Liquid photo-imageable alkali developable and anodizing resistant ink and preparation method thereof

A technology of anodic oxidation and alkali development, applied in the ink field, can solve the problems of low resolution, poor acid and strong alkali resistance, poor oxidation resistance, etc., and achieve simple synthesis operation process and good anti-sand blasting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

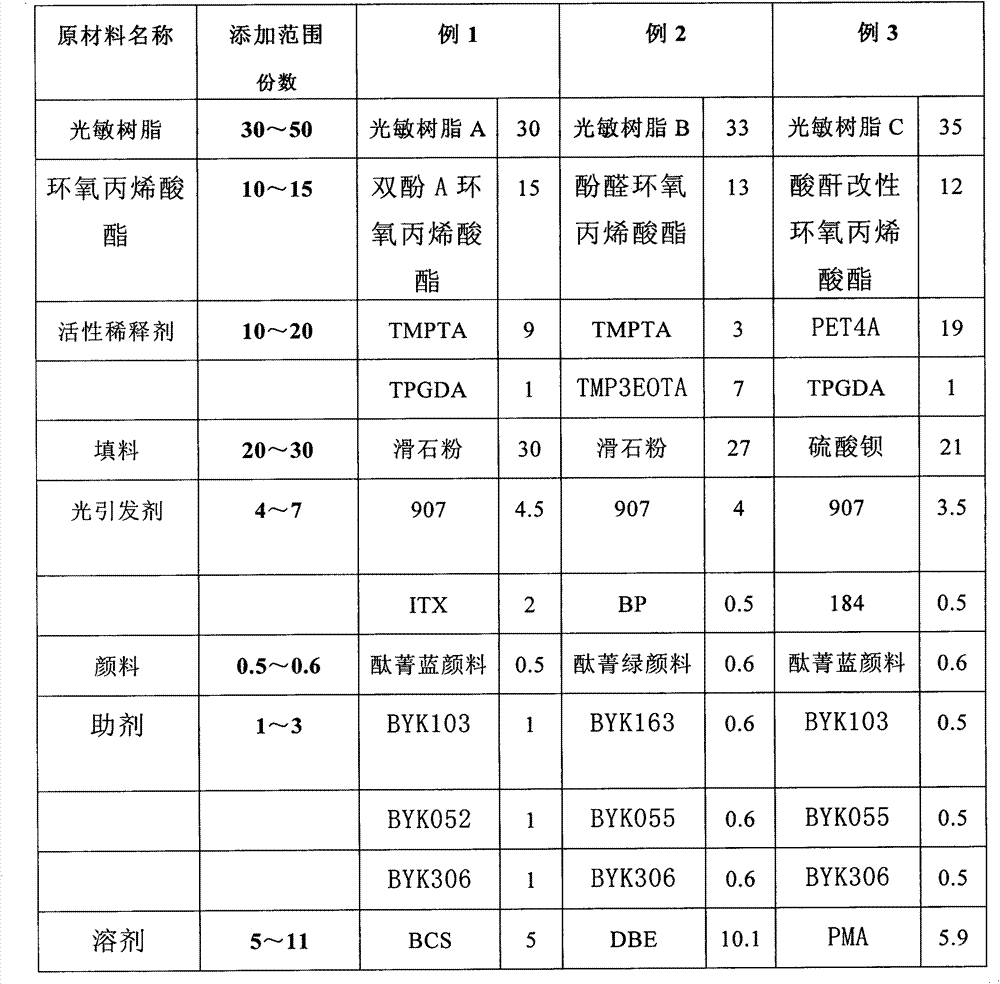

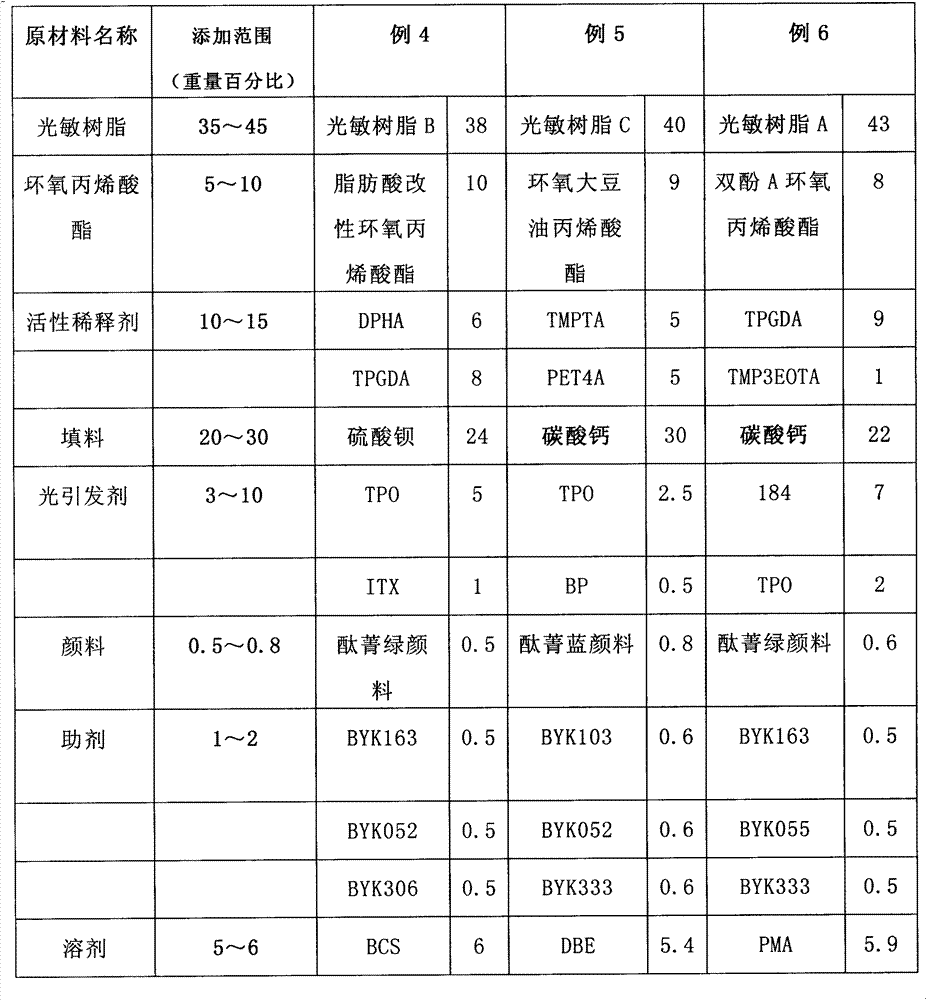

Examples

preparation example Construction

[0025] The preparation method of the liquid photosensitive imaging alkali development anti-anodizing ink of the present invention comprises the following steps:

[0026] A. Prepare raw materials: Prepare 30-50 parts of alkali-soluble photosensitive resin, 5-15 parts of epoxy acrylate resin, 10-20 parts of reactive diluent, 5-15 parts of solvent, 1-10 parts of photoinitiator, 1-3 parts of auxiliary agents, 20-40 parts of fillers and 0.5-0.8 parts of pigments, wherein the alkali-soluble photosensitive resin is acid anhydride modified novolak epoxy acrylate, when preparing the acid anhydride modified novolak epoxy acrylate Prepare according to parts by weight: 35-50 parts of epoxy resin, 20-40 parts of DBE, 15-20 parts of acrylic acid, 8-15 parts of maleic anhydride, 0.5-1 part of hydroquinone, 0.5-1 part of tetraethyl ammonium bromide;

[0027] B. Preparation of anhydride-modified novolac epoxy acrylate: heat and dissolve the epoxy resin in step A with 20-40 parts of DBE, add i...

specific Embodiment

[0030] The following are three self-made methods of photosensitive resin A, B, and C:

[0031] The synthetic method of photosensitive resin A is:

[0032] Take 40 parts of F-43 novolac epoxy resin, heat and dissolve with 30 parts of DBE, add it into a three-necked flask with a reflux condenser and a stirrer, add 0.5 parts of hydroquinone and 0.5 parts of tetraethylammonium bromide, After heating to 110°C and stabilizing at constant temperature, add 18 parts of acrylic acid dropwise with a constant pressure funnel, control the dropwise addition within 1 hour, stir and react for more than 2 hours, then add 11 parts of maleic anhydride and react for 5 hours to obtain photosensitive resin A.

[0033] The synthetic method of photosensitive resin B is:

[0034] Take 50 parts of JF-43 o-cresol type epoxy resin, heat and dissolve with 20 parts of DBE, put it into a three-necked flask with a reflux condenser and a stirrer, add 1 part of hydroquinone and 1 part of tetraethyl bromide A...

