Patents

Literature

393results about How to "No discoloration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing water-absorbing resin

InactiveUS20050085604A1Prevent discolorationNo discolorationAbsorbent padsBaby linensPolymer scienceProduced water

A process for preparing a water-absorbent resin made from an α,β-unsaturated carboxylic acid as an essential monomer characterized in that the process comprises allowing a metal chelating agent to be present at any step in the process in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid; and adding a reducing agent or an oxidizing agent thereto in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid before initiation of drying and / or during drying of a gelated product containing a water-absorbent resin obtained by polymerization.

Owner:SUMITOMO SEIKA CHEM CO LTD

Antimicrobial glass articles and methods of making and using same

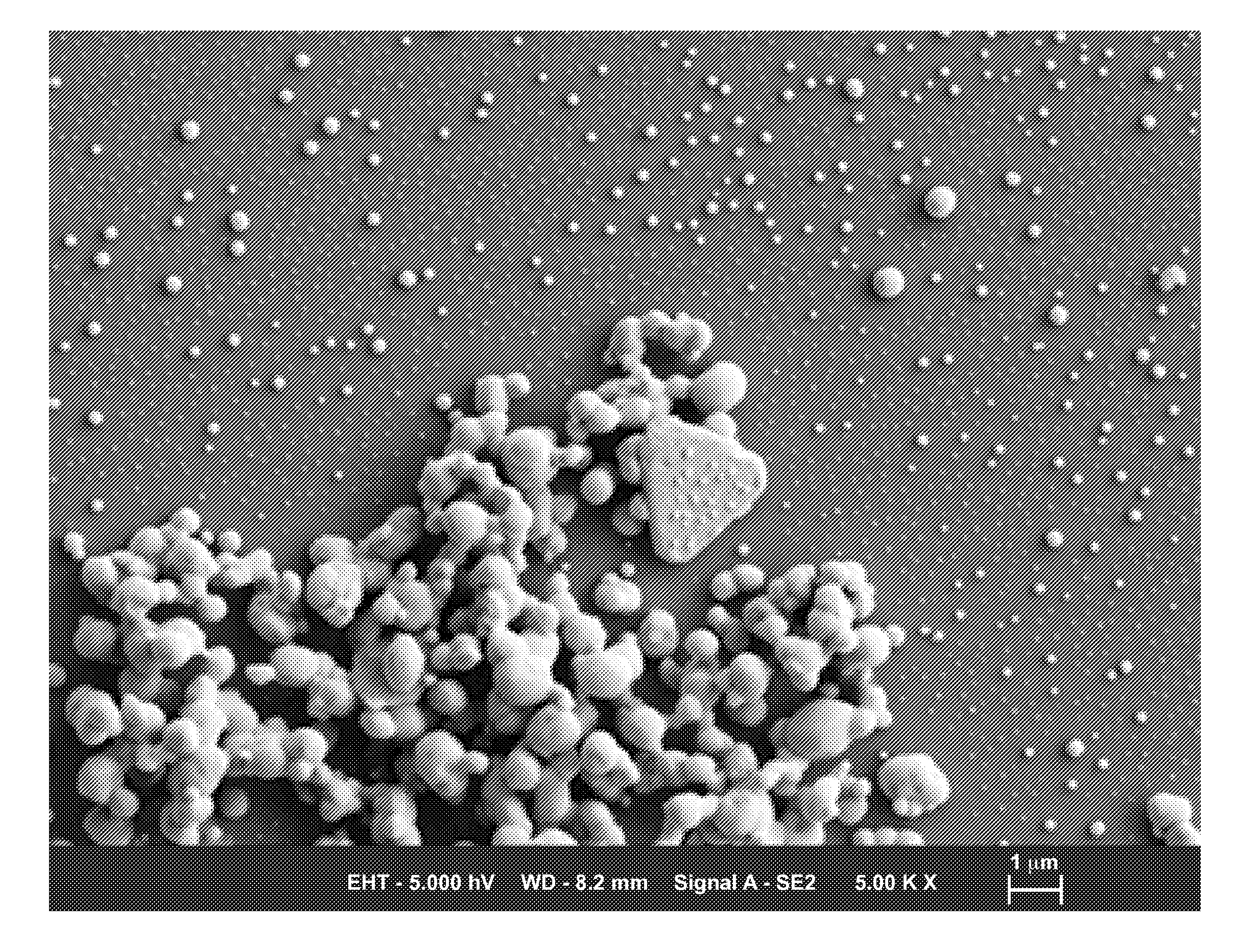

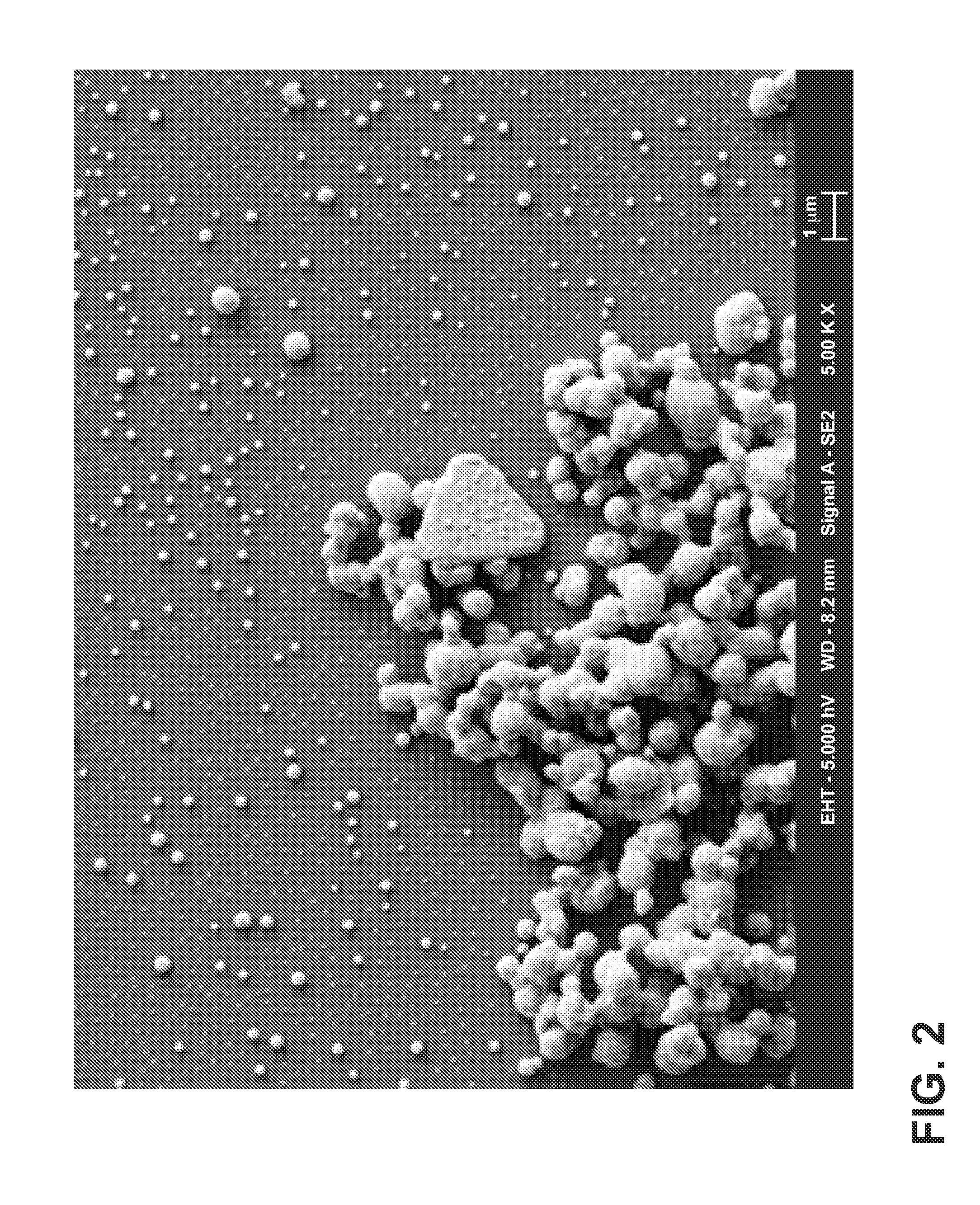

Described herein are various antimicrobial glass articles that have improved resistance to discoloration when exposed to harsh conditions. The improved antimicrobial glass articles described herein generally include a glass substrate that has a low concentration of nonbridging oxygen atoms, a compressive stress layer and an antimicrobial silver-containing region that each extend inward from a surface of the glass substrate to a specific depth, such that the glass article experiences little-to-no discoloration when exposed to harsh conditions. Methods of making and using the glass articles are also described.

Owner:CORNING INC

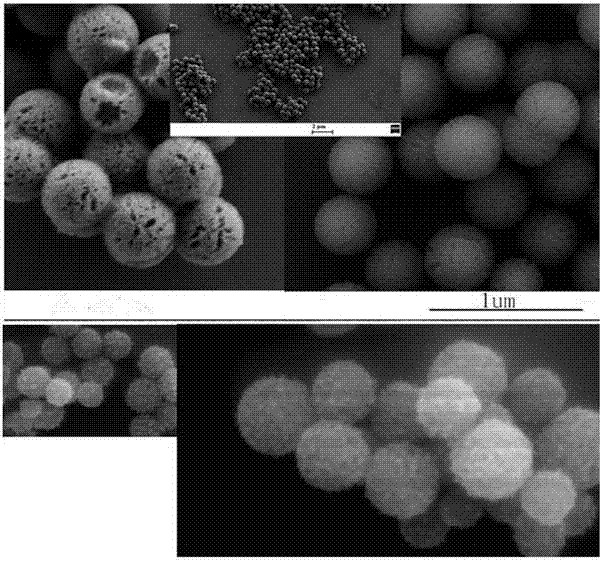

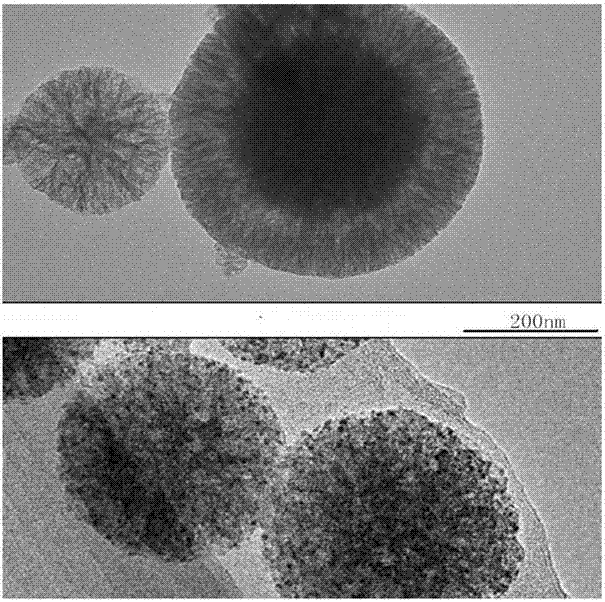

Silicon dioxide loaded nano-silver waterborne antibacterial paint and preparation method thereof

