Double-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of high solid content, high price, high cost, etc., and achieve good bonding performance and durability Good thermal performance and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

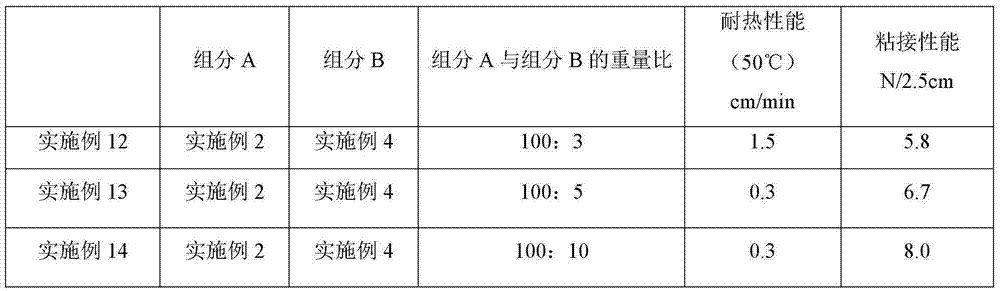

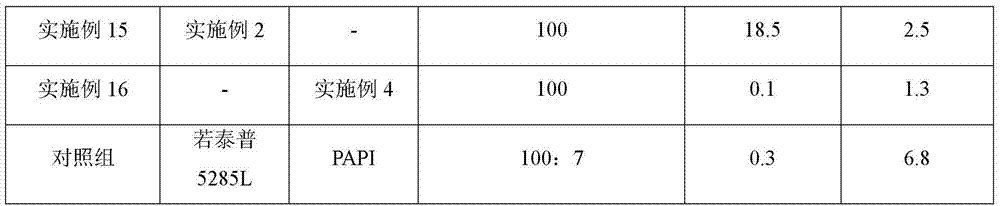

Examples

Embodiment 1

[0060] The preparation of embodiment 1 component A

[0061] Component A is prepared from the following ingredients in parts by weight:

[0062] Polyester polyol: PBA (2000 molecular weight)): 750g;

[0063] Diphenylmethane diisocyanate (MDI): 145g;

[0064] Chain extender: BDO: 18g;

[0065] Catalyst: 0.5 g of stannous octoate;

[0066] Diluent: ethyl ester 1300g, dimethyl carbonate 1300g, dichloromethane 450g, xylene 602g;

[0067] Put the polyester polyol into the reaction kettle, raise the temperature to 110-130°C, vacuum dehydrate for 1-3h, cool to 70-80°C, add diphenylmethane diisocyanate, and prepolymerize 1- 2h, cool down to 60-70°C, add chain extender, react at 70°C±5°C for 1-1.5h, then add organic tin catalyst, continue to react for 2h-3h, cool to 30-40°C, add diluent It can be obtained by adjusting the viscosity at 3500-4500mPa.s / 25℃.

Embodiment 2

[0068] The preparation of embodiment 2 component A

[0069] Component A is prepared from the following ingredients in parts by weight:

[0070] Polyester polyol: PBA (3000 molecular weight)): 750g;

[0071] Diphenylmethane diisocyanate (MDI): 135g;

[0072] Chain extender: BDO: 25g;

[0073] Catalyst: 0.65g of stannous octoate;

[0074] Diluent: ethyl ester 1000g, dimethyl carbonate 1000g, dichloromethane 456g, xylene 500g;

[0075] Put the polyester polyol into the reaction kettle, raise the temperature to 110-130°C, vacuum dehydrate for 1-3h, cool to 70-80°C, add diphenylmethane diisocyanate, and prepolymerize 1- 2h, cool down to 60-70°C, add chain extender, react at 70°C±5°C for 1-1.5h, then add organic tin catalyst, continue to react for 2h-3h, cool to 30-40°C, add diluent It can be obtained by adjusting the viscosity at 6500-7500mPa.s / 25℃.

Embodiment 3

[0076] The preparation of embodiment 3 component A

[0077] Component A is prepared from the following ingredients in parts by weight:

[0078] Polyester polyol: PBA (3000 molecular weight)): 750g;

[0079] Diphenylmethane diisocyanate (MDI): 145g;

[0080] Chain extender: BDO: 30g;

[0081] Catalyst: stannous octoate 1g;

[0082] Diluent: 1200g ethyl ester, 1200g dimethyl carbonate, 350g dichloromethane, 450g xylene;

[0083] Put the polyester polyol into the reaction kettle, raise the temperature to 110-130°C, vacuum dehydrate for 1-3h, cool to 70-80°C, add diphenylmethane diisocyanate, and prepolymerize 1- 2h, cool down to 60-70°C, add chain extender, react at 70°C±5°C for 1-1.5h, then add organic tin catalyst, continue to react for 2h-3h, cool to 30-40°C, add diluent It can be obtained by adjusting the viscosity at 5000-6000mPa.s / 25℃.

[0084] Part II Preparation of Component B

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com