Ultraviolet full-shielding printing ink and preparation method thereof

A technology of ultraviolet rays and inks, applied in inks, household utensils, applications, etc., can solve labor-intensive and time-consuming problems, and achieve the effects of solving pinching, good performance, and good metal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of ultraviolet full shielding ink of the present invention comprises the following steps:

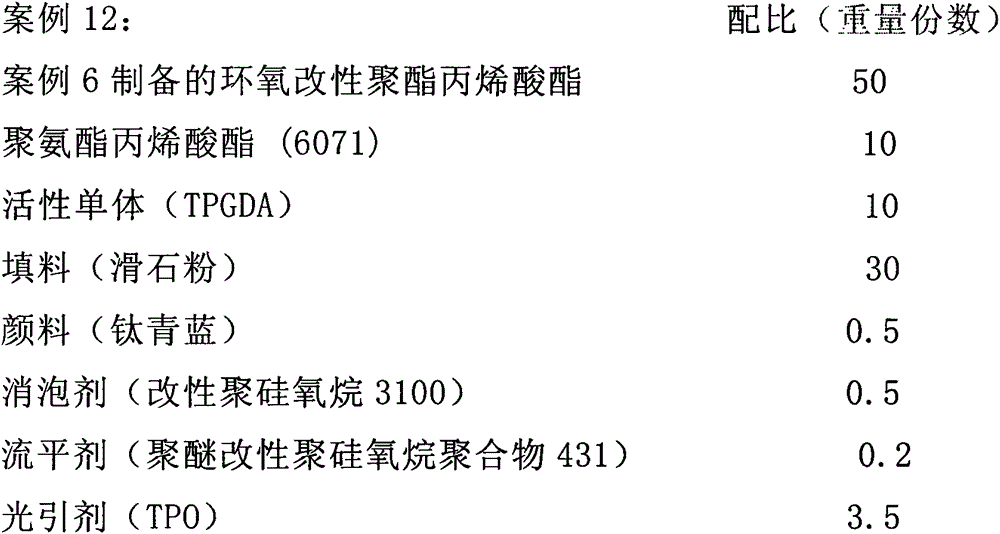

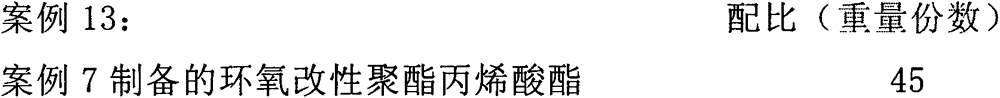

[0029] A. Prepare raw materials: according to the parts by weight, it is made from the following ratio: 40-60 parts of epoxy modified polyurethane acrylate, 10-30 parts of polyurethane acrylate, 10-30 parts of active monomer, 30 parts of filler -35 parts, 0.5-1.0 parts of pigments, 0.5-1.0 parts of additives, 3-5 parts of photoinitiators; wherein epoxy-modified urethane acrylate is prepared according to the following ratio according to parts by weight: epoxy-modified 60-80 parts of polyurethane prepolymer, 10-30 parts of acrylic acid monomer, and 0.8-1 part of polymerization inhibitor; and the epoxy-modified polyurethane prepolymer is prepared according to the following ratio in parts by weight: epoxy resin 15-20 parts, 40-60 parts of diol and 25-30 parts of isocyanate;

[0030] B. Preparation of epoxy-modified polyurethane prepolymer: 15-20 parts of epoxy...

specific Embodiment

[0055]

[0056] Mix and stir the above-mentioned formula raw materials together, then use a three-roller machine to roll into a blue ink with a fineness of 10-12μm, and then use a disperser to disperse at a speed of 1500rp / min for 30 minutes, and the obtained ink is adjusted and sprayed with the above-mentioned diluent A Viscosity, after spraying, bake at 70°C for 3-5 minutes, and then pass the energy of 1000-1200mj / cm 2 UV, the resulting oil film has good properties. Adhesion 5B, hardness 2H, resistant to cutting fluids and cleaning agents, no cracking and oil loss during CNC machining, easy to remove with weak alkali or paint stripper without residue, and has no effect on the appearance of 3D metal product substrates.

[0057]

[0058]

[0059] Mix and stir the above-mentioned formula raw materials together, and then use a three-roller machine to roll into a blue ink with a fineness of 10-12 μm, and then disperse it with a disperser at 1500rp / min for 30 minutes. Use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com