InactiveCN107189585AImprove antibacterial propertiesNo discolorationAntifouling/underwater paintsPaints with biocidesDispersityFoaming agent

The invention discloses silicon dioxide loaded nano-silver waterborne antibacterial paint and a preparation method thereof, and belongs to the field of chemical paint. The paint is prepared from the following components: water, acrylic resin, polyurethane resin, a porous silicon dioxide loaded nano-silver antibacterial agent, a dispersant, a curing agent, a de-foaming agent, a film-forming auxiliary agent and a flatting agent. According to the silicon dioxide loaded nano-silver waterborne antibacterial paint, nano-silver is loaded in porous silicon dioxide, so that the effect of protecting the nano-silver is realized; a releasing speed of the nano-silver can also be slowed down to a certain extent, so that the antibacterial time of the paint is more durable. A pore channel space is limited and a special preparation process is adopted (under the protection effect of PVP (Polyvinyl Pyrrolidone)), the size of the nano-Ag is controlled to be only 3nm to 5nm, so that the specific surface area of the nano-Ag is greatly increased. Furthermore, a special pore channel of the porous silicon dioxide has a fixation effect on the nano-Ag, so that the nano-Ag is not easy to aggregate and has good dispersity in a solution, and the antibacterial performance of the paint is improved.

Owner:FUZHOU UNIV

Single-core cable insulating rubber for low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V

ActiveCN101914244ASmall compression deformationImprove mechanical propertiesRubber insulatorsInsulated cablesHalogenFlame resistance

The invention discloses single-core cable insulating rubber for a low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V and temperature resistance of a 125 DEG C level. The single-core cable insulating rubber comprises the following components in parts by weight: 100 parts of crude rubber, 2-6 parts of organic peroxide curing agent, 1-5 parts of auxiliary curing agent, 1-4 parts of coupling agent, 3-8 parts of anti-aging agent, 10-25 parts of strengthening agent and 5-10 parts of plasticizing agent. The single-core cable insulating rubber has excellent insulating property and is very soft. A cable produced by the rubber is soft and is easy to bend, install and lay. The single-core cable insulating rubber has excellent insulating property, can continuously and normally work at voltage of 1000V and high temperature of 125 DEG C, can resist climates, ozone, heat, ageing, acid, alkali and fuel oil well and has low-smoke and zero-halogen flame resistance, environmental protection, safety and long service life.

Owner:JIANGSU JUYE CABLE

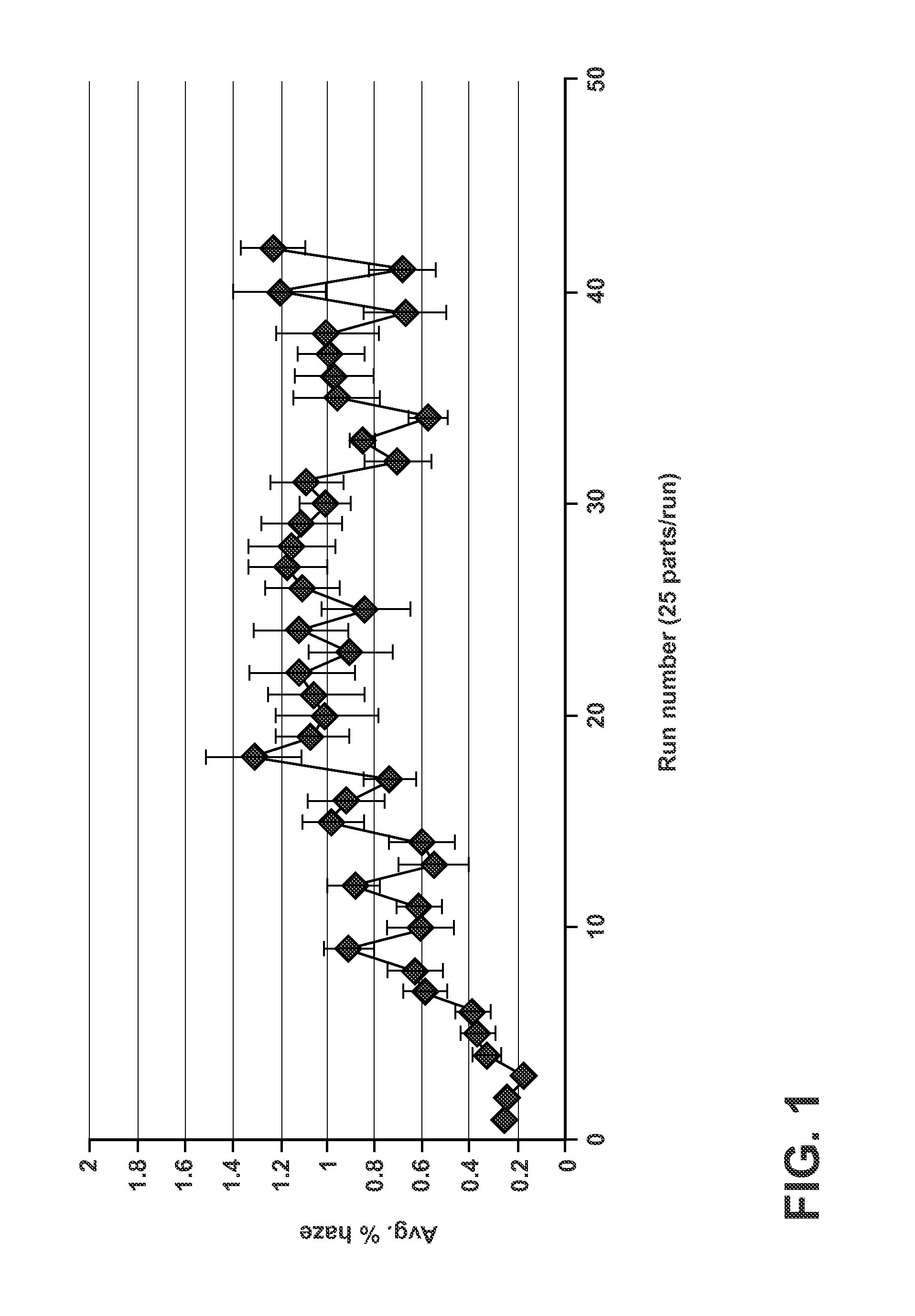

Preparation and application methods of selective laser sintering polypropylene powdery material

The invention relates to the technical field of high molecular materials and particularly relates to preparation and application methods of a selective laser sintering polypropylene powdery material. The method comprises the following steps: obtaining polypropylene powder by a freeze grinding method; grading and collecting by an airflow screening machine, selecting polypropylene powder with the granularity in a range of 200-800 meshes and returning coarse materials which do not meet the fineness requirement to a stock bin and continuously smashing; and adding 100 parts of polypropylene powder, 0.1-1 part of graphite powder, 0.01-0.5 part of antioxidant and 0.5-6 parts of metallic soap salt and uniformly mixing in a high speed mixer, wherein the granularity of the graphite powder is 1000-5000 meshes and the antioxidant is a compound antioxidant consisting of phenols and phosphonate or thioester in a weight ratio of 1:1. The polypropylene powder prepared by the invention has excellent sintering performance and the SLS (Selective Laser Sintering) formed piece prepared by the polypropylene powder has high mechanical property and dimensional precision.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

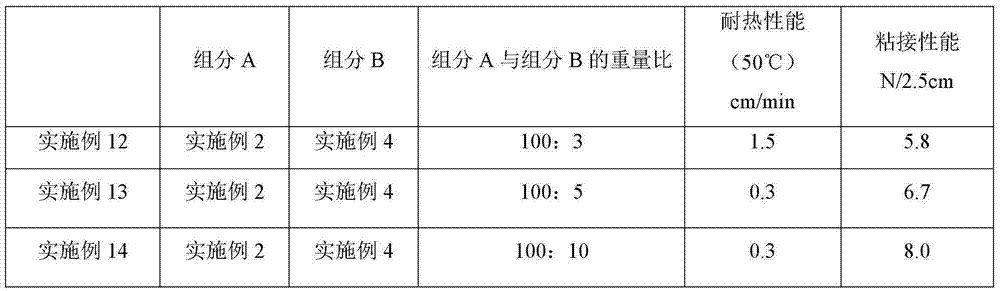

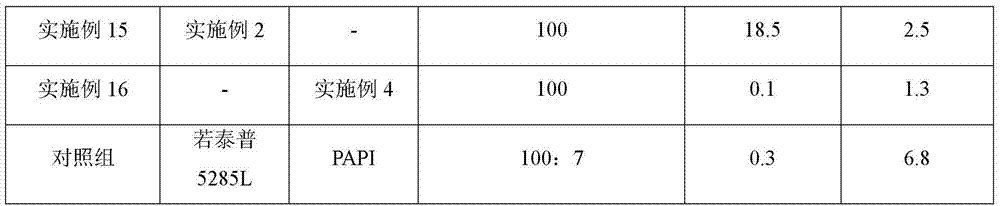

Double-component polyurethane adhesive and preparation method thereof

ActiveCN104745138AGood adhesionImprove heat resistancePolyureas/polyurethane adhesivesPolyesterEpoxy

The invention belongs to the field of polyurethane adhesives, relates to coating adhesive for woodworking industry, in particular to a double-component polyurethane adhesive and a preparation method thereof. The double-component polyurethane adhesive is obtained by compounding a component A and a polyurethane component B containing an isocyanate-terminated group, wherein the component A is polyurethane synthesized by polyester polyol and diphenylmethane diisocyanate (MDI) as well as accessory ingredients; the polyurethane component B containing the isocyanate-terminated group is synthesized by polyester polyol and / or polyether polyol, isocyanate, epoxy resin and accessory ingredients. The double-component polyurethane adhesive disclosed by the invention is good in adhesion performance, high in early-stage bonding strength and final bonding strength, and good in heat resistance, does not bounce at 80 DEG C, and is colorless, low in smell and low in cost.

