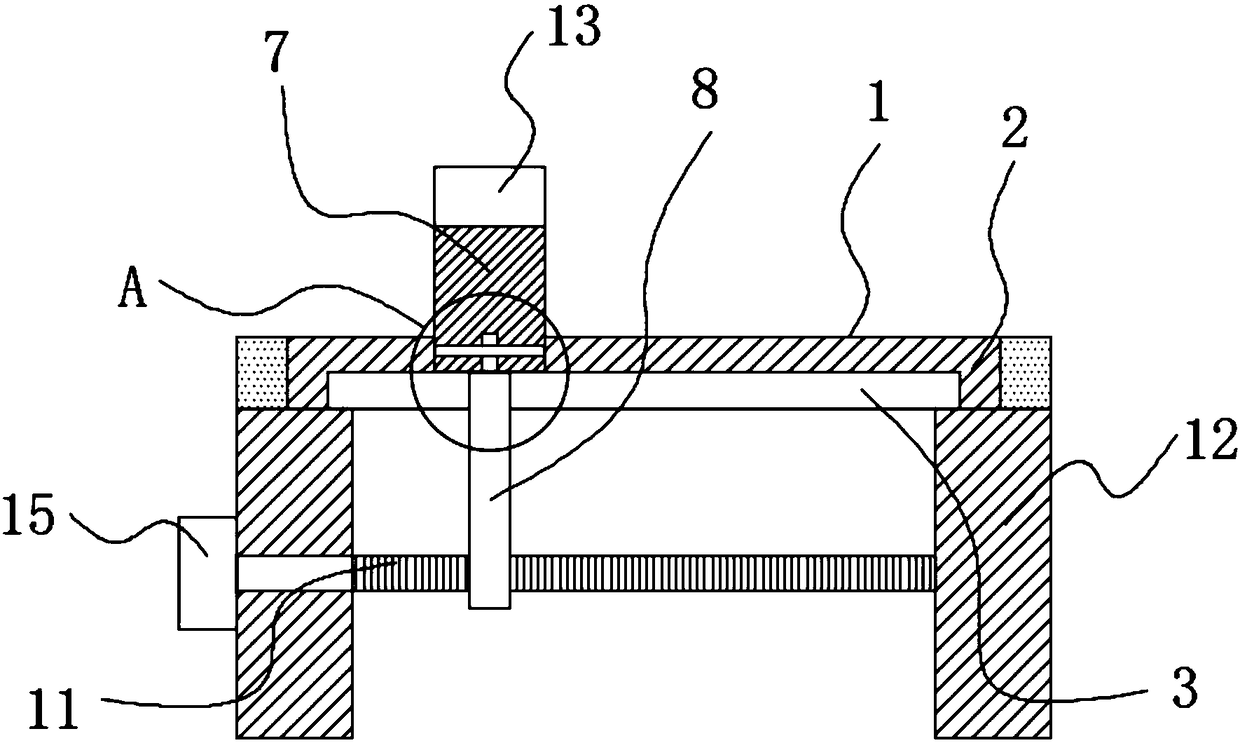

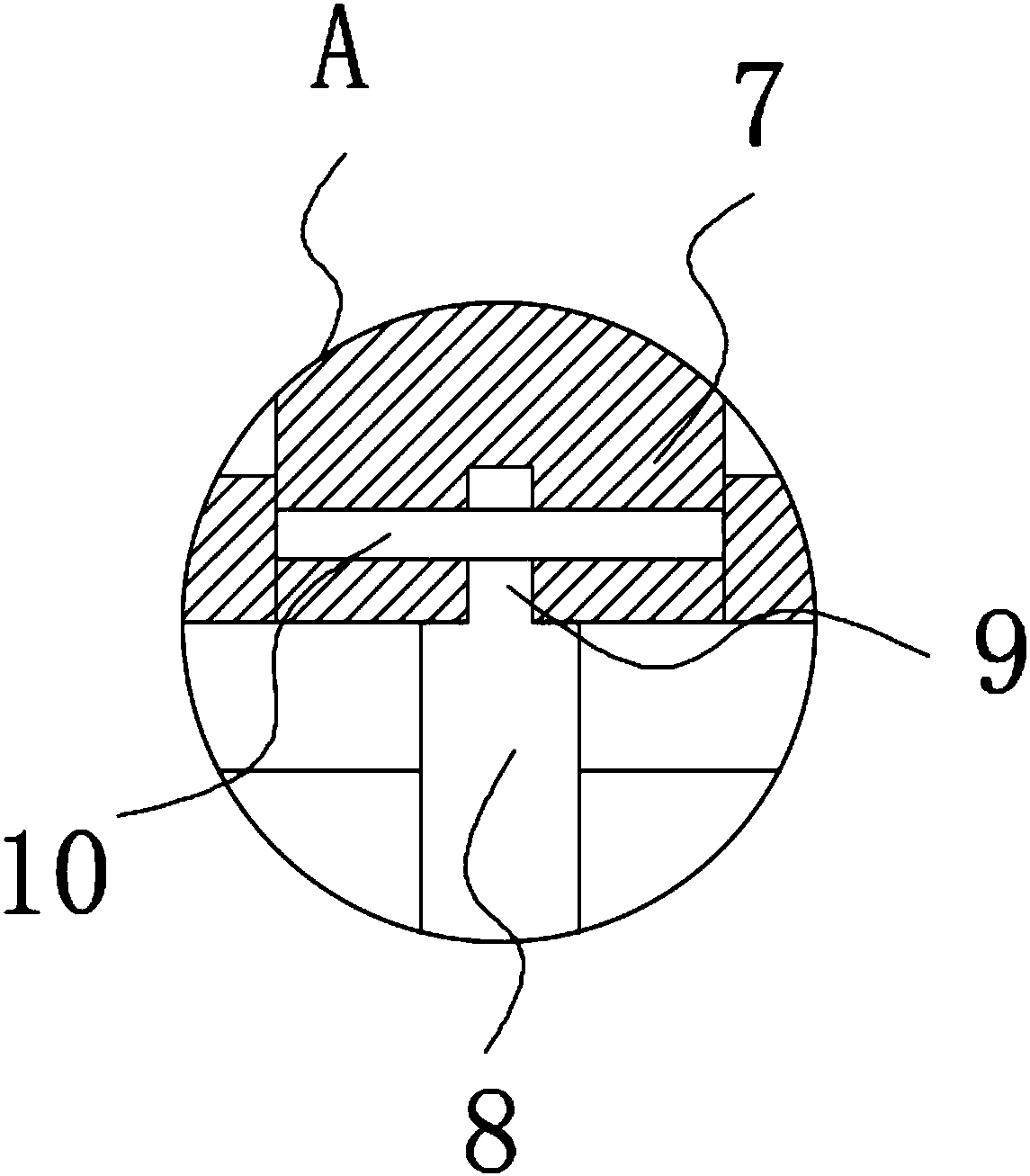

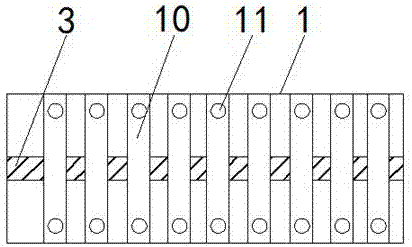

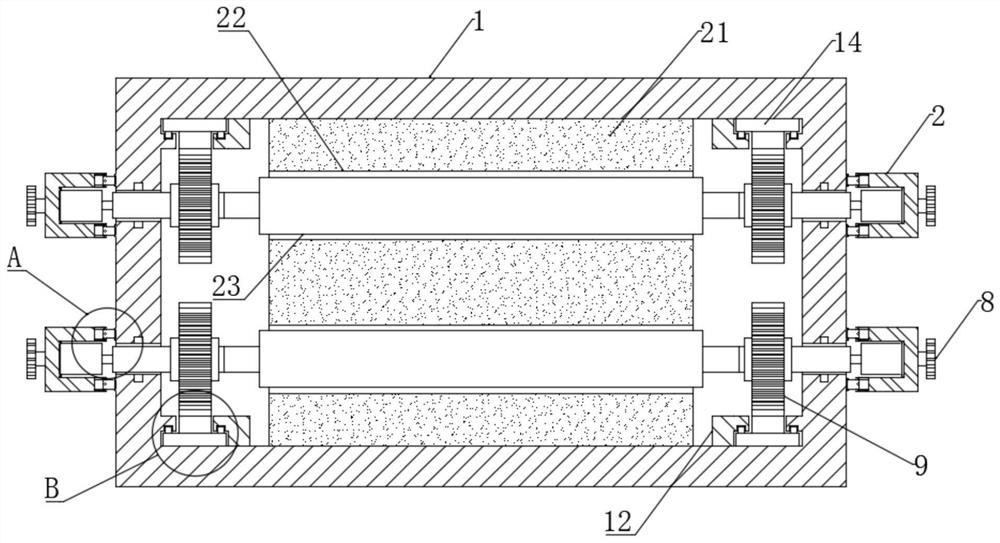

Needle bed for textile machine

The invention relates to a needle bed for a textile machine, which comprises a fixing rack and needles, wherein tail ends of the needles are buried in the fixing rack; the fixing rack is at least provided with a first row of needles and a second row of needles which are parallel to each other; the first row of needles and the second row of needles are staggered. The invention has the advantages of reduced contact area of needle bodies, improved strength of the needle bodies, uniform flax straps of flax textiles such as sisal, jute, flax and the like, reduced use amount of needles, reduced cost and increased efficiency.

