Silicon dioxide loaded nano-silver waterborne antibacterial paint and preparation method thereof

A technology of antibacterial coatings and porous silica, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem of low utilization rate of silver components, poor dispersion, antibacterial efficiency, and long-lasting antibacterial Insufficient resistance and other problems, to achieve the effect of improving the use efficiency and durability, increasing the specific surface area, and improving the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A porous silicon dioxide-loaded nano-silver water-based antibacterial coating, in parts by weight, its raw materials are composed of: 25 parts of water, 30 parts of acrylic resin, 20 parts of polyurethane resin, 2 parts of porous silica-loaded nano-silver antibacterial agent, 1.5 parts of dispersant, 1 part of curing agent, 0.8 part of defoamer, 0.5 part of film-forming aid and 0.5 part of leveling agent.

[0026] The preparation of described porous silicon dioxide loaded nano-silver antibacterial agent:

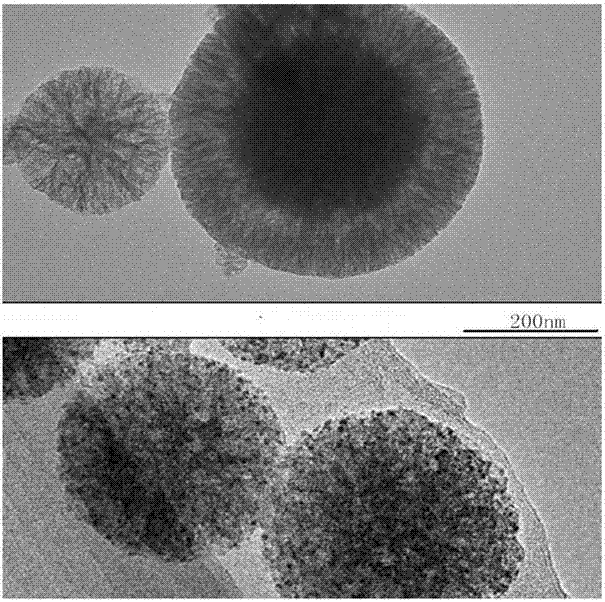

[0027] 1) Porous SiO 2 Preparation: Dissolve 0.5g of cetyl ammonium bromide (CTAB) in a mixed solution consisting of 50mL of water, 10mL of ethanol and 15mL of ether at room temperature, stir for 20min, add 1.2mL of ammonia water, stir for 20min, then add 3 mL of tetraethyl orthosilicate (TEOS), then add 0.15 m of 3-aminopropyltriethoxysilane (APTES) and stir for 4 h, wash the resulting dispersion with ethanol and deionized water for 3 times respectively. 2 ;

[00...

Embodiment 2

[0033] A kind of porous silicon dioxide loaded nano-silver water-based antibacterial coating, by weight, its raw material consists of: 35 parts of water, 40 parts of acrylic resin, 30 parts of polyurethane resin, 3 parts of antibacterial agent, 2.5 parts of dispersant, curing agent 1.5 parts, 1 part of defoamer, 0.8 parts of film-forming aid and 0.8 parts of leveling agent.

[0034] The preparation method of described antibacterial agent is with embodiment 1.

[0035] The preparation method of porous silicon dioxide loaded nano-silver water-based antibacterial coating is:

[0036] After mixing water, acrylic resin, polyurethane resin, dispersant, curing agent, defoamer, film-forming aid and leveling agent in proportion, add antibacterial agent, and then use mechanical shearing to mix evenly to prepare A new type of porous silica-loaded nano-silver high-efficiency water-based antibacterial coating was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com