Method for bleaching tossa

A jute fiber and fiber technology, applied in the field of jute fiber bleaching, can solve the problems of poor impurity removal effect, environmental pollution, and weak lignin removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

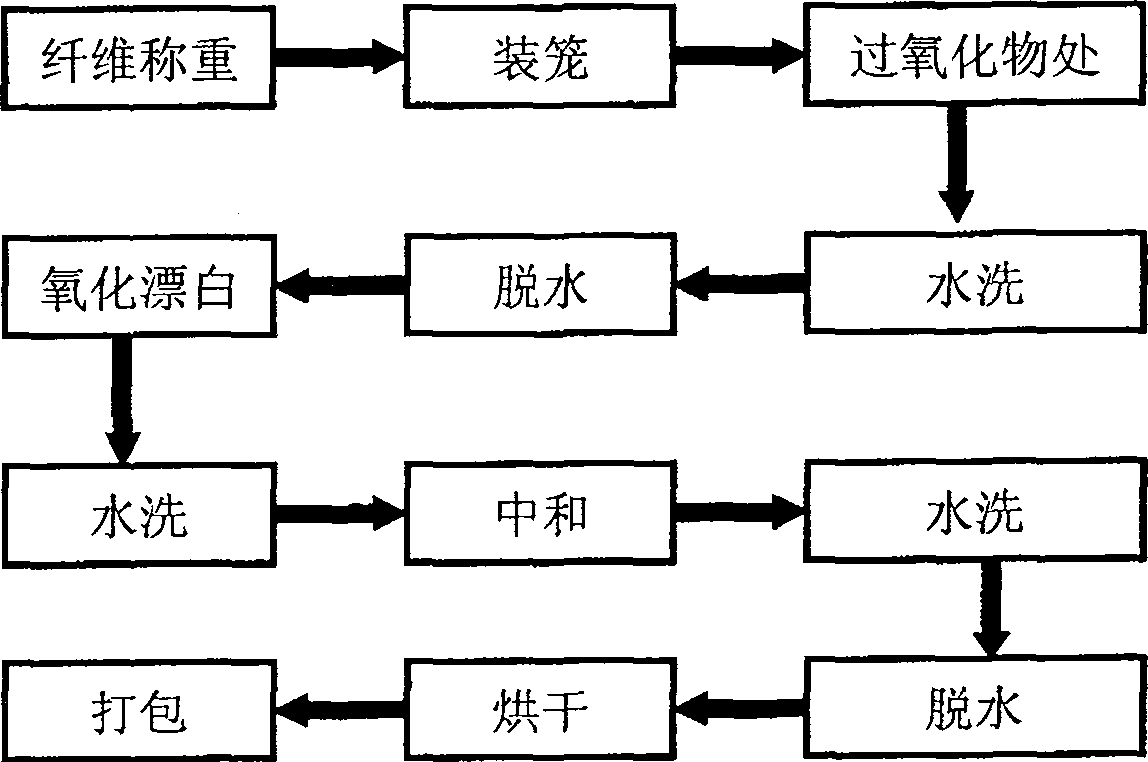

[0027] The jute used is the scorched tip fiber (80-120cm in length), see the specific bleaching steps figure 1 . During the bleaching step:

[0028] (1) peroxide treatment

[0029] Sequentially add 1% of the penetrant JFC, 1.5% of sodium pyrophosphate, 6% of soda ash, and 8% of peracetic acid according to the percentage of fiber weight within 8 minutes, control the bath ratio (weight ratio) 1:20, and then use 3°C / min to 80°C, hold for 60min;

[0030] (2) Two washes

[0031] The first water washing is to raise the room temperature water to 50 °C at a rate of 3 °C / min, and keep warm for 10 minutes before draining; the second water washing is to wash at room temperature for 5 minutes and then drain;

[0032] (3) oxidation bleaching

[0033] Add 0.3% penetrant JFC and 15% hydrogen peroxide according to fiber weight percentage in 4 minutes, adjust the pH value to 10.5, control the bath ratio (weight ratio) 1:10, and then rise to 1.5°C / min. 80°C, and keep warm for 80min;

[0...

Embodiment 2

[0041] The jute used is boiled root fiber (60-100cm in length), see the specific bleaching steps figure 1 . During the bleaching step:

[0042] (1) peroxide treatment

[0043] Add 1.5% of penetrant JFC, 1% of tetraacetylethylenediamine, 5% of soda ash, and 10% of sodium perborate according to the percentage of fiber weight within 4 minutes, and control the bath ratio (weight ratio) 1:15 , then rise to 70°C at 2°C / min and keep warm for 60min;

[0044] (2) Two washes

[0045] The first water washing is to raise the room temperature water to 50 °C at 5 °C / min, keep warm for 5 minutes and then drain; the second water washing is to wash at room temperature for 5 minutes and then drain;

[0046] (3) oxidation bleaching

[0047] Add 0.5% penetrant JFC and 20% hydrogen peroxide according to the fiber weight percentage in 8 minutes, adjust the pH value to 11, control the bath ratio (weight ratio) 1:15, and then increase it at 2°C / min to 85°C, and keep warm for 90min;

[0048] (4...

Embodiment 3

[0055] The jute used is cut and boiled short hemp (length 4-8cm), see the specific bleaching steps figure 1 . During the bleaching step:

[0056] (1) peroxide treatment

[0057] Add 1.5% penetrating agent JFC, 2% sodium phosphate, 7% soda ash, and 10% sodium percarbonate in percent by fiber weight within 6 minutes, control the bath ratio (weight ratio) 1:15, and then 2°C / min to 60°C, hold for 80min;

[0058] (2) Two washes

[0059] The first water washing is to raise the room temperature water to 50 °C at a rate of 5 °C / min, and keep warm for 10 minutes before draining; the second water washing is to wash at room temperature for 5 minutes and then drain;

[0060] (3) oxidation bleaching

[0061] Add 0.2% penetrant JFC and 25% hydrogen peroxide according to the fiber weight percentage in 8 minutes, adjust the pH value to 10, control the bath ratio (weight ratio) 1:10, and then increase the temperature at 1.5°C / min. to 80°C, and keep warm for 90min;

[0062] (4) Washing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com