Owner:钱俊

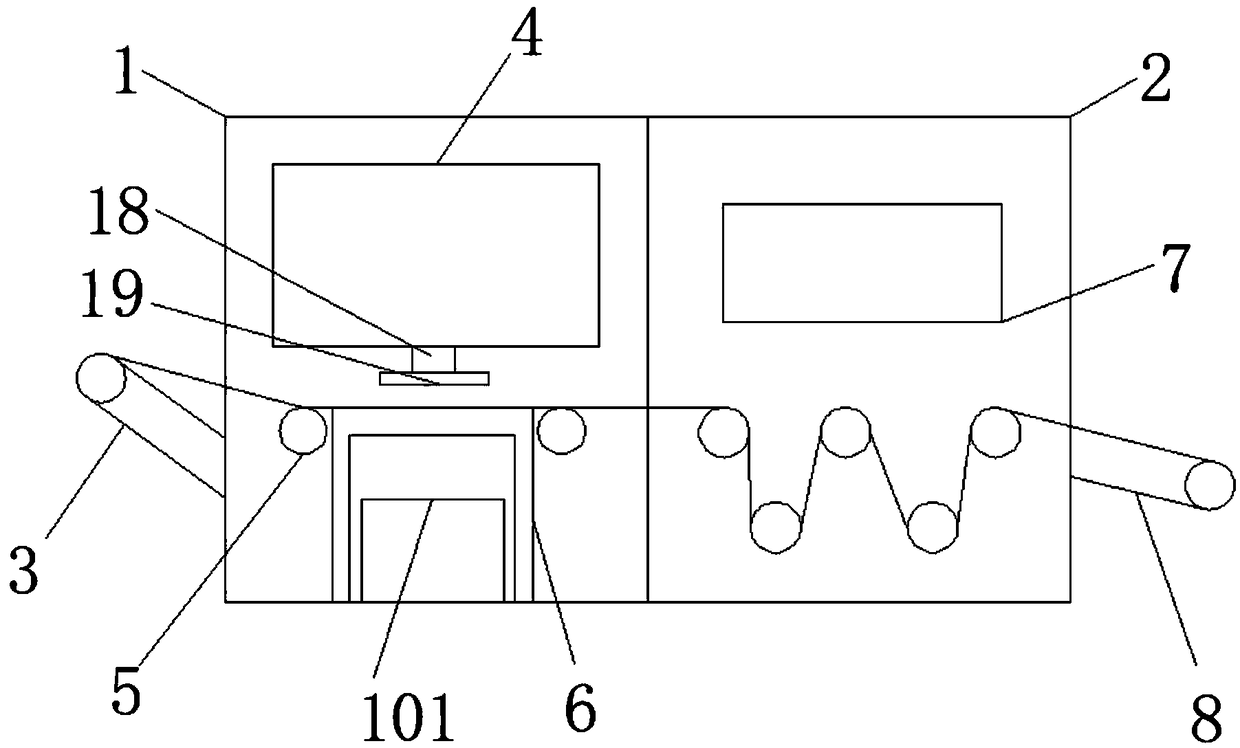

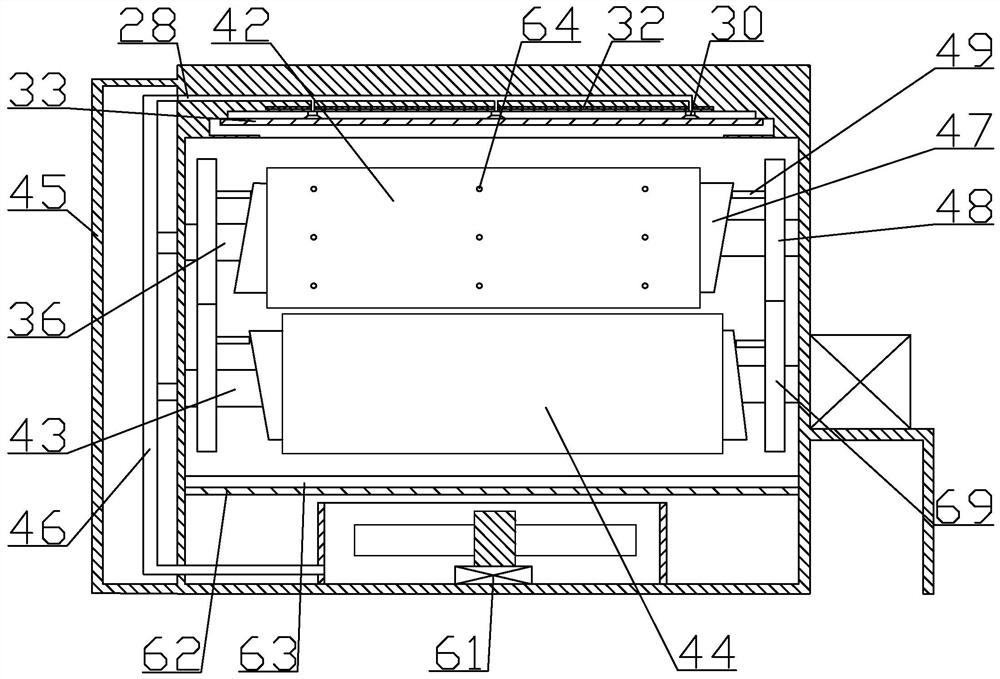

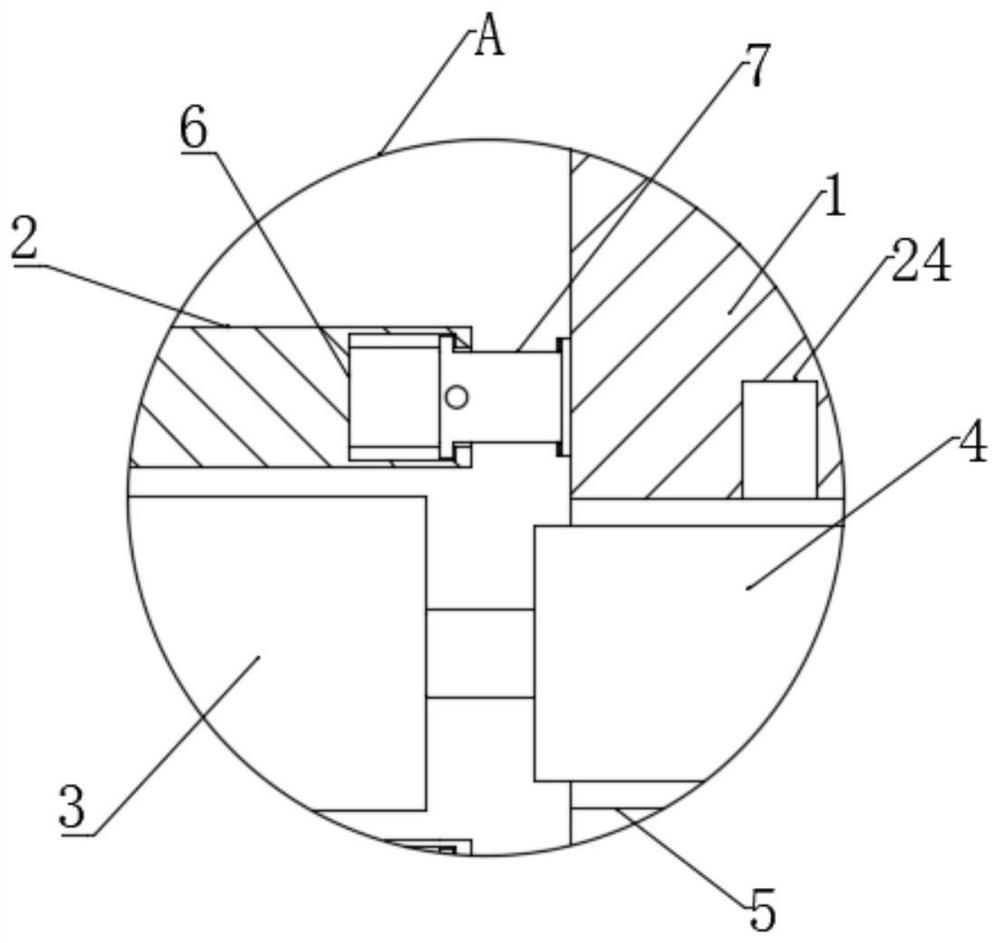

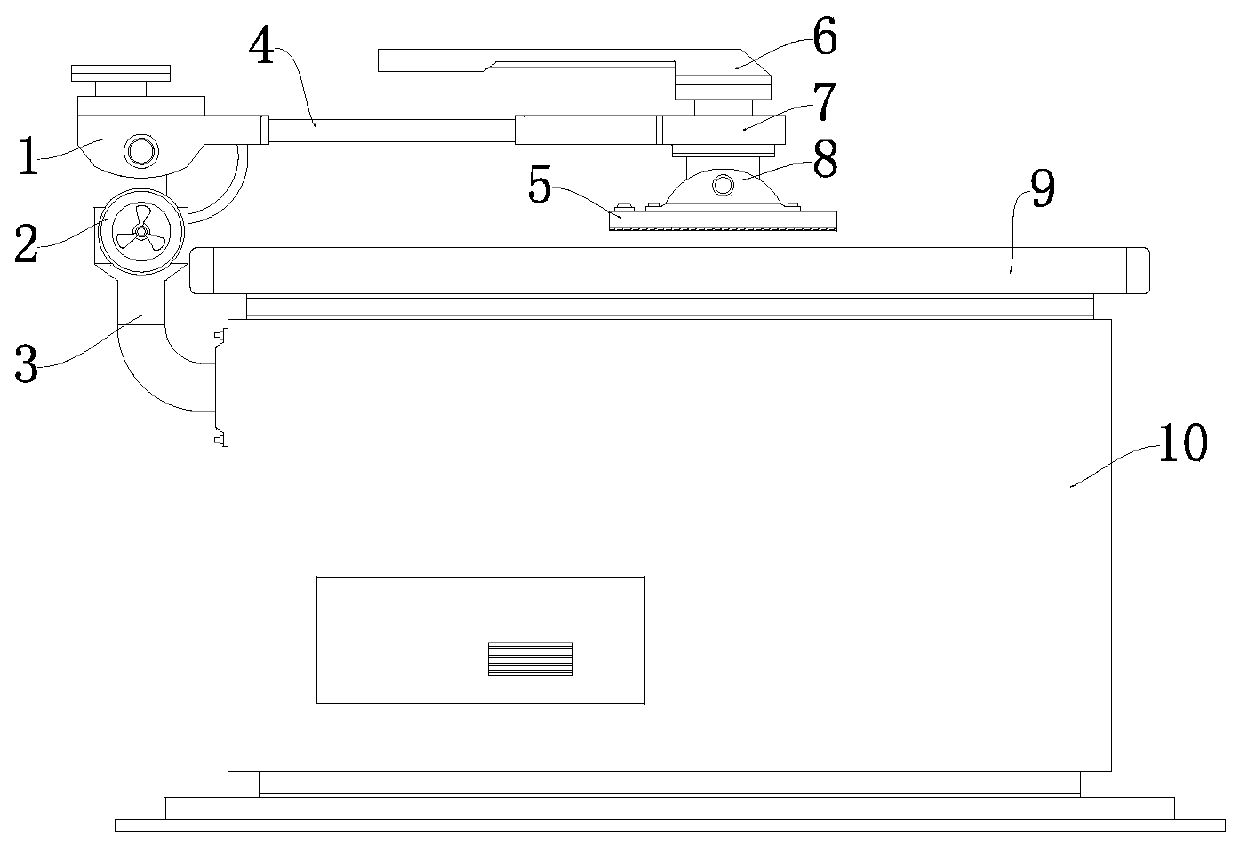

Textile finishing device for flax textile processing

InactiveCN109208216ASolve the situation that the large amount of moisture in linen textiles cannot be effectively removedAchieve dehydration effectLiquid/gas/vapor removal by squeezingTextile treatment carriersDewateringTextile processing

Owner:浙江载信亚麻科技有限公司

Flax textile fabric processing device capable of conveniently ironing

InactiveCN108457032AEasy ironingSolve the situation that it is not convenient to iron the textile fabricTextile shapingEngineeringSlide plate

The invention discloses a flax textile fabric processing device capable of conveniently ironing, and relates to the technical field of textile fabric processing. The flax textile fabric processing device capable of conveniently ironing comprises a box body, a gear, a supporting rod, a slide rail, a slide plate, a slide block, a cavity, a baffle plate, a telescopic pole, a spring and a connecting rod, wherein the gear is arranged at the top end of the inner cavity of the box body; the supporting rod and the slide rail are separately arranged at the upper end and the lower end of the inner cavity of the box body; the middle part of the bottom end of the slide block is fixedly connected with one end of the connecting rod; the other end of the connecting rod penetrates through the bottom end of the box body and is positioned at the outer side of the box body; and the other end of the connecting rod is fixedly connected with an ironing device. According to the flax textile fabric processingdevice capable of conveniently ironing disclosed by the invention, the gear, the supporting rod, the slide rail, the slide plate, the slide block, the connecting rod, the ironing device and the slideslot are matched, so that the effect of conveniently ironing the flax textile fabric is achieved, and therefore, the condition that an existing flax textile fabric processing device is inconvenient for ironing the textile fabric is solved.