Owner:重庆中科力泰高分子材料有限公司

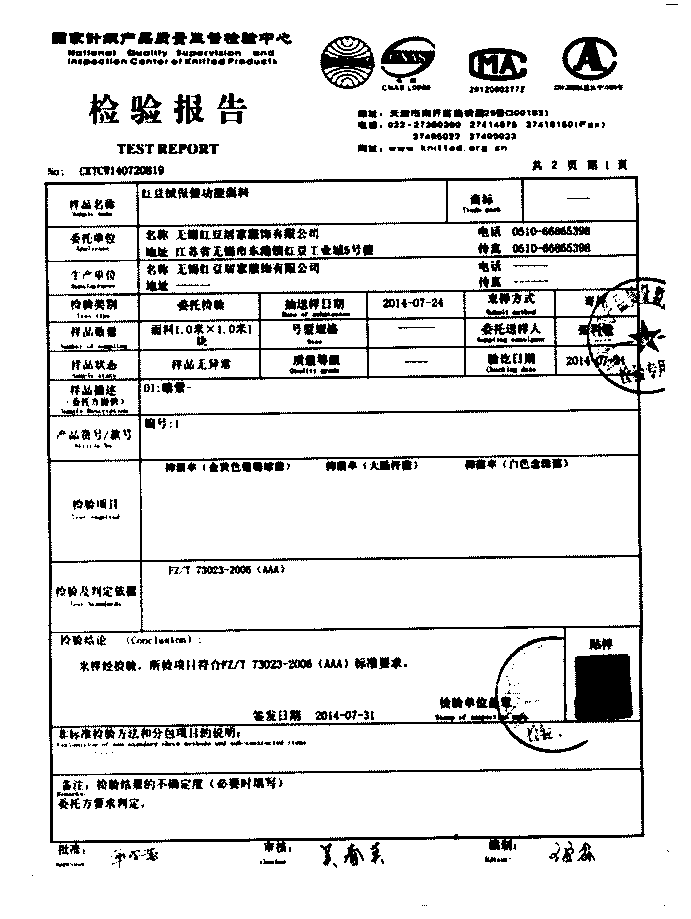

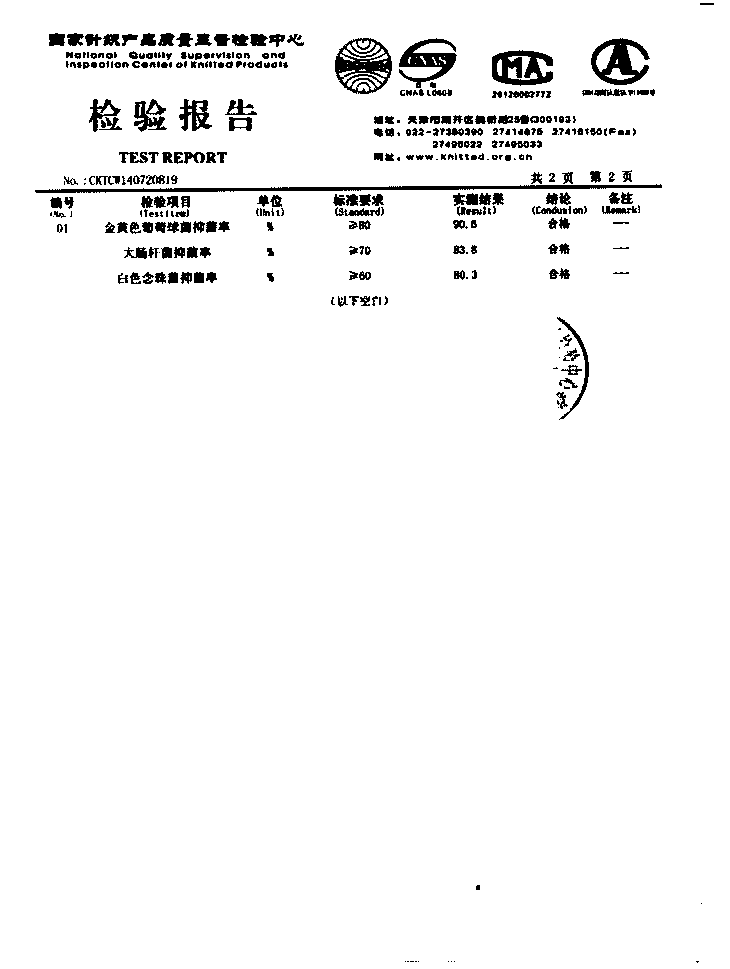

Red bean velvet healthcare functional fabric

ActiveCN104305541AImprove antibacterial propertiesGood washing stabilityWeft knittingHeating/cooling textile fabricsYarnColor changes

The invention relates to a red bean velvet healthcare functional fabric. The red bean velvet healthcare functional fabric is characterized by adopting the following technology (1) weaving into the fabric through all cotton combing yarns, processing through weak positive ion softening agent S200 after refining, bleaching and dying, performing napping processing on the front side and rear side through a sanding machine after preprocessing open width drying before napping and enabling the fabric speed to be 16 to 18 meters per minute and the rotary speed of a carbon brush hair roller to be 1800 to 2000 turns per minute; (2) sorting the red beam fabric in antibacterial agent, wherein the antibacterial agent comprises components of 1.5 to 5 % o.w.f (On weight the fabric) of nano-modification titanium dioxide, 2 to 5 % o.w.f of penetrating agent and 1 to 3 % of dispersing agent; (3) performing tentering sizing sorting; (4) performing organic silicon and organic fluorine sorting. The red bean velvet healthcare functional fabric has the advantages of not needing to adding extra chemical crosslinking agent, having an anti-bacterial function, being good in antibacterial performance, high in washing fastness, free of color change and fluffy and soft.

Owner:无锡红豆织造有限公司

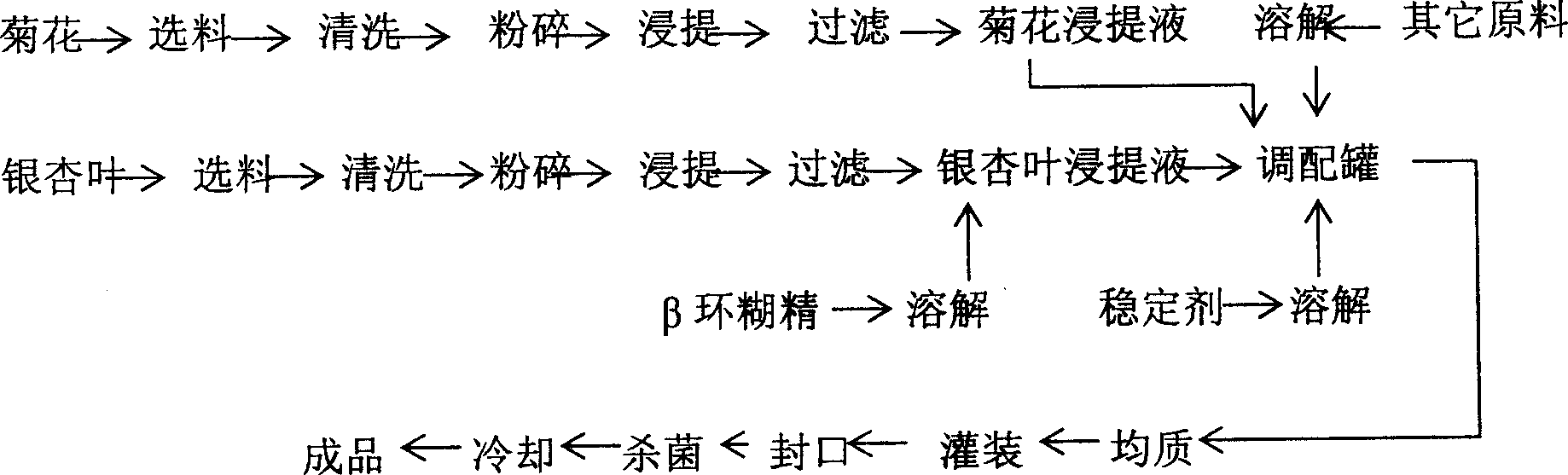

Prepn of functional beverage containing effective components from natural product

InactiveCN1672595AHigh yieldShorten the timeAlcoholic beverage preparationFood scienceNatural productFiltration

The functional beverage containing effective components from natural product is prepared with drinking water or spirit as main material and natural product with the functional components to be added as supplementary material. The technological process includes the steps of pre-treatment of supplementary material, high pressure extracting, filtering, compounding, packing, high pressure sterilizing, etc. During high pressure extracting, the crushed supplementary material and the main material as the solvent in certain ratio are mixed and high pressure and normal temperature treated inside a high pressure container to dissolve the effective in the supplementary material. The high pressure sterilizing has pressure of 100-600 MPa and treating period of 5-20 min. The present invention has the advantages of high effective component extracting rate, short production period, low power consumption, etc.

