Silica gel, preparation method and protective film using silica gel

A technology of silicone gel and silicone oil, applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of no experimental data support, complex structure, unsatisfactory optical properties, etc., to achieve convenient production and use , The effect of the synthesis operation process is simple and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

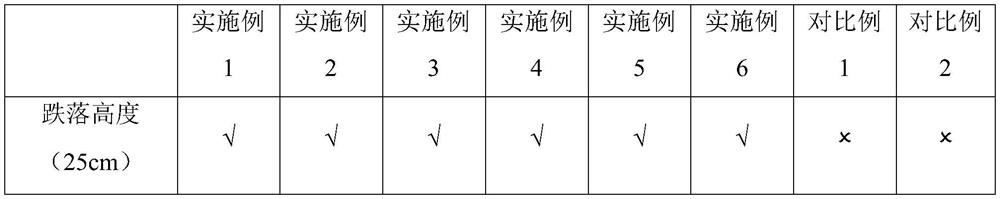

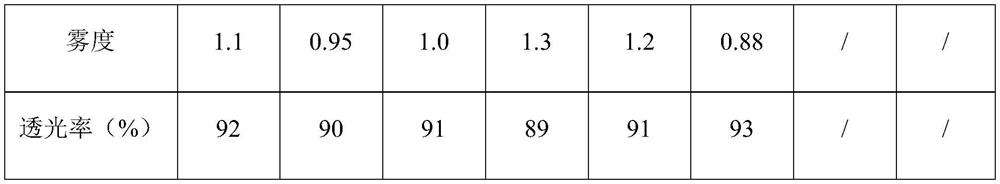

Examples

Embodiment 1

[0031] The silicone gel provided in this example, its raw materials include 100 parts by weight of vinyl polysiloxane, 20 parts of methyl MQ silicone resin, 0.8 parts of crosslinking agent, 0.6 parts of catalyst, 0.1 part of inhibitor, coupling 0.6 parts of agent and 150 parts of diluting solvent.

[0032] The vinyl polysiloxane used is terminal vinyl polysiloxane, and the specific chemical structure formula is ViMe 2 SiO(SiMe 2 O) n (SiMeViO) m SiMe 2 Vi, the vinyl content is 0.05wt%; Cross-linking agent adopts terminal hydrogen-containing silicone oil: hydrogen-terminated polydimethylmethylhydrogensiloxane, chemical structural formula is (CH 3 ) 2 (H)SiO[(CH 3 )(H)SiO] y Si(H)(CH 3 ) 2 , the hydrogen content is 0.17wt%, and the molar ratio of H in the silicon hydrogen group-containing silicone oil to the vinyl group is 0.8.

Embodiment 2

[0034] The silicone gel provided in this example, its raw materials include 100 parts by weight of vinyl polysiloxane, 20 parts of methyl MQ silicone resin, 1.1 parts of crosslinking agent, 0.6 parts of catalyst, 0.1 part of inhibitor, coupling 0.6 parts of agent and 150 parts of diluting solvent.

[0035] The vinyl polysiloxane used is terminal vinyl polysiloxane, and the specific chemical structure formula is ViMe 2 SiO(SiMe 2 O) n (SiMeViO) m SiMe 2 Vi, the vinyl content is 0.05wt%; Cross-linking agent adopts terminal hydrogen-containing silicone oil: hydrogen-terminated polydimethylmethylhydrogensiloxane, chemical structural formula is (CH 3 ) 2 (H)SiO[(CH 3 )(H)SiO] ySi(H)(CH 3 ) 2 , the hydrogen content is 0.17wt%, and the molar ratio of H in the silicone oil containing silicon hydrogen group to the vinyl group is 1.0.

Embodiment 3

[0037] The silica gel provided in this embodiment, its raw materials include 100 parts by weight of vinyl polysiloxane, 20 parts of methyl MQ silicone resin, 1.4 parts of crosslinking agent, 0.6 parts of catalyst, 0.1 part of inhibitor, coupling 0.6 parts of agent and 40 parts of diluting solvent.

[0038] The vinyl polysiloxane used is terminal vinyl polysiloxane, and the specific chemical structure formula is ViMe 2 SiO(SiMe 2 O) n (SiMeViO) m SiMe 2 Vi, the vinyl content is 0.05wt%; Cross-linking agent adopts terminal hydrogen-containing silicone oil: hydrogen-terminated polydimethylmethylhydrogensiloxane, chemical structural formula is (CH 3 ) 2 (H)SiO[(CH 3 )(H)SiO] y Si(H)(CH 3 ) 2 , the hydrogen content is 0.17wt%, and the molar ratio of H in the silicone oil containing silicon hydrogen group to the vinyl group is 1.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com