Railway structure concrete protecting coating and preparation method and using method thereof

A protective coating and concrete technology, applied in coatings, epoxy coatings, reflective/signal coatings, etc., can solve the problems of difficult construction of bridge cracks, difficult to guarantee maintenance quality, short maintenance time, etc. Environmental adaptability and aging resistance, improved elongation at break, stable internal humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

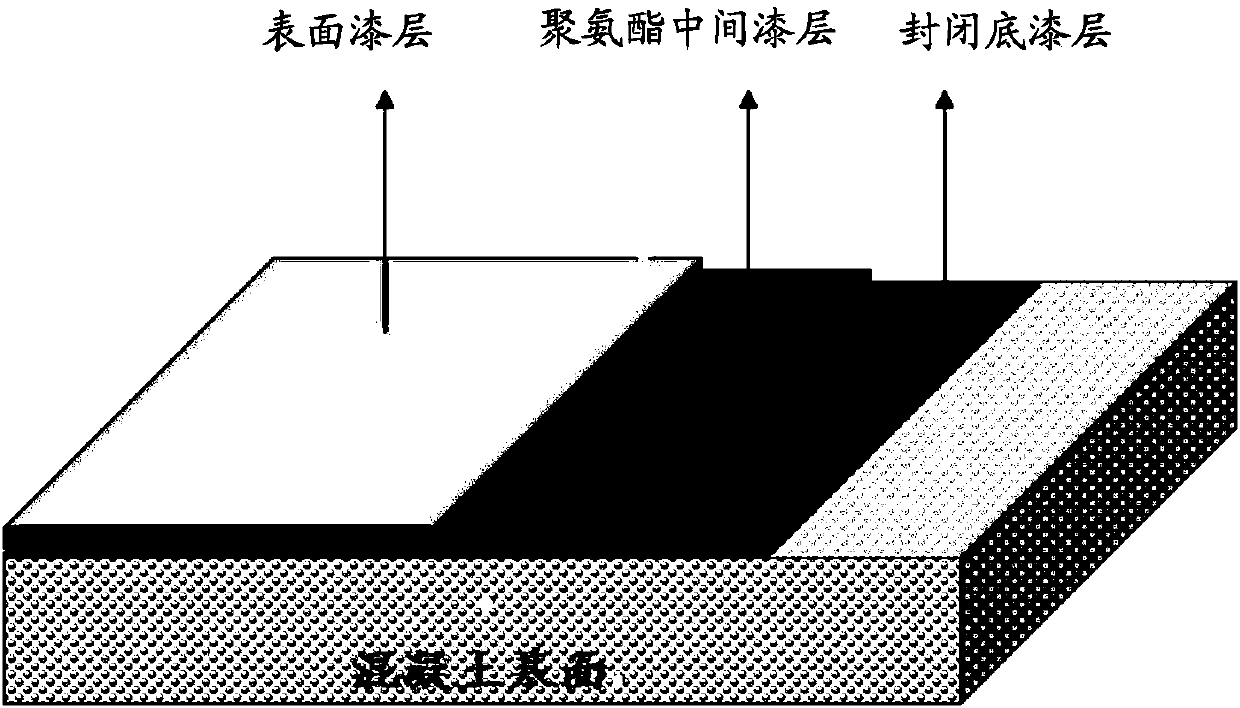

Method used

Image

Examples

Embodiment 1

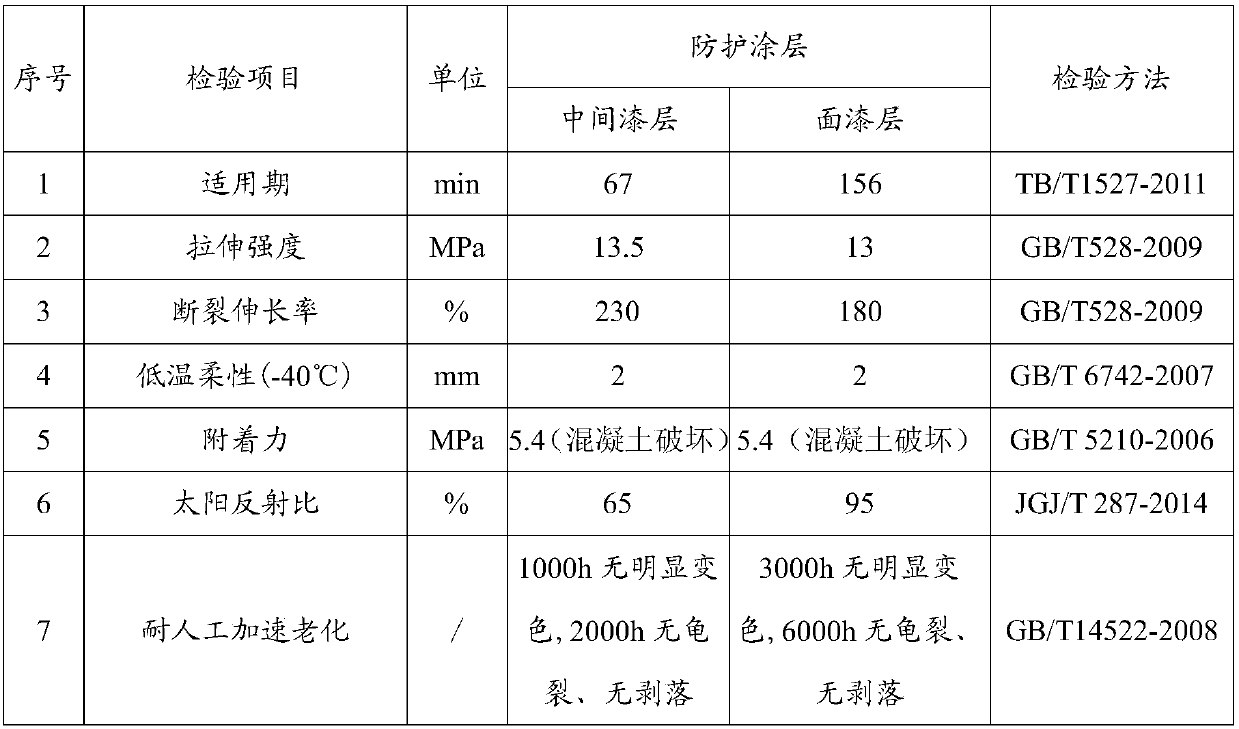

[0077] Embodiment 1: preparation and performance test of concrete bridge protective coating of the present invention

[0078] 1, the preparation of concrete bridge protective coating of the present invention:

[0079] (1) Sealing primer: epoxy sealing primer (provided by Langfang Santong Chemical Industry Co., Ltd.).

[0080] (2) Polyurethane intermediate paint:

[0081] A1 component raw materials: 45.7g polyether 4000, 14.3g polyether 330N, 13g sharp titanium dioxide, 5.0g talcum powder, 9.35g barium sulfate, 0.05g carbon black, 0.5g bentonite, 1.3g modified acrylic resin, 0.1g hydrophobic siloxane, 0.7g ethylene-ethyl acrylate copolymer, 10g ethylene glycol ether acetate;

[0082] B1 component raw materials: 60g of diphenylmethane diisocyanate (98% of analytical purity, white to pale yellow molten solid), 20g of ethylene glycol ether acetate;

[0083] Preparation:

[0084] Put polyether 4000 and polyether 330N in a dispersion tank, add sharp titanium dioxide, talcum po...