Owner:张守勤

Acrylic polyurethane silicofluoride coating as well as preparation method and application method thereof

ActiveCN104017480AImprove adhesionGood flexibilityAntifouling/underwater paintsPretreated surfacesPolymer scienceAcrylic resin

Owner:湖南惠电科技有限公司

Liquid photo-imageable alkali developable and anodizing resistant ink and preparation method thereof

InactiveCN103045015AThe synthesis operation process is simpleGood anti-sandblasting performanceInksPhotosensitive materials for photomechanical apparatusMaleic anhydrideAnodic oxidation

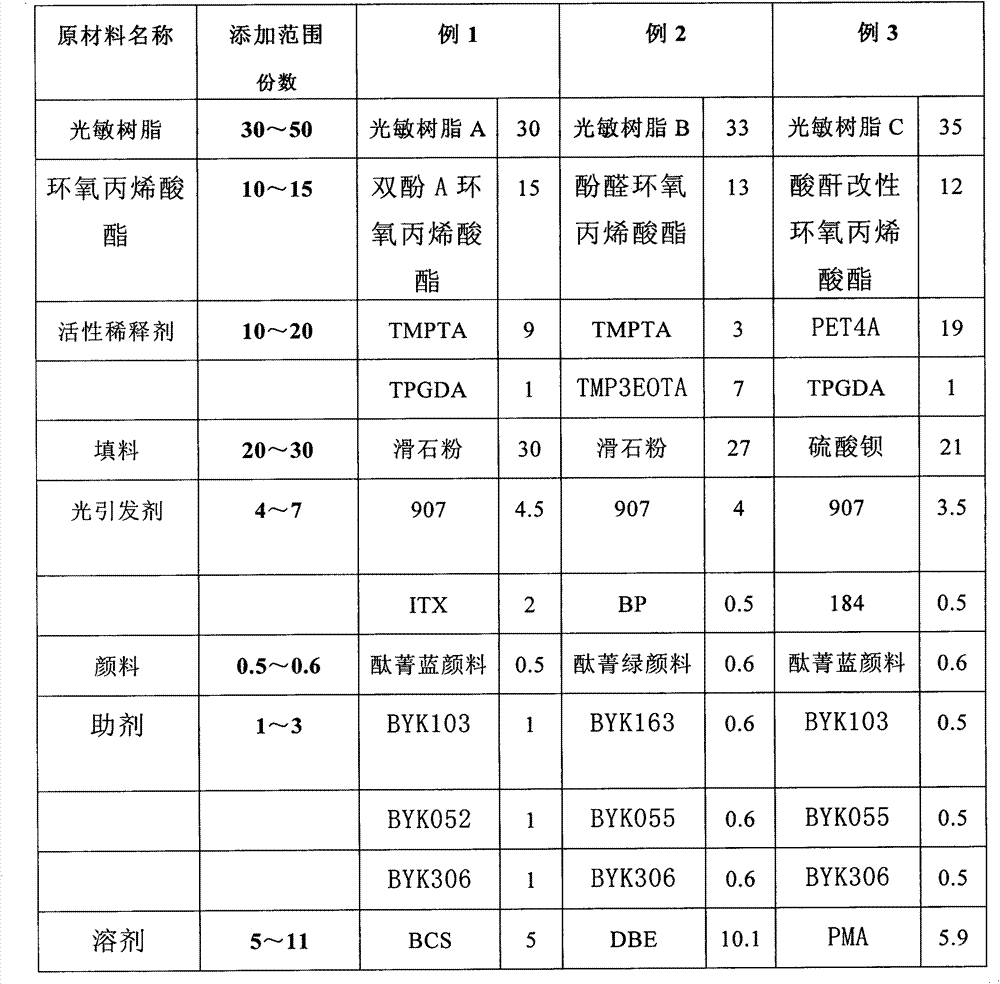

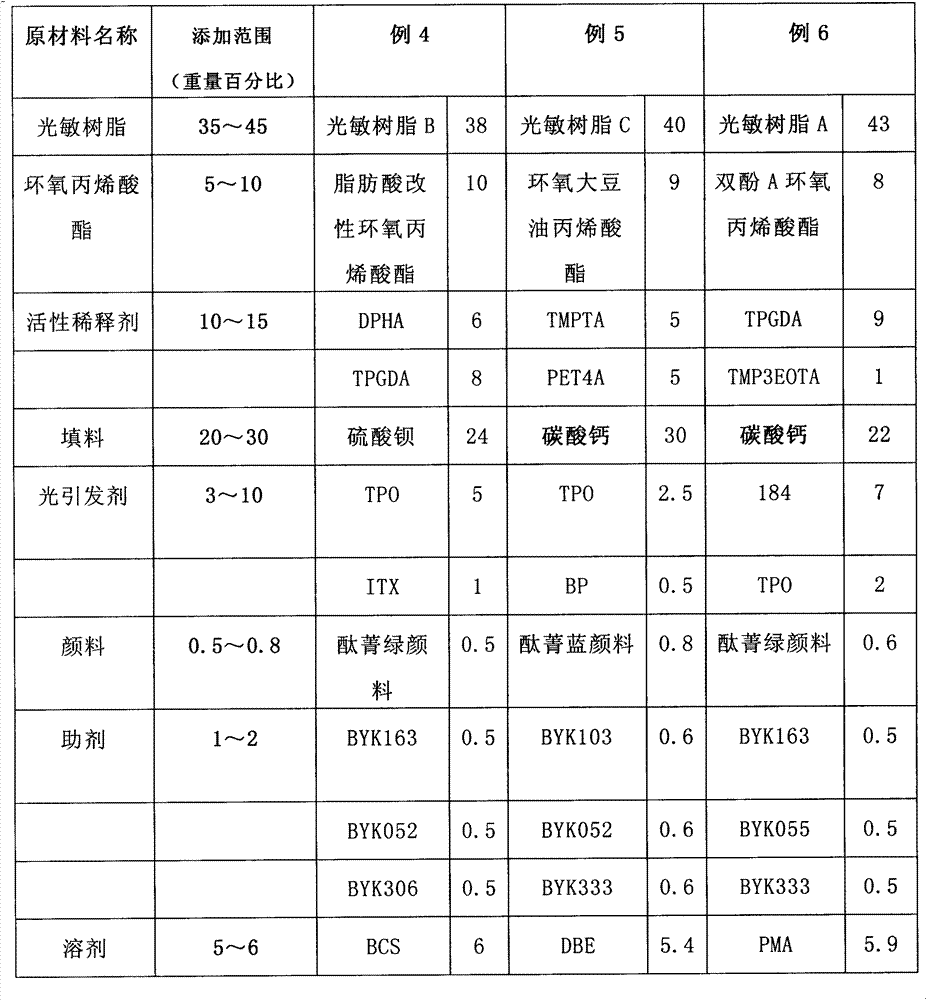

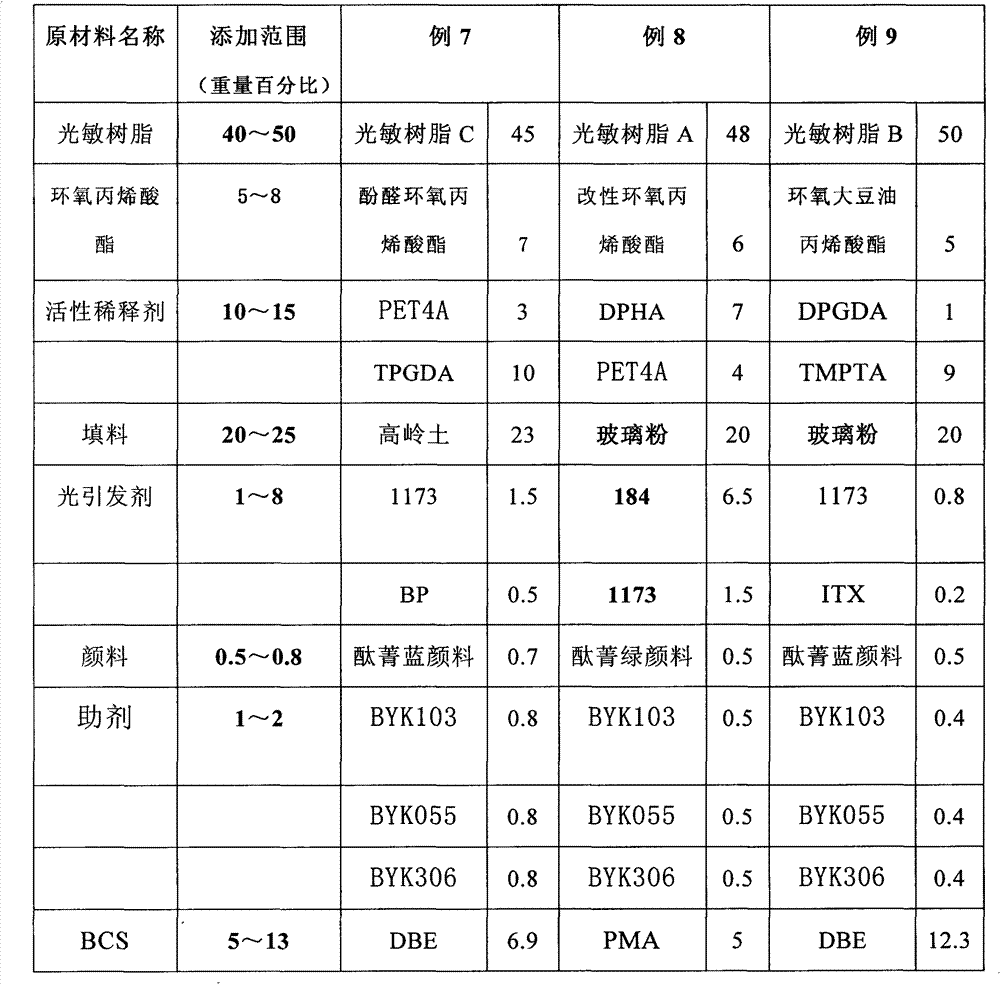

The invention discloses a liquid photo-imageable alkali developable and anodizing resistant ink and a preparation method of the liquid photo-imageable alkali developable and anodizing preventive ink. The liquid photo-imageable alkali developable and anodizing resistant ink comprises the following components in parts by weight: 30 to 50 parts of photosensitive resin, 5 to 15 parts of epoxy acrylic resin, 10 to 20 parts of reactive diluent, 5 to 15 parts of solvent, 1 to 10 parts of photoinitiator, 1 to 3 parts of assistant, 20 to 40 parts of filler, and 0.5 to 0.8 part of pigment; the alkali soluble photosensitive resin is manufactured from the following raw materials in parts by weight: 35 to 50 parts of epoxy resin, 20 to 40 parts of DBE (Dibasic Ester), 15 to 20 parts of crylic acid, 8 to 15 parts of maleic anhydride, 0.5 to 1 part of hydroquinone, and 0.5 to 1 part of tetraethylammonium bromide. The liquid photo-imageable alkali developable and anodizing resistant ink is high in sand blasting resistance, strong alkali resistance, strong acid resistance, anodizing resistance and resolution ratio and image resolution, has no corrosion to the surface of IXEF (Aramids) substrate and remains the colour of the surface, and can be quickly and completely stripped from a composite substrate.

Owner:VITAYON FINE CHEM SCI & TECH CO LTD SHENZHEN

Silicon fluoride super-amphiphobic non-stick coating material

The invention relates to a non-sticking paint containing fluorine-silicon materials, which comprises a coating material portion and a curing agent portion, wherein the amount of the curing agent is 6.5-12% of the coating material portion, the coating material portion mainly comprises fluorocarbon resin, 10-20% of organosilicon resin, 3-30% of color filler, 1-5% of silicon micronized quartz powder and 3-10% of fluorine micronized powder, the curing agent is at least one of biuret, HDI trimer and organotin, the fluorocarbon resin is prepared from perfluoroethylene monomer, alkyl vinyl ester and functional monomers through copolymerization, wherein the fluorine content is greater than 35wt%, the solid content is greater than 50%, the organosilicon resin is end monohydric organosilicon resin.

