Patents

Literature

32results about How to "Little strength damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

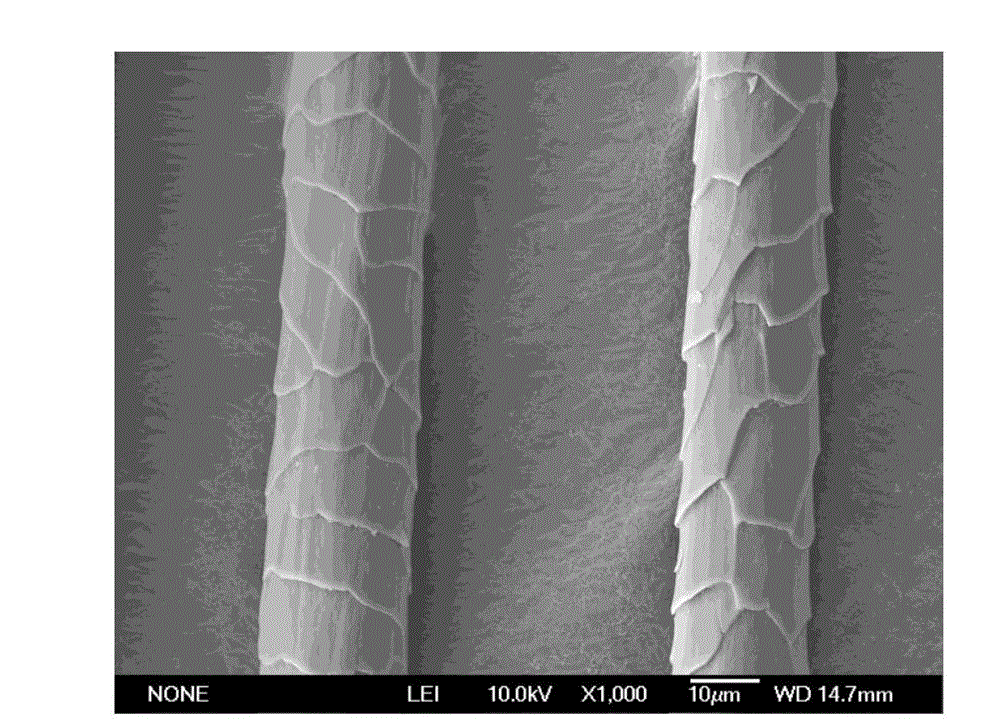

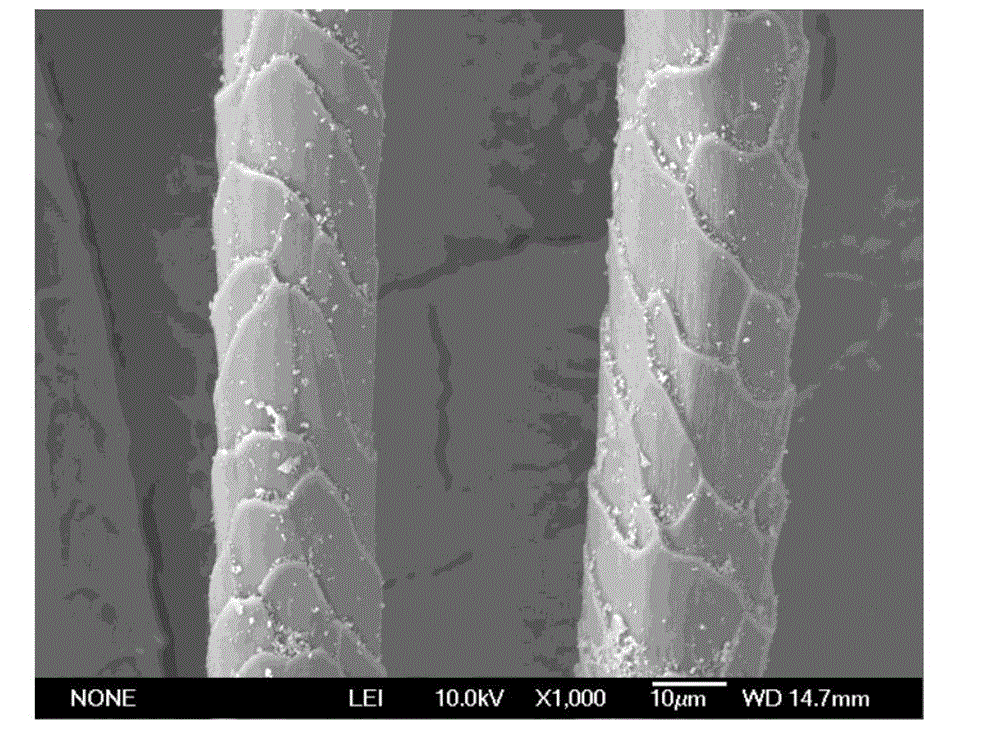

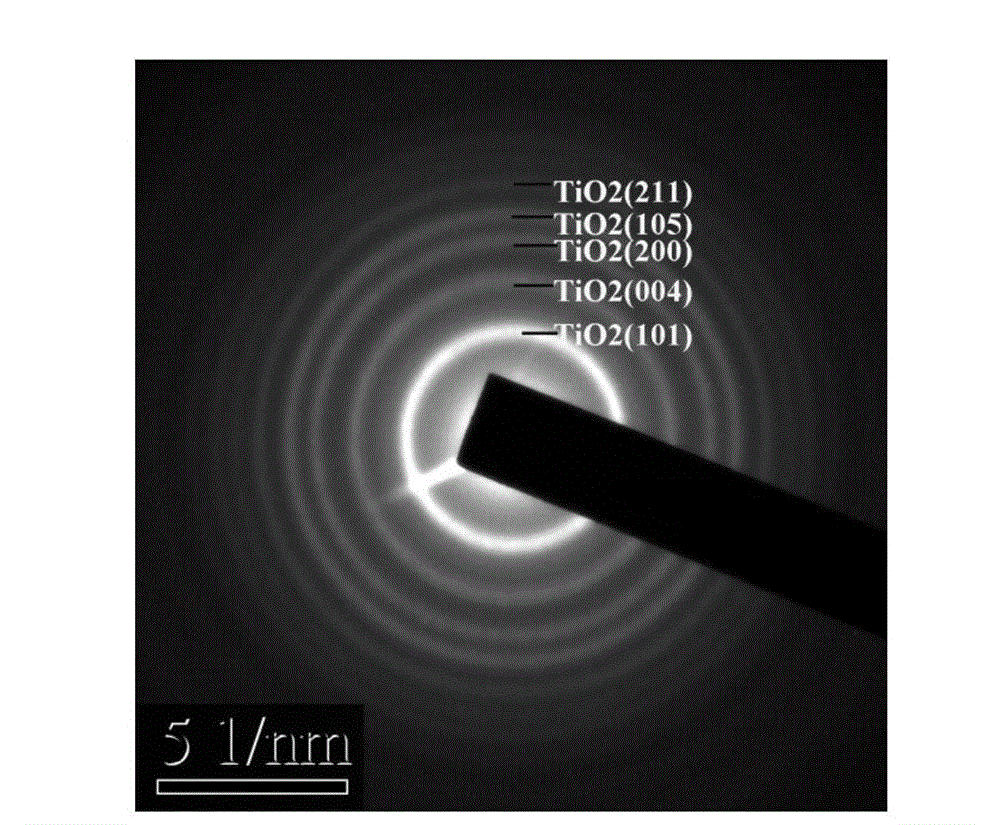

Method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan

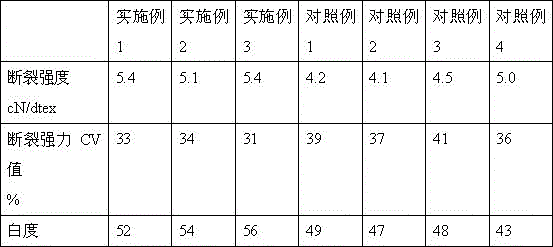

InactiveCN102912634ALittle strength damageSolve the problem of dyeingAnimal fibresPre treatmentWool fiber

The invention discloses a method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan; and the method is implemented in the following steps of: (1) soaking wool fibers in a sodium carbonate solution; pretreating the wool fibers in the sodium carbonate solution; and washing and drying the pretreated wool fibers; (2) preparing a chitosan mixed solution with low molecular weight; (3) preparing a precursor solution; (4) adding the chitosan mixed solution with low molecular weight to the precursor solution, so as to prepare a modifying solution; and (5) carrying out aftertreatment on the modified wool fibers, so as to finish the modification of the wool fibers by using the tetrabutyl titanate and the chitosan. Nanometer titanium dioxide and chitosan films are directly loaded on the surfaces of the wool fibers; and problems of difficulty in heavy-shade dyeing, poorer antibacterial property, low color fastness to sunlight and easiness for felting shrinkage in the wool fibers obtained by the traditional modifying method are solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Pre-processing, polishing and dyeing one-bath process for cotton knitted fabric

InactiveCN102505503ALow dyeabilityImprove dyeing effectBiochemical fibre treatmentDyeing processPectinaseWax

The invention relates to a pre-processing, polishing and dyeing one-bath process for cotton knitted fabric; the pre-processing, polishing and dyeing one-bath process comprises the following steps of: processing the cotton knitted fabric by adopting pectinase, neutral cellulase, a refined penetrating agent and a buffer solution, removing a part of or all pectin, wax, oil stains, ash contents and other impurities affecting the dyeing performance on the knitted fabric, endowing the fabric with good wettability and then carrying out a conventional reactive dye dyeing process. As a method of combining biological enzyme and a chemical assistant is adopted, the fabric is deeply colored and has good hand feeling. The pre-processing, polishing and dyeing one-bath process provided invention has the beneficial effects that as the three procedures, i.e. processing, polishing and dyeing the cotton knitted fabric are combined into one bath, the processing procedure is reduced, the production efficiency is improved, the high-temperature treatment is avoided, and the wastewater discharge quantity is reduced; and moreover, the requirements of energy conservation and emission reduction in the dyeing industry are satisfied.

Owner:ZHEJIANG FURUN DYEING & PRINTING

Bleaching method of fenther fabric

The present invention discloses a bleaching method of feather fabric. It includes the following steps: firstly, using ferrous ions to pretreat the feather fabric, then making selective oxidation in hydroperoxide solution, finally making reduction bleaching in sodium hydrosulfite. Said method not only can remove natural colour mater containing in feather fabric, but also can raise whiteness of fabric.

