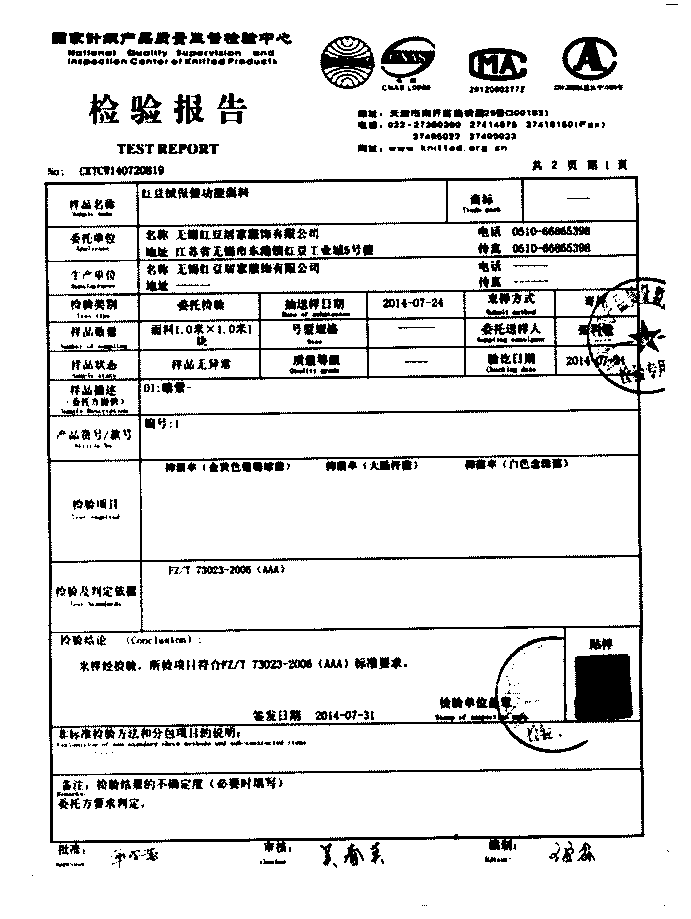

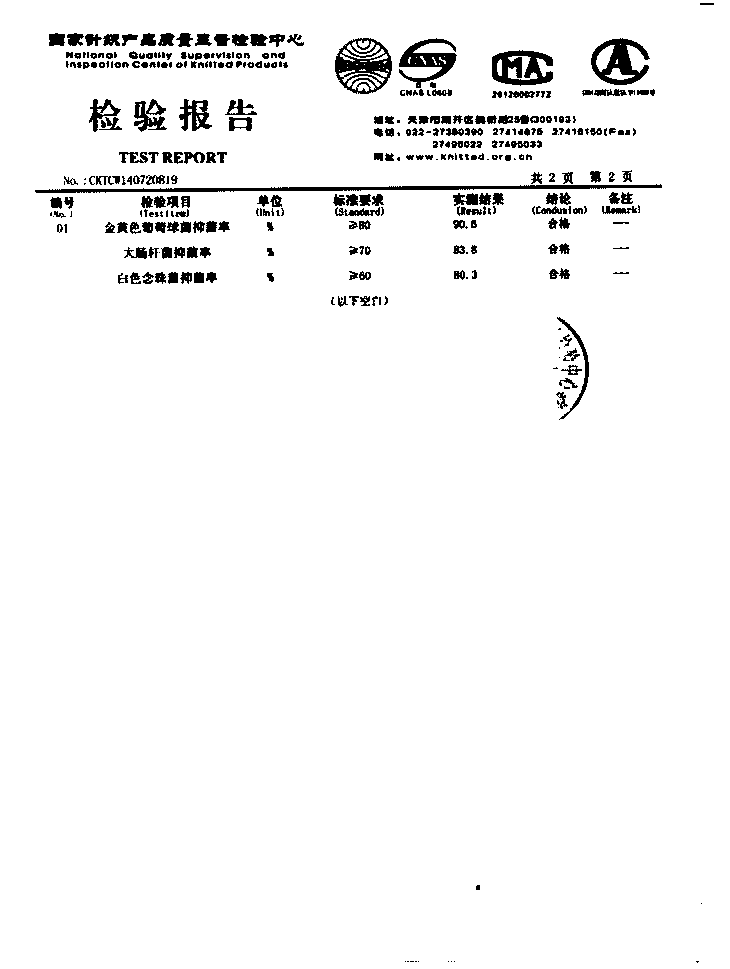

Red bean velvet healthcare functional fabric

A technology of red bean velvet and fabric, which is applied in the direction of fabric surface trimming, application, and fabric elongation. It can solve the problems of unsuitable underwear fabric materials, easy to fall off after washing, and poor wearing comfort. It has good application prospects and good washing stability. , Excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of red bean cashmere health-care functional fabric adopts the following process steps:

[0034] (1) Production of red bean velvet fabric:

[0035] a. The raw material is 100% cotton combed yarn, the yarn fineness is 32 pounds, and the yarn twist coefficient is 325;

[0036] B, knitting on the machine: use a double-sided knitting weft knitting machine with a tube diameter of 34 inches and a needle count of 28 needles / inch or a cylinder warp of 38 inches and a needle count of 24 needles / inch to weave the yarn into a fabric;

[0037] c. Refining and bleaching: refining and bleaching the fabric obtained in step (b);

[0038] The refining conditions are as follows: the refining liquid components are: 3g / L knitting refining agent 729, 1g / L soda ash, and the balance is water; the refining bath ratio is 10:1, the refining temperature is 90°C, and the refining time is 50 minutes;

[0039] The bleaching conditions are as follows: the bleaching solution is 1...

Embodiment 2

[0050] Embodiment 2: a kind of red bean cashmere health-care functional fabric adopts the following process steps:

[0051] (1) Production of red bean velvet fabric:

[0052] a. The raw material is 100% cotton combed yarn, the yarn fineness is 36 pounds, and the yarn twist coefficient is 330;

[0053] B, knitting on the machine: use a double-sided knitting weft knitting machine with a tube diameter of 34 inches and a needle count of 28 needles / inch or a cylinder warp of 38 inches and a needle count of 24 needles / inch to weave the yarn into a fabric;

[0054] c. Refining and bleaching: refining and bleaching the fabric obtained in step (b);

[0055] The refining conditions are as follows: the refining liquid components are: 7g / L knitting refining agent 729, 5g / L soda ash, and the balance is water; the refining bath ratio is 20:1, the refining temperature is 100°C, and the refining time is 45 minutes;

[0056] The bleaching conditions are as follows: the bleaching solution is ...

Embodiment 3

[0067] Embodiment 3: a kind of red bean cashmere health-care functional fabric adopts the following process steps:

[0068] (1) Production of red bean velvet fabric:

[0069] a. The raw material is 100% cotton combed yarn, the yarn fineness is 40 British counts, and the yarn twist coefficient is 330;

[0070] B, knitting on the machine: use a double-sided knitting weft knitting machine with a tube diameter of 34 inches and a needle count of 28 needles / inch or a cylinder warp of 38 inches and a needle count of 24 needles / inch to weave the yarn into a fabric;

[0071] c. Refining and bleaching: refining and bleaching the fabric obtained in step (b);

[0072] The refining conditions are as follows: the refining liquid components are: 5g / L knitting refining agent 729, 2g / L soda ash, and the balance is water; the refining bath ratio is 15:1, the refining temperature is 95°C, and the refining time is 46 minutes;

[0073] The bleaching conditions are as follows: the bleaching solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com