Owner:ZIBO YINGQIANG CHEM TECH

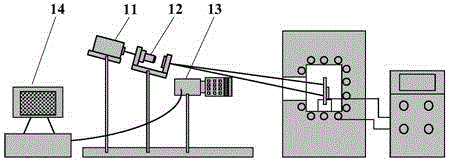

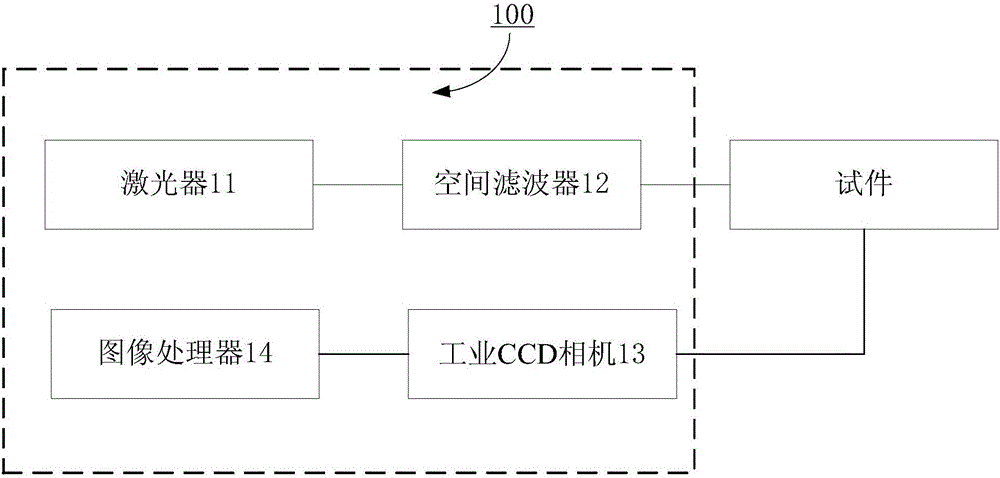

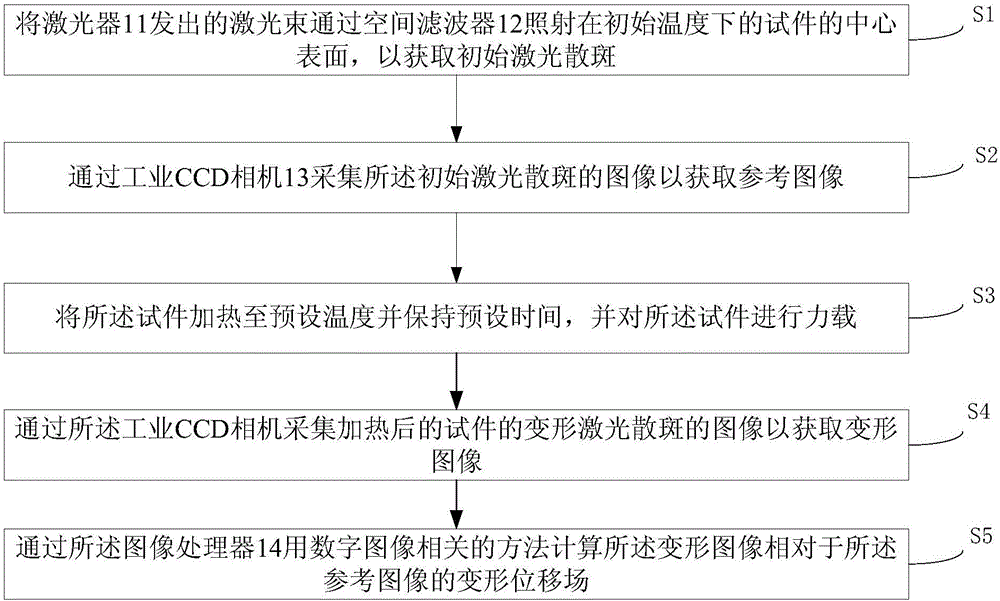

Material component high temperature deformation noncontact measurement system and method

The present invention discloses a material component high temperature deformation noncontact measurement system. The system comprises a laser, a spatial filter, an industrial CCD (Charge Coupled Device) camera and an image processor. The laser beam emitted by the laser is illuminated through the spatial filter to the central surface of a test piece in the initial temperature to obtain an initial laser speckle; the CCD camera is configured to obtain a reference image and a deformation image; and the image processor employs the method related to digital images to calculate the deformation displacement field of the reference image relative to the deformation image. According to the embodiment of the invention, the material component high temperature deformation noncontact measurement method effectively improve the precision of the material component high temperature noncontact deformation measurement in the high temperature and is wide in the temperature application range so as to provide a new thinking for the mechanical property of the high-temperature environment measurement material components.

Owner:UNIV OF SCI & TECH BEIJING

Oral care compositions for promoting gum health

ActiveUS20190298636A1Improved Gum Health benefitDeep penetrationCosmetic preparationsToilet preparationsMedicineChewing gum

Oral care compositions comprising an amino acid and stannous ion source, especially in the absence of zinc ion source, are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

Palladium plating solution

A palladium plating solution, characterized in that it comprises a soluble palladium salt in an amount of 0.1 to 40.0 g / liter in terms of palladium, 0.01 to 10 g / liter of a pyridine-carboxylic acid and / or at least one selected from among a soluble iron salt, zinc salt, thalium salt and tellurium salt and the like in an amount of 0.002 to 1.0 g / liter in terms of metal, 0.005 to 10 g / liter of amine derivative of pyridine-carboxylic acid, an aldehydobenzoic acid derivative, and 0.001 to 1.2 g / liter of an anionic surfactant or an amphoteric surfactant. The palladium plating solution allows the preparation of a highly pure and stable palladium precipitate which is excellent in specular gloss, forms a plating film having a thickness of 5 um or more and is free from the occurrence of a crack.

Owner:KOJIMA CHEM CO LTD

Fabric formaldehyde-free fixing agent

InactiveCN103669050AImprove color fixationHigh color fastnessDyeing processColour fastnessPolymer science

The invention discloses a fabric formaldehyde-free fixing agent. The fixing agent comprises the following raw materials in parts by mass: 10-15 parts of poly dimethyl diallyl ammonium chloride, 15-18 parts of 2-hydroxypropyltrimethyl ammonium chloride chitosan, 25-34 parts of water, 20-25 parts of ethanol and 5-10 parts of fatty alcohol polyoxyethylene ether. The fixing agent disclosed by the invention has an excellent fixation effect, and can effectively improve colour fastness of fabric dyes and wet rubbing fastness in the processes of dyeing and printing. The fabric treated by the fabric formaldehyde-free fixing agent does not discolor.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

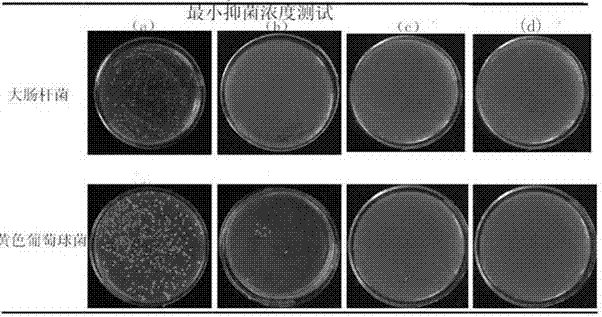

Gynecological gel containing silver-ion bactericide, preparation method and application thereof

ActiveCN106334067AExciting fatal flaws to overcomeOvercoming irritationAntipyreticInorganic active ingredientsAdditive ingredientGlycerol

The invention relates to the field of medical technology, especially to gynecological gel containing a silver-ion bactericide, a preparation method and application thereof. The gynecological gel containing a silver-ion bactericide comprises the following ingredients (by weight): 2.0-10.0% of glycerin, 3.0-10.0% of propylene glycol, 0.5-3.0% of carbomer, 0.4-0.6% of triethanolamine, 0.0-6.0% of blue copper polypeptide, 0.0-6.0% of alum, 0.05-0.2% of hyaluronic acid, 0.0-2.0% of water-soluble vitamin E, 0.0-6.0% of a motherwort extract, 0.0-2.0% of a witch hazel extract, 1.0-36.0% of a medicinal and edible plant extract, and the rest of a silver-ion bactericide and water, wherein use amount of the silver-ion bactericide is the use amount which makes concentration of silver ion in the gynecological gel to be 0.05-5.0 ppm; and the medicinal and edible plant extract contains a purslane extract which accounts for 1.0-6.0% of total mass of the gynecological gel. The gel of the invention is efficient, safe and mild, and can be used for greatly treating various gynecological diseases and nursing the vagina.

Owner:广州洁康医药科技有限公司

Oral care compositions for promoting gum health

ActiveUS20190298634A1Deep penetrationAdd depthCosmetic preparationsToilet preparationsCitrullineMedicine

Oral care compositions comprising citrulline and stannous ion source with a specific pH range are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

Oral care compositions for promoting gum health

ActiveUS20190298620A1Deep penetrationAdd depthCosmetic preparationsImpression capsMouth careMedicine

Oral care compositions comprising an acidic amino acid and stannous ion source are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

Mung bean pea edible separation protein and producing method thereof

InactiveCN101238846AHigh yieldReduce difficultyProtein composition from vegetable seedsProtein solutionFiber

The invention relates to a kind of isolating edible protein in the mung bean and pea and the producing method thereof, which belongs to the field of the edible protein producing method technology. It is characterized in that, the steps are as follows: a. alkali dissolving: adding alkali solution into the waste mud after starch processing of the mung bean and pea, adjusting pH to 9.0-11.0; b. impurity isolation: separating by separator, discharging parts of fiber and residues of the protein solution; c. acid precipitation: adding hydrochloric acid solution into acid tank for adjusting pH to 4.5-5.5; d. protein concentration: secondary separation, adding water for adjusting the density of the protein solution to 8-15%; e. neutralizing: adding alkali solution for adjusting pH up to 7.0; f. sterilizing, removing soy smell: high temperature sterilizing, flashing and then degassing and removing soy smell; g. homogenizing: homogenizing in homogenizer; h. spray drying: spray drying for acquiring edible isolating protein. The invention uses the seriflux produced by starch process as the raw materials to produce edible protein, the product has good appearance, good quality, and has solubility, emulsifying property, water absorbing and oil protecting ability, foamability and other good characteristics, and is environment protected.

