Low-impurity-rate flax textile technology

A technology of impurity content and linen yarn, which is applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of high impurity content of flax yarn, unstable quality of flax fabric, low impurity content of linen yarn, etc. Excellent spinnability, length and breaking length, and low trash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

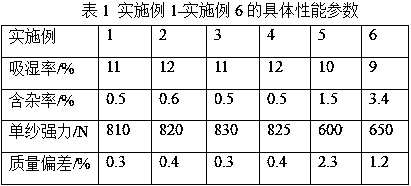

Examples

Embodiment 1

[0031] A flax yarn weaving process with low impurity content comprises the steps:

[0032] Step 1. Perform the first health care and cleaning process on the flax fiber in sequence, manually remove the flax knots and super long fibers, and then cut the flax to obtain dry flax, carding, combing, drawing, and roving the flax fibers and the second health-preserving process to obtain the flax roving for use;

[0033] Step 2, sequentially carrying out pickling, scouring, hydrogen peroxide bleaching and enzymatic desizing processes on the flax roving in step 1 to obtain pretreated flax roving for use;

[0034] Step 3, carrying out the spun and winding process of the flax roving pretreated in the step 2 to obtain dry hemp cheese for use;

[0035] Step 4, the dry hemp cheese in the step three is made into a dry hemp fabric through the processes of warping and reeding, weft winding, weaving and cloth inspection.

[0036] Specifically, the specific steps of the first health preservatio...

Embodiment 2

[0046] A flax yarn weaving process with low impurity content comprises the steps:

[0047] Step 1. Perform the first health care and cleaning process on the flax fiber in sequence, manually remove the flax knots and super long fibers, and then cut the flax to obtain dry flax, carding, combing, drawing, and roving the flax fibers and the second health-preserving process to obtain the flax roving for use;

[0048] Step 2, sequentially carrying out pickling, scouring, hydrogen peroxide bleaching and enzymatic desizing processes on the flax roving in step 1 to obtain pretreated flax roving for use;

[0049] Step 3, carrying out the spun and winding process of the flax roving pretreated in the step 2 to obtain dry hemp cheese for use;

[0050] Step 4, the dry hemp cheese in the step three is made into a dry hemp fabric through the processes of warping and reeding, weft winding, weaving and cloth inspection.

[0051] Specifically, the first health-preserving step in step 1 is: mix...

Embodiment 3

[0061] A flax yarn weaving process with low impurity content comprises the steps:

[0062] Step 1. Perform the first health care and cleaning process on the flax fiber in sequence, manually remove the flax knots and super long fibers, and then cut the flax to obtain dry flax, carding, combing, drawing, and roving the flax fibers and the second health-preserving process to obtain the flax roving for use;

[0063] Step 2, sequentially carrying out pickling, scouring, hydrogen peroxide bleaching and enzymatic desizing processes on the flax roving in step 1 to obtain pretreated flax roving for use;

[0064] Step 3, carrying out the spun and winding process of the flax roving pretreated in the step 2 to obtain dry hemp cheese for use;

[0065] Step 4, the dry hemp cheese in the step three is made into a dry hemp fabric through the processes of warping and reeding, weft winding, weaving and cloth inspection.

[0066] Specifically, the specific steps of the first health preservatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com