Owner:SOUTH CHINA UNIV OF TECH

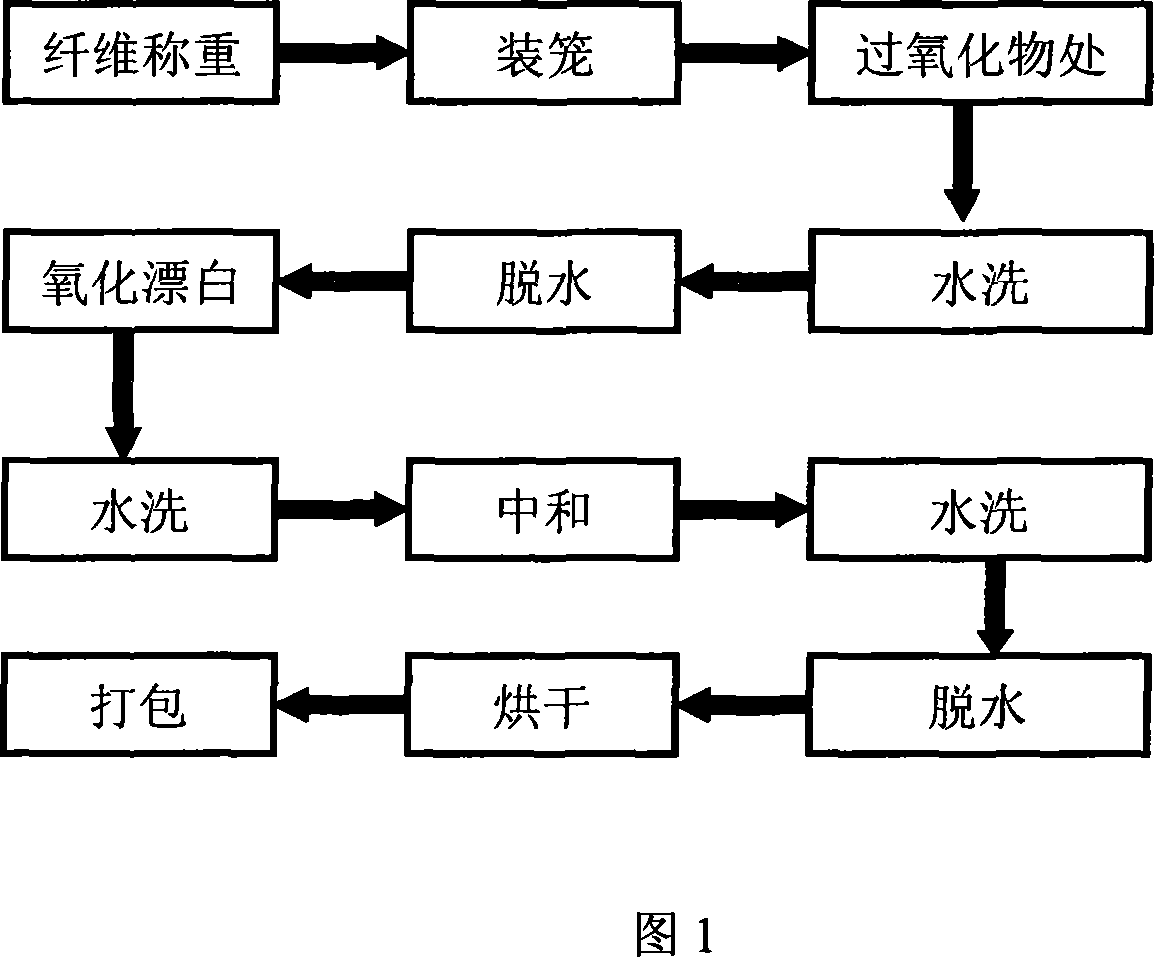

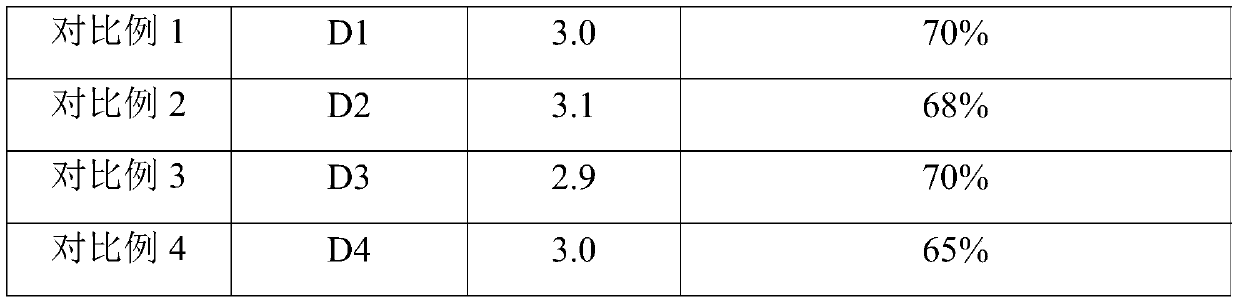

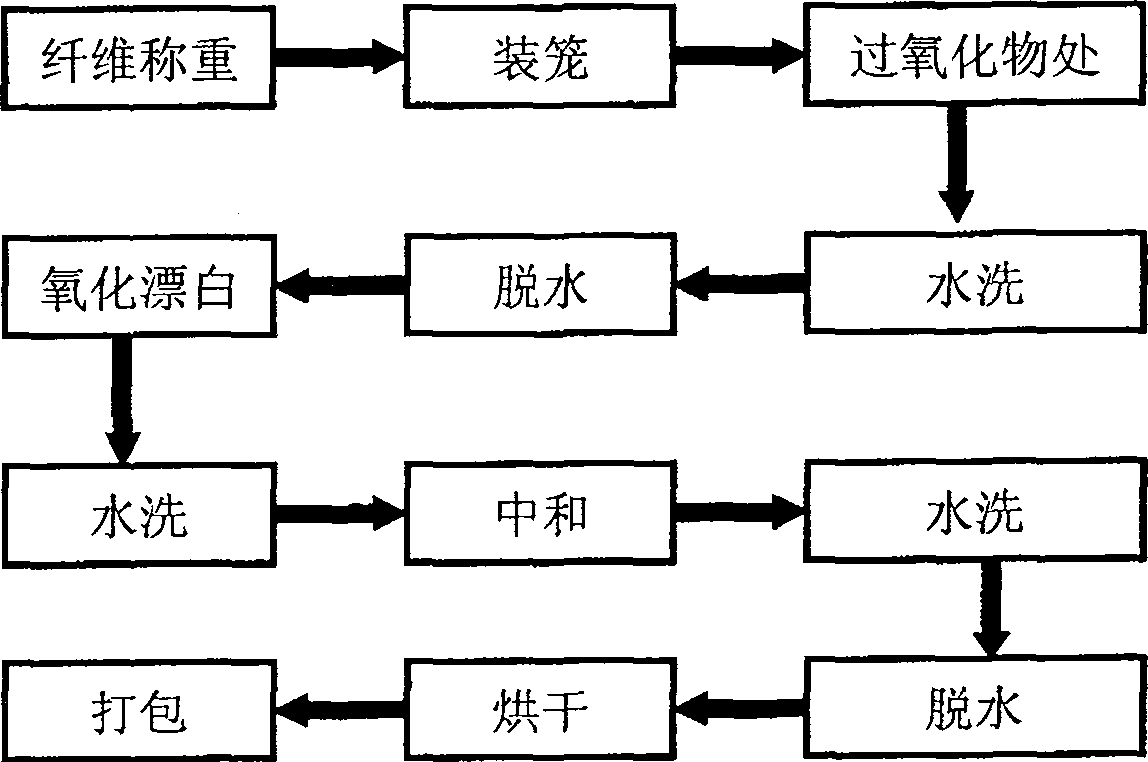

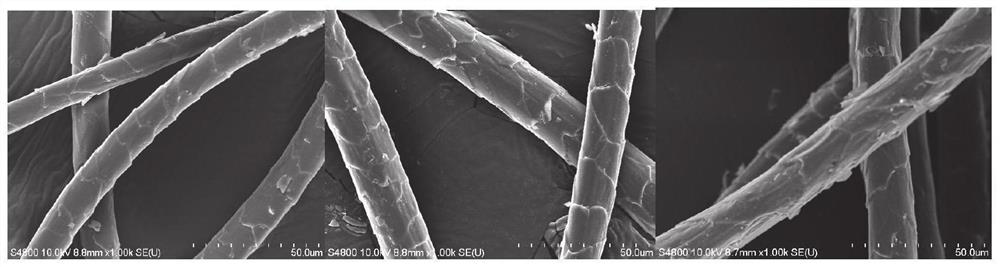

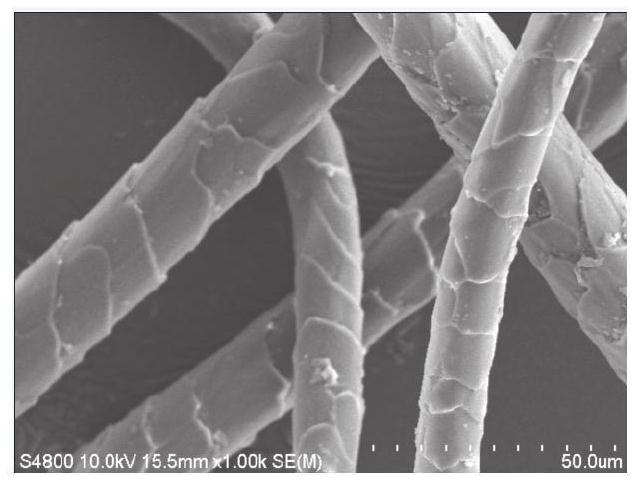

Method for bleaching tossa

InactiveCN101148820ALittle strength damageEasy to splitBleaching apparatusFiberUltimate tensile strength

The process of bleaching jute fiber includes the following steps: treating with peroxide, twice water washing, oxidization bleaching, water washing, neutralizing and water washing. The bleaching process has high fiber whiteness, less damage on fiber, high fiber separating index, high impurity eliminating effect, less yellowing of the fiber product, and capacity of improving the spinnability and dyeing and finishing performance of the fiber.

Owner:DONGHUA UNIV

Degumming technology of natural bamboo fiber

ActiveCN106012044AImprove degumming efficiencyImprove degumming effectFibre treatment to obtain bast fibrePlant fibreHigh pressure

The invention relates to a degumming technology of natural bamboo fiber, and belongs to the technical field of plant fiber manufacturing. The technology comprises the steps that bamboo chips are pretreated to be hammered into thin filaments, then the thin filaments are sequentially subjected to the processes such as acid soaking, steaming, fermenting, enzymolysis, bleaching, oiling, softening, dewatering, opening and drying, and the natural bamboo fiber is prepared. Accordingly, the acid soaking-high pressure steaming-microbial degumming composite technology is adopted, the synergist effect is generated among the steps, therefore, the degumming effect of the natural bamboo fiber is improved, and the prepared fiber has the advantages of being high in degumming efficiency and little in damage to the fiber intensity.

