Preparation method for organic silicon resin with high curing activity and high temperature resistance

An organosilicon, high temperature resistant technology, used in chemical materials and light industry fields, can solve the problem of high cost of silicone resin, and achieve the effects of long curing time, good light stability and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

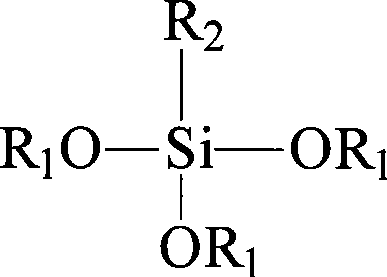

Method used

Image

Examples

Embodiment 1

[0043] Step 1. Preparation of hydrolyzate

[0044] Put 10ml of ethyltriethoxysilane, 30ml of propyltriethoxysilane, and 89.5ml of absolute ethanol into a four-necked flask. After stirring evenly, add 0.83ml (0.83×10 -3 mol) hydrochloric acid solution, heated under mechanical stirring, and kept constant after rising to a certain temperature. Then measure 4.5ml of deionized water, slowly drop it into a four-neck flask with a dropping funnel, stir rapidly, and hydrolyze at constant temperature for a certain period of time. Draw the stannate ester of 2.36ml (0.007mol) with the pipetting hall, and after dissolving with the organic solvent of 20ml, slowly drip into the hydrolyzate of the four-necked flask with the dropping funnel, then drip into the deionized water of 0.5ml, Then continue constant temperature hydrolysis for a certain period of time. After completion of the reaction, the hydrolysis mixture was still a clear and transparent liquid.

[0045] Step 2. Polycondensation...

Embodiment 2

[0048] Step 1. Preparation of hydrolyzate

[0049] Put 15ml of propyltriethoxysilane, 30ml of n-octyltriethoxysilane, and 125ml of propanol into a four-necked flask, stir well, then add 1ml (1×10 -3 mol) of sodium hydroxide solution, heated under mechanical stirring, and kept constant after rising to a certain temperature. Then measure 6.93ml of deionized water, slowly drop it into a four-necked flask with a dropping funnel, stir rapidly, and hydrolyze at constant temperature for a certain period of time. Use a pipette to absorb 3.01ml of lead ester, dissolve it with 10ml of organic solvent, slowly drop it into the hydrolyzate in the four-neck flask with a dropping funnel, then add 0.8ml of deionized water, and then continue the constant temperature hydrolysis certain time. After the reaction was completed, the hydrolysis mixture was still a clear and transparent liquid.

[0050] Step 2. Polycondensation reaction of silanol

[0051] The reaction device in step 1 is changed...

Embodiment 3

[0053] Step 1. Preparation of hydrolyzate

[0054] Put 20ml of n-butyltriethoxysilane, 20ml of n-hexyltriethoxysilane, and 125ml of n-butanol into the four-necked flask. After stirring evenly, add 0.9ml (0.9×10 -3 mol) of sodium hydroxide solution, heated under mechanical stirring, and kept constant after rising to a certain temperature. Then measure 7.2ml of deionized water, slowly drop it into a four-necked flask with a dropping funnel, stir rapidly, and hydrolyze at constant temperature for a certain period of time. Draw 2.89ml of titanate with a pipette, dissolve it with 15ml of organic solvent, slowly drop it into the hydrolyzate in the four-necked flask with a dropping funnel, then add 0.6ml of deionized water, and then continue the constant temperature hydrolysis certain time. After the reaction was completed, the hydrolysis mixture was still a clear and transparent liquid.

[0055] Step 2. Polycondensation reaction of silanol

[0056] The reaction device in step 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com