Owner:浙江载信亚麻科技有限公司

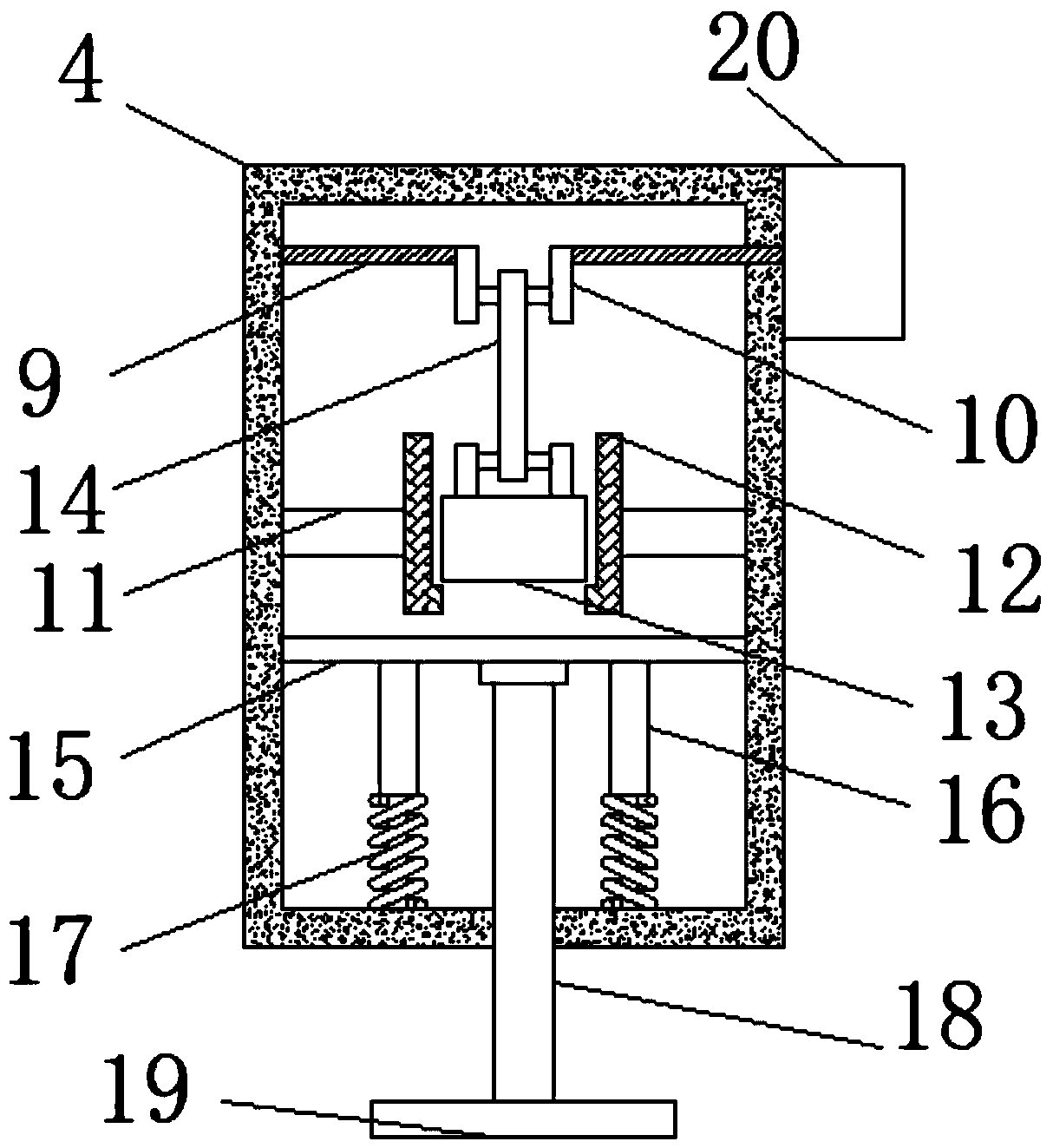

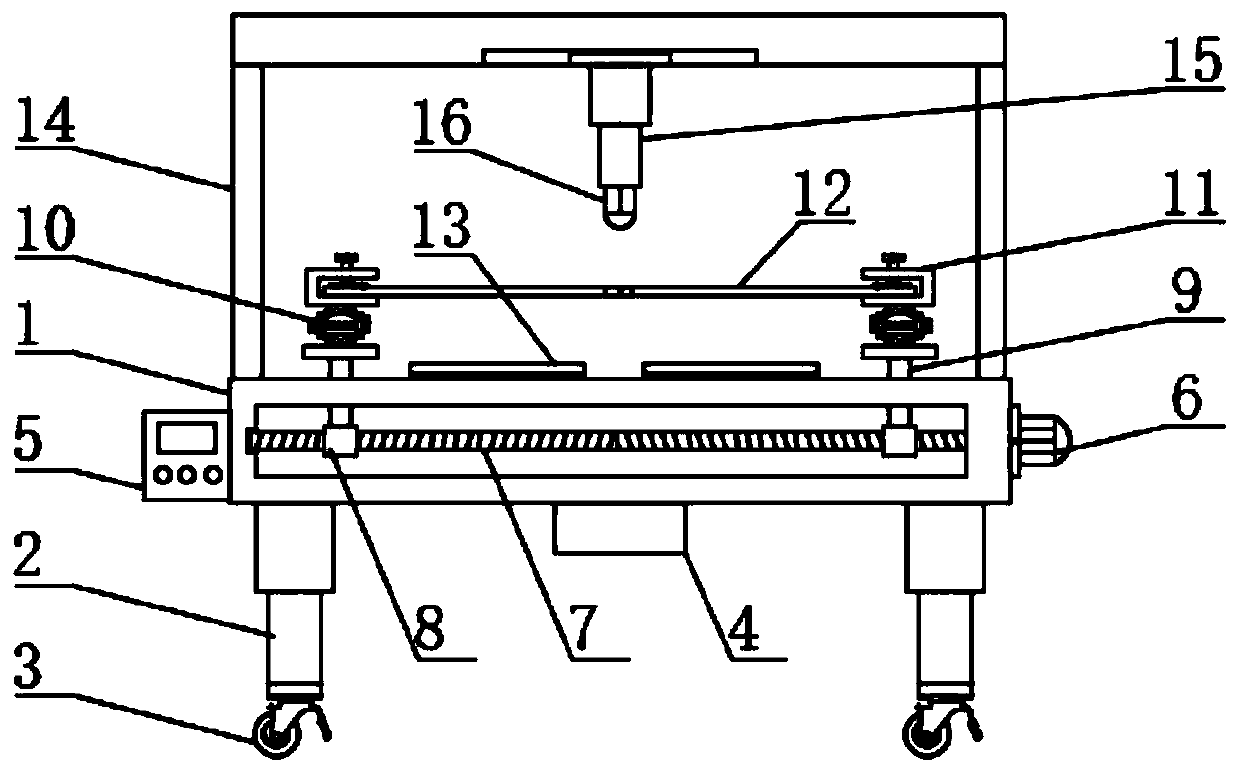

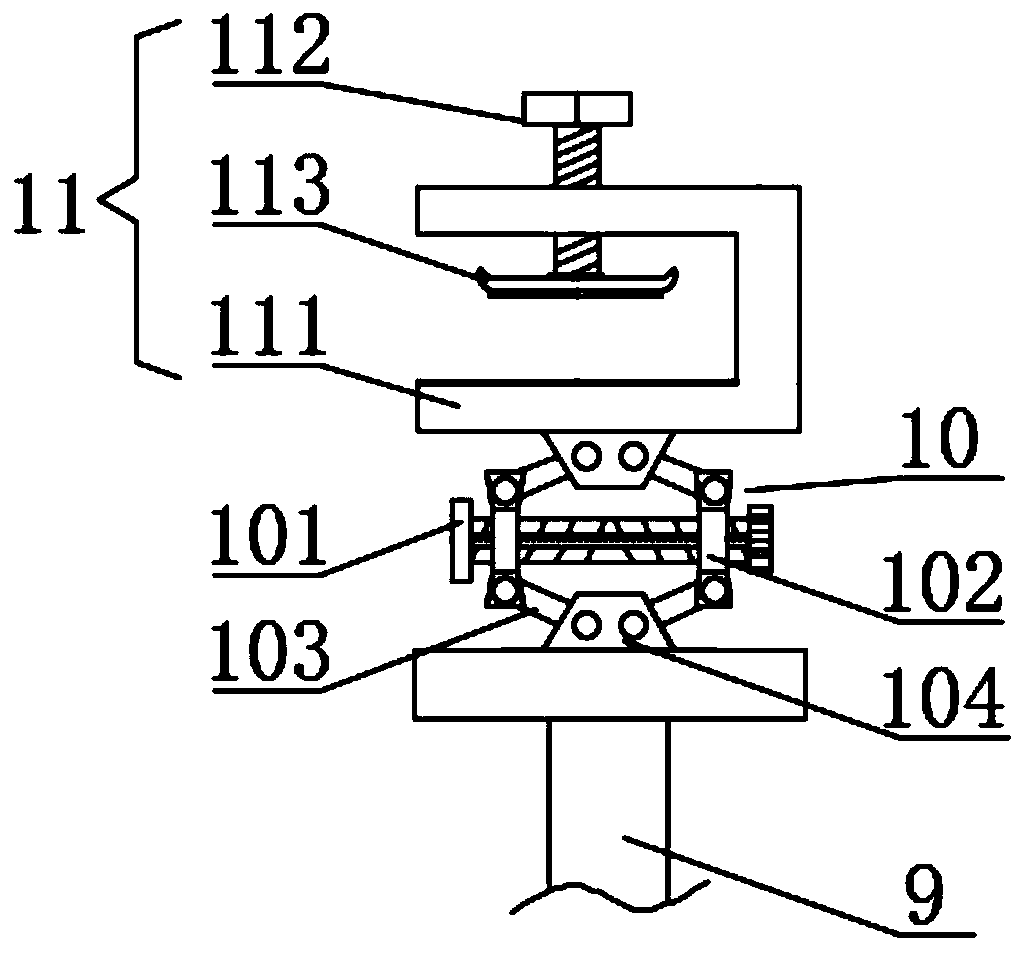

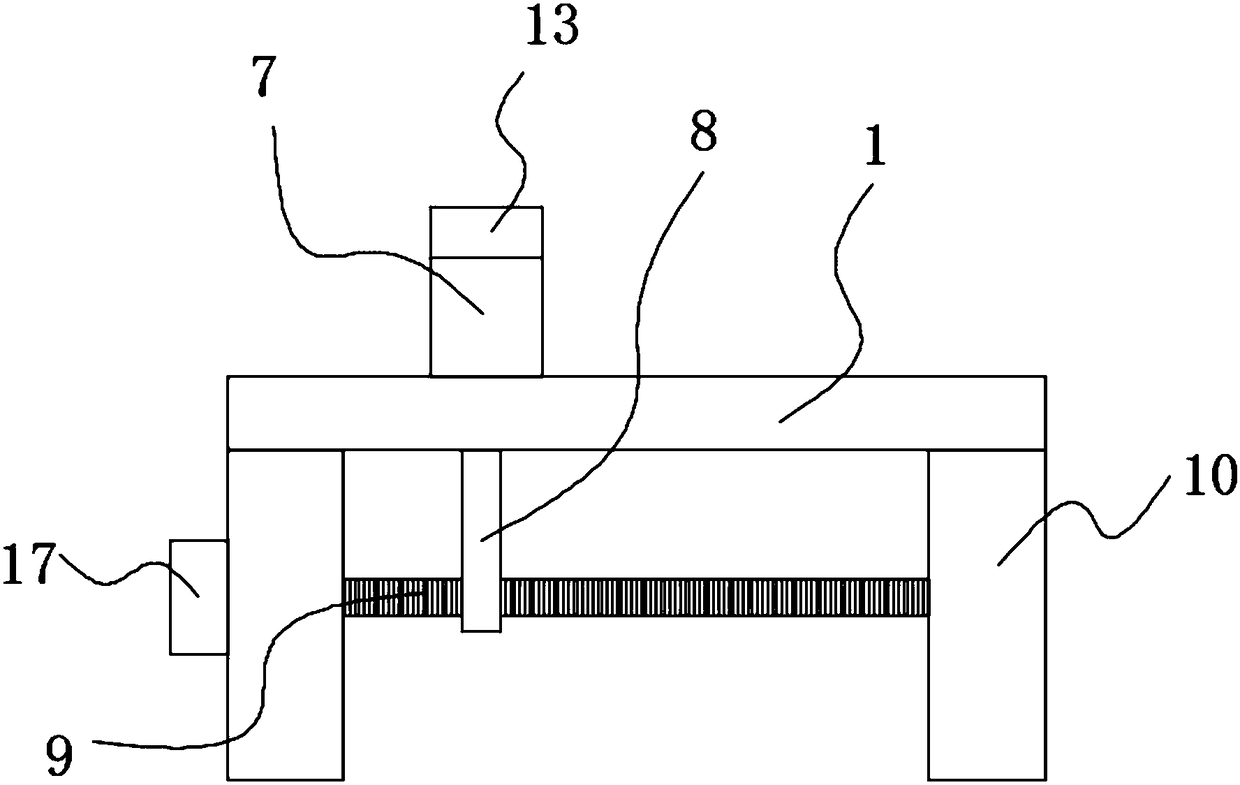

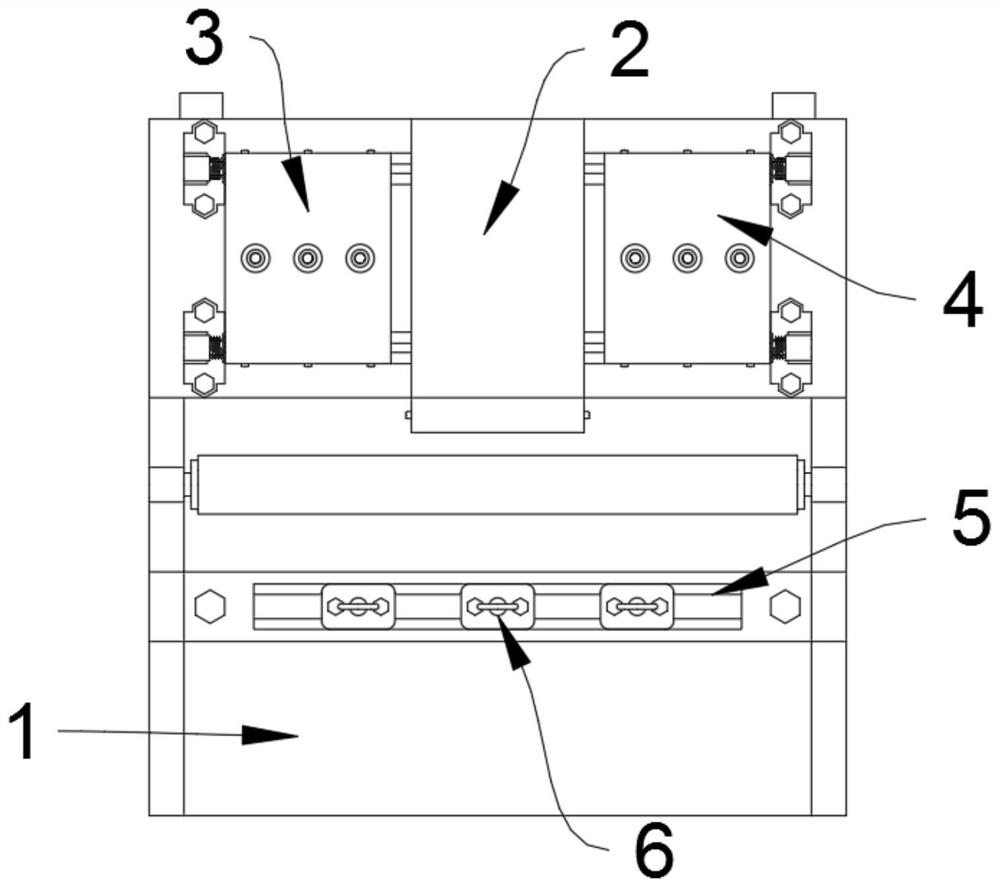

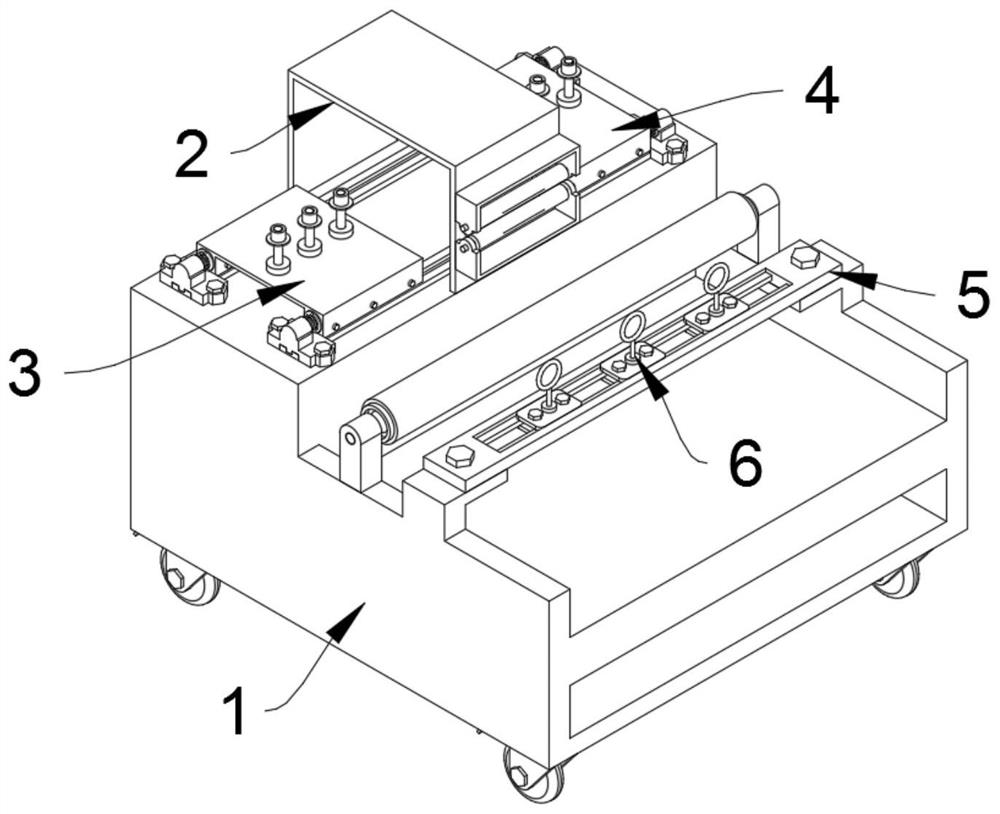

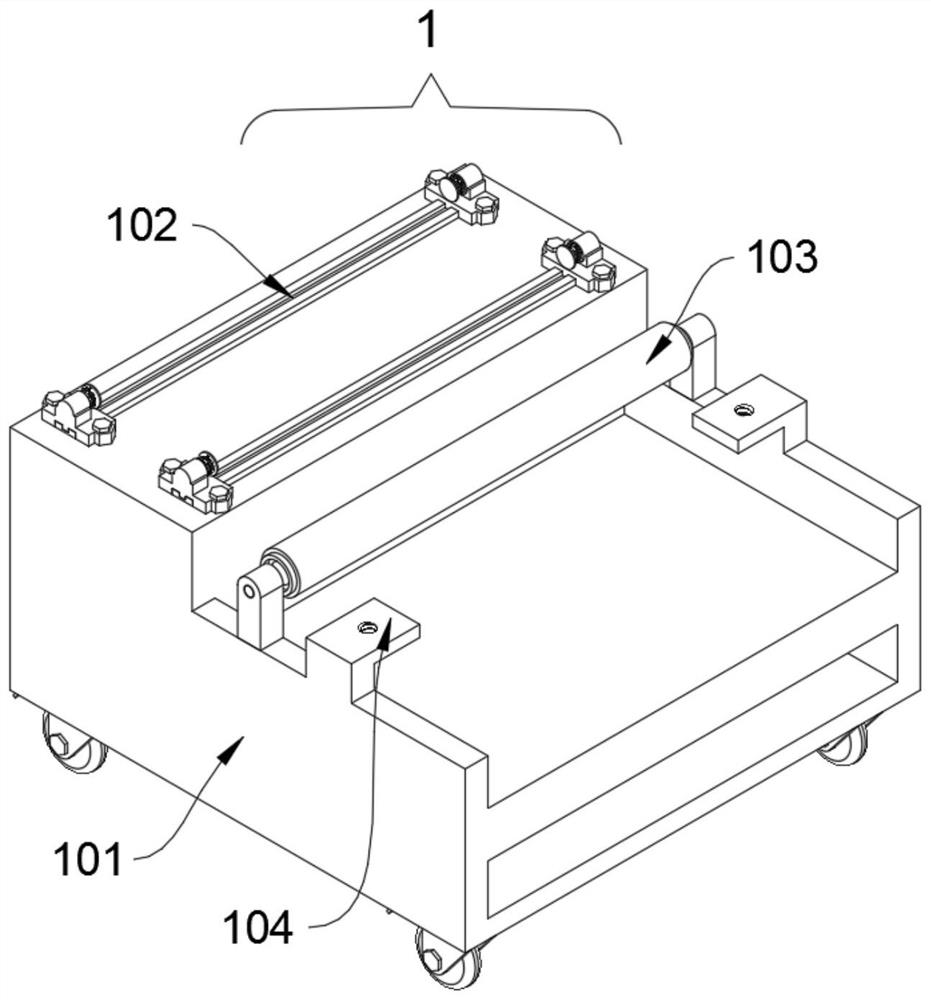

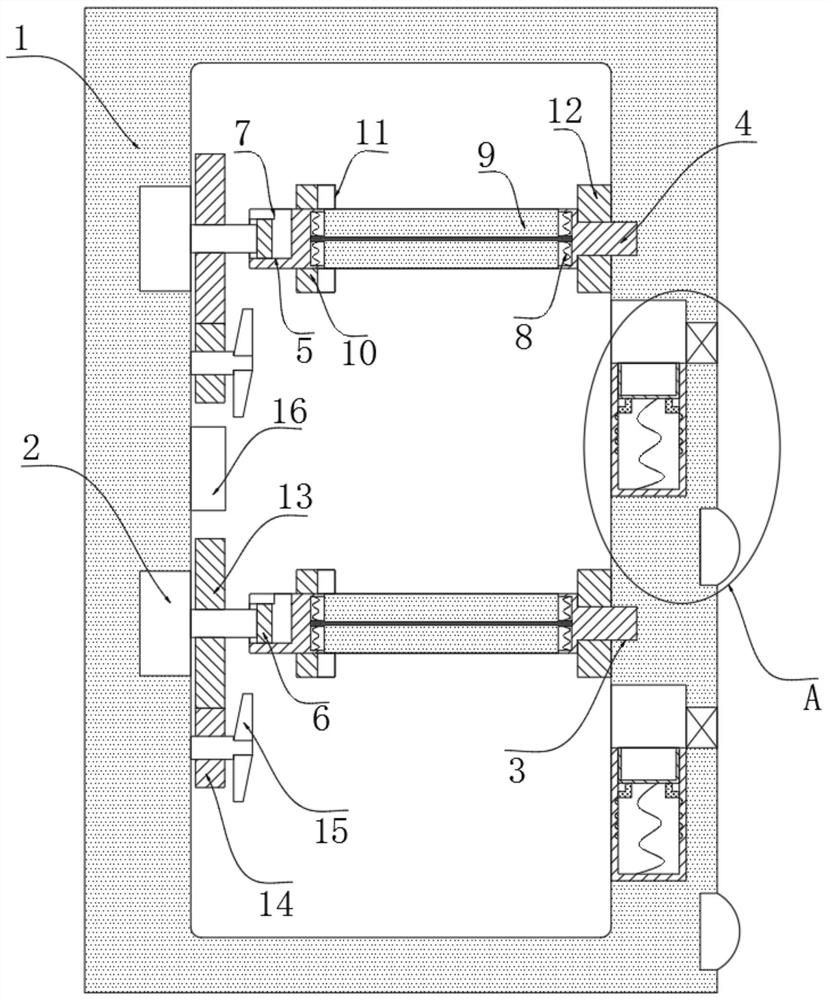

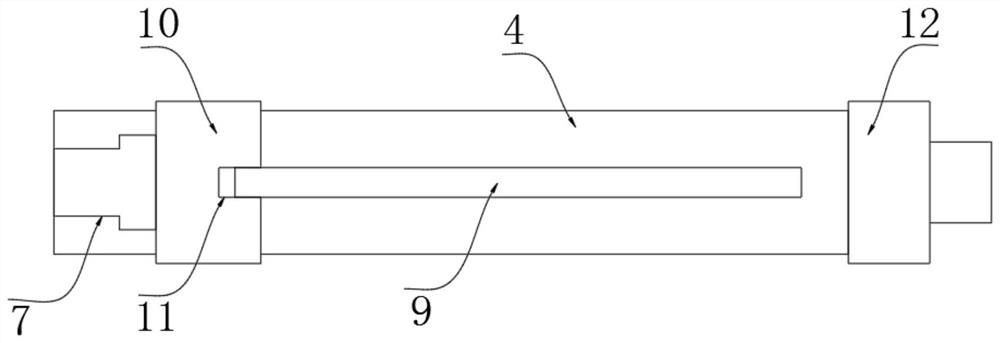

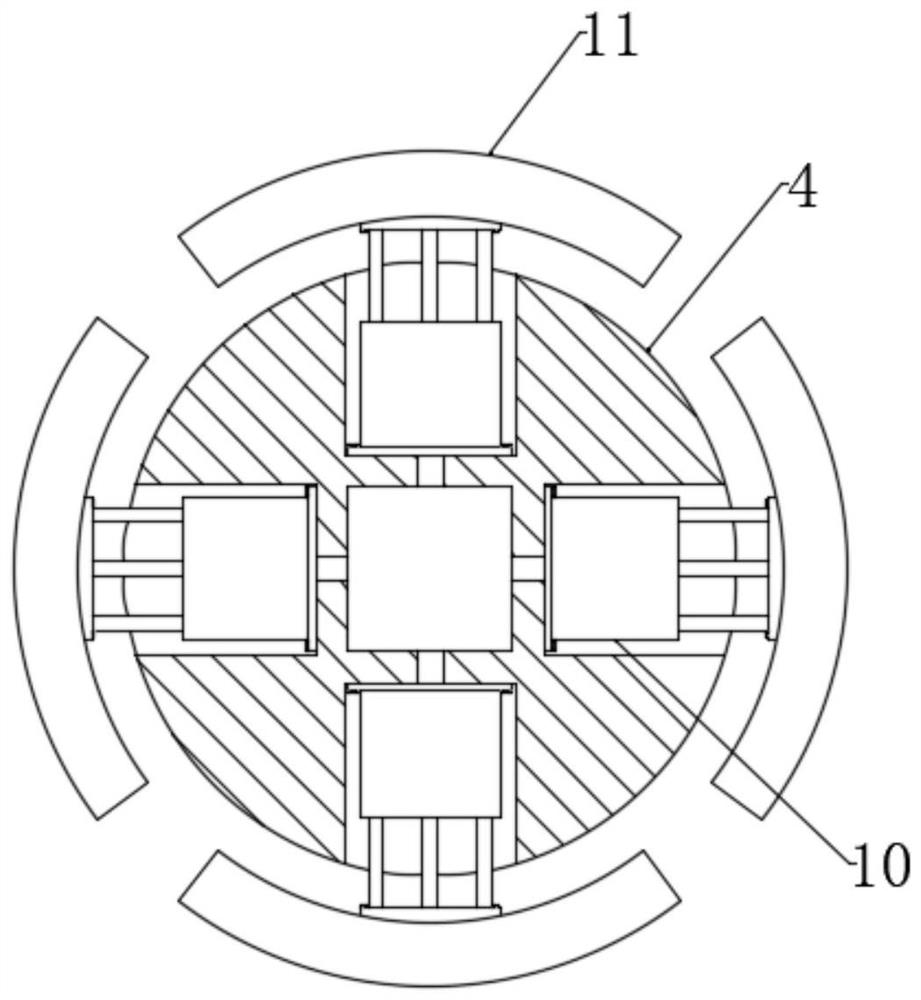

Convenient-to-clamp quality detection device and method for flax textile production

The invention discloses a convenient-to-clamp quality detection device for flax textile production in the technical field of flax textile production. The quality detection device comprises a workbenchwith a hollow structure, wherein a control box and a motor are mounted on the outer walls of the left and right sides of the workbench respectively; two nuts I are symmetrically mounted on the outerwalls of the left and right sides of a bidirectional screw; four lighting devices are symmetrically mounted on the top of the workbench; a thimble is mounted at the bottom end of an electric telescopic rod II. The device is simple to operate, realizes adjustment of the height of the workbench, and can be conveniently operated by workers of different heights, clamping devices can fix flax textile bodies of different widths conveniently, workers can conveniently check all flaws and holes in the flax textile bodies clearly by irradiation of lamp tubes, the stretching, topping and expansion conditions that the joints of the flax textile body can be known by the workers conveniently, and whether quality of the produced flax textile bodies is up to standard can be judged conveniently.

Owner:刘霄

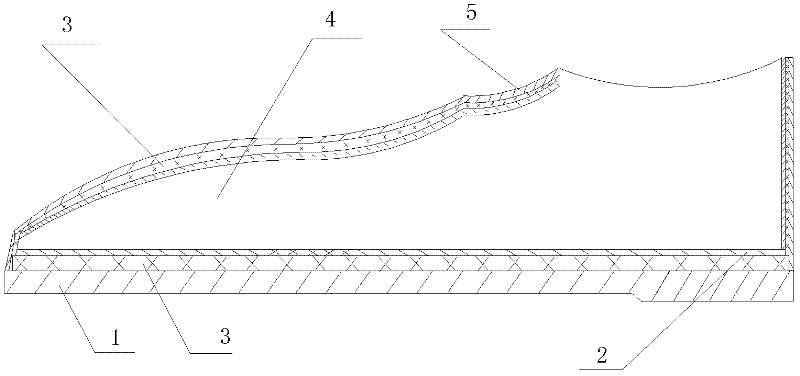

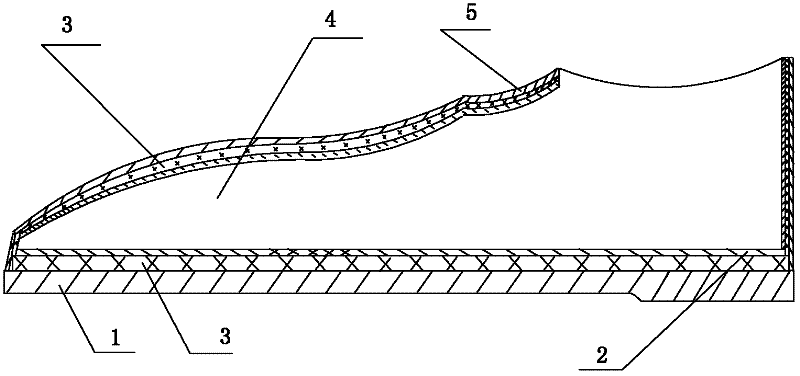

Silver-bearing antibacterial deodorizing shoe

The invention relates to a shoe, in particular to a silver-bearing antibacterial deodorizing shoe, which belongs to the field of daily articles. The silver-bearing antibacterial deodorizing shoe comprises a sole and an upper, the sole comprises a big sole and an insole, a vamp and a shoe lining are sewed together to form the upper, and the upper and the sole are stuck together with glue or sewed together with threads. The silver-bearing antibacterial deodorizing shoe is characterized in that: a layer of silver-bearing antibacterial agent is applied on the insole, a layer of silver-bearing antibacterial agent is applied on the shoe lining, the vamp, the shoe lining and the insole are made of an animal fur, a bamboo fiber textile, a hemp textile, a flax textile, a ramie textile or other plant fiber textiles with antibacterial and sterilizing properties and air permeability, and the silver-bearing antibacterial agent is metal silver plated on the plant fiber textiles by the electroplating technology, or nano-silver applied on the plant fiber textiles or silver nitrate powder, silver sulfate powder or other silver salt powder applied on the plant fiber textiles. The silver-bearing antibacterial deodorizing shoe has a simple structure and remarkable antibacterial, deodorizing, moisture-absorbing and drying effects, and is economic and practical.

