Anti-pilling finishing method and anti-pilling finishing liquid for fluffy fabric

An anti-pilling and finishing liquid technology, applied in the field of anti-pilling finishing liquid for pile fabrics and anti-pilling finishing of pile fabrics, can solve the problems of long processing time, complex process, fiber damage, etc., and achieve short finishing time and simple process. , the effect of small damage to fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

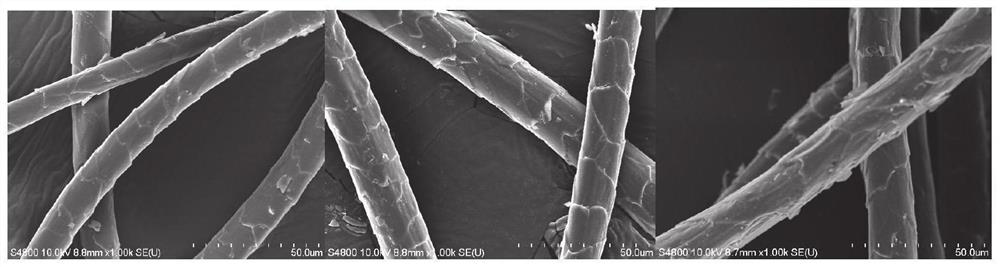

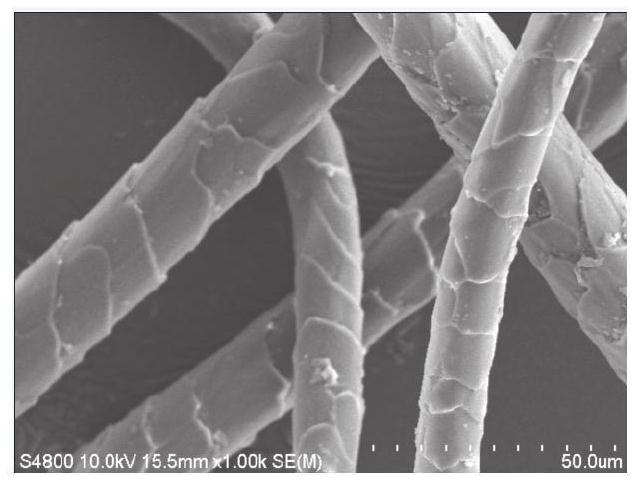

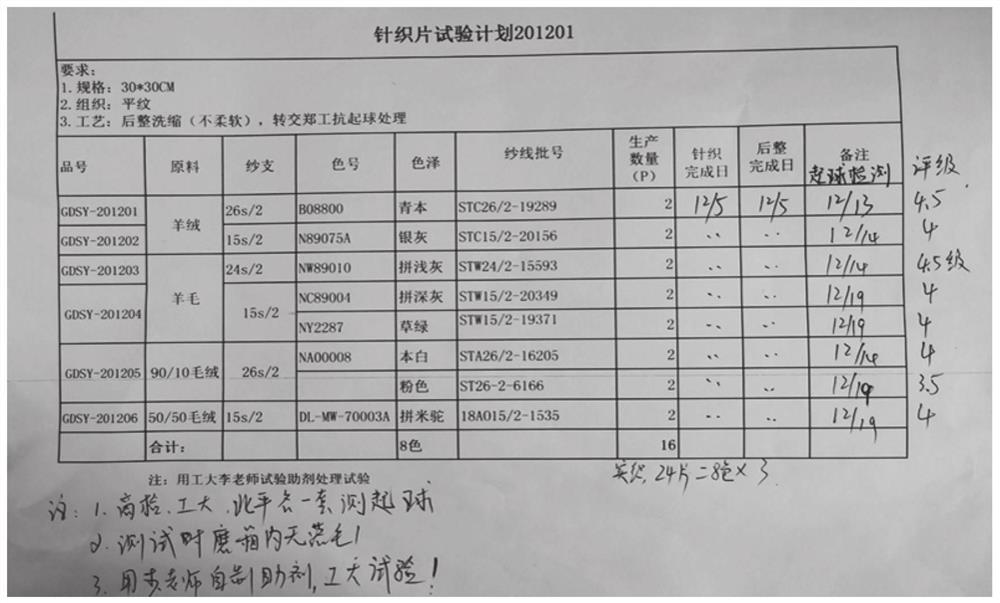

Image

Examples

Embodiment 1

[0039] Embodiment 1: pile fabric anti-pilling finishing liquid, it comprises the component of following parts by weight: reducing agent 1.5% (o.w.f), penetrating agent 1% (o.w.f), amino silicone oil 3% (o.w.f) and protease 0.1% (o.w.f ). In this example, the reducing agent is TCEP; the penetrating agent is JFC; the amino silicone oil is amino silicone oil SL-2006; the protease is 16L enzyme.

[0040] Among them, the 16L enzyme adopts Novozymes’ 16L enzyme, also known as subtilisin, its main component is serine endopeptidase, and its appearance color is a translucent amber liquid. The optimum enzyme activity condition is: pH=7-10. Under the condition of alkaline pH=8.5-9, at 50°C, the enzyme activity is the highest, which can reach about 500,000 U / g.

[0041] TCEP is soluble in water, its chemical name is tris(2-carboxyethyl)phosphine, and its chemical formula is C 9 h 16 CLOs 6 P; is a very effective thiol reducing agent. It is a colorless transparent liquid with good st...

Embodiment 2

[0044] Embodiment 2: a method for anti-pilling finishing of pile fabrics, which comprises the following steps: (1) soaking and pretreatment of pile fabrics; (2) preparing an anti-pilling finishing liquid for pile fabrics; (3) anti-pilling finishing of pile fabrics; (4) Dehydration and drying after finishing. in:

[0045](1) Soaking pretreatment of fluffy fabric: Soak the fluffy fabric in warm water at 45°C for 10 minutes, with a bath ratio of 1:20;

[0046] (2) Prepare anti-pilling finishing solution for fluffy fabric: after soaking, keep the temperature constant, add reducing agent under running conditions, then quickly adjust the pH value to 7.5, then add penetrant, amino silicone oil and protease in sequence, and you are done. Prepared as an anti-pilling finishing solution; the addition of the reducing agent is 1.5% of the weight of the pile fabric, the addition of the penetrating agent is 1% of the weight of the pile fabric, and the addition of the amino silicone oil is 1...

Embodiment 3

[0050] Embodiment 3: pile fabric anti-pilling finishing liquid, it comprises following components: reducing agent 2.0% (o.w.f), penetrating agent 1.5% (o.w.f), amino silicone oil 4% (o.w.f) and protease 0.15% (o.w.f). In this example, the reducing agent is TCEP; the penetrating agent is JFC; the amino silicone oil is amino silicone oil SL-2006; the protease is 16L enzyme.

[0051] Among them, the 16L enzyme adopts Novozymes’ 16L enzyme, also known as subtilisin, its main component is serine endopeptidase, and its appearance color is a translucent amber liquid. The optimum enzyme activity condition is: pH=7-10. Under the condition of alkaline pH=8.5-9, at 50°C, the enzyme activity is the highest, which can reach about 500,000 U / g.

[0052] TCEP is soluble in water, its chemical name is tris(2-carboxyethyl)phosphine, and its chemical formula is C 9 h 16 CLOs 6 P; is a very effective thiol reducing agent. It is a colorless transparent liquid with good stability and solubilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com