Method for preparing alcohol soluble polyurethane coating

A polyurethane coating, alcohol-soluble technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of uneven thickness, slow evaporation of water, adhesion of dust, etc., and achieve the effect of simple synthesis operation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

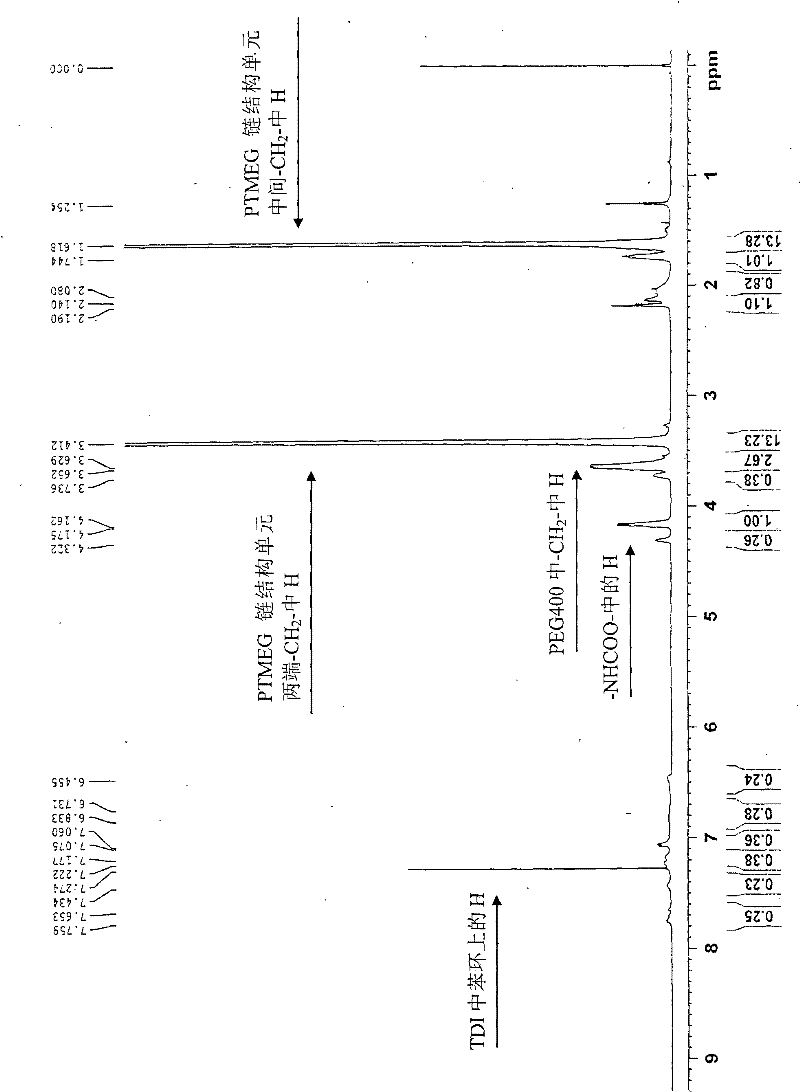

[0037] Synthesis:

[0038] 1. Weigh about 26 g of polytetrahydrofuran ether glycol (PTMEG, molecular weight Mn=1000) and put it into a three-necked flask;

[0039] 2. Put the three-necked bottle into a vacuum drying oven and heat it to 120°C for 2 hours, then weigh 25g accurately after drying to remove moisture;

[0040] 3. Under the protection of nitrogen, add 4.3ml of measured toluene diisocyanate (TDI) and stir at 80°C for 1h;

[0041] 4. Add metered 4g PEG-400 to continue the reaction for about 1h;

[0042] 5. When the reaction system is slightly viscous, add an appropriate amount of ethanol solution to dilute to ensure the stirring, continue the reaction for 1 hour, and obtain the product (sample one, see figure 1) ;

[0043] 6. Slowly pour the product into continuously stirring water to obtain a milky white flocculent precipitate, take out the precipitate and dry it, then dissolve it in ethanol to obtain a transparent solution. Repeat this twice to purify the produc...

Embodiment 2

[0052] Synthesis:

[0053] 1. Weigh about 26 g of polytetrahydrofuran ether glycol (PTMEG, molecular weight Mn=1000) and put it into a three-necked flask;

[0054] 2. Put the three-necked bottle into a vacuum drying oven and heat it to 120°C for 2 hours, then weigh 25g accurately after drying to remove moisture;

[0055] 3. Under nitrogen protection, add 4.3ml of measured toluene diisocyanate (TDI) and stir at 80°C for 1 hour;

[0056] 4. Add 40g PEG-4000 and continue the reaction for about 30 minutes;

[0057] 5. When the reaction system is slightly viscous, add an appropriate amount of ethanol solution to dilute, and continue the reaction for 1 hour to obtain the product (sample 2, see figure 2) ;

[0058] 6. Slowly pour the product into continuously stirring water to obtain a milky white flocculent precipitate, take out the precipitate and dry it, then dissolve it in ethanol to obtain a transparent solution. Repeat this twice to purify the product and remove PEG that h...

Embodiment 3

[0067] Synthesis:

[0068] 1. Weigh about 26 g of polytetrahydrofuran ether glycol (PTMEG, molecular weight Mn=1000) into a three-necked flask.

[0069] 2. Put the three-necked bottle into a vacuum drying oven and heat it to 120°C for 2 hours, then weigh 25g accurately after drying to remove moisture;

[0070] 3. Under nitrogen protection, add 4.3ml of measured toluene diisocyanate (TDI) and stir at 80°C for 1 hour;

[0071] 4. Add 0.67g DMPA, react for half an hour, add 20g PEG-4000, react for about 10min;

[0072] 6. When the reaction system is slightly viscous, add a large amount of ethanol solution to dilute, and continue the reaction for 1 hour to obtain the product (sample three, see Figure 9) ;

[0073] 7. Slowly pour the product into continuously stirring water to obtain a milky white flocculent precipitate, take out the precipitate and dry it, then dissolve it in ethanol to obtain a transparent solution. Repeat this twice to purify the product and remove the unre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com