Owner:王雪源

Spray cleaning agent for metal assembly

The invention discloses a spray cleaning agent for a metal assembly. The cleaning agent is prepared from polyether carboxylate, carboxylate, block polyether, an alcohol ether surfactant, sodium gluconate, diethylenetriam inepentaacetate, ethylene diamine tetraacetic acid disodium salt, sodium metasilicate, sodium benzoate, triazole, triethanolamine, alcohols, glycol ether and deionized water. The cleaning agent is applicable to the oil-removing and rust-preventing cleaning of black metals, non-ferrous metals and assemblies formed by the black metals and the non-ferrous metals, has extremely high cleaning performance and a relatively long corrosion inhibition period, cannot cause the change of the color, is environment-friendly and low-foam, does not contain substances such as phosphorus and sodium nitrite, cannot pollute the environment, is particularly applicable to the spray cleaning at normal temperature, and is low in energy consumption in the cleaning process, the residue is avoided, corrosion spots are not generated, and waste liquor of the cleaning agent is can be easily disposed. The corrosion inhibition period of a copper-aluminum assembly exceeds 10 days; the corrosion inhibition period of a brass-cast iron assembly exceeds 7 days; the corrosion inhibition period of an aluminum-cast iron assembly exceeds 7 days; and the corrosion inhibition period of a copper tin-aluminum-low-carbon steel assembly exceeds 10 days.

Owner:AMER TECH CO LTD

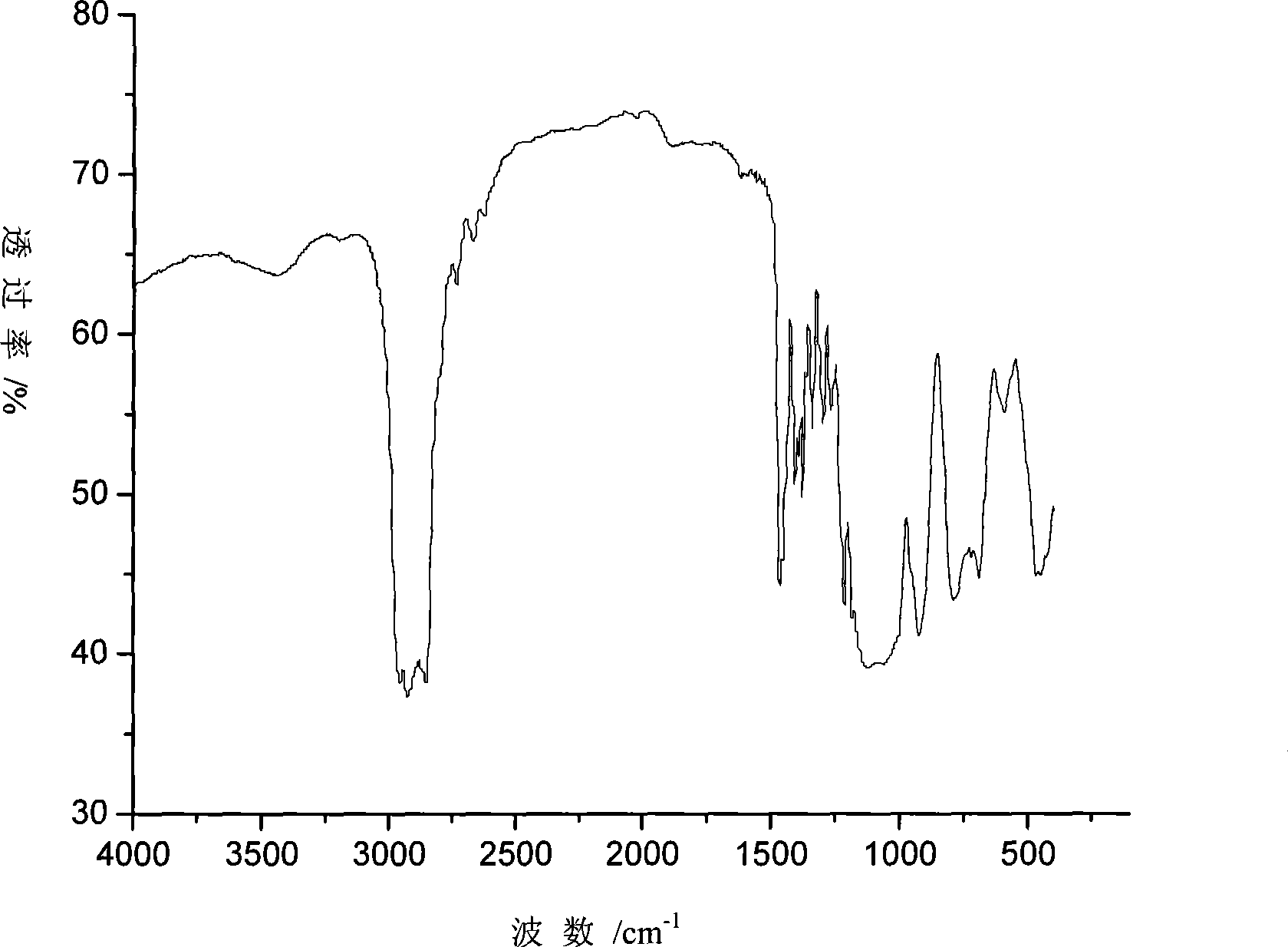

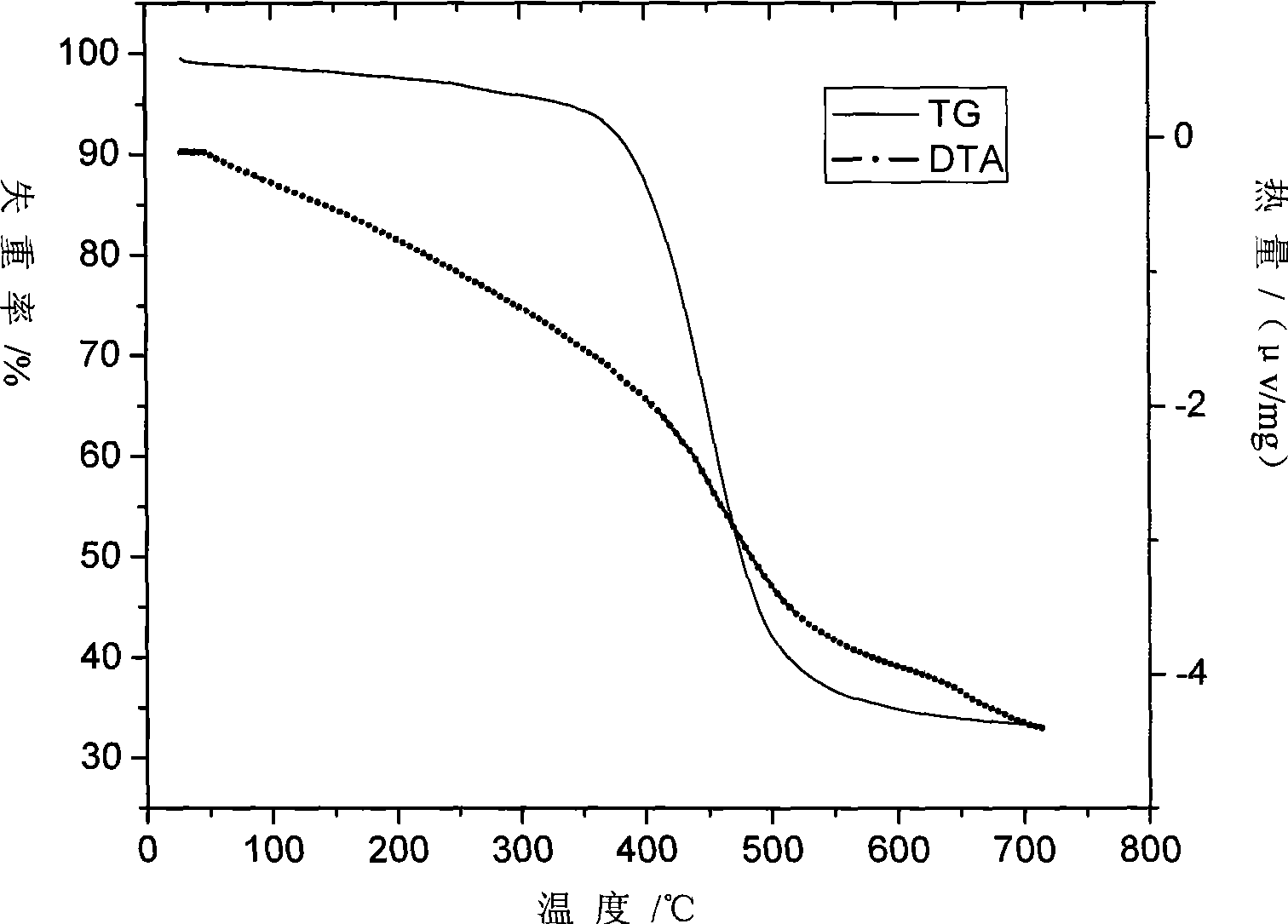

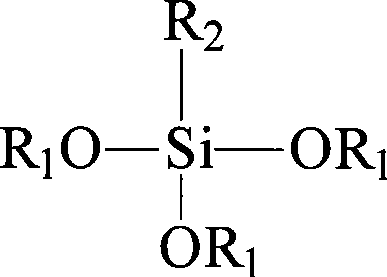

Preparation method for organic silicon resin with high curing activity and high temperature resistance

The invention discloses a preparation method for an organic silicon resin with high curing activity and high temperature resistance, which comprises the following steps: carrying out hydrolytic polycondensation on two kinds of alkyl alkoxy silane and one kind of metal acid ester to polymerize into a silicone resin polymer with proper molecular weight; and using a low-toxic organic solvent as a diluting agent, and adding a curing agent into the low-toxic organic solvent so as to obtain the organic silicon resin with high curing activity and high temperature resistance which can be used as a coating matrix resin. Compared with the common organic silicon resin, the synthetical organic resin has the advantages of excellent heat resistance, high curing activity, good adhesive force, considerable stability, excellent light stability, and excellent environmental friendliness; the preparation method has simpler synthetic route, easily-obtained raw materials, and low price; and the synthetical silicon resin is a low-cost and high performance resin, and is suitable for large-scale preparation and industrialized production.