Owner:四川长盛新材料科技有限公司

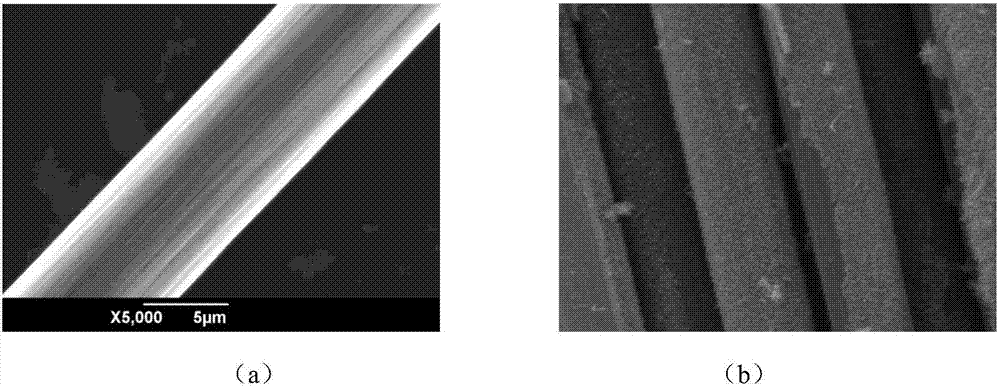

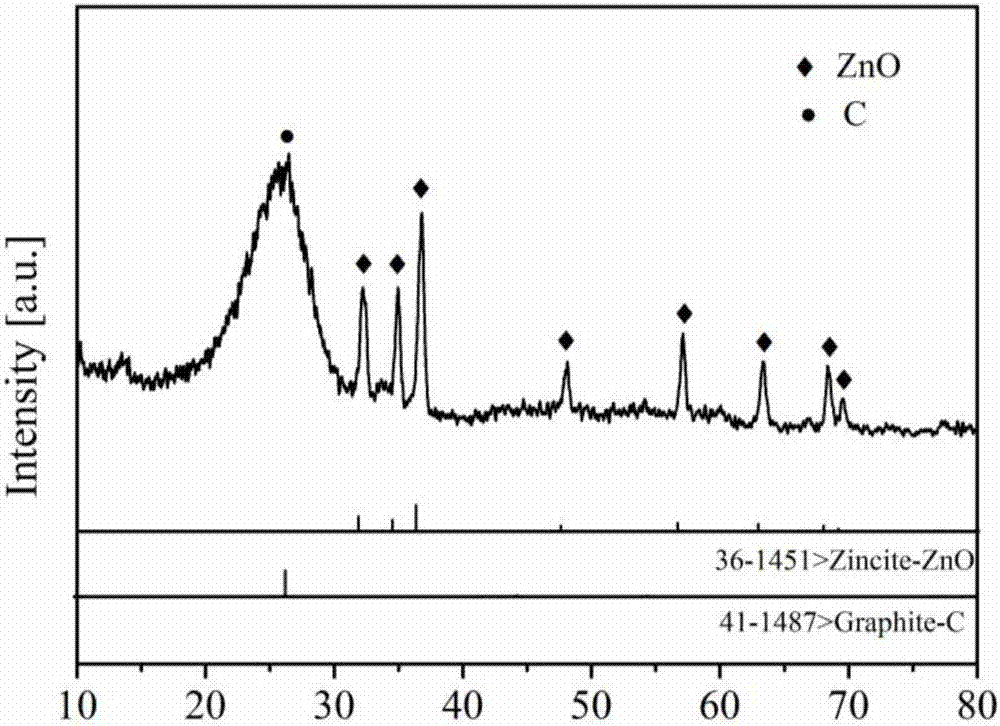

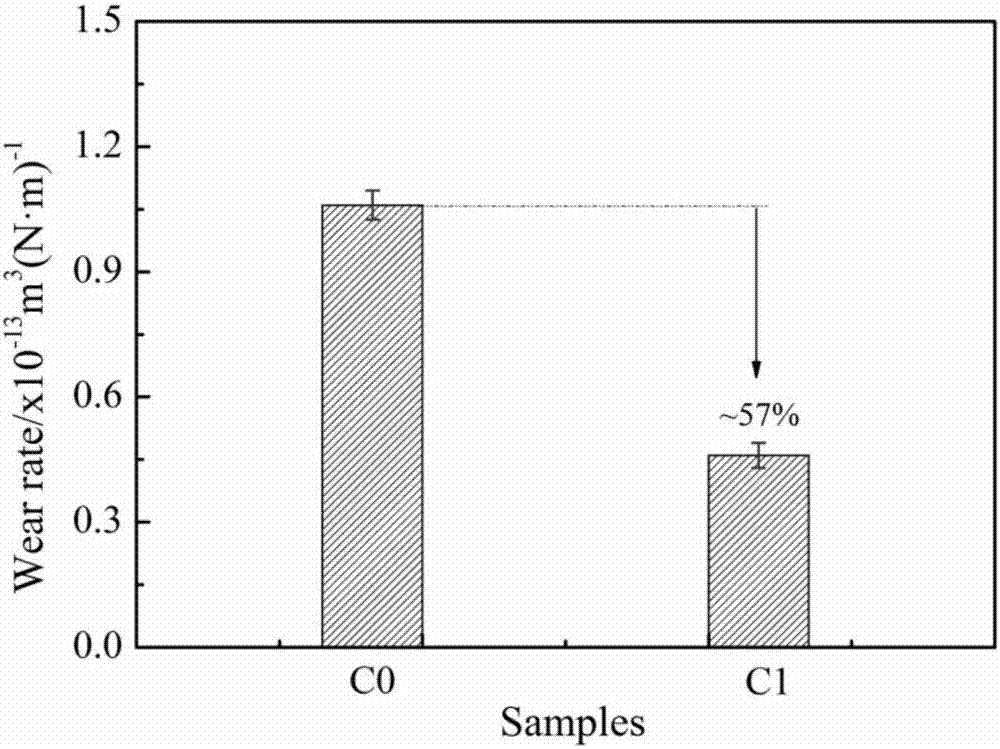

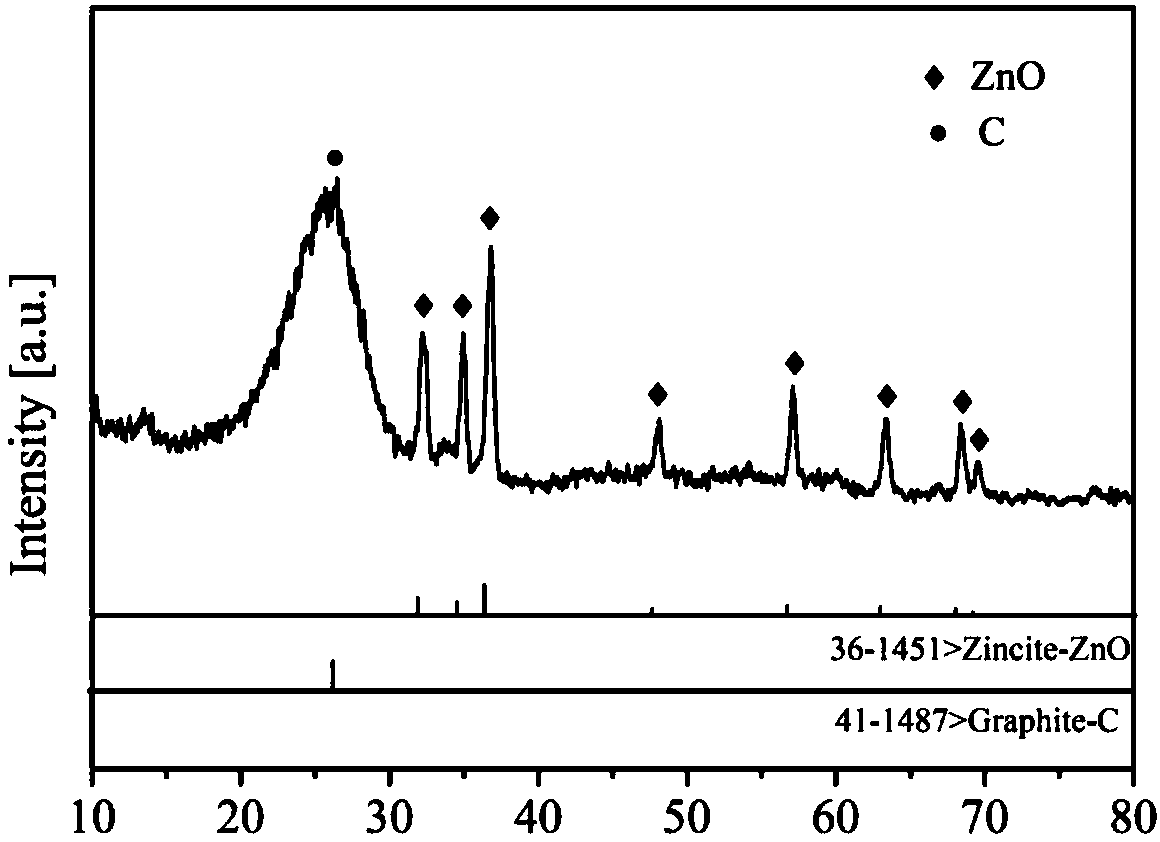

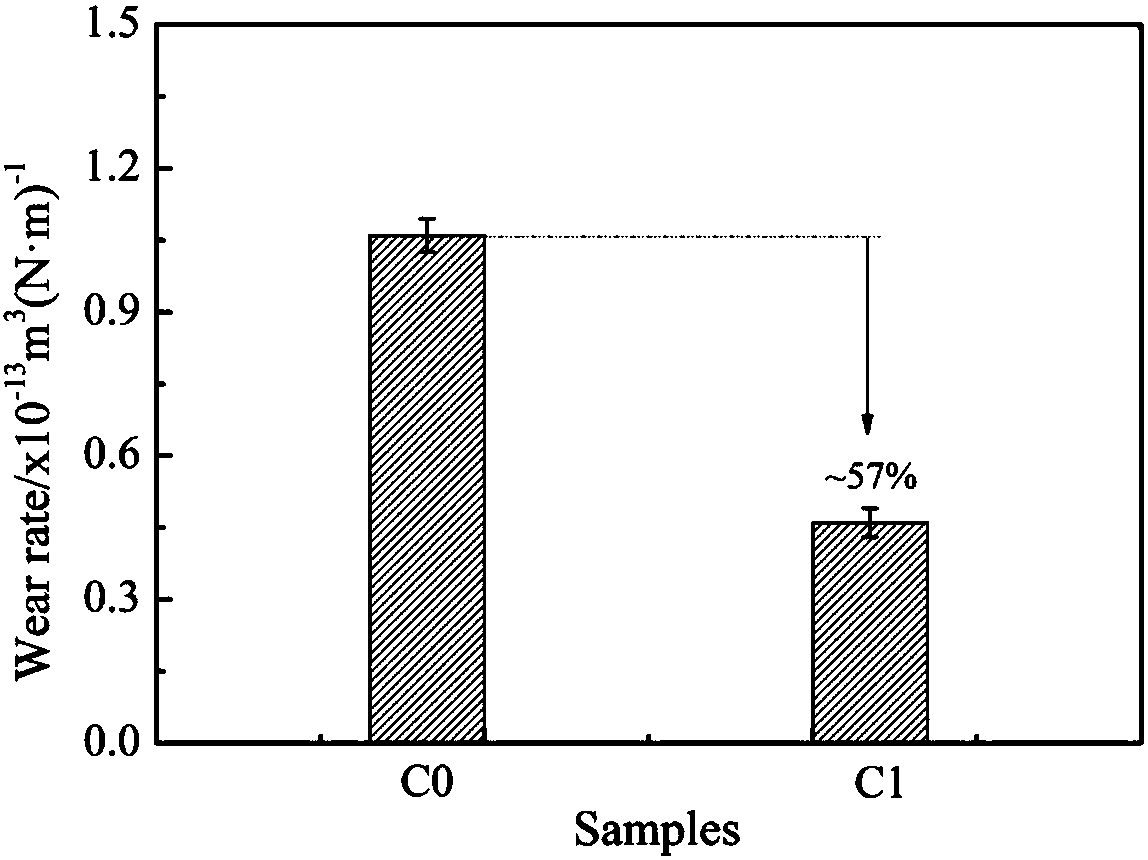

Preparation method of zinc oxide nanowire/carbon clothfriction material

ActiveCN106867450AUniform growthPromote growthOther chemical processesCarbon fibresTalc / Zinc OxideHardness

The invention discloses a preparation method of a zinc oxide nanowire / carbon clothfriction material. The preparation method comprises the steps of firstly soaking carbon cloth cleaned by acetone in hydrogen peroxide, then carrying out crystal seed layerimpregnation on the processed carbon cloth, then adjusting pH of a growth solution to range from 8 to 10, putting the carbon cloth in a hydrothermal reaction liner for hydrothermal growth, and finally successfully growing a zinc oxide nanowire on the carbon cloth; impregnating prepared the zinc oxide nanowire / carbon cloth multi-scale enhanceosome in a resin solution, taking out for naturally drying, and hot pressing through a vulcanizing machine to obtain the friction material. According to the preparation method of the zinc oxide nanowire / carbon clothfriction material provided by the invention, the carbon cloth is processed, so that surface oxygenic functional groups are increased; a crystal seed layer is impregnated, so that the zinc oxide nanowire grows uniformly in a certain hydrothermal environment. The zinc oxide is significant in activity, moderate in hardness, and suitable for building the multi-scale enhanceosome of the friction material so as to improve a frictional wear performance of the friction material.