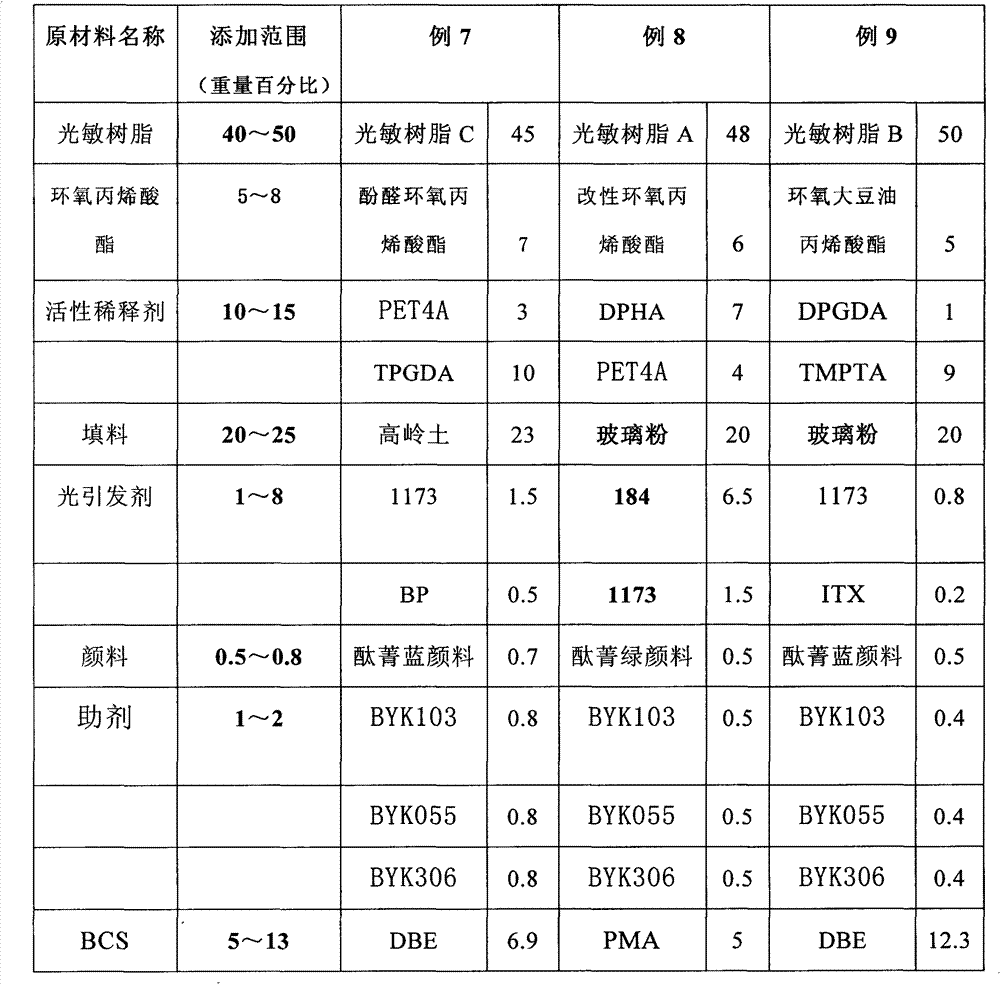

Embodiment 7 to 9

[0044]

[0045] Mix the raw materials of the above-mentioned Examples 1 to 9 and use a three-roller machine to form a blue ink with a fineness of 10 μ and a viscosity of 195 dpa.s (25° C.). The resulting ink has good performance. Ink film hardness 4H, adhesion 5B. Anti-sandblasting 2kgf / cm 2 , no shedding. Anti-anodization ink is intact, no drop. From the above-mentioned examples and the results of performance tests, it can be concluded that the liquid photosensitive imaging alkali-developing anti-anodizing ink prepared by the above-mentioned ratio and the above-mentioned method is screen-printed or sprayed on the surface of an aluminum material, and baked at 90-100°C for 15-30 Make the surface dry in 10 minutes, stick the film tightly, expose it under the ultraviolet light, and then use 0.5-0.8% Na 2 CO 3 Develop in aqueous solution for 30-60 seconds, then pass through UV machine at 800-1500mj / cm 2 After curing, the formed ink film is resistant to sandblasting, strong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com