Prepn of functional beverage containing effective components from natural product

A natural product and functional beverage technology, applied in the preparation of alcoholic beverages, food science, etc., can solve the problems of low extraction rate and volatilization loss of effective functional components, and achieve the effects of avoiding water pollution, stable extracting solution, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

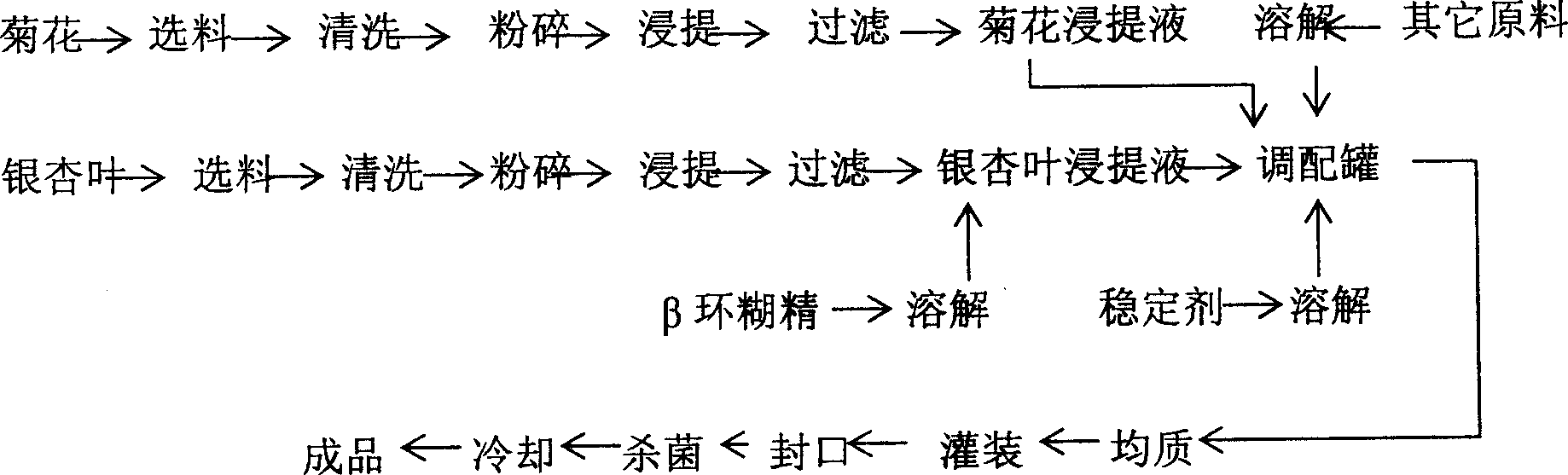

Method used

Image

Examples

Embodiment 1

[0067] Preparation of jasmine tea functional drink.

[0068] Main ingredient: mineral water;

[0069] Accessories: jasmine tea;

[0070] Main process and conditions:

[0071] Mix with the ratio of jasmine tea: mineral water=1g: 120ml;

[0072] The mixed solution is placed in an ultra-high pressure container for ultra-high pressure extraction,

[0073] Process conditions for ultra-high pressure extraction: pressure is 100-250MPa, and the pressure is maintained for 1-5 minutes;

[0074] Use ordinary medium-speed quantitative filter paper or equivalent grade sand filter or membrane filter;

[0075] The filtrate is packaged in a food plastic bag with a thickness of 0.08mm;

[0076] Sterilize the plastic bag in which the filtrate is packaged in an ultra-high pressure container,

[0077] The process conditions of ultra-high pressure sterilization: the pressure is 300-600MPa, and the pressure is maintained for 5-10 minutes;

[0078] Product features: It maintains the unique fr...

Embodiment 2

[0080] Preparation of chrysanthemum tea functional drink.

[0081] Main ingredient: tap water;

[0082] Accessories: green tea (variety optional), dried chrysanthemum;

[0083] Main process and conditions:

[0084] Mix with the ratio of green tea: dried chrysanthemum: water=1g: 2g: 150ml;

[0085] The mixed solution is placed in an ultra-high pressure container for ultra-high pressure extraction,

[0086] The process conditions of ultra-high pressure extraction: the pressure is 200-400MPa, and the pressure is maintained for 5-15 minutes;

[0087] Use ordinary medium-speed quantitative filter paper or the same grade of sand filter or membrane filter;

[0088] Add 2% rock sugar to the filtrate;

[0089] After the rock sugar is completely dissolved, the filtrate is packaged in a food plastic bag with a thickness of 0.08mm;

[0090] Sterilize the plastic bag in which the filtrate is packaged in an ultra-high pressure container,

[0091] The process conditions of ultra-high ...

Embodiment 3

[0094] Preparation of Epimedium functional wine.

[0095] Main ingredient: ordinary edible liquor (variety and alcohol content in it are optional, preferably above 35°);

[0096] Excipients: Epimedium leaves;

[0097] Main process and conditions:

[0098] Crush the Epimedium leaves to a particle size of 0.84-0.42mm (20-40 mesh);

[0099] Mix with crushed Epimedium leaves: wine = 1g: 20ml ratio;

[0100] Put the mixed solution in an ultra-high pressure container for ultra-high pressure extraction,

[0101] Ultra-high pressure extraction process conditions: 100-200MPa, holding time 1-7min;

[0102] Use ordinary medium-speed quantitative filter paper or the same grade of sand filter or membrane filter; the filtrate is the final product.

[0103] Product features: This product has the effects of improving cardiovascular function and strengthening yang.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com