Owner:李星海

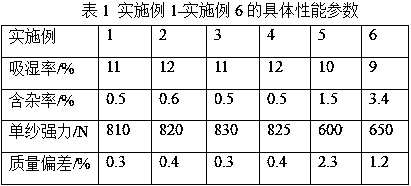

Low-impurity-rate flax textile technology

InactiveCN109295591ALittle strength damageImprove spinnabilityDry-cleaning apparatus for textilesWoven fabricsTextile technologyYarn

The invention relates to the technical field of flax textile, in particular to a low-impurity-rate flax textile technology. The technology comprises the following advantages that 1, flax fiber is subjected to first curing and cleaning in sequence, flax cutting is conducted to obtain dry flax, the dry flax is subjected to cotton carding, combing, drawing, roving and secondary curing, and flax roving is obtained; 2, the flax roving is subjected to acid pickling, boiling off, oxygen bleaching and desizing, and preteated flax roving is obtained for use; 3, the pretreated flax roving is subjected to spinning and spooling, and dry flax bobbin yarn is obtained for use; 4, the dry flax bobbin yarn is made into a dry flax fabric through warping, reeding, weft winding, weaving and cloth inspecting.Accordingly, the problems that the flax yarn impurity rate is high, the flax fabric quality is unstable are solved, the prepared flax yarn is low in impurity rate, and the flax fabric obtained throughspinning is stable in quality and excellent in performance.

Owner:福建利瑶纺织制衣有限公司

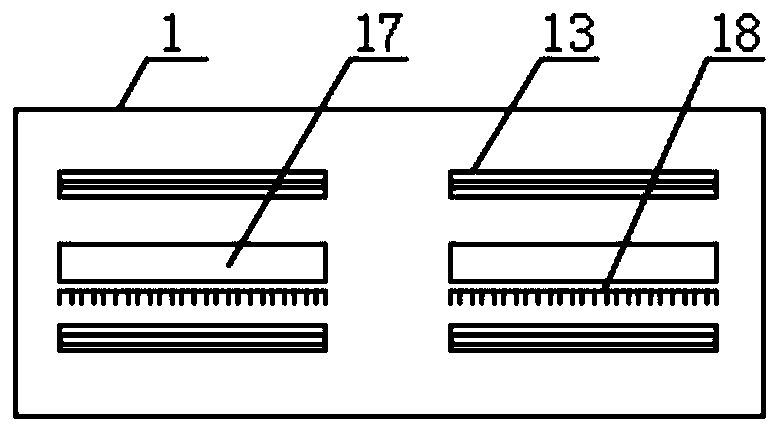

Dyeing device for flax textile processing

InactiveCN108589097AMove at a constant speedEasy to moveLiquid/gas/vapor removalTextile treatment by spraying/projectingEngineeringFriction force

The invention discloses a dyeing device for flax textile processing, and relates to the technical field of flax textile dyeing devices. The dyeing device comprises a workbench, sliding channels are formed in the two ends of the workbench, a sliding groove is formed in the middle of each sliding channel, and moving grooves are formed in the two ends of each sliding channels, and supporting rods arearranged in the middles of the moving grooves. The surfaces of the supporting rods are movably connected with roll wheels, supporting plates are movably connected in the sliding channels, a movable rod is arranged at one end of each supporting plate, a clamping column is fixedly connected with one end of each movable rod, and the other end of each movable rod is movably connected with a lead screw. According to the dyeing device for flax textile processing, the movable rods can drive a top plate to move through rotation of the lead screws, and therefore spray heads evenly dye flax textile cloth; the roll wheels are arranged in the moving grooves, the friction force of the supporting plates on the sliding channels can be reduced, the supporting plates smoothly move, the work efficiency ofdyeing is improved, and the phenomena of uneven dyeing and dyeing omissions are reduced.

Owner:浙江载信亚麻科技有限公司

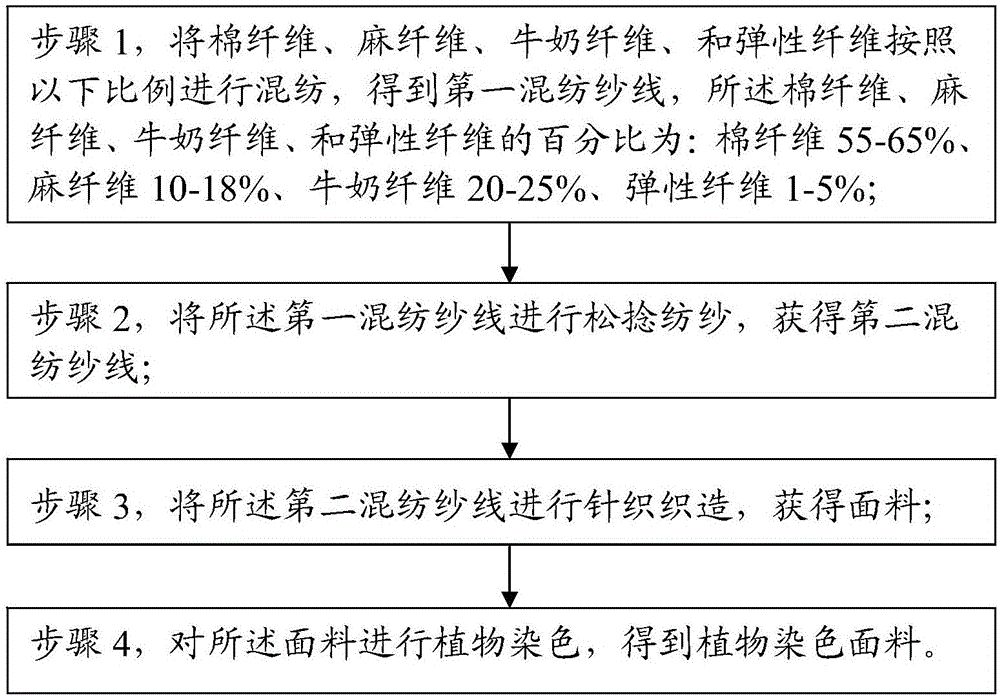

Special fabric for underpants and preparation method for special fabric

The invention discloses a special fabric for underpants and a preparation method for the special fabric. The special fabric is formed by knitting and weaving blended yarns consisting of cotton fibers, hemp fibers, milk fibers and elastic fibers, wherein the percentages of the cotton fibers, the hemp fibers, the milk fibers and the elastic fibers are 55-65%, 10-18%, 20-25% and 1-5% respectively. The special fabric achieves the following effects: (1) the special fabric has the characteristics of softness and skin affinity, and achieves the effect of bacterial inhibition; (2) the special fabric has good bacterial inhibition performance, in addition, a hemp fabric has the functions of temperature adjustment, allergy resistance, static electricity prevention and bacterial resistance, and a flax textile can automatically adjust the temperature, gives a comfortable, natural and relaxed feeling to people and is beneficial to physical and psychological health of people; and (3) due to planting dyeing, the harm of dyes on a human body can be reduced, natural renewable resources can be fully utilized, and the toxicity of dyeing wastewater can be greatly reduced, so that the wastewater treatment burden can be reduced and the environment can be protected.

Owner:BEIJING FLAX CENTURY FLAX TECH DEV

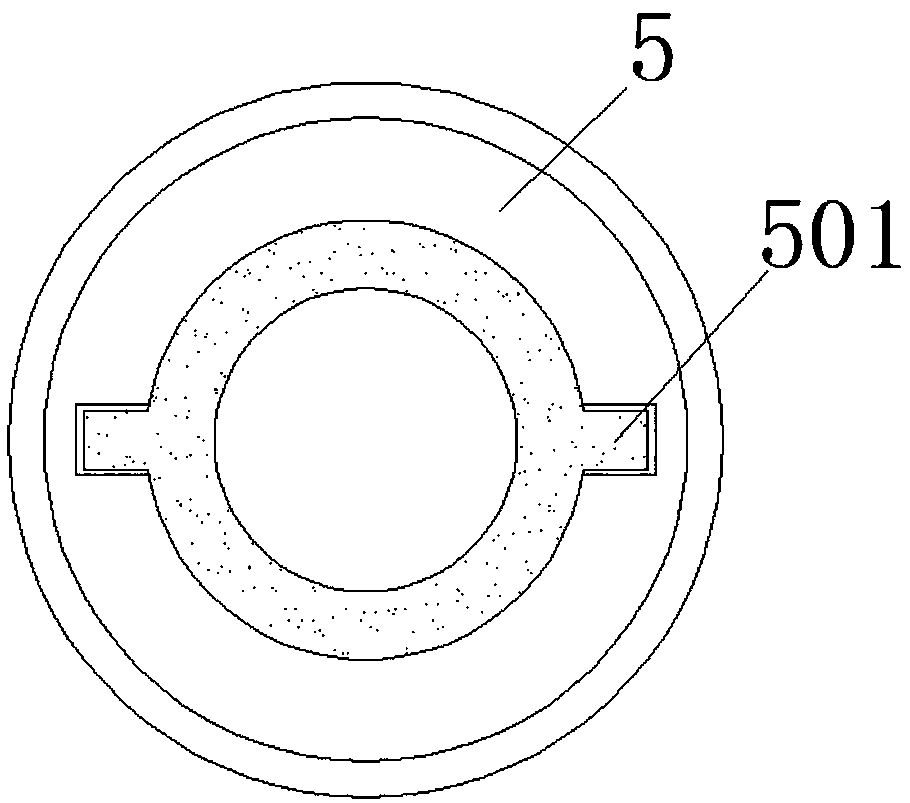

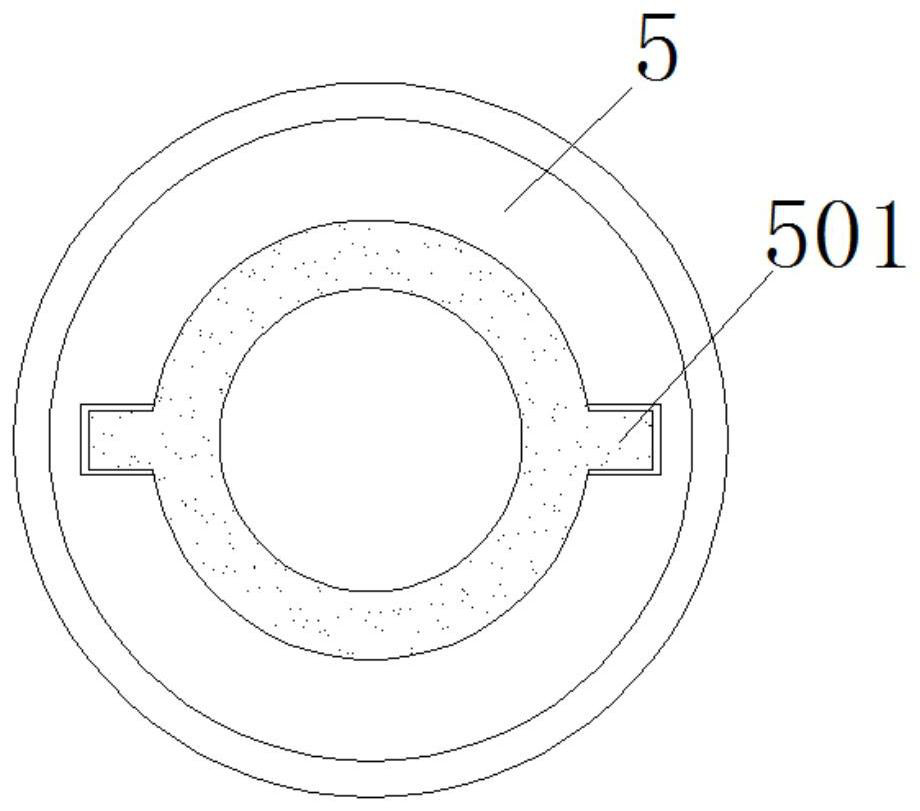

Singeing roll used for dyeing and finishing of flax textile

The invention relates to the technical field of flax textiles, and discloses a singeing roller for dyeing and finishing of flax textiles, comprising a roller body, a motor and a frame body, the output end of the motor is fixedly connected with a rotating shaft, and one end of the rotating shaft is connected to one end of the roller body. Side fixed connection, the outer surface of the roller body is provided with grooves, both sides of the inner wall of the groove are fixedly connected with sliders, the outer surface of the sliders is slidably connected with sliders, and the surface of the sliders is provided with flame nozzles, the roller body The interior is equipped with a cold air duct. In the present invention, by setting the roller body, the motor, the rotating shaft, the groove, the slide rod, the slider, the fire nozzle, the valve and the fire door, the fire nozzle performs singeing operation on the surface of the cloth, and once the singeing operation is completed, the fire door is closed Into the cooling and hair blowing operation, one multi-purpose, greatly simplifies the existing structure, saves multiple processes, does not need to install additional cooling devices or hair blowing devices, and saves enterprise costs for singeing, dehairing and cooling operations.

Owner:盐城金科亚麻纺织有限公司

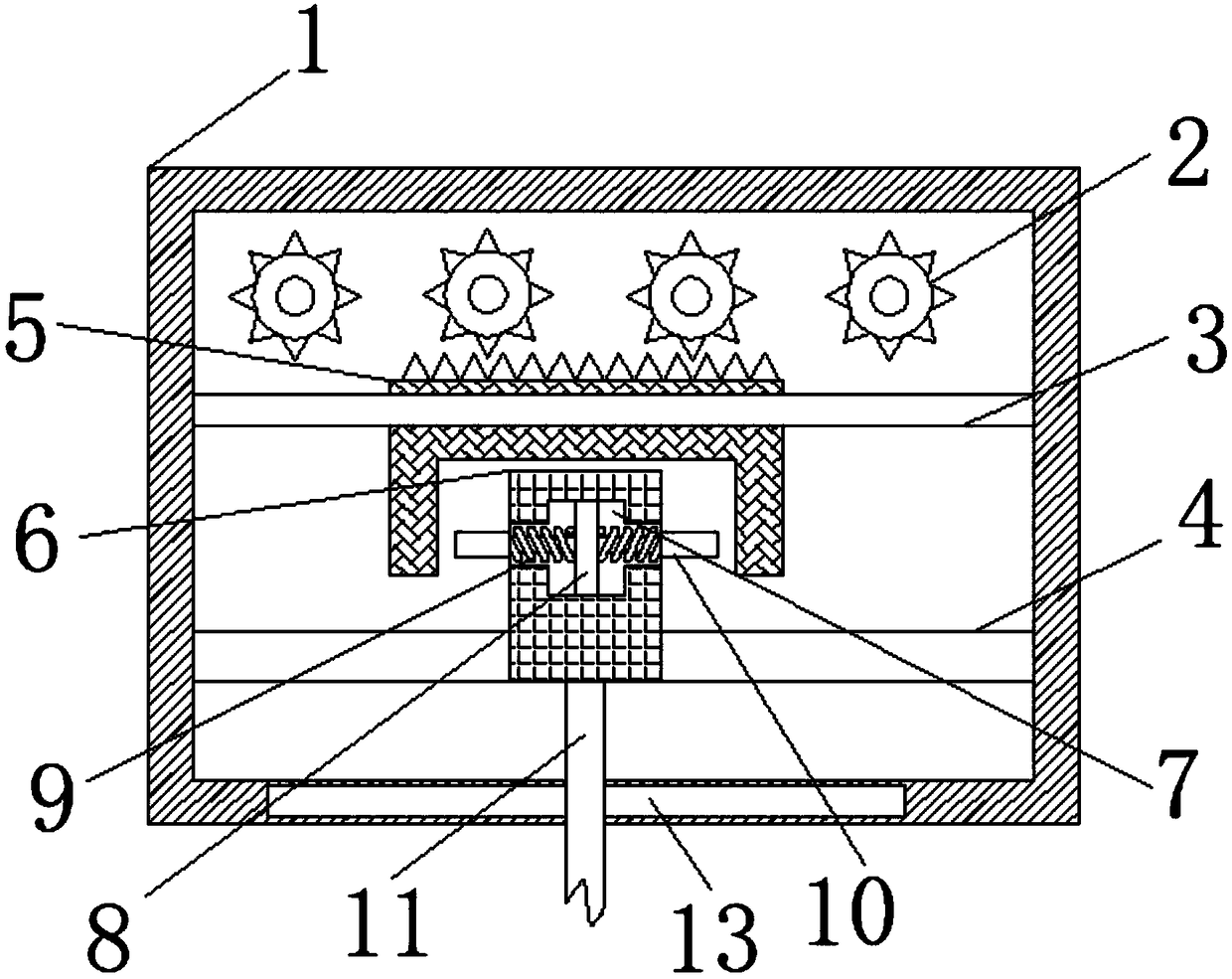

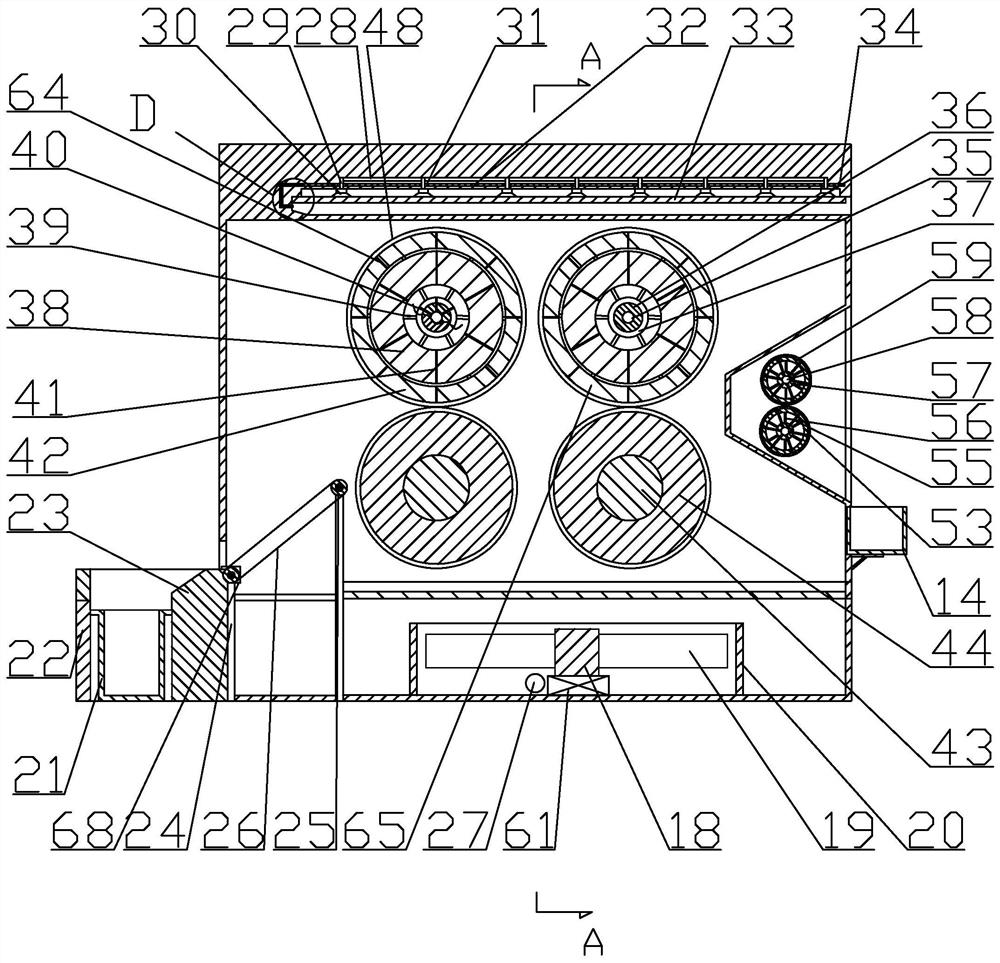

Dust removing device for two surfaces of textile machine for flax textile processing