Owner:GUANGDONG UNIV OF TECH

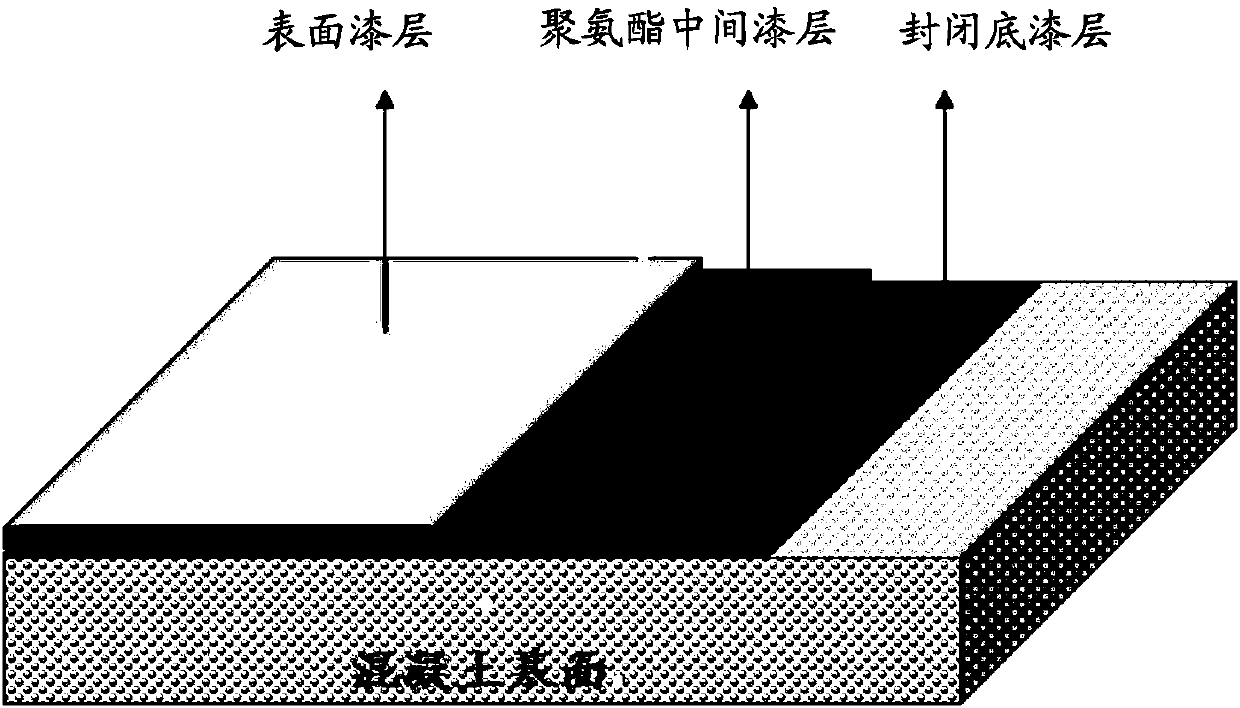

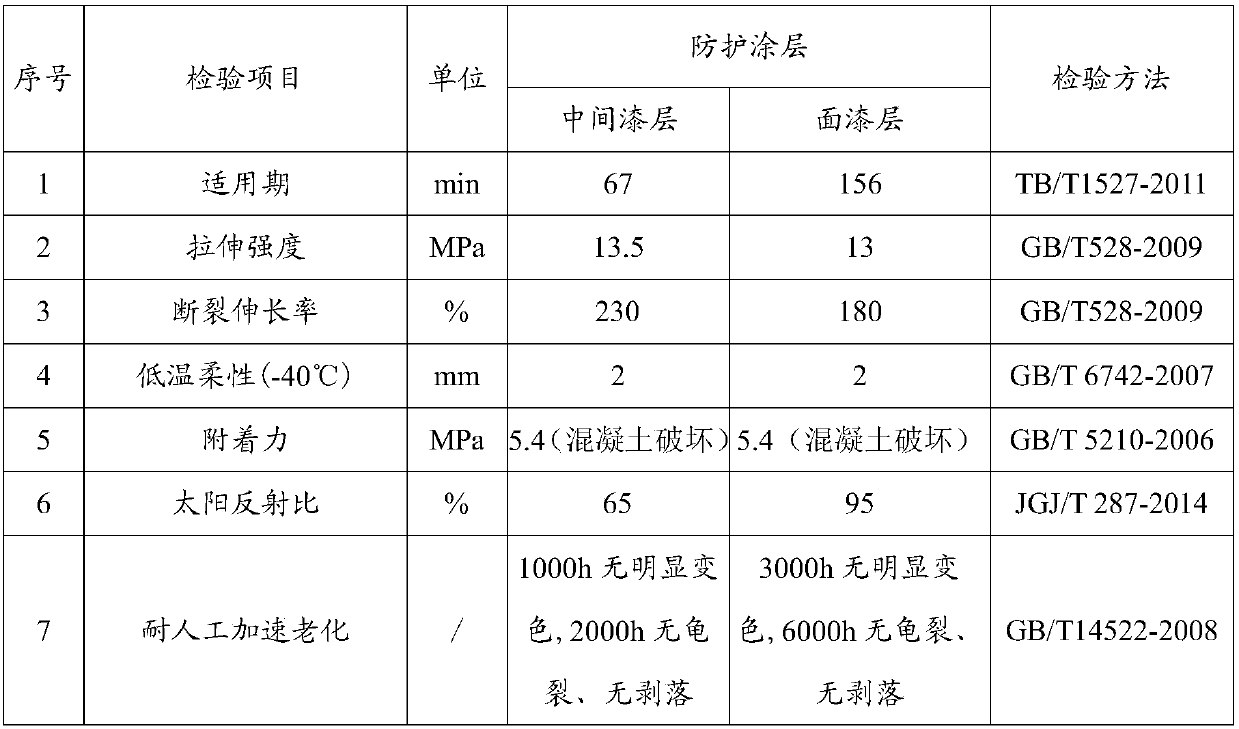

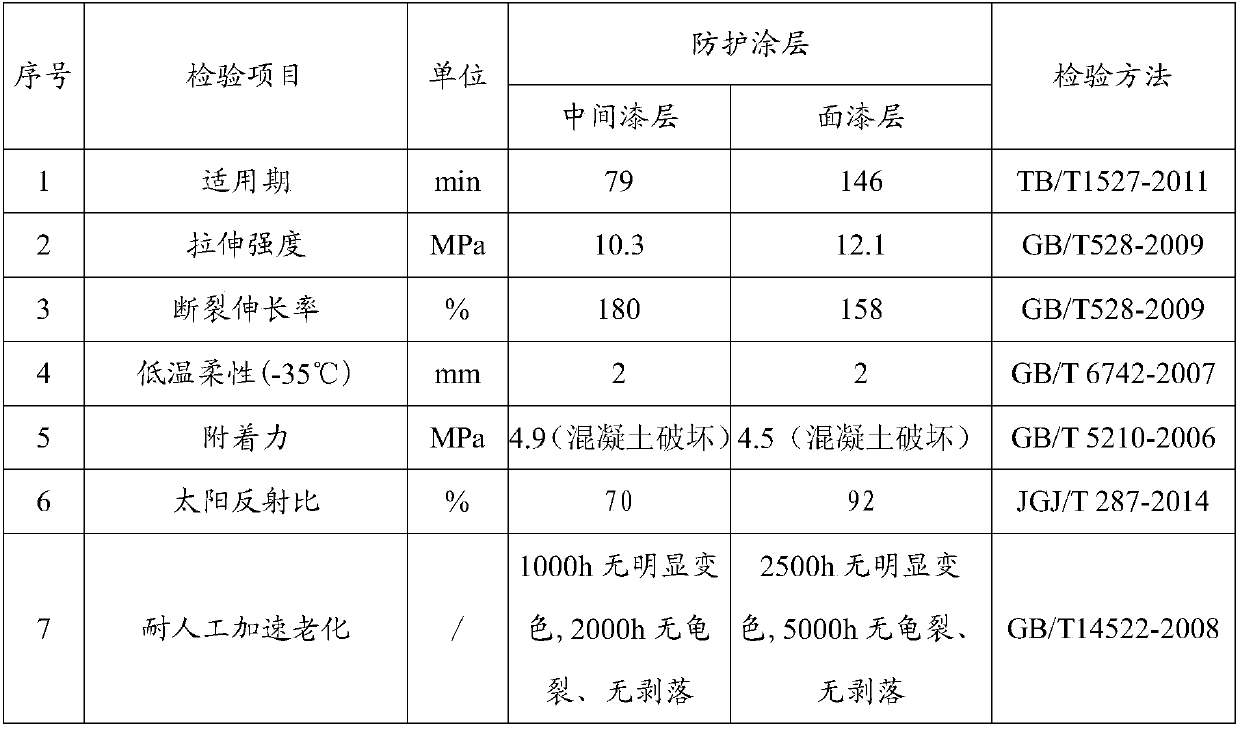

Railway structure concrete protecting coating and preparation method and using method thereof

ActiveCN107603359AImprove adaptabilityImprove aging resistancePolyurea/polyurethane coatingsEpoxy resin coatingsTemperature differenceFluorocarbon

The invention provides railway structure concrete protecting coating and a preparation method and a using method thereof. The protecting coating comprises a sealing primer layer, a polyurethane middlepaint layer and a fluorocarbon finish paint layer. The protecting coating has excellent adhesion; when the protecting coating is used for protecting a railway concrete bridge, the protecting coatingcan avoid occurrence of a situation that the railway concrete bridge cracks first and then is repaired in a special environmental region, significantly improves the durability of the railway concretebridge, prolongs the service life the railway concrete bridge, can achieve an excellent concrete protecting effect in the case of relatively thin concrete bridge coating thickness, and is convenient and fast to use; the protecting coating can also be used for protecting the surface of a ballastless track structure, and when the protecting coating is applied to the surface of a concrete track plateunder a steel rail or the surface of a ballast bed plate, the temperature difference between day and night due to sunlight irradiation can be reduced, the warpage amount of the track plate can be reduced, the open joints of plate corners or upwarp of the ballast bed plate or other damages can be reduced or even eliminated, and the effect of improving the durability of a ballastless track high-speed railway with a strict requirement on the smoothness is relatively good.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +4

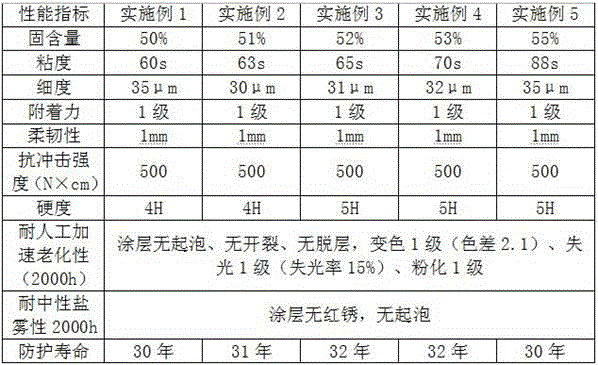

Bicomponent silicofluoride acrylic polyurethane coating as well as preparation and application methods thereof

ActiveCN104017479AImprove adhesionGood flexibilityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention relates to the technical field of protection coatings and in particular relates to a bicomponent silicofluoride acrylic polyurethane coating. The coating comprises a first component and a second component, wherein the mass ratio of the first component to the second component is (3 : 1) to (5 : 1); the first component comprises the following raw materials by weight parts: 50-70 parts of hydroxy acrylic resin, 15-24 parts of a solvent, 0.1-3 parts of fluorine-containing micropowder, 10-25 parts of a pigment, 1-3 parts of high-hardness oxide and 2-5 parts of aids; the second component comprises the following raw materials in parts by weight: 50-80 parts of a closed isocyanate curing agent and 20-50 parts of a solvent. According to the coating, the capability of protecting a steel structure can be improved; the coating has the characteristics of good ageing resistance, scratch resistance, corrosion prevention, color change prevention, pollution prevention and the like, and can achieve a very good long-acting protection effect on the steel structure by combination with other base paint and intermediate paint with excellent performance; and the protection life can be 30 years.