Owner:SHAANXI UNIV OF SCI & TECH

Natural plant fiber modifying agent and surface modifying method of natural plant fibers

InactiveCN105113250ALow costImprove modification efficiencyDry-cleaning apparatus for textilesVegetal fibresPlant fibreSurface-active agents

The invention discloses a natural plant fiber modifying agent. The natural plant fiber modifying agent comprises, by weight, 2-5 parts of surfactant, 5-10 parts of bridging agent and 780-800 parts of solvent. A surface modifying method of natural plant fibers comprises the following steps that firstly, the natural plant fibers are soaked into a cleaning agent to be cleaned to remove impurities, water is used for cleaning, and drying is conducted; secondly, the natural plant fibers dried in the first step are soaked into the natural plant fiber modifying agent and bathed in water for 10-20 min at the temperature of 70-90 DEG C, the natural plant fibers are taken out, standing and natural drying are conducted, and surface-modified natural plant fibers are obtained. According to natural plant fiber strengthened polymer composite materials processed through the natural plant fiber modifying agent and the modifying method, the tensile strength is increased by more than 20%, and the impact strength is increased by more than 15%.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

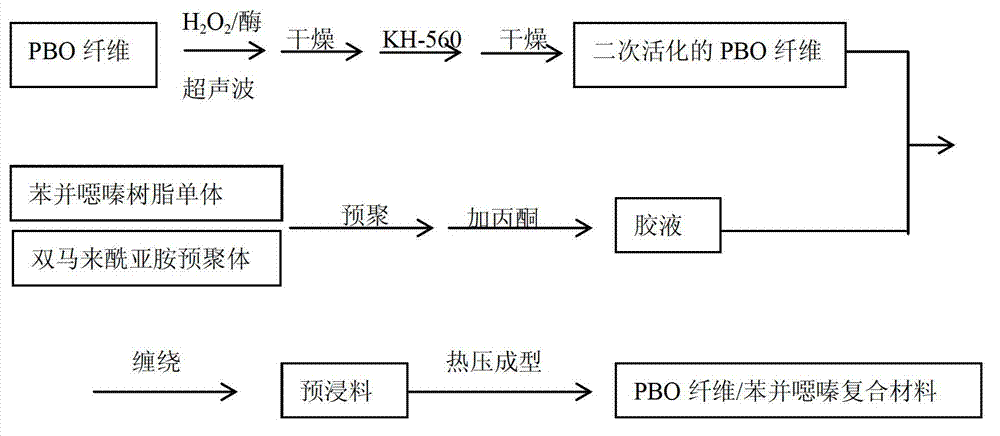

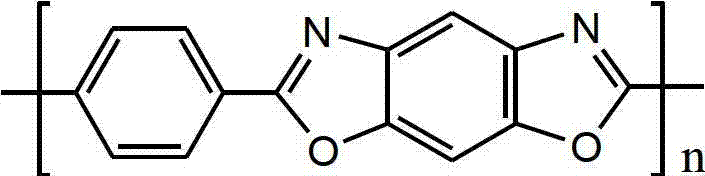

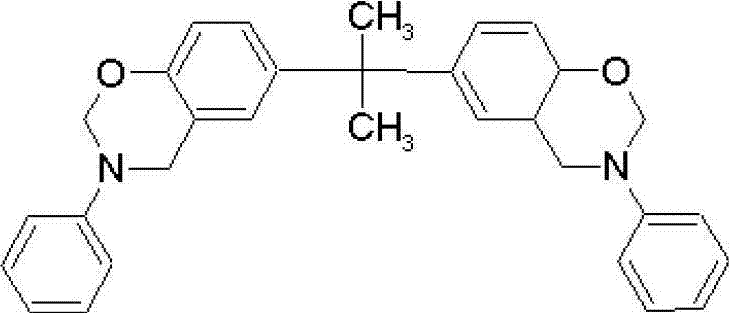

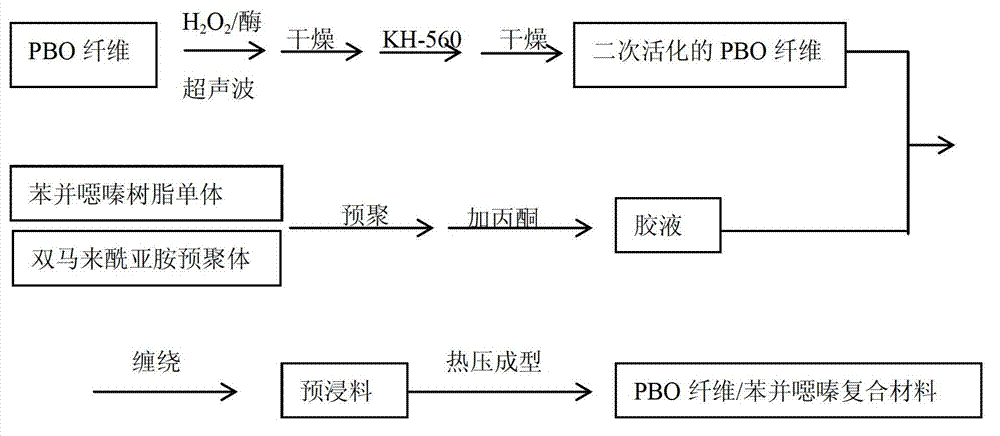

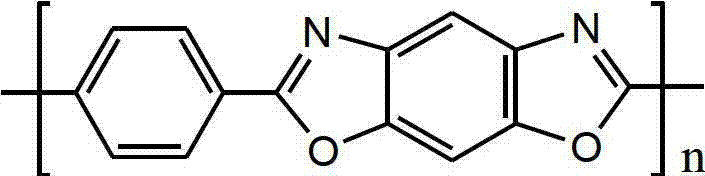

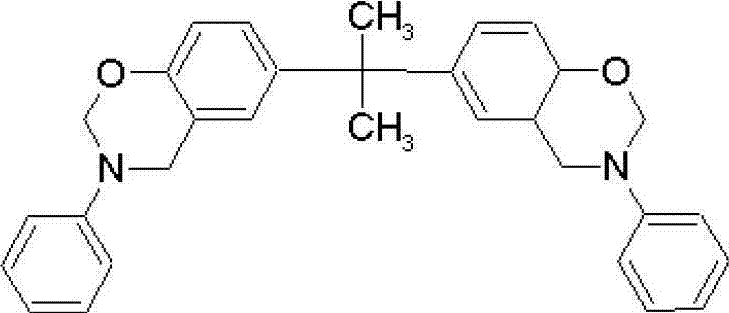

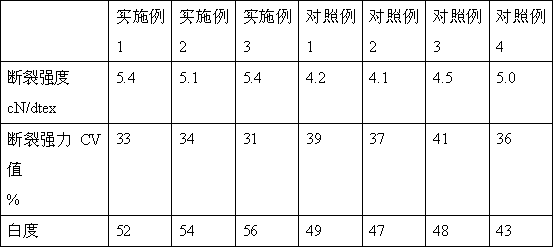

Process for preparing poly-p-phenylenebenzobisthiazole (PBO) fiber/benzoxazine composite material

InactiveCN102863634AHigh strengthHigh modulusBiochemical fibre treatmentPolymer scienceDielectric loss factor

The invention relates to a process for preparing a PBO fiber / benzoxazine composite material. The process is characterized by comprising the steps of firstly, immersing PBO fibers into an organic solution of horseradish peroxidase, dropping in an aqueous solution of 4 wt.% hydrogen peroxide, immersing in acetone containing KH-560, mixing bismaleimide prepolymers with benzoxazine resin monomers, conducting prepolymerization at the temperature in a range of 120-160 DEG C for 1-6 hours, then adding an acetone solution which is in a volume fraction of 1-5 times into the mixture to produce a glue solution, and conducting gum dipping on processed PBO fibers to obtain a prepreg. Finally, the prepreg is subjected to high-temperature compression moulding. The composite material which is prepared by the process has the advantages of being high in strength, high in modulus, resistant to high temperatures, high in interlaminar shear strength, low in dielectric constant and dielectric loss factor and capable of meeting the strict requirements of modern aviation fields for the composite material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

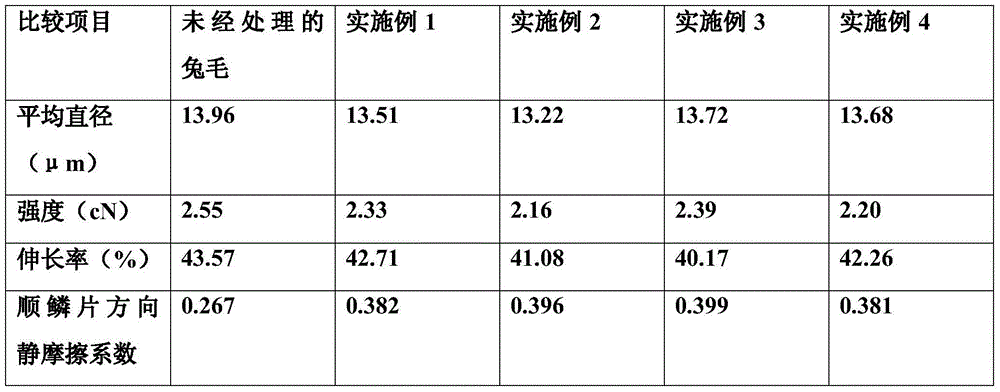

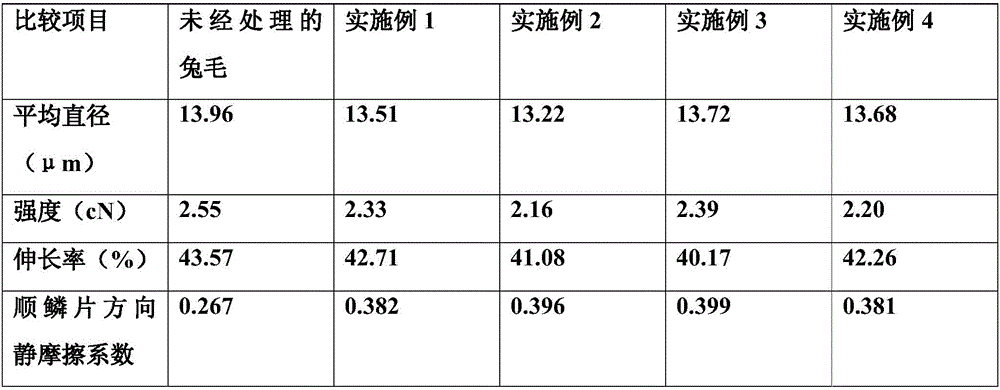

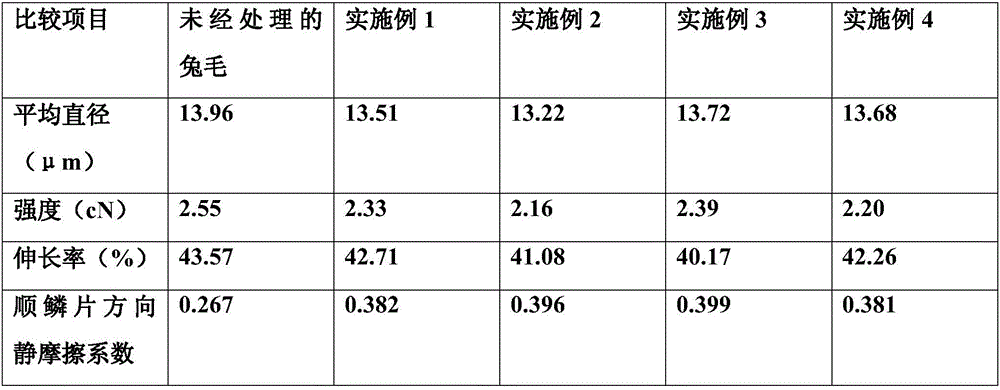

Rabbit hair fiber processing method

ActiveCN104894848AAvoid damageIncrease frictionBiochemical fibre treatmentDyeing processFiberReduction treatment

The invention provides a rabbit hair fiber processing method. The rabbit hair fiber processing method has the advantages that rabbit hair fibers are dyed after oxidation treatment, enzyme treatment and reduction treatment, so that the rabbit hair fibers are bright in color and luster, clear in grain, soft in hand feeling, high in elasticity, free from hair shedding and machine washable, cleaning and flattening effects on the rabbit hair fibers are achieved, intertwining of the rabbit hair fibers during spinning is reduced, high durability is achieved, and the rabbit hair fibers do not fade and discolor during long-term use.