InactiveCN108729180AImprove adsorption capacityAdsorption fineMechanical cleaningPressure cleaningEngineeringTextile bleaching

The invention discloses a dust removing device for two surfaces of a textile machine for flax textile processing, and relates to the technical field of textile dust removing. The dust removing devicecomprises a dust removing room, and the interior of the dust removing room is fixedly provided with a plurality of conveying belts. The central parts of the upper and lower surfaces of the dust removing room are fixedly connected with dust suction ports, and one end of each dust suction port is located in the dust removing room. The other ends of the two dust suction ports pass through the centralpart of the upper surface of the dust removing room, and are fixedly connected with one end of one dust suction pipe. The other ends of the dust suction pipes are respectively fixedly connected withthe upper and lower ends of a combiner. The dust removing device enables textile fabric to be conveyed to the dust removing room through a conveying belt, and achieves the absorption of the flocculesand accumulated dust on the textile fabric through the two dust suction ports. Moreover, the combiner enables the ends of the two dust suction pipes to be combined, and to enter an accommodation roomfrom one side of the combined through an attracting force of an air pump.

Owner:浙江载信亚麻科技有限公司

Method for modifying and degumming jute fibers

InactiveCN103710764AImprove grade and add valueHigh economic and social benefitsFibre treatment to obtain bast fibreChemistrySodium sulfites

The invention discloses a method for modifying and degumming jute fibers, relating to the technical field of jute spinning. The degumming method comprises the following steps: (1) putting jute in a steamer, submerging all the jute into water, then adding sodium sulfite and a softening agent and steaming the jute at a high temperature being 105-115 DEG C for 6-9 hours; (2) fishing up the jute, washing the jute with clear water cleanly, then dehydrating the jute with a spin dryer and then drying the jute in the sun or drying the jute; (3) sending the jute onto a softening machine and adding linen softening oil and cellulase while beating the jute; (4) stowing the jute to be preserved at 20-30 DEG C for 3-7 days, thus degumming and modifying the jute into linen fabrics. Compared with the prior art, the method has the advantages and positive effects that the softness of the jute is improved and the spinnability of the jute is enhanced, thus solving the problem of scratchiness to the skins; the grade and the added values of the jute products are increased and great social and economic benefits are achieved; the state that the jute fiber resources are only used for extensive spinning for a long time and cannot be effectively utilized in the fields of garments and home textile fabrics is changed.

Owner:WUXUE XINJI JUTE TEXTILE CO LTD

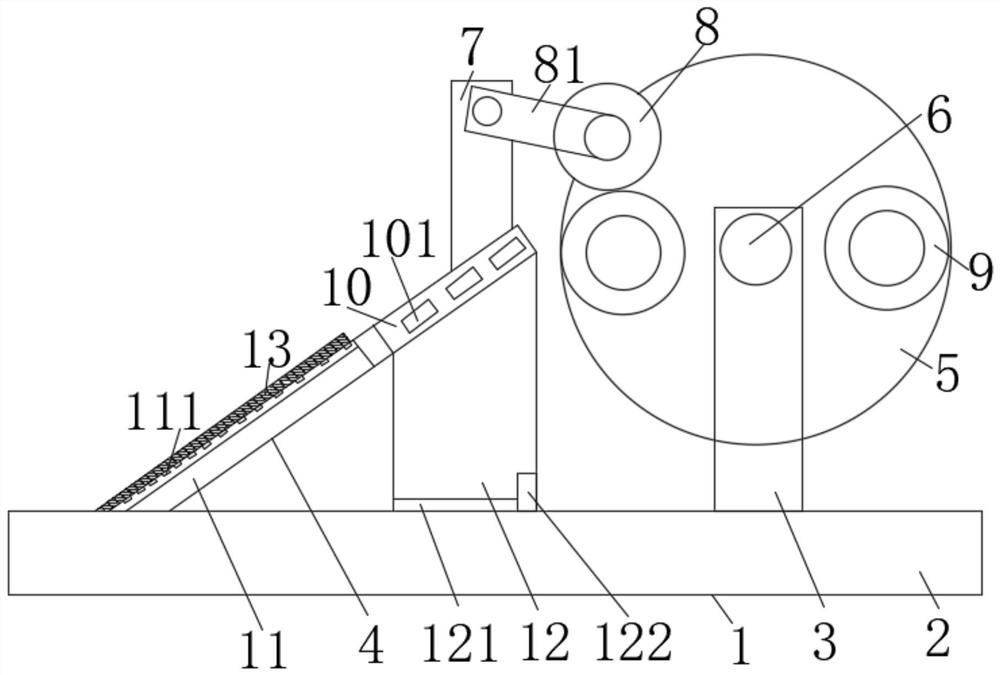

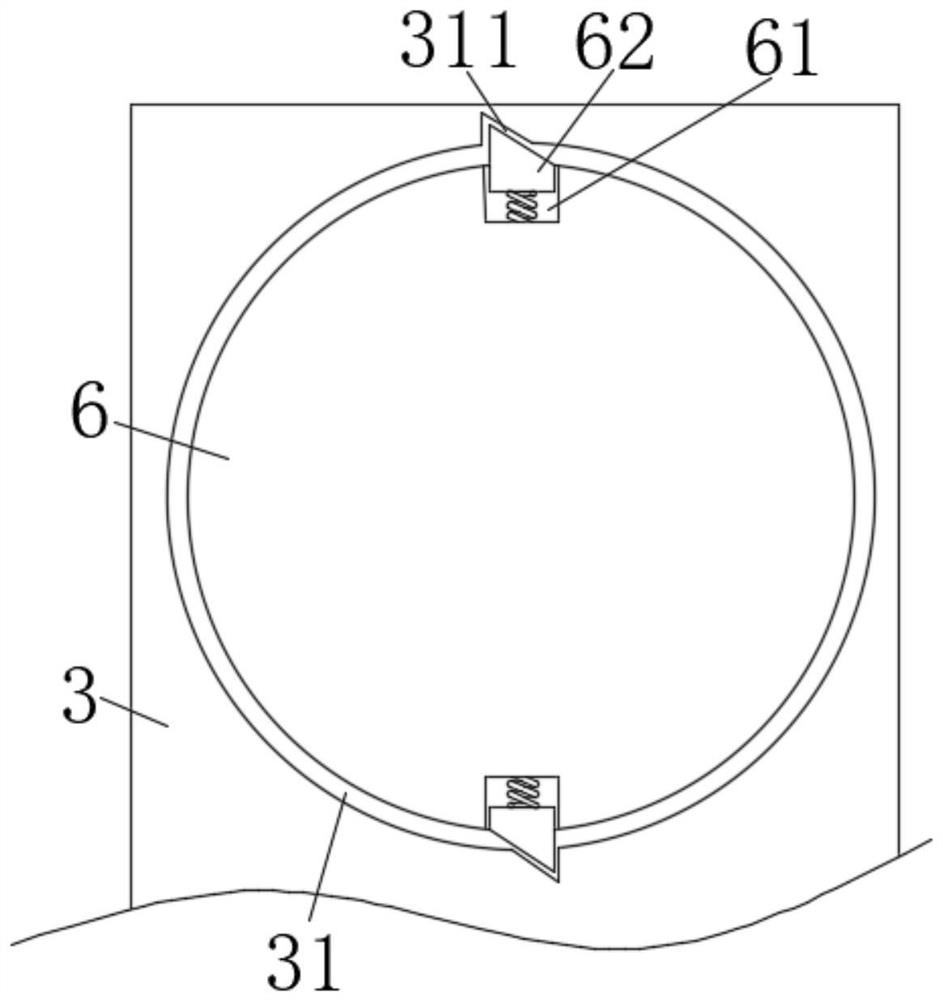

Cloth winding device for flax textile processing

ActiveCN108820979BEasy to flattenImprove work efficiencyCleaning using toolsCleaning using gasesEngineeringMechanical engineering

The invention discloses a cloth winding device for flax textile processing, which relates to the technical field of linen textile and includes a winding device body. The winding device includes a base, a first support rod, a cloth transport plate, a turret, and a rotating shaft. The second support rod, cloth pressing roller and cloth winding roller, the lower end of the first support rod is fixedly connected to the upper end side of the base, and the turret is movably connected to the first support rod through a rotating shaft. This cloth rewinding device for linen textile processing, on the one hand, the cloth pressing roller can flatten the cloth when the cloth is rolled into the cloth rolling roller; on the other hand, the rotating shaft can drive the turret to rotate, and the rewinding roller that has rolled up the cloth rotates Go to the other end to disassemble, and then the two cloth roll rollers can be disassembled. When one of the cloth roll rollers is disassembled, the other cloth roll roller can continue to work, increasing work efficiency. In addition, the cloth pressing roller and the second support rod are movablely connected, so that the cloth pressing roller can The height of the roller can be adjusted to facilitate flattening of fabrics.

Owner:嘉兴市新荣成纺织股份有限公司

Flax blended fabric preparation method and equipment

InactiveCN107904745AFill in the blanksSolve the problem of low production efficiency of blended spinningWoven fabricsYarnPolyesterYarn

The invention discloses a flax blended fabric preparation method and equipment. The flax blended fabric preparation method comprises the following steps that raw materials are prepared, wherein the raw materials include flax, polyester filaments, Sirospun yarn, FDY75D flax and FDY blended yarn; the flax is sequentially subjected to scotching, hackling, slivering, drawing, roving, scouring and bleaching and spinning procedures, and flax yarn is prepared; the flax yarn is placed in a spinning frame, the FDY75D flax and the FDY blended yarn are added, and a flax textile is prepared; the polyesterfilaments are added into the flax textile and blended; the Sirospun yarn is added into the spinning frame and combined with the blended textile, and flax blended fabric is prepared; the flax blendedfabric is subjected to singeing, printing and dyeing and forming. The production equipment used for the flax blended fabric comprises the wet spinning frame, a rapier loom, a dyeing machine and a singeing machine. The method has the advantages that the blank of a flax wet spinning anti-wrinkle fabric is filled; the problem that elastic fiber and flax fiber blending is low in production efficiencyis solved; the grade of the flax textile and clothing is improved; the problems that the flax blended fabric is difficult to weave and dye are solved.

Owner:TUNGGA LINENANDCOTTON CO LTD

Equipment nozzle device for flax textile processing

ActiveCN109082789ASpray the dye evenlyImprove dyeing efficiencyLiquid spraying apparatusTextile treatment by spraying/projectingSpray nozzleEngineering

The invention discloses an equipment nozzle device for flax textile processing, and relates to the technical field of textile nozzle devices. The equipment nozzle device comprises a main pipeline, themiddle of the lower surface of the main pipeline is fixedly connected with one end of a connecting pipe, and the other end of the connecting pipe penetrates through the upper surface of the conveyingpipeline and is fixedly arranged in the middle of the upper surface of a conveying pipeline; a plurality of openings are formed in the lower surface of the conveying pipeline, one end of each branchpipe is fixedly installed at the corresponding opening, and the other end of each branch pipe is fixedly connected with the middle of the upper surface of a buckling device. The equipment nozzle device for the flax textile processing is characterized in that a prepared dye is input into the conveying pipeline through the connecting pipe by using the main pipeline; the conveying pipeline sprays thedye through a distributor from nozzles by using the branch pipes, and then a textile fabric is dyed; the nozzles are evenly arranged in the peripheral direction of the branch pipes so that the sprayed dye can be more uniform, and the dyeing efficiency is improved.