Owner:广东惠电科技发展有限公司

Process for producing water-absorbing resin

InactiveUS7737231B2Prevent discolorationNo discolorationAbsorbent padsBaby linensPolymer scienceProduced water

A process for preparing a water-absorbent resin made from an α,β-unsaturated carboxylic acid as an essential monomer characterized in that the process comprises allowing a metal chelating agent to be present at any step in the process in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid; and adding a reducing agent or an oxidizing agent thereto in an amount of 0.001 to 6 parts by weight, based on 100 parts by weight of the α,β-unsaturated carboxylic acid before initiation of drying and / or during drying of a gelated product containing a water-absorbent resin obtained by polymerization.

Owner:SUMITOMO SEIKA CHEM CO LTD

Normal temperature curing fluorocarbon resin coating and preparation method thereof

The invention discloses a normal temperature curing fluorocarbon resin coating. The coating comprises the following components in percentage by weight: 38 to 60 percent of chlorotrifluoroethylene-vinyl ester polymer, 5 to 10 percent of coupling agent, 1 to 6 percent of pigment, 1 to 5 percent of nanoparticles, 0.05 to 2 percent of aid, 20 to 45 percent of solvent, 5 to 15 percent of curing agent and 0.003 to 0.05 percent of drier, wherein the coupling agent is fluorosilane with -CF3 and -CF2 groups; the aid is a defoamer or a surfactant; the solvent is xylene and methyl isobutyl ketone or butyl acetate and the methyl isobutyl ketone; and the drier is dibutyltin dilaurate. By adopting a specific coating formula, the solubility of fluorocarbon resin in the solvent is improved, the added aid, pigment and the like are soluble, various components are easy to disperse in various dispersion modes, the coating is convenient to operate on site, the adhesion of the coating can reach level 0 and the coating has high scratch resistance and high acid, alkali and salt resistance.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Touch screen protective ink

The invention discloses a touch screen protective ink, which is prepared by mixing the following raw materials in portion: 100 to 250 portions of chlorethylene-vinyl acetate copolymer fluororesin, 100 to 300 portions of polyvinyl chloride A, 150 to 300 portions of polyvinyl chloride B, 1 to 3 portions of C23H16n8Cu, 20 to 60 portions of non-migrating macromolecular polyester plasticizer, 120 to 300 portions of diisononyl trimellitate, 20 to 70 portions of butyl benzyl phthalate, and 30 to 80 portions of dioctyl phthalate. The touch screen protective ink is used for protecting the surfaces of an ITO film and ITO glass in a raw material for preparing a touch screen. The touch screen protective ink plays a role in protection after heat curing or ultraviolet irradiation after printing and can be completely peeled off after use; and the touch screen protective ink has no residual adhesive bright edges, good toughness, no color change, easy peeling off, no holes, no residues and the like when peeled off after use. The touch screen protective ink can be applied to all ITO films and ITO glass on markets.

Owner:刘恒全

Co-conveying nano composition of phenylethyl resorcinol and preparation method and application of co-conveying nano composition

ActiveCN108743430ANo leakageStable structureCosmetic preparationsToilet preparationsSolubilityHigh concentration

The invention relates to the field of cosmetics and provides a co-conveying nano composition of phenylethyl resorcinol. The co-conveying nano composition comprises phenylethyl resorcinol, other skin whitening active components, a nano medicine carrier as well as solvent complex lipid and water, wherein the phenylethyl resorcinol accounts for 0.1-10% of the total mass of the co-conveying nano composition; the other skin whitening active components comprise at least one of an antioxidant, a cutin peeling type active substance, a melanosome transferring inhibition active substance, an anti-glycation active substance and an anti-allergic agent; the nano medicine carrier comprises raw materials of an emulsifier, a Anti-allergic agent and polyhydric alcohols. Due to compounding of different skinwhitening components and carrying of the nano medicine carrier, a remarkable synergetic effect can be achieved, irritation of high-concentration phenylethyl resorcinol can be remarkably reduced, andthe co-conveying nano composition is good in stability, excellent in skin whitening effect, good in water solubility, good in skin permeability and widely applicable to cosmetics.

Owner:WUHAN BEST CARRIER NANO TECH

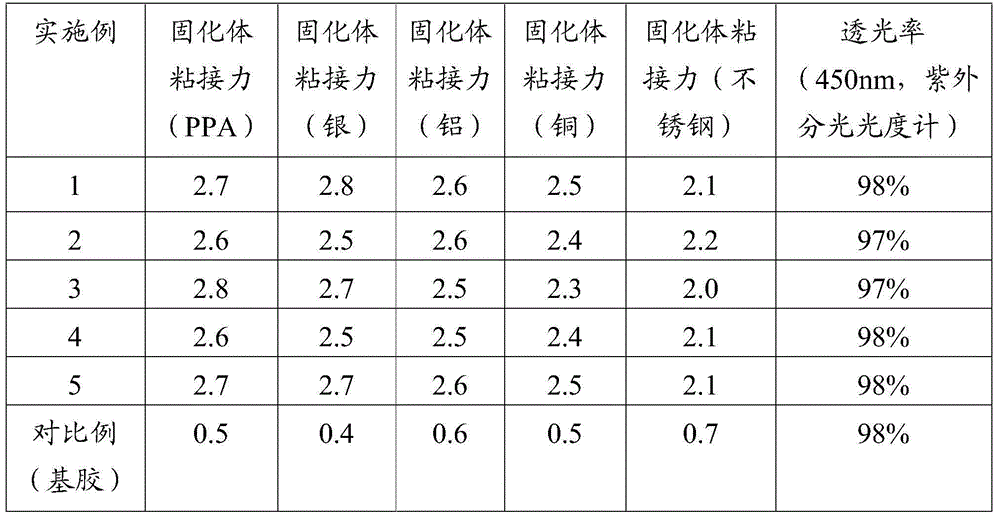

Tackifier for LED packaging adhesive and preparation method of tackifier

InactiveCN104877139AGood compatibilityGood miscibilityAdhesivesSemiconductor devicesLed packagingSiloxane

The invention discloses a tackifier for an LED packaging adhesive and a preparation method of the tackifier. The tackifier is faint yellow or colorless, and obtained by virtue of the following steps: performing a non-hydrolytic condensation reaction on diphenyl silanediol, siloxane with an epoxy group and siloxane with an acryloyloxy group under the catalysis of alkali, and then performing a further condensation reaction under the vacuum condition. After the tackifier is added to an organic silicon LED packaging material, the tackifier is capable of remarkably improving the adhesive properties of the cured organic silicon LED packaging material with a plurality of substrates such as PPA, silver, aluminum, copper and stainless steel; the tackifier has excellent compatibility with the organic silicon LED packaging material; the tackifier has extraordinarily good intersolubility with a double-component added silicon resin without color changing phenomenon and any peculiar smell; the method for preparing the tackifier is easily available in raw materials, mild in reaction conditions, simple in process, high in operability, and prone to industrial production.

Owner:SHENZHEN CAPCHEM TECH

Synthetic method for preparing retanning agent of modified starch for leather

This is the method of preparing the modified starch-based retanning agent of leather. It oxidates and decomposes the starch, then react with vinyl monomer to polymerize. This retannage is used to leather cure of retanning, after retanning the leather feels soft and comfortable, exquisite surface, color uniformity, augment ply efficiently, no color withdraw. This chrome tanning can be used before retanning, and it can increase the absorption of the augmet, and decrease the quantity of chrome in the waste solution. The modified starch-based retanning agent of leather is a product valuable to environment protection, and has a significant mean of decreasing industrial pollution.

Owner:SHAANXI UNIV OF SCI & TECH

Low-smoke halogen-free flame-retardant insulating rubber with rated voltage of 750V for single-core cable for railway vehicles

InactiveCN101928427AHigh temperature resistanceStable jobPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention discloses a low-smoke halogen-free flame-retardant insulating rubber with a rated voltage of 750V for a single-core cable for railway vehicles. The insulating rubber comprises the following components by weight parts: 100 parts of cross-linked polyolefin, 1-5 parts of organic peroxide vulcanizing agents, 1-4 parts of assistant curing agents, 1-4 parts of stabilizing agents, 2-5 parts of coupling agents, 3-8 parts of age resistor and 5-20 parts of reinforcing agents, wherein the cross-linked polyolefin is preferably ethylene-vinyl acetate copolymer EVA-40L-03 produced by the Dupont Company; the organic peroxide vulcanizing agents are preferably dicumyl peroxide (DCP); the assistant curing agents are triallyl isotricaynate (TAIC); the coupling agents are preferably vinyl tri-(beta-methoxy / ethoxy) silane; the age resister is preferably age resister DP; and the reinforcing agents are preferably carbon black Type N550. A cable with a rated voltage of 750V and resistance to 150 DEG C, prepared by the insulating rubber, has favorable insulating property, excellent temperature resistance, good weatherability, ozone resistance, thermal aging resistance, acid and alkalis resistance, fuel oil resistance, low smoke, no halogen, flame retardance, environmental friendliness, safety and long service life.

Owner:JURONG GUANGDA INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com