Embodiment 2

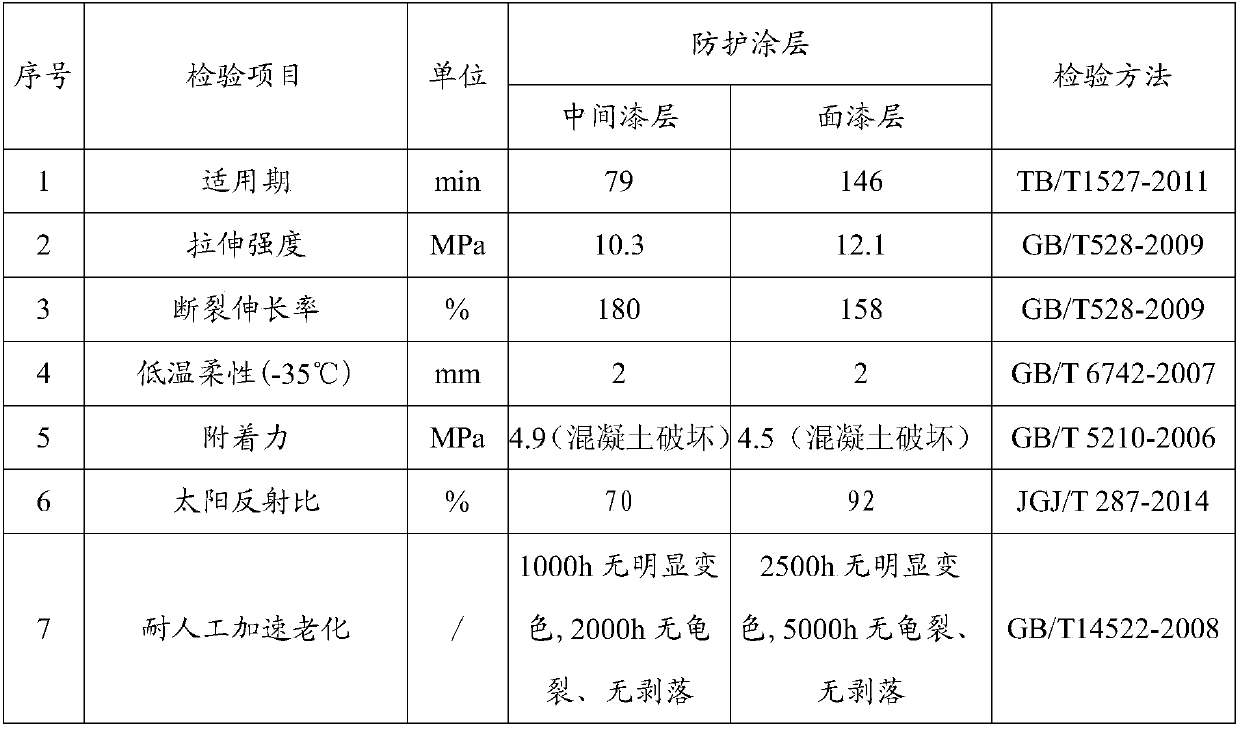

[0105] Embodiment 2: preparation and performance test of concrete bridge protective coating of the present invention

[0106] 1, the preparation of concrete bridge protective coating of the present invention:

[0107] (1) Sealing primer: epoxy sealing primer (provided by Langfang Santong Chemical Industry Co., Ltd.).

[0108] (2) Polyurethane intermediate paint:

[0109]A1 component raw materials: 30.5g polyether 4000, 9.5g polyether 330N, 28g sharp titanium dioxide, 5.0g ceramic beads, 14.35g barium sulfate, 0.05g carbon black, 0.5g bentonite, 1.3g modified acrylic resin , 0.1g hydrophobic siloxane, 0.7g ethylene-ethyl acrylate copolymer, 10g ethylene glycol ether acetate;

[0110] Raw material of B1 component: 48g of diphenylmethane diisocyanate (98% of analytical purity, white to pale yellow molten solid), 12.0g of xylene;

[0111] Preparation:

[0112] Put polyether 4000 and polyether 330N in the dispersing tank, add sharp titanium dioxide, ceramic microbeads, barium...

Embodiment 3

[0130] Embodiment 3: preparation and performance test of concrete bridge protective coating of the present invention

[0131] 1, the preparation of concrete bridge protective coating of the present invention:

[0132] (1) Sealing primer: epoxy sealing primer (provided by Langfang Santong Chemical Industry Co., Ltd.).

[0133] (2) Polyurethane intermediate paint:

[0134] A1 component raw materials: 38g polyether 4000, 12g polyether 330N, 24g sharp titanium dioxide, 5.0g talc, 8.35g barium sulfate, 0.05g carbon black, 0.5g bentonite, 1.3g modified acrylic resin, 0.1g Hydrophobic siloxane, 0.7g ethylene-ethyl acrylate copolymer, 10g ethylene glycol ether acetate;

[0135] B1 component raw materials: 53g of diphenylmethane diisocyanate (98% of analytical purity, white to light yellow molten solid), 18g of ethylene glycol ether acetate;

[0136] Preparation:

[0137] Put polyether 4000 and polyether 330N in a dispersion tank, add sharp titanium dioxide, talcum powder, barium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com