Owner:滨州市科创孵化器有限公司

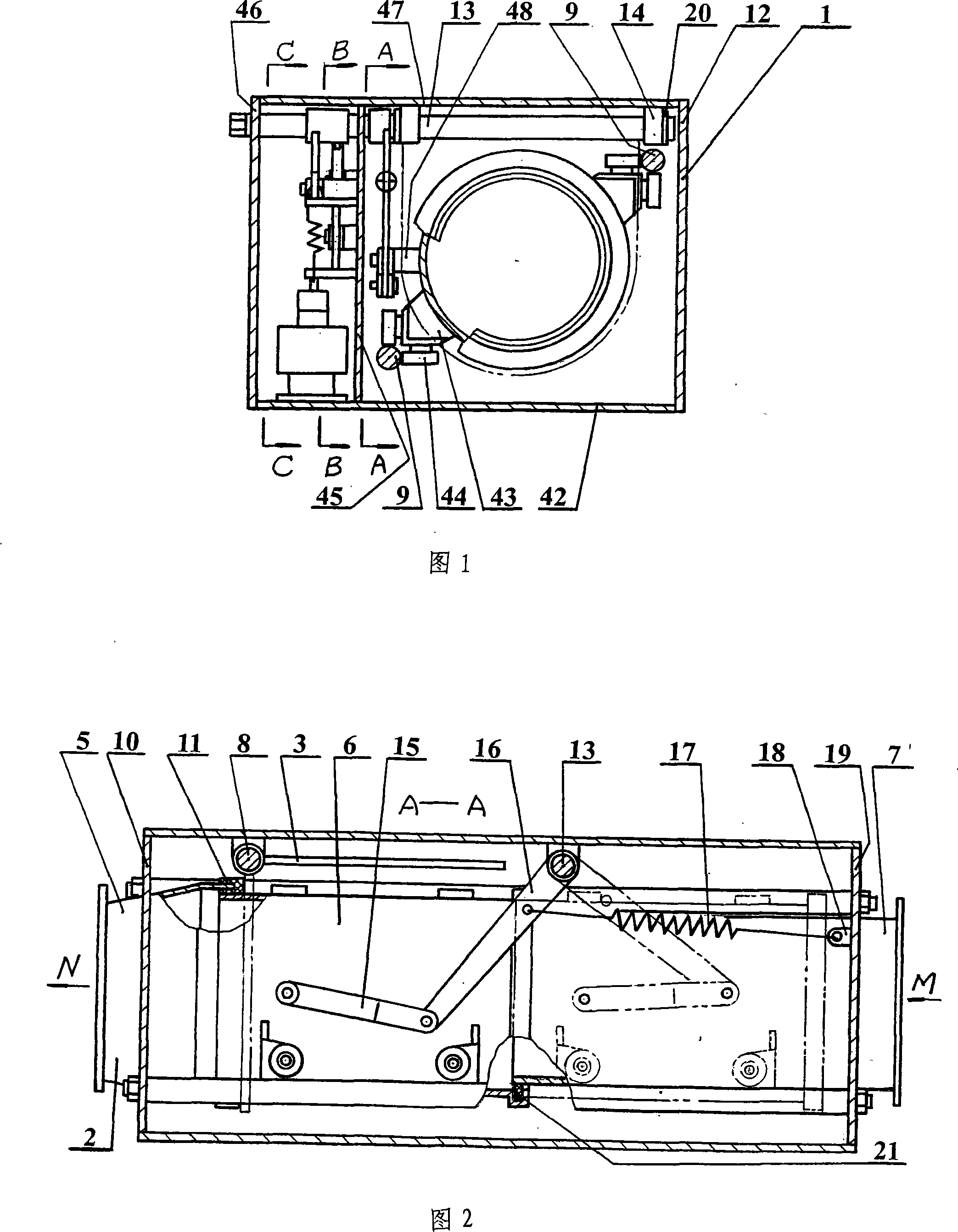

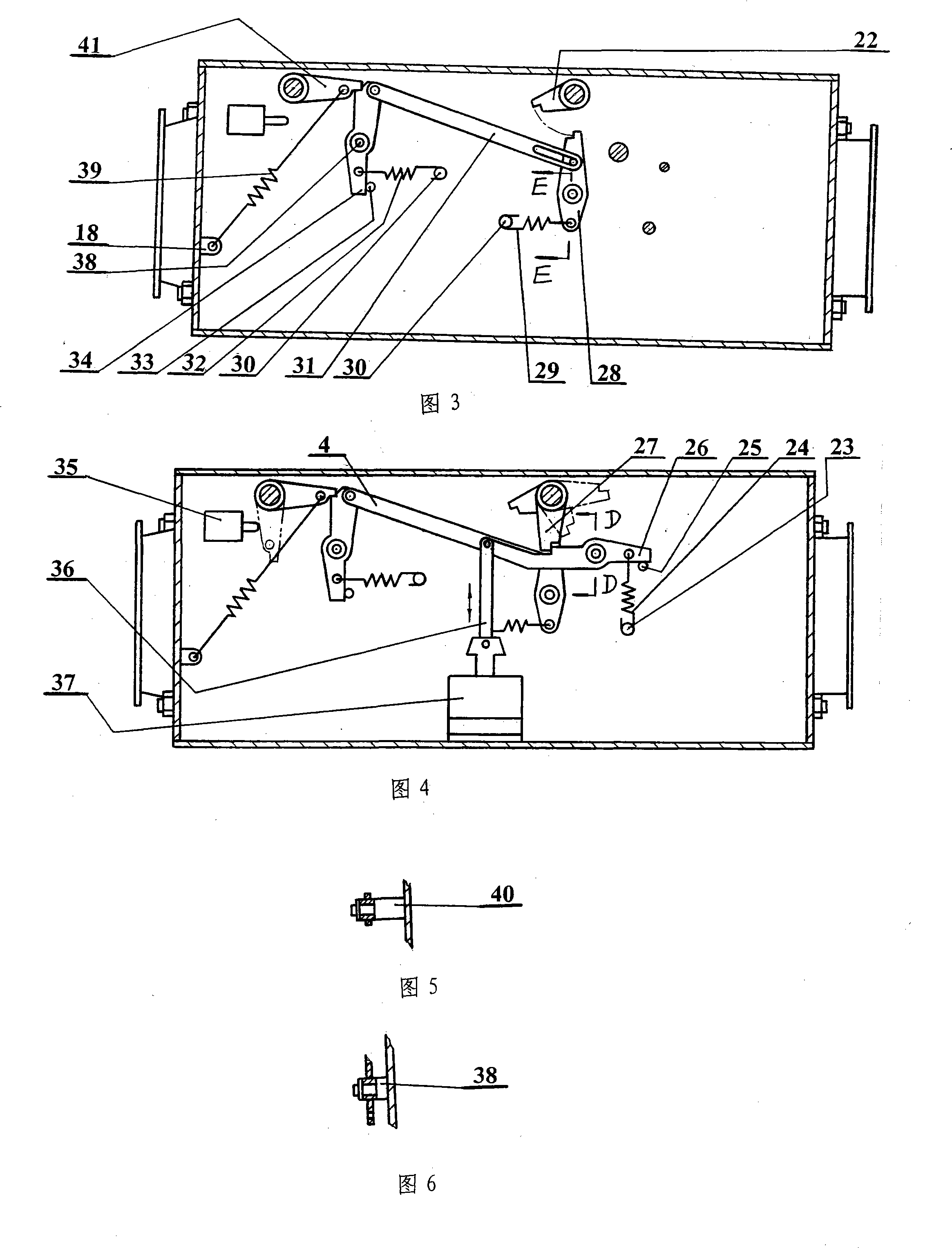

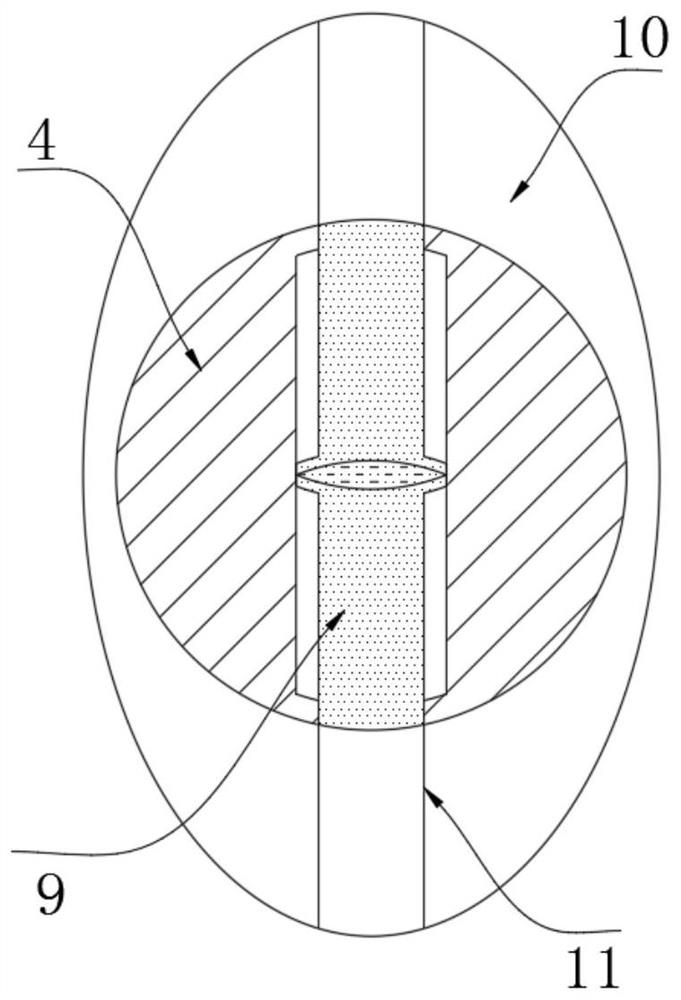

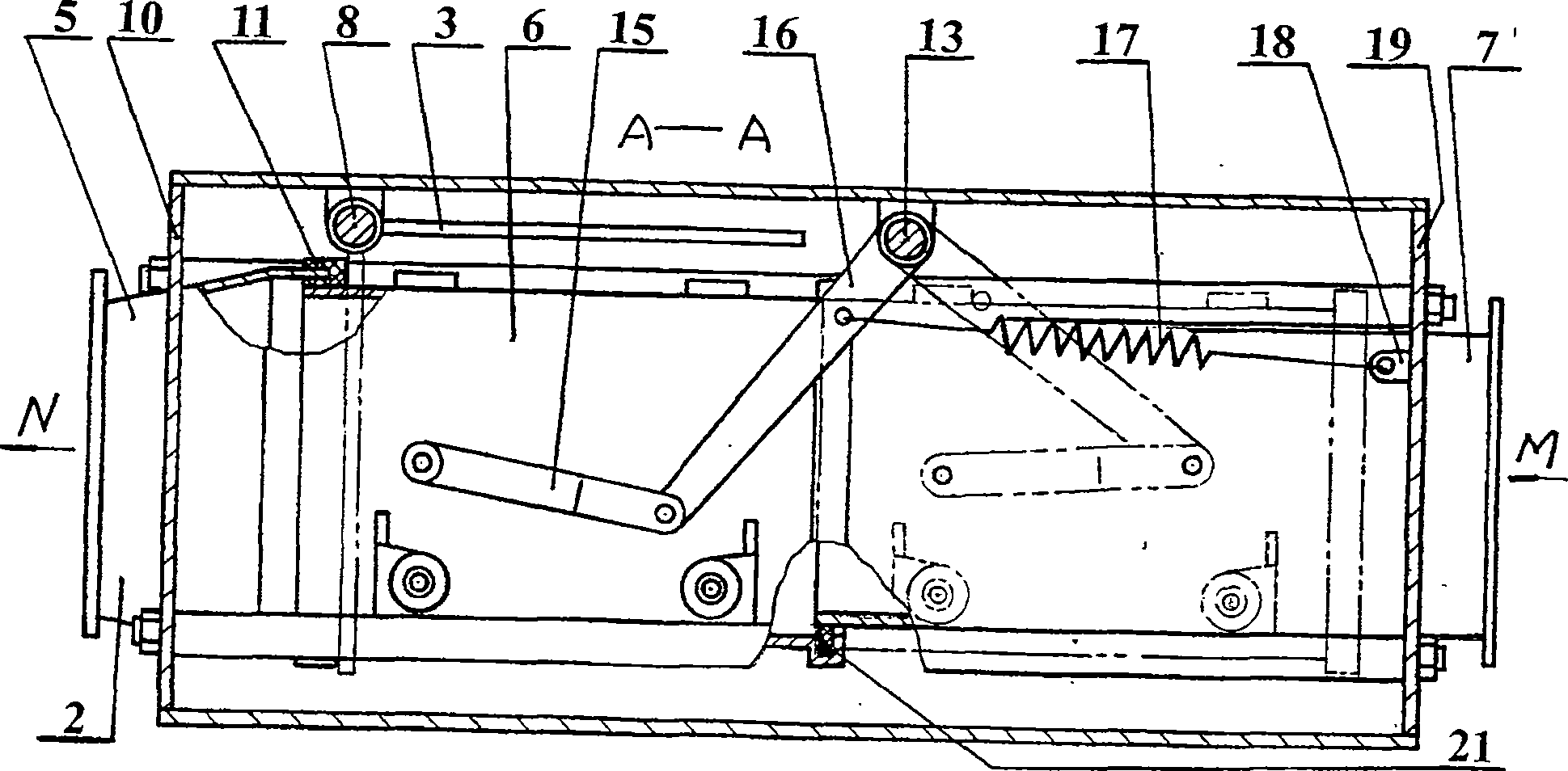

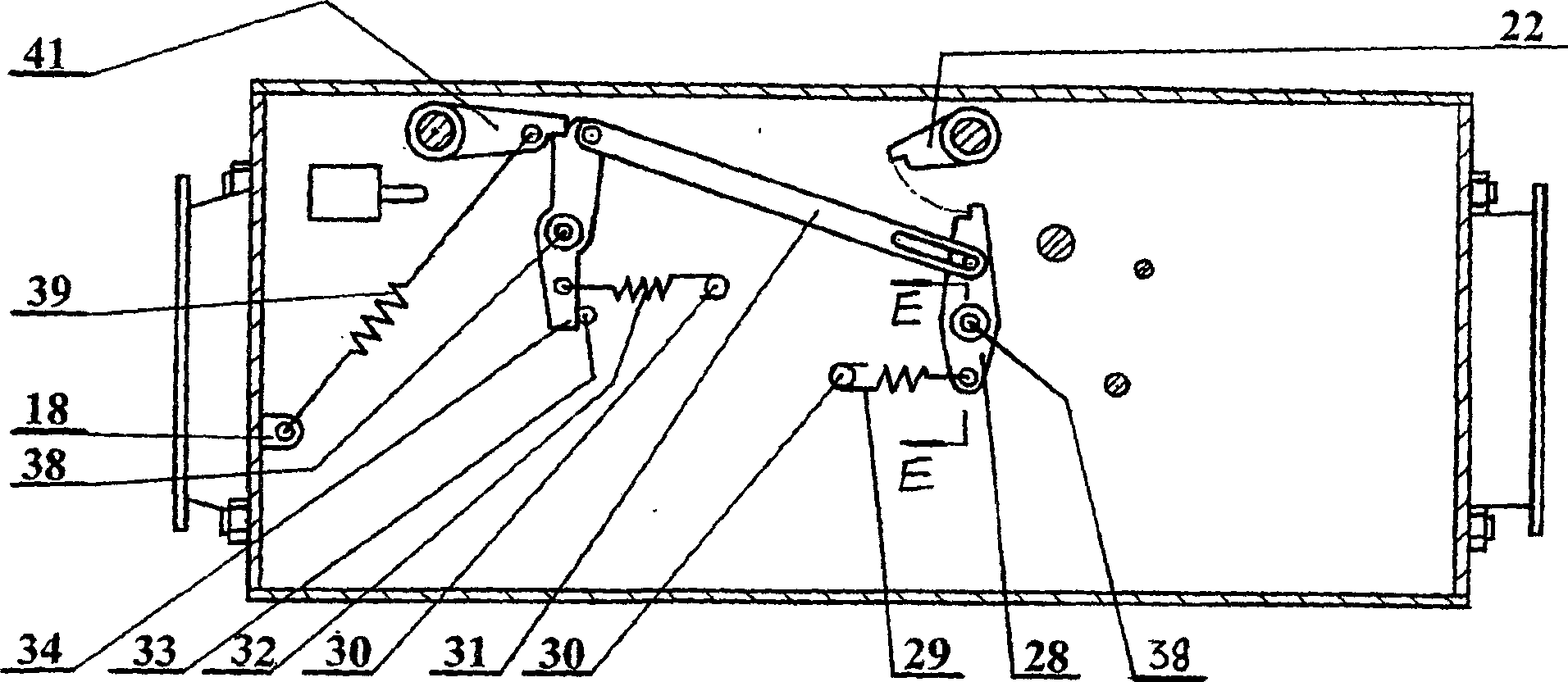

Fireproof and explosion-proof tubing safety valve

InactiveCN101220882ACompact structureReasonable designEqualizing valvesSafety valvesFiberSafety valve

The invention relates to a safety valve for a fireproof and explosion-proof pipeline, comprising a shell, a ventilation cylinder, a rocking plate and a transmission and control mechanism; the ventilation cylinder consists a taper cylinder, a movable cylinder and a straight cylinder which are movably connected with each other; the shell is internally provided with a rocking plate shaft and the rocking plate; the rocking plate can be rotated around the rocking plate shaft. The invention has the advantages of compact structure, reasonable design, easy processing and low cost. The invention is suitable for the dust and fibre transmission pipeline system of flax textile industry and similar industries, which prevents the fire source from entering a dust and fibre collector which is flammable and explosive and prevents fire and explosive accidents.

Owner:周维 +2

Crack-resistant, thermal-insulation and fire-proof mortar dry powder material and preparation method

InactiveCN104058675AGood mechanical propertiesImprove bindingSolid waste managementCrack resistanceThermal insulation

The invention provides a flax fiber cement-based cementing material and a preparation method thereof. The preparation method comprises the steps of carrying out oven-drying on flax wastes carded in a flax weaving process at a temperature of 50-55 DEG C, and cutting into flax fibers of which the lengths are less than 10mm; mixing the flax fibers of which the weight ratio is 2.5-3.5%, rubber powder for construction of which the weight ratio is 0.4-0.6% and a certain amount of a cement mortar matrix material which comprises polystyrene beads and the balance of cement and sand based on an energy requirement to obtain a cement mortar dry powder material of flax fiber, polystyrene beads, cement and sand. The cement-based cementing material of flax fiber and polystyrene beads disclosed by the invention has advantages of superior tensile strength, crack resistance, thermal insulation property, fire resistance and low cost; furthermore, since an excellent adhesion strength is generated between the cement-based cementing material prepared by the invention and a base, the cement-based cementing material can be used as a cement-based cementing material for an exterior wall liner of a building. The flax fiber cement-based cementing material disclosed by the invention also opens up a new way for processing flax wastes carded in the flax weaving process, thereby being conducive to the rational utilization of resources and environmental protection.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

Preparation and application of a flax adsorbent

InactiveCN103464115BGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionEpoxyFiber

The invention discloses a preparation method and application technology of an epoxy chloropropane modified flax adsorbent. The preparation method is characterized by washing waste short fiber flax of a flax textile factory by using water, drying and crushing; processing by using NaOH and OP water solution and drying to obtain degummed flax; adding the following components in percentage by mass in a reactor: 22-40% of epoxy chloropropane, 12-25% of degummed flax, 4-8% of NaOH, 5-10% of isopropyl alcohol and 32-55% of water, wherein the sum of all the components is 100%; stirring at the constant temperature of 55-65 DEG C, carrying out backflow reaction for 1.0-4h, cooling, washing by using de-ionized water, carrying out suction extracting and filtering until the filtrate is neutral, washing by using a small amount of ethanol, drying in a 50-55 DEG C vacuum drying box, so as to obtain the epoxy chloropropane modified flax. The adsorbent has very high adsorbing capacity to basic dye, has high regeneration property, can be used repeatedly for several times, and is low in cost and environment-friendly.

Owner:UNIV OF JINAN

Method for modifying and degumming jute fibers

InactiveCN103710764BGood flexibilityImprove spinnabilityFibre treatment to obtain bast fibreSpinningEconomic benefits

Owner:WUXUE XINJI JUTE TEXTILE CO LTD

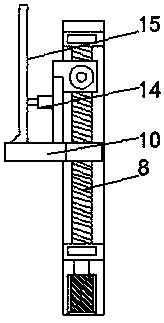

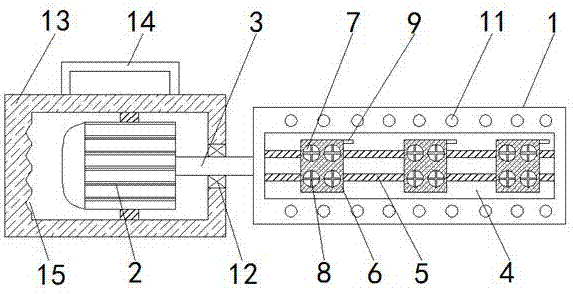

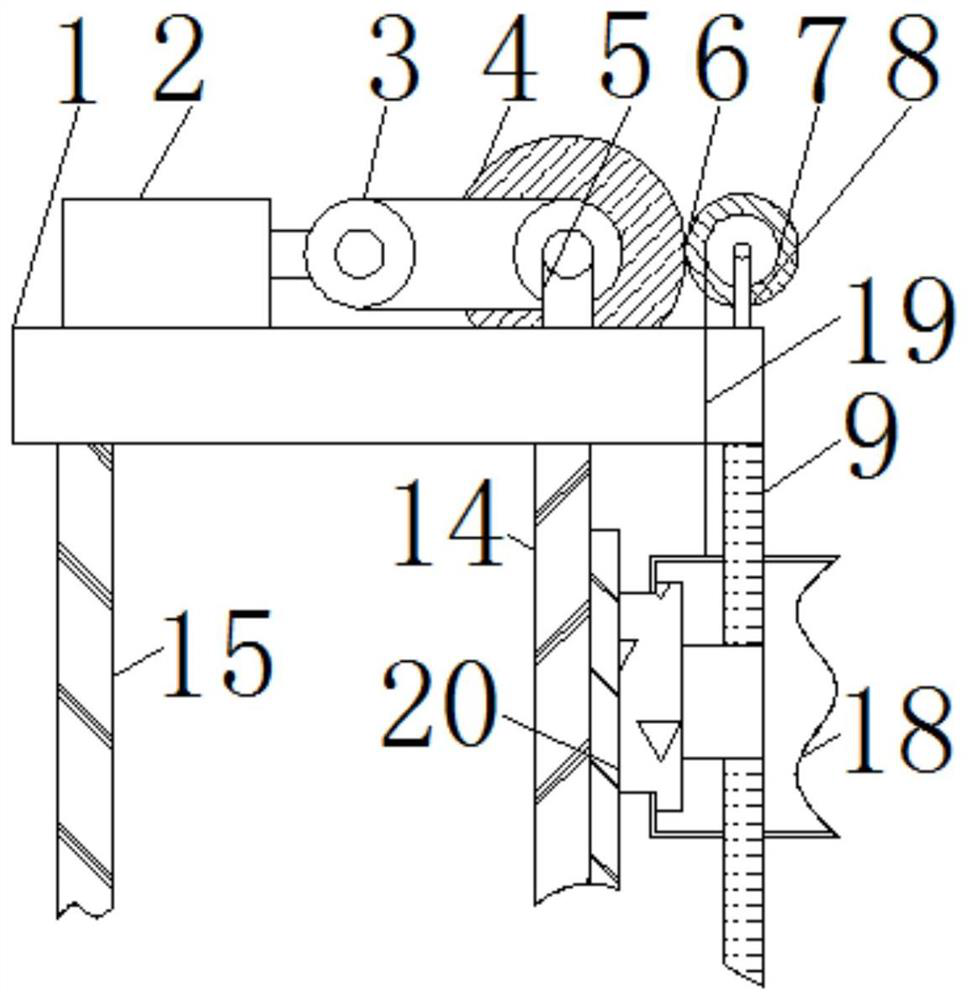

Anti-thread-loose type spinning processing device used for flax textile device

The invention provides an anti-thread-loose type spinning processing device used for a flax textile device, and relates to the technical field of textile devices. The problems that existing textile anti-thread-loose equipment only limits spun threads in a clamping groove, the situation that spun threads are knotted to directly influence normal use of a textile device is caused by large-amplitude movement, the winding positions of spun threads cannot be adjusted, the equipment is not suitable for most textile machines, and time is quite consumed due to the fact that the equipment needs to be suspended for a period of time to replace spun threads when spun threads are added every time are solved. The anti-thread-loose type spinning processing device used for the flax textile device comprisesa frame body mechanism, a limiting mechanism, a first thread table mechanism, a second thread table mechanism, an adjusting mechanism and anti-thread-loose devices. Movable base plates are slidably connected into a platen clamping groove, sliding of the movable base plates is limited through screws connected with the movable base plates and auxiliary mounting plates, and the positions of the three anti-thread-loose devices can be adjusted on an adjusting mechanism.