Owner:NINGBO ZHENHAI DEXIN RABBIT FUR PROCESSING FACTORY

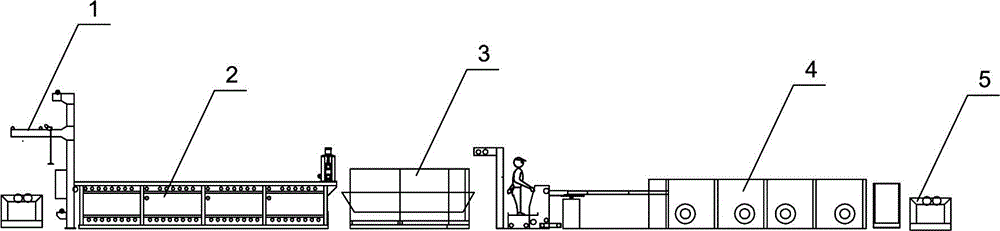

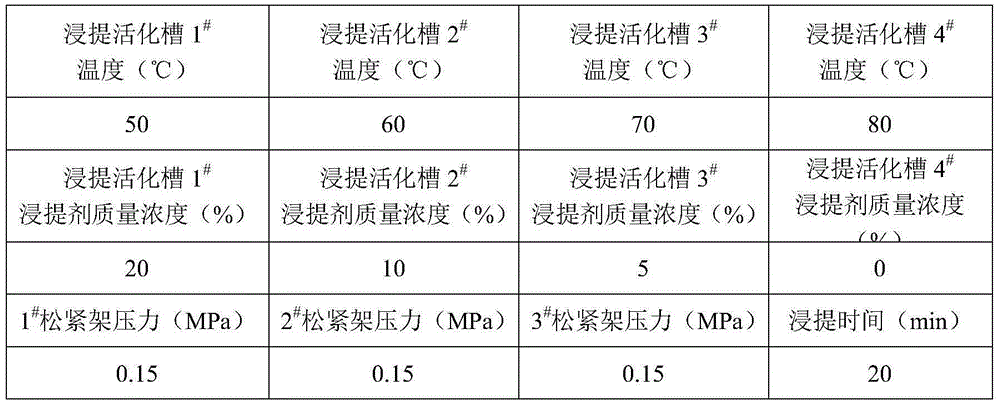

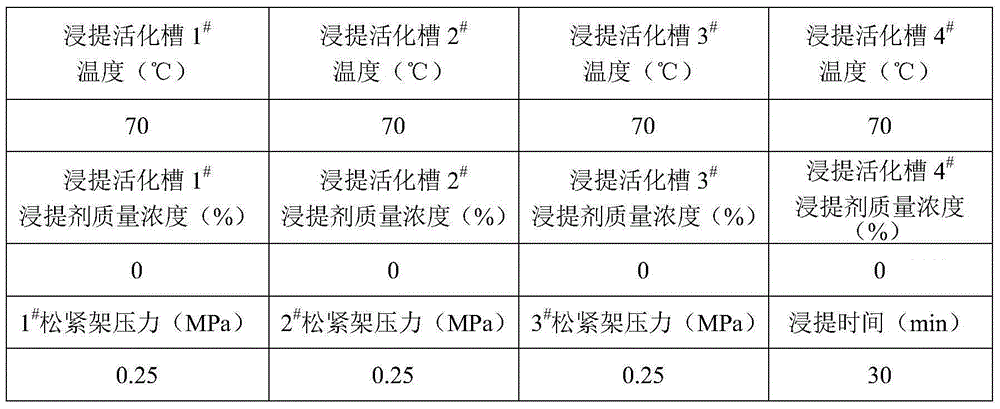

Modacrylic carbon-doped fiber gray fabric after-treatment process and device

ActiveCN105133225AImprove reliabilityReduce tensionSolvent-treatmentTextile treatment machine partsCarbon dopedChemistry

The invention discloses a modacrylic carbon-doped fiber gray fabric after-treatment process and device. The process comprises the following steps: firstly, conducting extraction treatment on modacrylic carbon-doped fiber gray fabric, wherein the mass concentration of an extracting agent is 0-20%, the extracting temperature is 50-80 DEG C, and the extracting time is 20-30 min; then pre-baking the treated gray fabric, wherein the drying temperature is 70-90 DEG C, and the drying time is 1-3 min; finally, conducting tentering and shaping on the gray fabric, wherein the tentering and shaping temperature is controlled to be 135-145 DEG C, and the vehicle speed is 2-4 m / min; finishing the after-treatment operation. Through the extraction and activation treatment, adsorption capacity of the modacrylic carbon-doped fiber fabric can be restored, abrasion on the fabric can be reduced due to the integrated after-treatment, possibility of critical defects of yarn breaking and the like is low, and the reliability of chemical toxic agent protection is improved.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

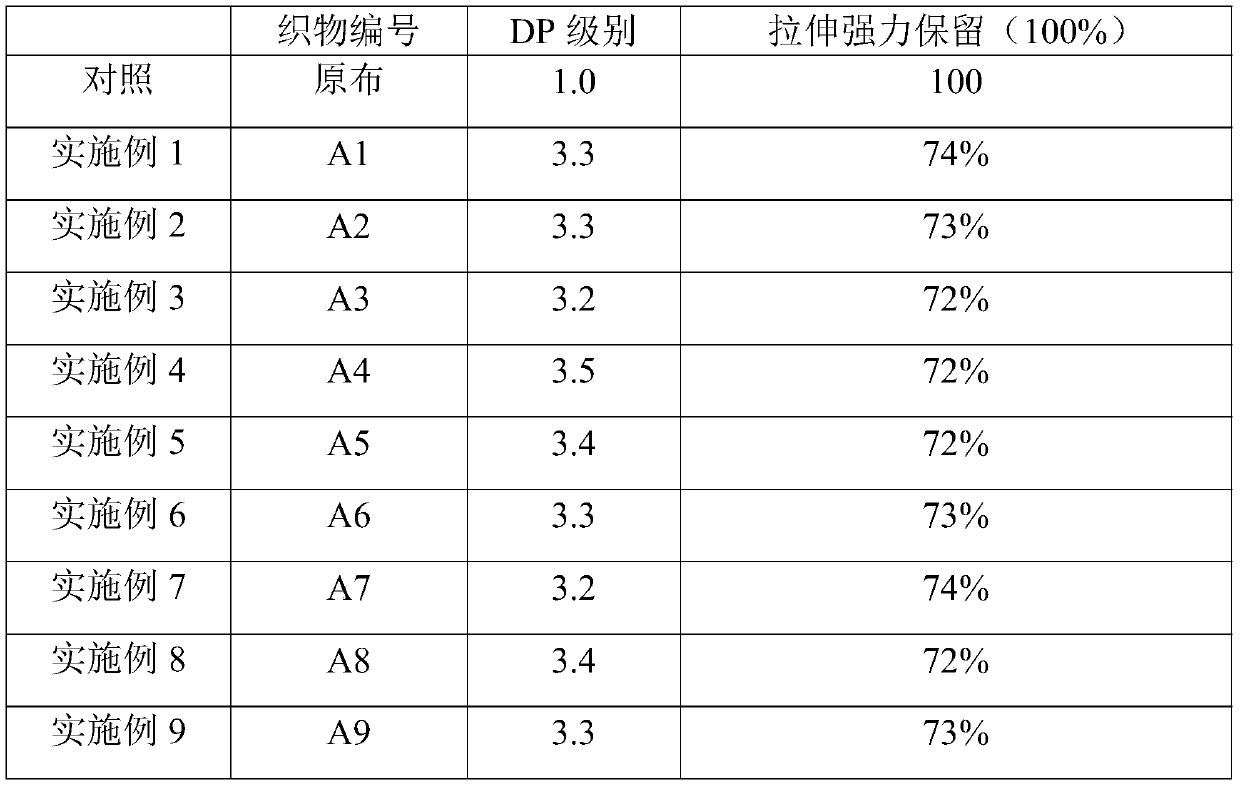

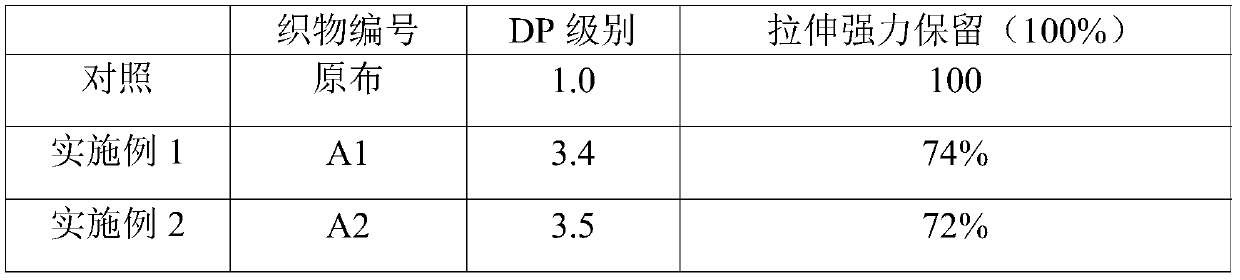

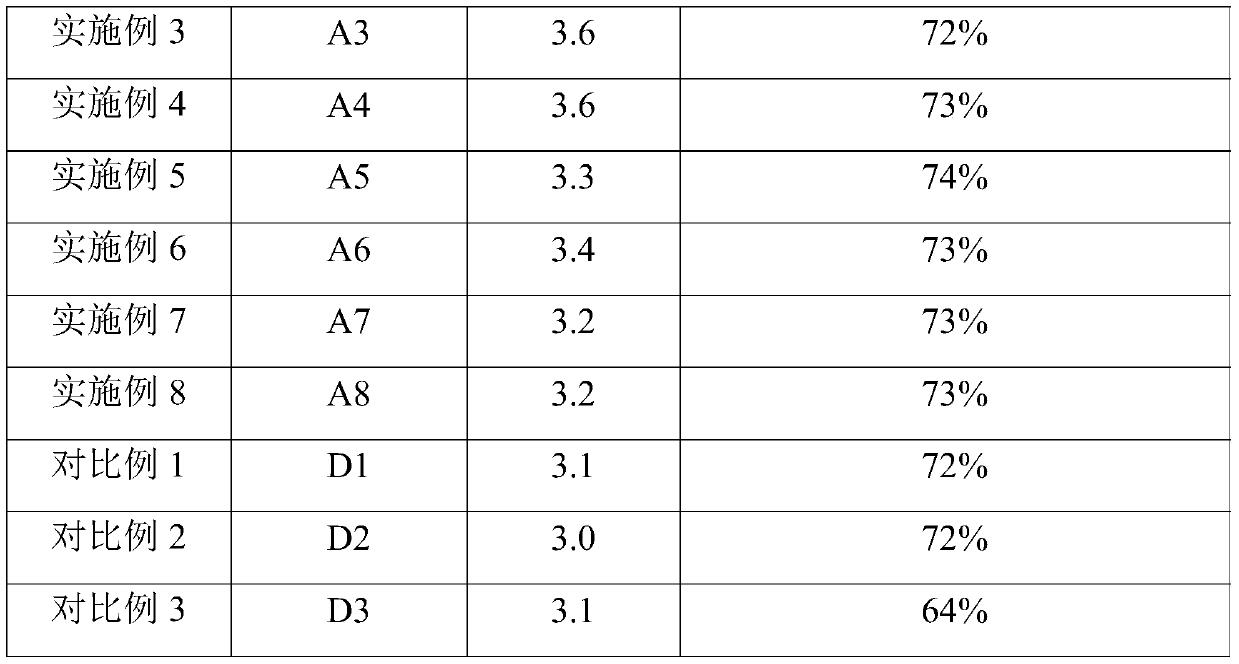

In-situ wash-and-wear finishing method of cotton fabric by acrylic acid and glyoxal

ActiveCN110820338AImprove permeabilityEfficient use ofVegetal fibresTextile technologyPolymer science

The invention relates to an in-situ wash-and-wear finishing method of cotton fabric by acrylic acid and glyoxal, which comprises the steps of (1) adding ethanol to water, adding cotton fabric, and stirring at 40-60 DEG C for 10-30 minutes; (2) adding acrylic acid at 40-60 DEG C for 30-60 minutes; (3) adding glyoxal, unsaturated acid salt and persulfates sequentially under ultrasonic stirring, raising the temperature to 80-100 DEG C, and holding the temperature to allow to react for 30-90 minutes; and (4) taking out the treated cotton fabric before washing with water and airing. The cotton fabric finished by adopting the in-situ wash-and-wear finishing method disclosed by the invention has better easy-care and crease-resistant performances, and also has higher strength retention.

