A method for in-situ non-ironing finishing of cotton fabrics with acrylic acid and glyoxal

A non-iron finishing and glyoxal technology, applied in the directions of plant fiber, fiber treatment, textile and paper making, etc., can solve the problems of fabric strength damage and achieve good non-iron effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

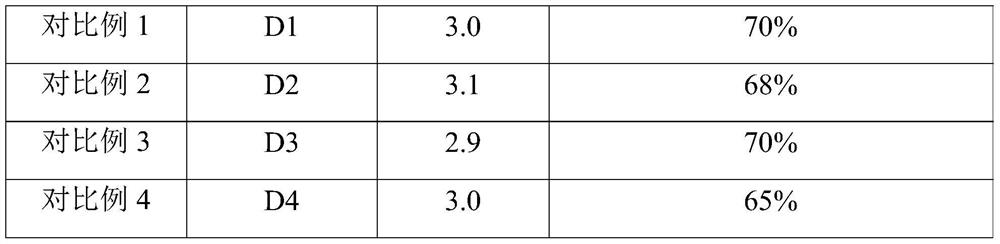

Examples

Embodiment 1

[0042] Add 11 parts by weight of ethanol to 100 parts by weight of water, add cotton fabric (the mass ratio of cotton fabric to water is 1:6), and stir at 50° C. for 20 minutes. 13 parts by weight of acrylic acid was added, followed by stirring at 50° C. for 30 minutes. Next, under ultrasonic stirring, 3 parts by weight of glyoxal, 3 parts by weight of maleic acid salt and 3 parts by weight of ammonium persulfate were sequentially added, the temperature was raised to 90° C., and the reaction was kept for 60 minutes. Then the above-mentioned treated cotton fabric is taken out, washed with water, and dried in the air, so as to obtain the non-ironing cotton fabric A1.

Embodiment 2

[0044] Add 10 parts by weight of ethanol to 100 parts by weight of water, add cotton fabric (the mass ratio of cotton fabric to water is 1:5), and stir at 40° C. for 30 minutes. 10 parts by weight of acrylic acid was added, followed by stirring at 40° C. for 60 minutes. Next, under ultrasonic stirring, 5 parts by weight of glyoxal, 2 parts by weight of fumarate and 4 parts by weight of ammonium persulfate were sequentially added, the temperature was raised to 80° C., and the reaction was maintained for 90 minutes. Then the above-mentioned treated cotton fabric was taken out, washed with water, and dried to obtain the non-ironing cotton fabric A2.

Embodiment 3

[0046] Add 12 parts by weight of ethanol to 100 parts by weight of water, add cotton fabric (the mass ratio of cotton fabric to water is 1:7), and stir at 60° C. for 10 minutes. 15 parts by weight of acrylic acid was added, followed by stirring at 60° C. for 30 minutes. Next, under ultrasonic stirring, 4 parts by weight of glyoxal, 4 parts by weight of itaconate and 2 parts by weight of ammonium persulfate were sequentially added, the temperature was raised to 100° C., and the reaction was kept for 30 minutes. Then the above-mentioned treated cotton fabric is taken out, washed with water, and dried in the air, thereby obtaining the non-ironing cotton fabric A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com