Owner:章小燕

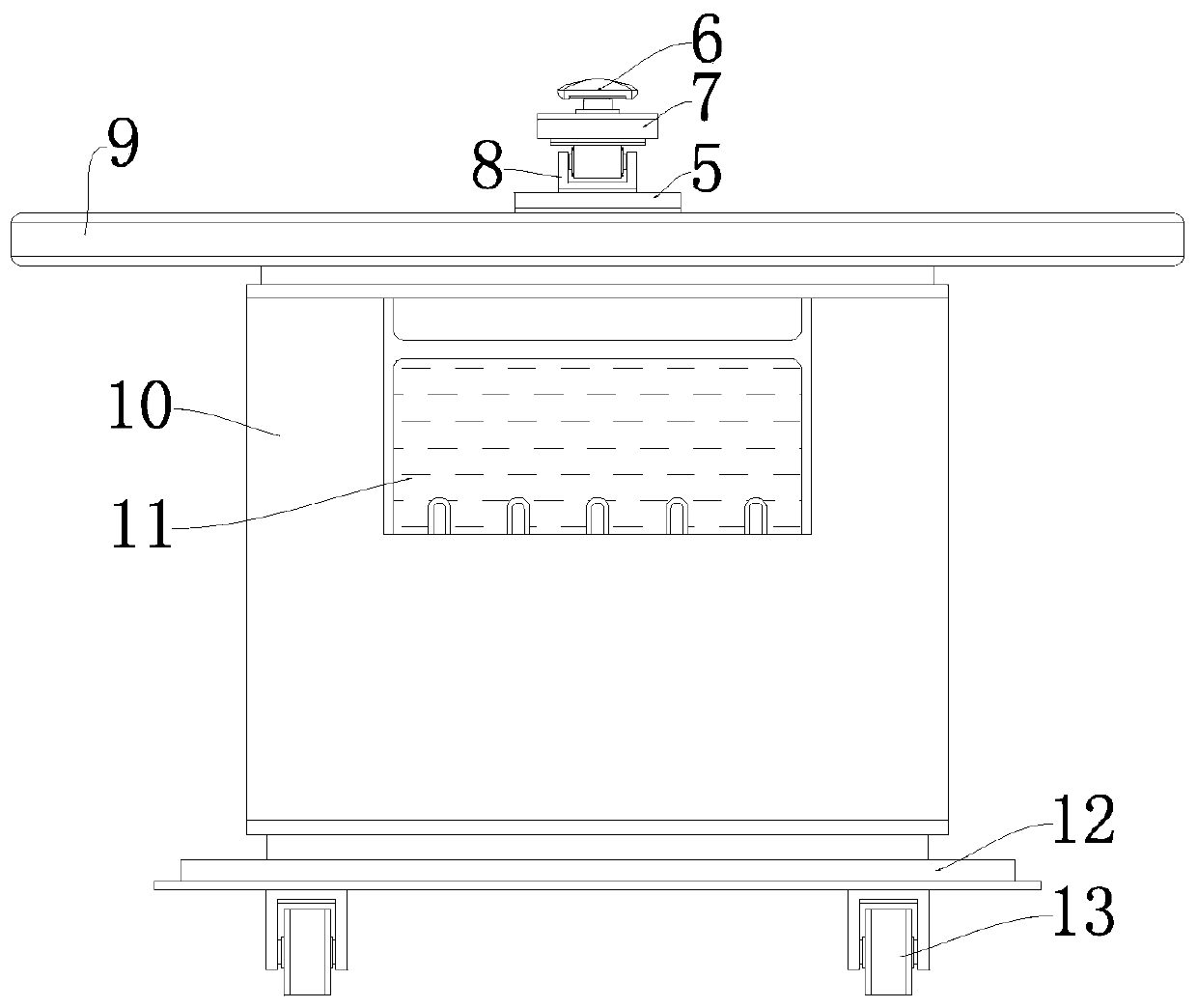

Flax textile storage device

ActiveCN112407616ARealize automatic windingVolume stabilityContainers preventing decayShock-sensitive articlesElectric machineryStructural engineering

The invention discloses a flax textile storage device. The flax textile storage device comprises a storage box, wherein a plurality of collecting mechanisms are arranged inside the storage box; each collecting mechanism comprises a motor fixed on the inner wall of the storage box; a rotary groove is formed in the inner wall of the storage box; the inner wall of the rotary groove is rotatably connected with a rotary shaft; a blocking slot is formed in the end part of the rotary shaft; the output shaft of the motor is fixedly equipped with a rotary disc which is in sliding connection with the inner wall of the blocking slot; a dismounting slot is formed in the inner wall of the blocking slot in a penetrating mode; and the side wall of the rotary shaft is equipped with a rolling auxiliary mechanism. The flax textile storage device has the advantages that: the motor drives the rotary shaft to rotate, so that automatic rolling of cloth is realized, rolling and storage are integrated, carrying and operation are not needed, and integral efficiency is greatly improved; meanwhile, a supporting plate is supported to be flush with an edge plate and a dismounting plate, so that a cloth rollingprocess is stably performed, the middle position does not collapse, and rolling quality is guaranteed; and moreover, cloth rolling and storage do not extrude each other, so that the defect that moisture in a gap is difficult to remove is eliminated.

Owner:宁波谦屹节能科技有限公司

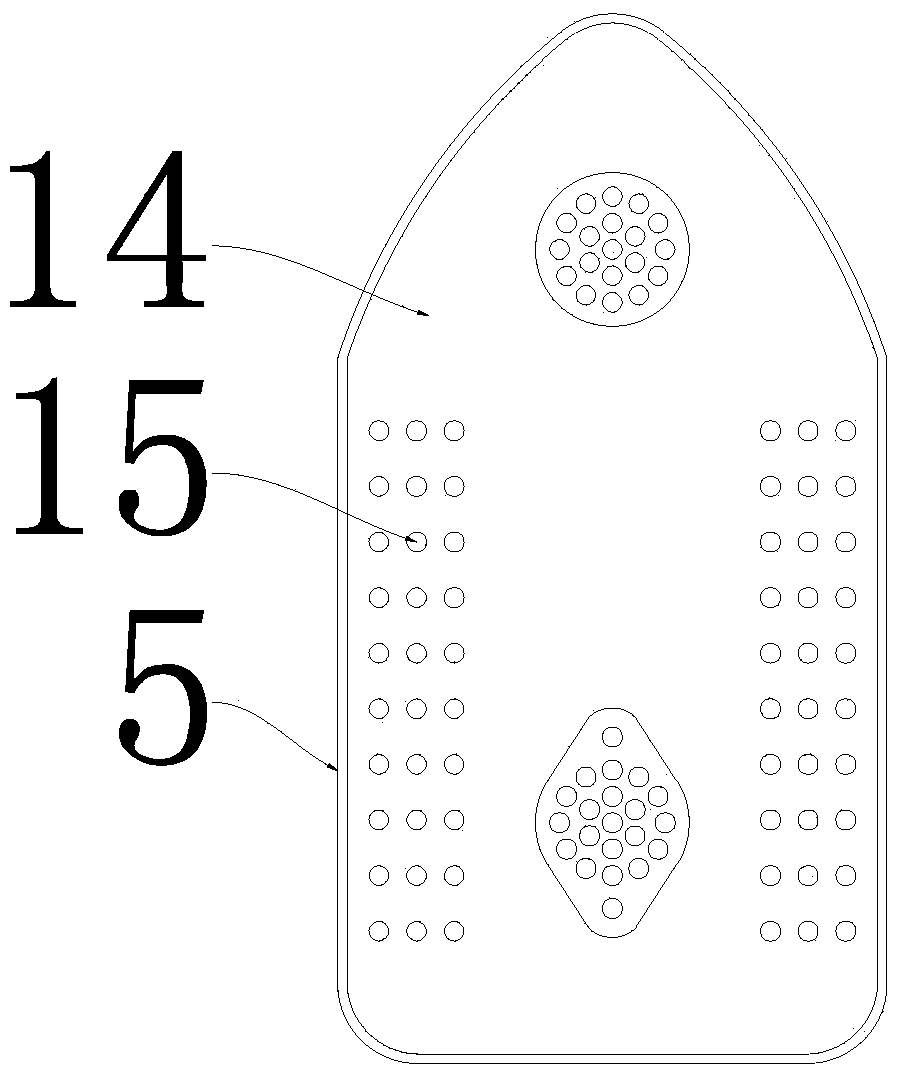

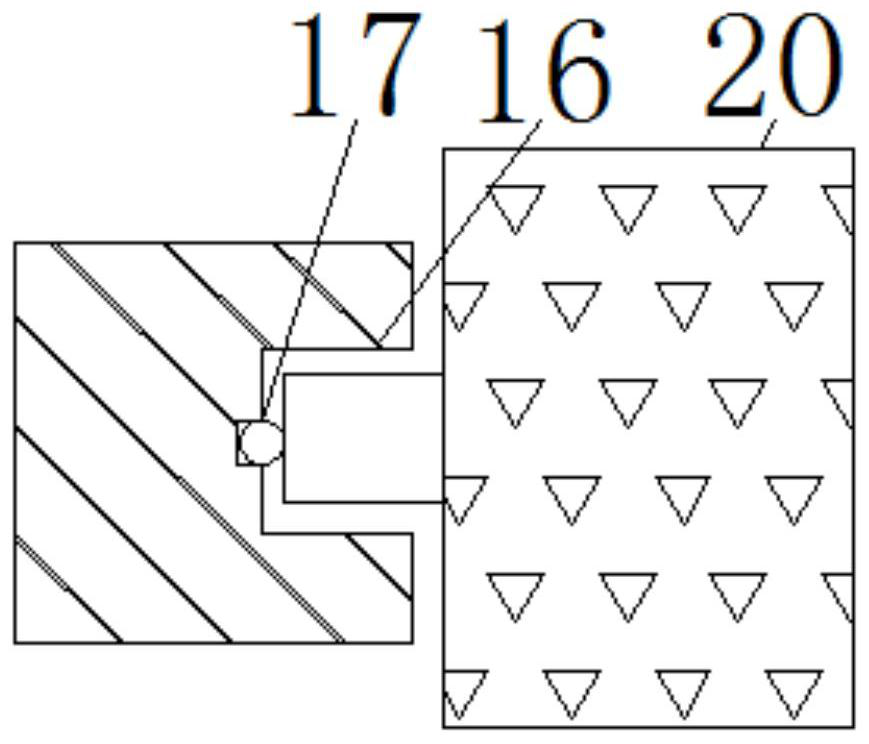

Flax textile thread pretreatment system

ActiveCN113668071AKeep drySmooth entryMechanical fibre separationBacteriological rettingElectric machineryFlax fiber

The invention relates to the field of flax textile thread production, in particular to a flax textile thread pretreatment system. The system comprises an equipment shell; a nylon hook plate opening is formed in the upper portion of the front side of the equipment shell; a detection sensor is arranged on the surface of the nylon hook plate opening; a conical opening is formed in the lower portion of the front side of the equipment shell; two drying roll shafts are arranged in the conical opening; a waste liquid tank is arranged below the conical opening; a supporting plate is arranged on the left side of the equipment shell; a main motor is arranged above the supporting plate; a heat discharge pipe is arranged on one side of the main motor and connected with the interior of the equipment shell; a collecting box is arranged behind the equipment shell; and an air suction channel is arranged on the right side of the equipment shell for protection. Through the arrangement, the system can be used for dehydrating and scutching flax stems subjected to retting treatment, and meanwhile, generated short fibers, retting waste liquid, wood fragments and flax fibers can be classified in the treatment process, so that the labor cost is reduced, and the working efficiency and the yield are improved.