Owner:WUHAN TEXTILE UNIV

Method for bleaching tossa

InactiveCN100503959CLittle strength damageEasy to splitBleaching apparatusFiberUltimate tensile strength

Owner:DONGHUA UNIV

Elastic swimwear fabric printing technology

The invention discloses an elastic swimwear fabric printing technology. The technological process comprises steps as follows: printing, steaming, cleaning, reduction cleaning, washing and drying. The printing paste has good stability, printed fabric has high color fastness, high color fixation and high color yield, the technology is simple, the operation is easy, the strength damage is small, and the application range is wide.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Anti-pilling finishing method and anti-pilling finishing liquid for fluffy fabric

PendingCN112962318AGood solubilityGood compatibilityBiochemical treatment with enzymes/microorganismsGrip property fibresSilicone fluidProtease

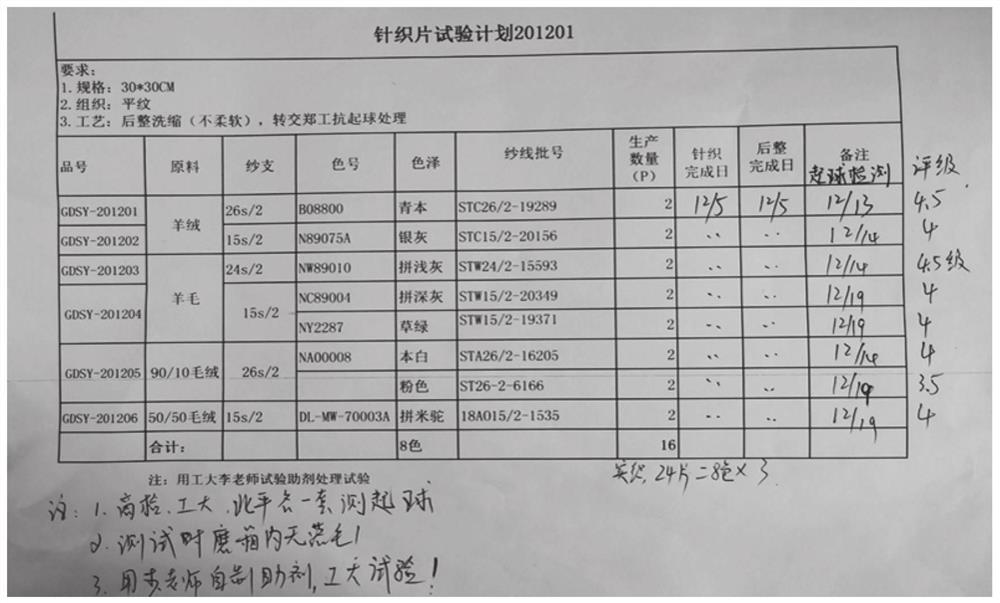

The invention discloses an anti-pilling finishing method and an anti-pilling finishing liquid for a fluffy fabric. The anti-pilling finishing method for the fluffy fabric comprises the following steps of (1) conducting soaking pretreatment of the fluffy fabric; (2) preparing the anti-pilling finishing liquid for the fluffy fabric; (3) conducting anti-pilling finishing of the fluffy fabric; and (4) dewatering and drying after finishing. The anti-pilling finishing liquid for the fluffy fabric comprises the following components of 1.5-2.0% (o.w.f) of a reducing agent, 1-1.5% (o.w.f) of a penetrating agent, 3-4% (o.w.f) of amino silicon oil and 0.1-0.15% (o.w.f) of protease. The fluffy fabric finished by the method is measured by a box-type pilling instrument, the anti-pilling grade can reach 4-5 grade after 2 hours of rolling friction, and the anti-pilling grade can reach 4 grade after 5 hours of rolling friction. The technology is simple, the finishing time is shortened to only 20 min, damage to fiber strength is small, discoloration is avoided, the hand feeling is good, and wool falling does not exist in a box after 2-5 hours of rolling friction.

Owner:INNER MONGOLIA UNIV OF TECH

Double bleaching process for woolen knitwear

The invention relates to a double bleaching process for woolen knitwear. The bleaching process comprises a step of oxidation bleaching and a step of re-reduction brightening. According to the step of oxidation bleaching, hydrogen peroxide with a concentration of 15 mol / L and ammonia water with a concentration of 0.3 to 0.5% are used; the hydrogen peroxide is added when temperature is 30 DEG C; heating is carried out in 20 min so as to allow the temperature to rise to 50 DEG C, and heat preservation is carried out for 10 min; then the ammonia water is added, and heat preservation is carried out for 90 min; and after bleaching, cooling and flushing are carried out until no hydrogen peroxide is left. According to the step of re-reduction brightening, rinse powder with a concentration of 12 to 18% and a brightening agent WG with a concentration of 0.2 to 0.7% are used; the rinse powder and a solution of the brightening agent are added when temperature is 30 DEG C; heating is carried out so as to allow the temperature to rise to 75 to 80 DEG C within 45 to 50 min; bleaching is carried out for 60 while the temperature is maintained; and after bleaching, cooling and cleaning are carried out. A wool fabric produced by using the process has long-lasting whiteness, is not prone to yellowing, presents good hand feeling, suffers from little strength loss and is applicable to bleaching of worsted wool fabrics.

Owner:WUXI ERQUAN KNITTING MILL

Preparation method of C/C-SiC composite material with high thermal conductivity

The invention provides a preparation method of a high-thermal-conductivity C / C-SiC composite material, which comprises the following steps: carbonizing mesophase pitch carbon fibers by using a two-stage carbonization method, weaving the carbonized mesophase pitch carbon fibers into carbon cloth, and puncturing the carbon cloth in the Z direction by using PAN-based carbon fibers by using a fine weaving puncture method to obtain a three-dimensional prefabricated body; and after the three-dimensional prefabricated body is subjected to graphitization treatment, densifying the three-dimensional prefabricated body through a pyrolytic carbon method, then subjecting the three-dimensional prefabricated body to graphitization, and densifying the three-dimensional prefabricated body through a chemical vapor reaction method, so as to obtain the three-dimensional high-thermal-conductivity C / C-SiC composite material.

Owner:湖南东映碳材料科技有限公司

In-situ non-ironing method for finishing cotton fabric through acrylic acid series of finishing agents

ActiveCN110835847AImprove permeabilityEfficient use ofWrinkle resistant fibresVegetal fibresTextile technologyPolymer science

The invention relates to the field of the textile technology, and discloses an in-situ non-ironing method for finishing cotton fabric through acrylic acid series of finishing agents. The method includes the following steps: (1) adding ethanol into water, adding the cotton fabric, and stirring at 40-60 DEG C for 5-30 minutes; (2) adding acrylate, and stirring at 40-60 DEG C for 10-60 minutes; (3) adding unsaturated acid salt and persulfate in sequence under ultrasonic stirring, increasing the temperature to 80-100 DEG C, and carrying out a reaction under heat insulation for 10-60 minutes; and (4) taking out, washing and air-drying the treated cotton fabric. The cotton fabric obtained by the in-situ non-ironing method has good non-ironing and anti-wrinkle performance and high strength retention.