Owner:河北格雷服装股份有限公司

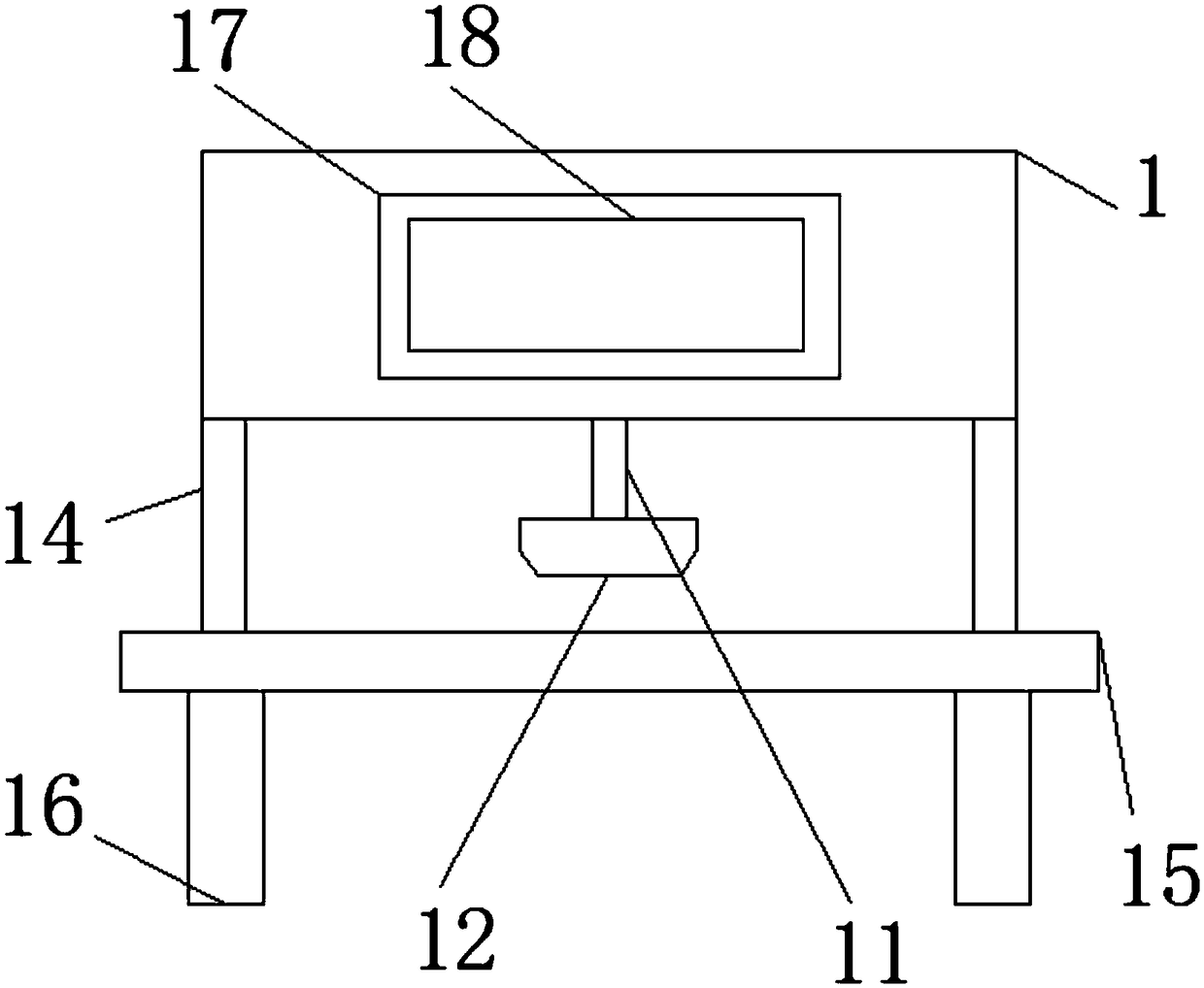

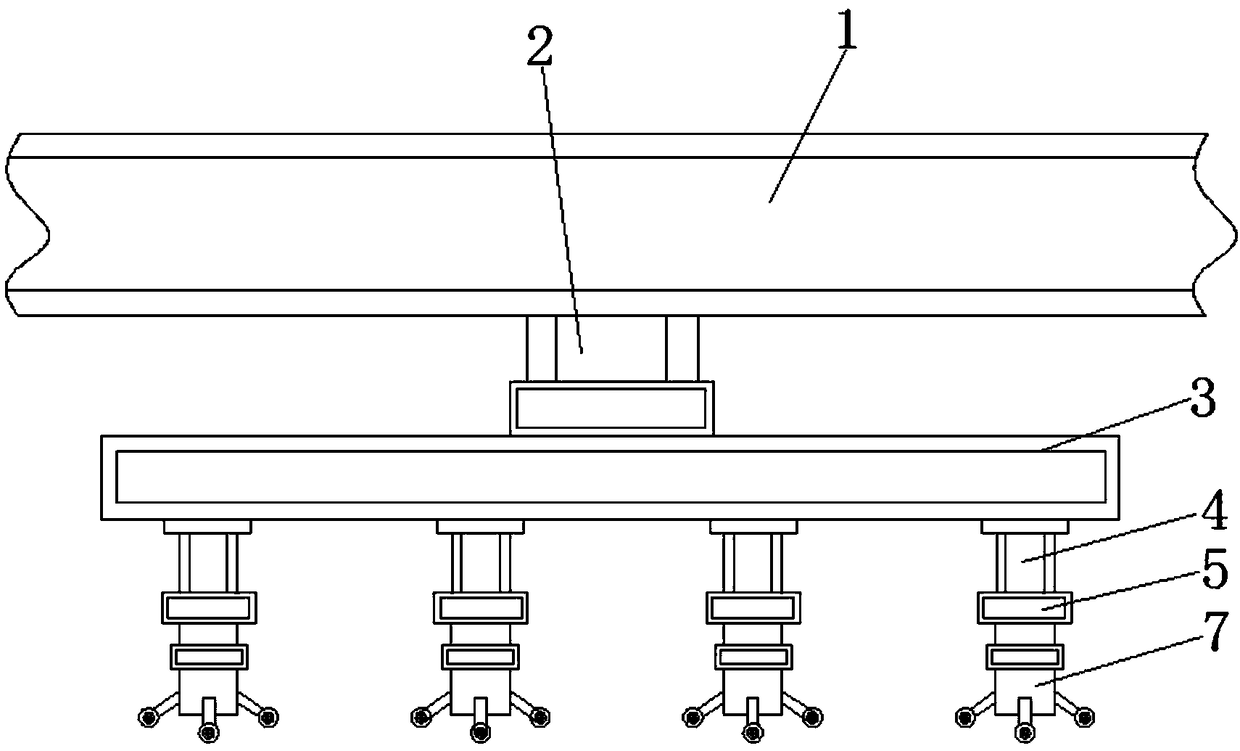

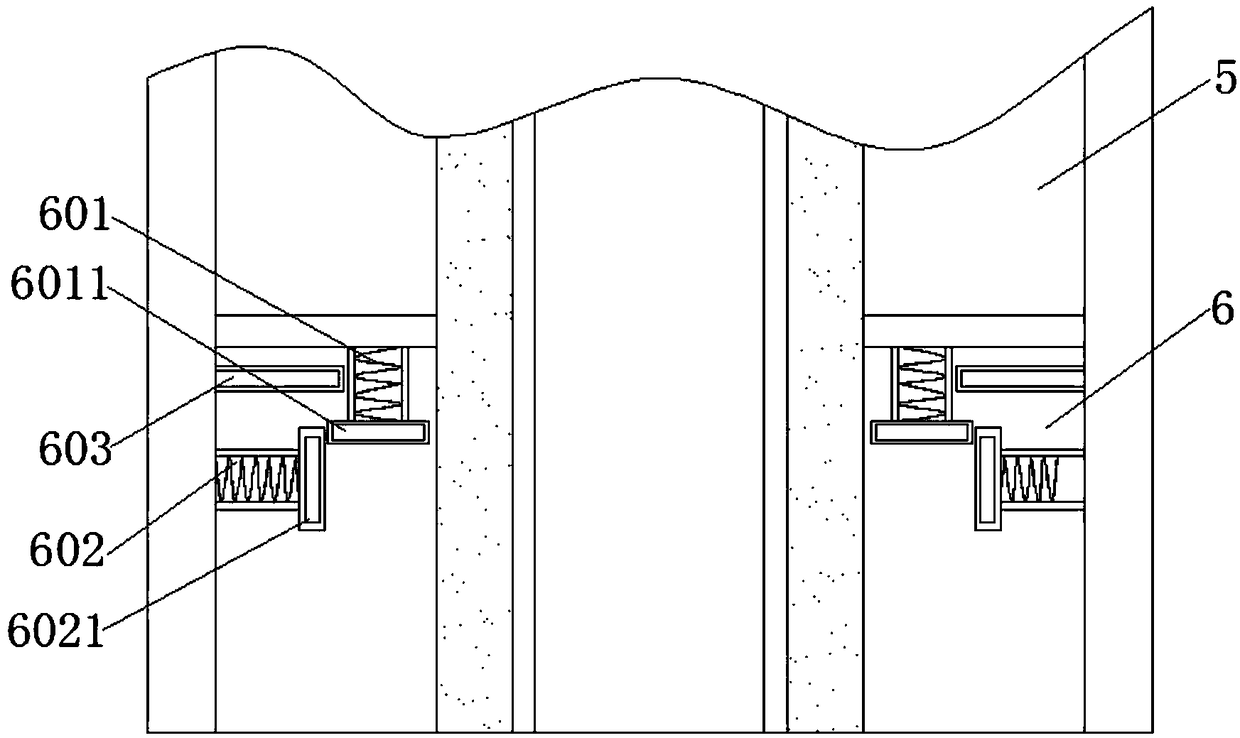

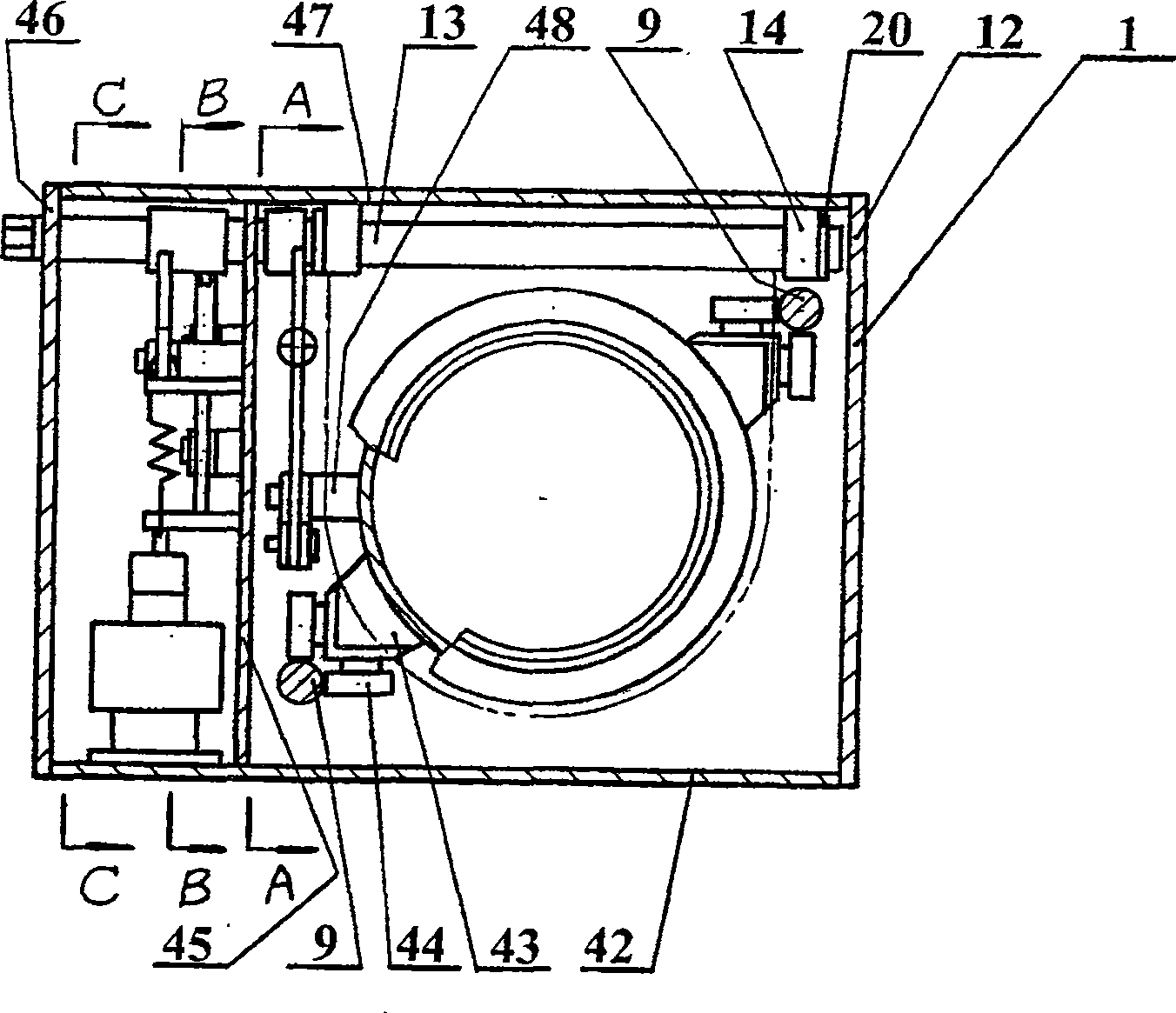

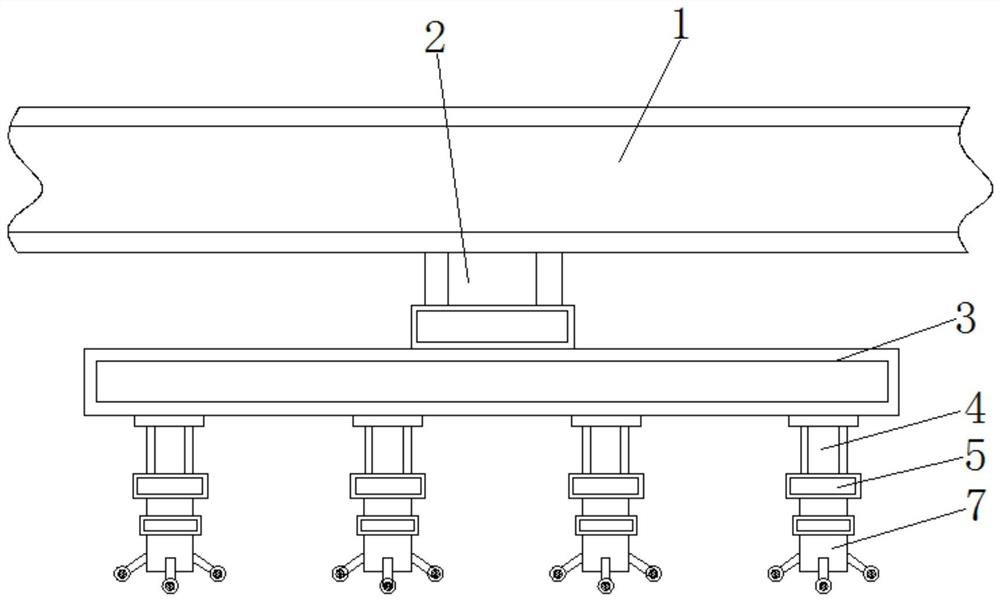

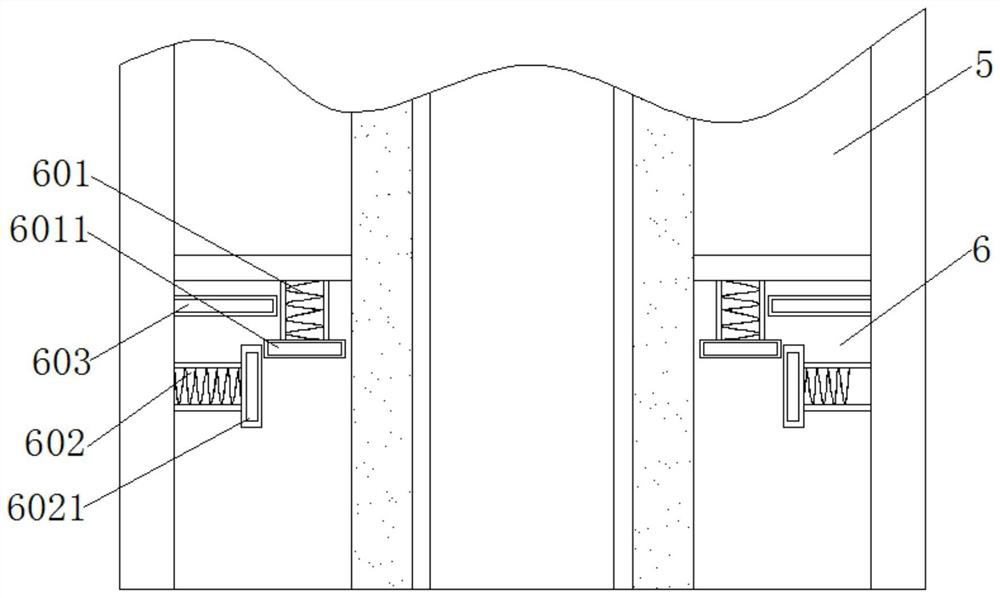

A toilet-adjustable lifting device for flax textile processing

The invention relates to the technical field related to textile processing, in particular to a convenient-adjustable-type lifting device for linen textile processing. The convenient-adjustable-type lifting device comprises a lifting frame, the surface of the lifting frame is connected with a mounting frame in a screwed mode, and the inner wall of the mounting frame is connected with a gear motor in a screwed mode; a positioning rod is welded to the surface of a connecting seat, and a positioning sleeve rod is welded to the surface of a supporting seat; and a connecting rotating groove is formed inside the supporting seat, connecting shafts are rotatably connected to the inside of the connecting rotating groove, and the connecting shafts are welded to the surfaces of gears. The convenient-adjustable-type lifting device has the beneficial effects that a plurality of groups of gears are arranged, every two groups of gears are connected through one group of connecting shafts, the stabilityof the lifting device during use is improved, meanwhile, the supporting seat is fixed to the inner wall of the lifting frame, the structural strength of the lifting frame is improved, the positioningrod slides in the positioning sleeve rod in a positioned mode during the adjustment process, the stability of the height adjustment of textile equipment is ensured, the quality of textile processingis further ensured, and the convenient-adjustable-type lifting device is suitable for promotion.

Owner:浙江汉保利罗针织股份有限公司

Fireproof and explosion-proof tubing safety valve

InactiveCN100494752CCompact structureReasonable designEqualizing valvesSafety valvesFiberSafety valve

Owner:周维 +2

Nozzle equipment for linen textile processing equipment

ActiveCN109082789BSpray the dye evenlyImprove dyeing efficiencyLiquid spraying apparatusTextile treatment by spraying/projectingStructural engineeringMechanical engineering

The invention discloses a nozzle device for flax textile processing equipment, relates to the technical field of textile nozzle devices, and comprises a main pipe, one end of a connecting pipe is fixedly connected to the middle part of the lower surface of the main pipe, and the other end of the connecting pipe runs through the conveying pipe. The upper surface of the pipeline is fixedly installed in the middle of the upper surface of the delivery pipeline, the lower surface of the delivery pipeline is provided with a plurality of openings, one end of the branch pipe is fixedly installed with the opening, and the other end of the branch pipe is fixedly connected with a fastening device The nozzle device of the linen textile processing equipment in the middle part of the upper surface, on the one hand, the main pipeline feeds the prepared dye into the delivery pipeline through the connecting pipe; on the other hand, the delivery pipeline sprays the dye from the nozzle head through the diverter Out, the textile fabric is dyed, and secondly, the nozzle head is evenly distributed in the circumferential direction of the branch pipe, which can make the spraying of the dye more uniform and improve the dyeing efficiency.

Owner:滨州市科创孵化器有限公司

Flax textile fabric processing device with good ironing convenience

InactiveCN110644212AEasy to placeImprove stabilityIroning apparatusTextiles and paperStructural engineeringMechanical engineering

The invention discloses a flax textile fabric processing device with good ironing convenience, comprising a case; an ironing table is mounted on the top of the case; a support seat is mounted at the bottom of the case, and a roller is mounted at the bottom of the support seat; an evaporation cavity is arranged in the case, and an upper air pipe is arranged on one side of the case; a telescopic rodis mounted on a rocking arm, and a handle is mounted at the top of one end of the rocking arm; an ironing head is mounted at the bottom of one end of the rocking arm, and a metal bottom plate is mounted at the bottom of the ironing head; the metal bottom plate is provided with steam holes. The ironing head is mounted at the bottom of one end of the rocking arm in a hinged mode, the telescopic rodis mounted on the rocking arm, the position of the rocking arm can be accurately controlled through the telescopic rod, the rocking arm is mounted at the top of an upper air head through a hinging joint, and the rocking arm is supported through the telescopic rod, so that the device does not need continuous load during using and is convenient to use.

Owner:JIANGSU SUNSHINE

A dyeing device for flax textile processing

ActiveCN110820202BReduce firmnessAvoid weight gainTextile treatment by spraying/projectingTextile treatment carriersPolymer scienceEngineering

The invention discloses a dyeing device for flax textile processing, which comprises a dyeing tank, a spreading board, a sealing cover, a cloth outlet, an installation base and a control box. Beneficial effects: the present invention utilizes the glue removing board provided, and under the interaction of the acid cloth strip and the steam strip, realizes the softening treatment of the fat wax remaining on the surface of the flax, so as to avoid the problem of secondary dyeing of the cloth due to The hydrophobicity of fat wax affects the immediacy and adsorption of dyes, which leads to the aggregation of dye particles at low temperature and concentrated dyeing at high temperature, so as to reduce the fastness of dyeing. In order to avoid the heavy weight of the linen fabric with too much dye solution during the lifting process, the linen fabric runs at a low speed, causing its tension to expand and deform, and at the same time, the linen fabric is continuously changed by shaking State, in order to reduce the phenomenon of creases.

Owner:SHAOXING YONGFENG TEXTILE DYEING PRINTING

A toilet-adjustable lifting device for flax textile processing

The invention discloses an adjustment-convenient lifting device for linen textile processing, and relates to the technical field of linen textile processing. The device comprises a top fixed plate; the top of the top fixed plate is fixedly connected with the bottom of a first driving motor; one end of the first driving motor is movably connected with a driving device through a pin shaft; the middle part of one end of the driving device is fixedly connected with the middle part of a first gear through a pin shaft; the driving device is movably connected to the top of a support rod; the bottom of the support rod is fixedly connected with the top of the top fixed plate; the outer side of the first gear is movably connected with the outer side of a second gear; and the middle part of the second gear is fixedly connected with the middle part of a rotating wheel through a pin shaft. In the adjustment-convenient lifting device for linen textile processing, the height of a reinforcement rope is adjusted through rotation of the rotating wheel; the lifting of a lifting frame is finished through adjustment of the height of the reinforcement rope; and through a chute and a ball arranged on a slide plate, the lifting effect of the lifting frame can be improved, and the vibration generated in the lifting process is reduced.

Owner:浙江载信亚麻科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com