Owner:WUHAN TEXTILE UNIV

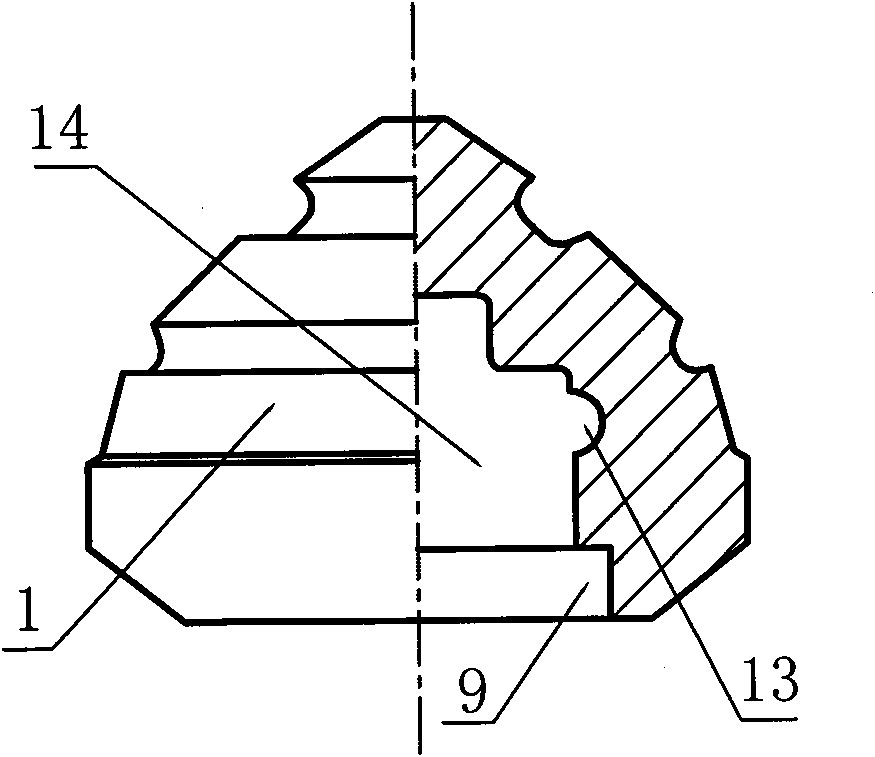

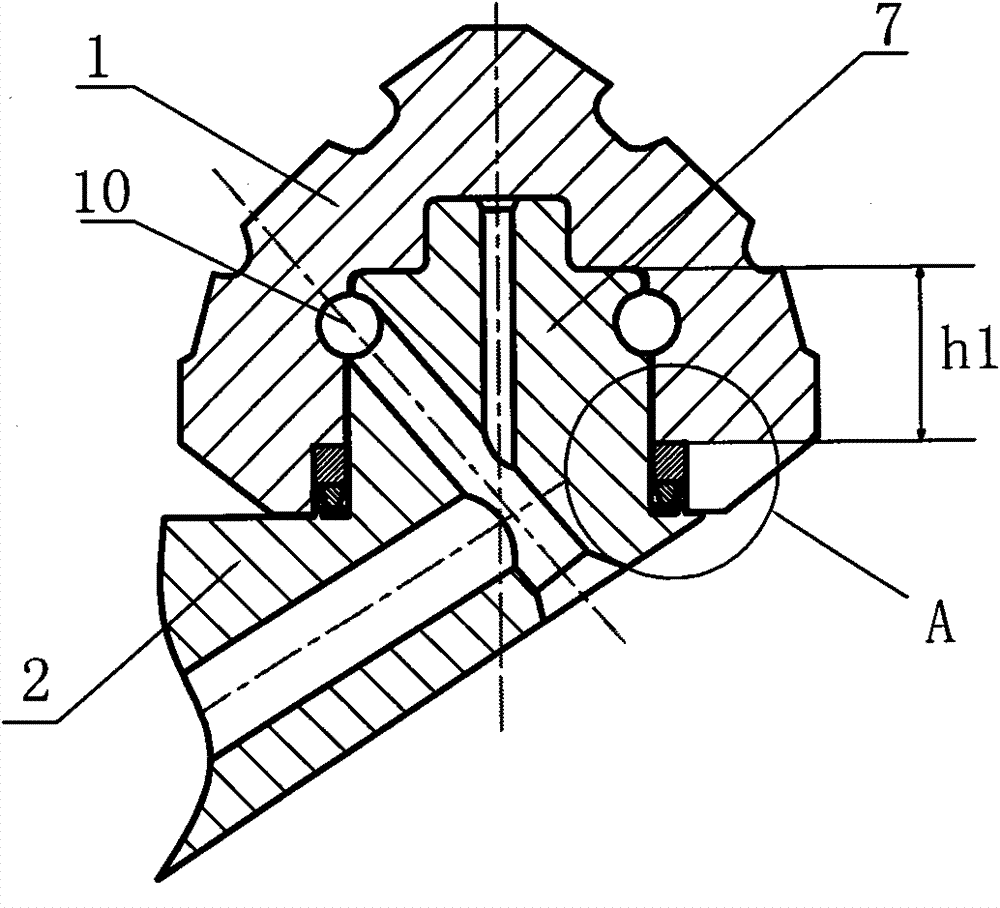

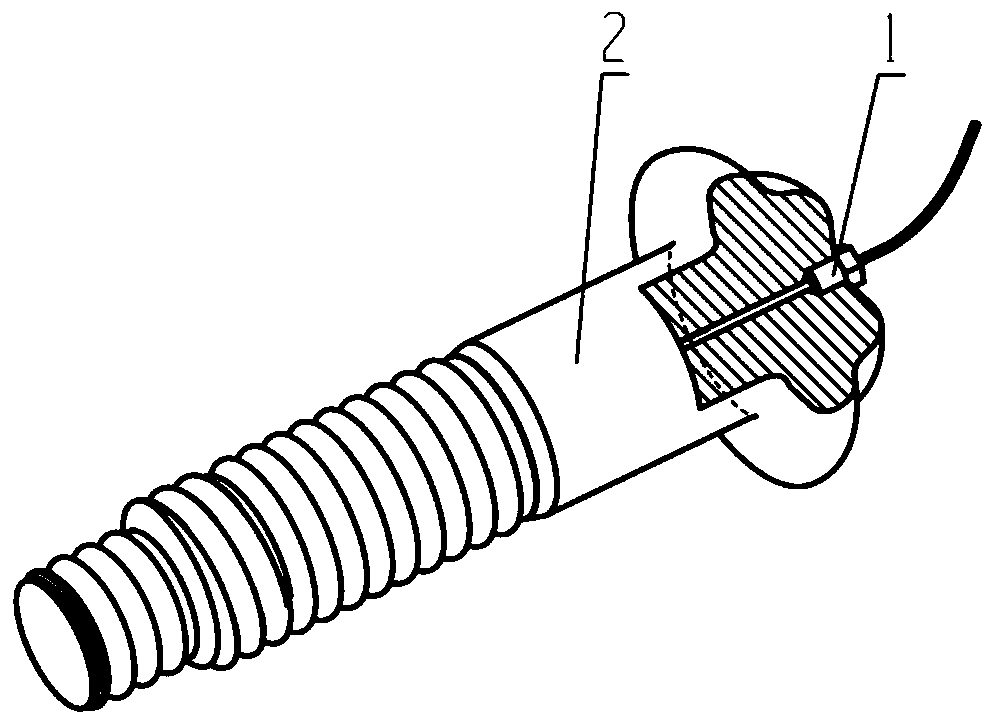

Bearing seal of single-sealing ring cone bit

InactiveCN101956529BIncrease heightIncrease the areaConstructionsEngineeringUltimate tensile strength

Owner:烟台瑞邦石油钻头有限公司

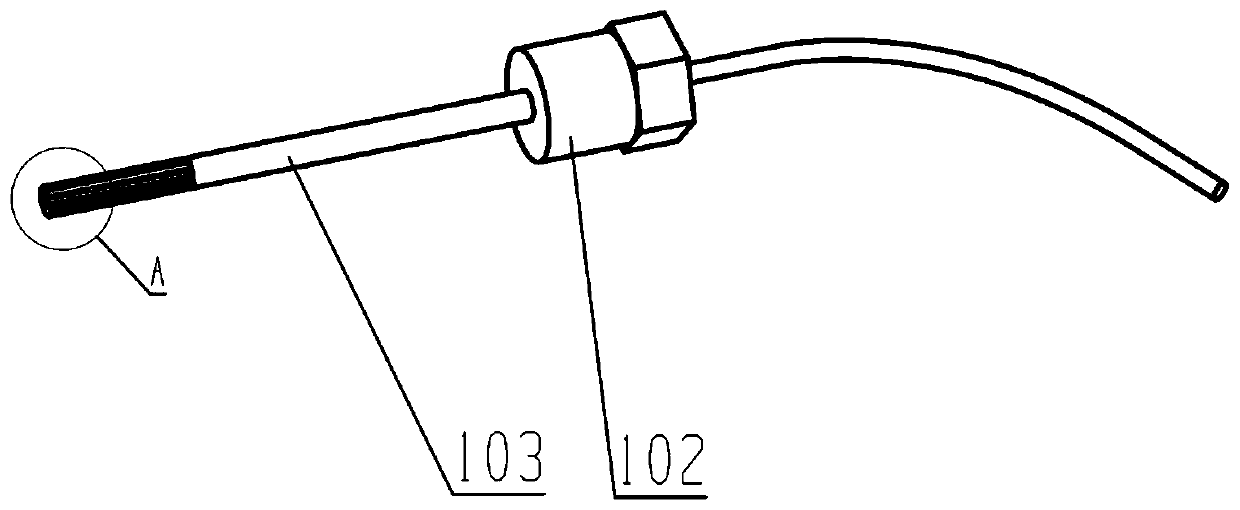

Grating smart ring groove rivet

PendingCN111503112AReduced pre-compressionLittle strength damageRivetsForce measurement by measuring optical property variationGratingRivet

The invention discloses a grating smart ring groove rivet which comprises a grating sensor and a ring groove rivet body; a blind hole with a step structure is formed in the position, from a head to arivet bar, of the center of a rivet shaft of the ring groove rivet body; the measuring end of the grating sensor is located in the blind hole and is in contact with the bottom of the blind hole; and the grating sensor is provided with an end fixing device to be in threaded connection and fixing with a step portion of the blind hole of the ring groove rivet body. By adopting the grating smart ringgroove rivet provided by the invention, the problem that axial force cannot be monitored in real time in the installation and use process of the ring groove rivet is solved; and meanwhile, the servicelife of the sensor is prolonged through the grating sensor armored by a stainless steel protective sleeve; as the grating sensor and the ring groove rivet are in threaded connection, the grating sensor is detachable and used for multiple times, the use rate of the grating sensor is increased, and the cost can be saved; and with arrangement of the grating sensor, strength damages to the ring groove rivet can be reduced, and the grating sensor is suitable for the tail pull-off type ring groove rivet at the same time to realize monitoring of the axial force in the riveting process.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

Bleaching method of fenther fabric

The present invention discloses a bleaching method of feather fabric. It includes the following steps: firstly, using ferrous ions to pretreat the feather fabric, then making selective oxidation in hydroperoxide solution, finally making reduction bleaching in sodium hydrosulfite. Said method not only can remove natural colour mater containing in feather fabric, but also can raise whiteness of fabric.

Owner:SOUTH CHINA UNIV OF TECH

A preparation method of zinc oxide nanowire/carbon cloth friction material

ActiveCN106867450BUniform growthPromote growthOther chemical processesCarbon fibresEnhanceosomeHardness

The invention discloses a preparation method of a zinc oxide nanowire / carbon clothfriction material. The preparation method comprises the steps of firstly soaking carbon cloth cleaned by acetone in hydrogen peroxide, then carrying out crystal seed layerimpregnation on the processed carbon cloth, then adjusting pH of a growth solution to range from 8 to 10, putting the carbon cloth in a hydrothermal reaction liner for hydrothermal growth, and finally successfully growing a zinc oxide nanowire on the carbon cloth; impregnating prepared the zinc oxide nanowire / carbon cloth multi-scale enhanceosome in a resin solution, taking out for naturally drying, and hot pressing through a vulcanizing machine to obtain the friction material. According to the preparation method of the zinc oxide nanowire / carbon clothfriction material provided by the invention, the carbon cloth is processed, so that surface oxygenic functional groups are increased; a crystal seed layer is impregnated, so that the zinc oxide nanowire grows uniformly in a certain hydrothermal environment. The zinc oxide is significant in activity, moderate in hardness, and suitable for building the multi-scale enhanceosome of the friction material so as to improve a frictional wear performance of the friction material.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of processing method of rabbit hair fiber

ActiveCN104894848BAvoid damageIncrease frictionBiochemical fibre treatmentDyeing processFiberReduction treatment

The invention provides a rabbit hair fiber processing method. The rabbit hair fiber processing method has the advantages that rabbit hair fibers are dyed after oxidation treatment, enzyme treatment and reduction treatment, so that the rabbit hair fibers are bright in color and luster, clear in grain, soft in hand feeling, high in elasticity, free from hair shedding and machine washable, cleaning and flattening effects on the rabbit hair fibers are achieved, intertwining of the rabbit hair fibers during spinning is reduced, high durability is achieved, and the rabbit hair fibers do not fade and discolor during long-term use.

Owner:NINGBO ZHENHAI DEXIN RABBIT FUR PROCESSING FACTORY

A kind of surface modification method of natural plant fiber modifying agent and natural plant fiber

InactiveCN105113250BLow costImprove modification efficiencyDry-cleaning apparatus for textilesVegetal fibresVegetable fibersSolvent

The invention discloses a natural plant fiber modifying agent. The natural plant fiber modifying agent comprises, by weight, 2-5 parts of surfactant, 5-10 parts of bridging agent and 780-800 parts of solvent. A surface modifying method of natural plant fibers comprises the following steps that firstly, the natural plant fibers are soaked into a cleaning agent to be cleaned to remove impurities, water is used for cleaning, and drying is conducted; secondly, the natural plant fibers dried in the first step are soaked into the natural plant fiber modifying agent and bathed in water for 10-20 min at the temperature of 70-90 DEG C, the natural plant fibers are taken out, standing and natural drying are conducted, and surface-modified natural plant fibers are obtained. According to natural plant fiber strengthened polymer composite materials processed through the natural plant fiber modifying agent and the modifying method, the tensile strength is increased by more than 20%, and the impact strength is increased by more than 15%.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

A kind of processing method of rabbit hair

ActiveCN104963190BDamage intensityAvoid damageBiochemical fibre treatmentDyeing processFiberReduction treatment

The invention provides a processing method of rabbit hair fibers. Multiple rabbit hair fibers are merged, drawn and carded on a needle carding machine to obtain straight fiber rabbit hair strips. After oxidation treatment, enzyme treatment and reduction treatment, Dyeing treatment, finally twisting and steam permanent setting, processing the rabbit hair fiber, making the rabbit hair fiber bright in color, clear in texture, soft to the touch, good in elasticity, non-shedding, machine washable, and suitable for rabbit hair fiber The cleaning and spreading effect reduces the entanglement of rabbit hair fibers in weaving. It has superior durability and will not fade or change color in long-term use.

Owner:NINGBO ZHENHAI DEXIN RABBIT FUR PROCESSING FACTORY

Cotton knitwear low-temperature bleaching pre-treatment method

PendingCN111501324AImprove bleaching effectLittle strength damageDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsComposite materialCotton fibre

The invention discloses a cotton knitwear low-temperature bleaching pre-treatment method. The method comprises cotton knitwear low-temperature bleaching, water washing, acid neutralization and deoxygenization. Cotton knitwear is formed through blending of cotton fibers, cellulose acetate fibers and / or chitosan fibers, the content of the cellulose acetate fibers and / or chitosan fibers is above 20%,the low-temperature bleaching temperature is 70 to 80 DEG C, the time is 30 to 60 min, a treatment solution comprises 0.5 to 2 g / L of emulsifying agent, 0.5 to 1 g / L of penetration agent, 4 to 10 g / Lof caustic soda, 6 to 12 g / L of hydrogen peroxide and the balance water. It is unexpectedly found that acyl contained in special fibers such as the cellulose acetate fibers and the chitosan fibers can catalyze activated hydrogen peroxide to bleach cotton knitwear, it is ensured that the good bleaching effect is obtained at the low bleaching temperature, low-temperature bleaching is achieved without adding of activator / catalyst, the method is more friendly to the environment, and finally, energy saving and environment friendliness are achieved at the same time.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING +1

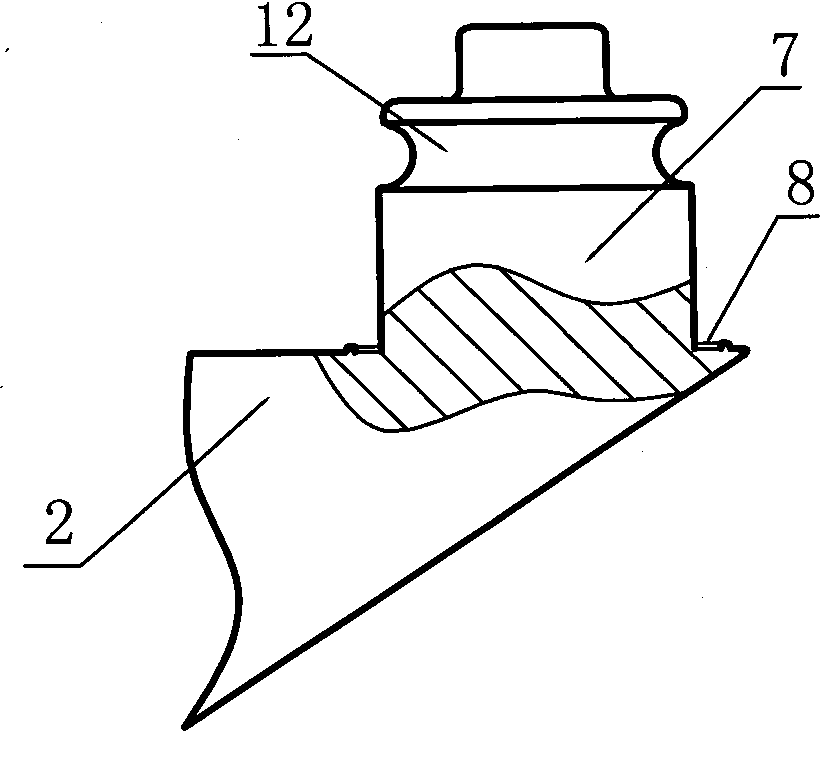

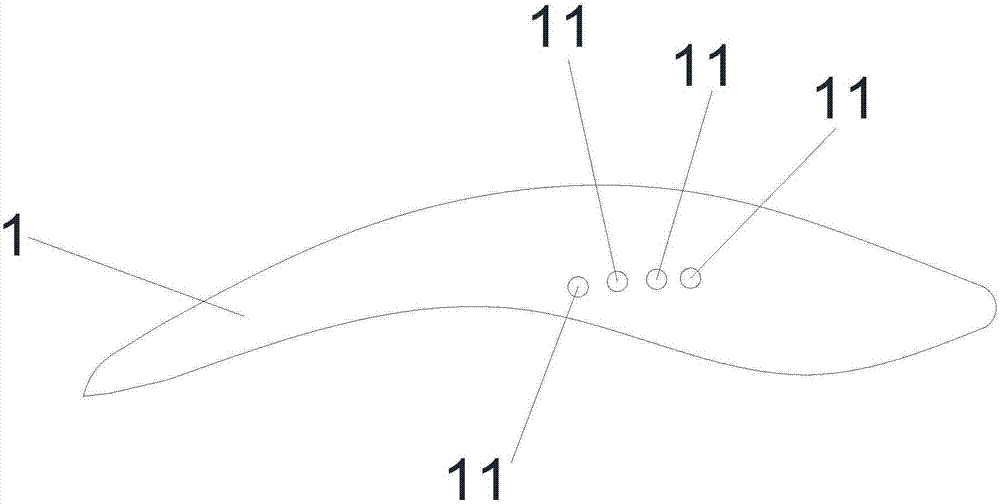

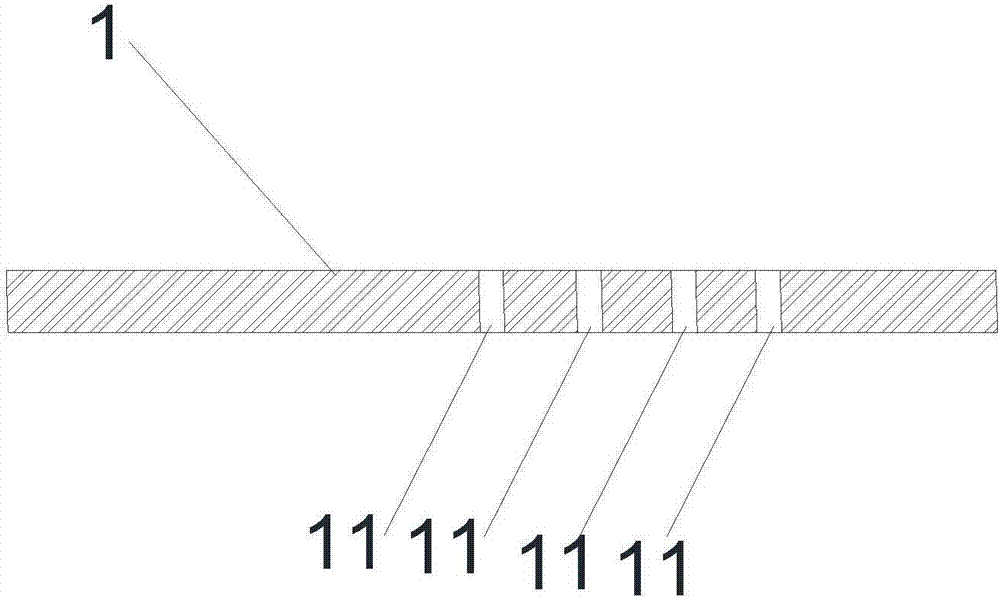

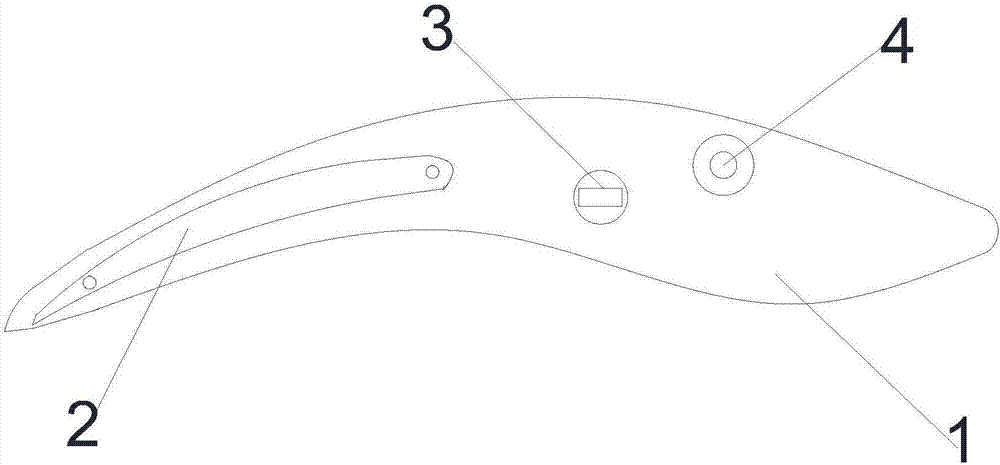

Weft insertion mechanism faller for circular weaving machines

InactiveCN106948069ALittle strength damageGuaranteed compressive strengthCircular loomsWear resistantEngineering

The invention provides a weft insertion mechanism faller for circular weaving machines, which comprises a faller body, a reversing roller, a tensioner and a weft-blocking plate, and the weft-blocking plate, the tensioner and the reversing roller are arranged sequentially from the left to the right on the surface of the faller body. Compared with the prior art, the weft insertion mechanism faller for circular weaving machines has the following advantages: a weft sequentially passes through the reversing roller, the tensioner and the weft-blocking plate of the weft insertion mechanism faller disclosed by the invention, the materials of the surfaces for the passage of the weft are all wear-resistant ceramic, and tension for inserting the weft is controlled by manually adjusting the magnitude of the elastic force of the spring of the tensioner; and the weft insertion mechanism faller has the advantages of simplicity and convenience in operation, extremely little injury on weft strength, and ensures the compressive strength of a woven fabric.

Owner:NANTONG BECA MACHINERY TECH

Process for preparing poly-p-phenylenebenzobisthiazole (PBO) fiber/benzoxazine composite material

InactiveCN102863634BHigh strengthHigh modulusBiochemical fibre treatmentPolymer scienceInterlaminar shear

The invention relates to a process for preparing a PBO fiber / benzoxazine composite material. The process is characterized by comprising the steps of firstly, immersing PBO fibers into an organic solution of horseradish peroxidase, dropping in an aqueous solution of 4 wt.% hydrogen peroxide, immersing in acetone containing KH-560, mixing bismaleimide prepolymers with benzoxazine resin monomers, conducting prepolymerization at the temperature in a range of 120-160 DEG C for 1-6 hours, then adding an acetone solution which is in a volume fraction of 1-5 times into the mixture to produce a glue solution, and conducting gum dipping on processed PBO fibers to obtain a prepreg. Finally, the prepreg is subjected to high-temperature compression moulding. The composite material which is prepared by the process has the advantages of being high in strength, high in modulus, resistant to high temperatures, high in interlaminar shear strength, low in dielectric constant and dielectric loss factor and capable of meeting the strict requirements of modern aviation fields for the composite material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of degumming process of raw bamboo fiber

ActiveCN106012044BImprove degumming efficiencyImprove degumming effectPulping with acid salts/anhydridesFibre treatment to obtain bast fibrePlant fibrePulp and paper industry

Owner:四川长盛新材料科技有限公司

A method for in-situ non-ironing finishing of cotton fabrics with acrylic acid and glyoxal

ActiveCN110820338BImprove permeabilityRealize non-ironing in situVegetal fibresTextile technologyPolymer science

The invention relates to the technical field of textiles, and discloses a method for in-situ non-ironing finishing of cotton fabrics with acrylic acid and glyoxal. The method comprises the following steps: (1) adding ethanol to water, adding cotton fabric, stirring at 40-60°C for 10-30 minutes; (2) adding acrylic acid, stirring at 40-60°C for 30-60 minutes; (3 ) under ultrasonic stirring, sequentially add glyoxal, unsaturated acid salts and persulfates, heat up to 80-100°C, and keep warm for 30-90 minutes; (4) Take out the above-mentioned treated cotton fabrics, wash them, to dry. The cotton fabric obtained by adopting the in-situ non-ironing method of the invention not only has good non-ironing and anti-wrinkle properties, but also has relatively high strength retention.

Owner:WUHAN TEXTILE UNIV

Method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan

InactiveCN102912634BLittle strength damageSolve the problem of dyeingAnimal fibresPre treatmentWool fiber

The invention discloses a method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan; and the method is implemented in the following steps of: (1) soaking wool fibers in a sodium carbonate solution; pretreating the wool fibers in the sodium carbonate solution; and washing and drying the pretreated wool fibers; (2) preparing a chitosan mixed solution with low molecular weight; (3) preparing a precursor solution; (4) adding the chitosan mixed solution with low molecular weight to the precursor solution, so as to prepare a modifying solution; and (5) carrying out aftertreatment on the modified wool fibers, so as to finish the modification of the wool fibers by using the tetrabutyl titanate and the chitosan. Nanometer titanium dioxide and chitosan films are directly loaded on the surfaces of the wool fibers; and problems of difficulty in heavy-shade dyeing, poorer antibacterial property, low color fastness to sunlight and easiness for felting shrinkage in the wool fibers obtained by the traditional modifying method are solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com