Tackifier for LED packaging adhesive and preparation method of tackifier

A technology of LED encapsulation and tackifier, used in adhesives, electrical components, circuits, etc., can solve problems such as Pt catalyst poisoning, and achieve the effects of mild reaction conditions, good compatibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

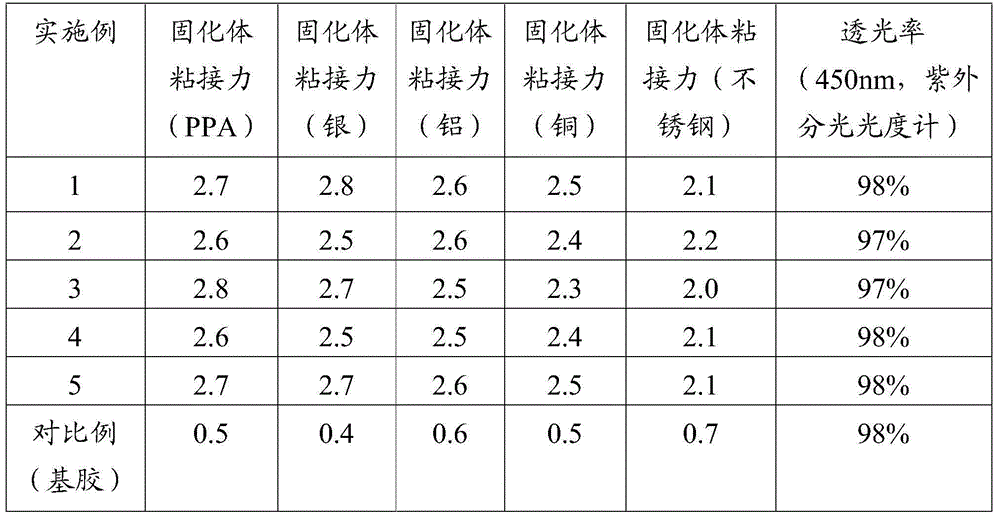

Examples

Embodiment 1

[0036] With 210 parts by weight of diphenylsilanediol (Green Chemical Industry Co., Ltd., Xiantao City), 130 parts by weight of γ-glycidyl ether oxypropyltriethoxysilane (Bailingwei Technology Co., Ltd.), 120 parts by weight of γ-methacryloxypropyltrimethoxysilane (Hangzhou Dadi Chemical Co., Ltd.) was added to the reactor. Then add 2 parts by weight of Ba(OH) 2 2H 2 O is used as a catalyst, and the temperature is raised to 80°C for non-hydrolytic condensation reaction. After 3 hours of reaction, further condensation reaction is carried out under vacuum for 0.5 hours. Stop the vacuum, lower the temperature, discharge, and centrifuge to remove the catalyst base to obtain a light yellow or colorless tackifier.

Embodiment 2

[0038] With 250 parts by weight of diphenylsilanediol (Great Chemical Industry Co., Ltd., Xiantao City), 100 parts by weight of β-(3,4-epoxycyclohexyl) ethyl trimethoxysilane (Hangzhou Yiyuan Chemical Industry Co., Ltd. company), 100 parts by weight of γ-methacryloxypropyl triethoxysilane (Bailingwei Technology Co., Ltd.) was added to the reactor. Then add 0.5 parts by weight of Ba(OH) 2 2H 2 O is used as a catalyst, and the temperature is raised to 60°C for non-hydrolytic condensation reaction. After 5 hours of reaction, further condensation reaction is carried out under vacuum conditions for 2 hours. It is advisable to control the degree of vacuum so that the feed liquid does not foam. Stop the vacuum, lower the temperature, discharge, and centrifuge to remove the catalyst base to obtain a light yellow or colorless tackifier.

Embodiment 3

[0040] With 230 parts by weight of diphenylsilanediol (Green Chemical Industry Co., Ltd., Xiantao City), 120 parts by weight of γ-glycidyl ether oxypropyltriethoxysilane (Bailingwei Technology Co., Ltd.), 110 parts by weight of γ-Methacryloxypropyltriethoxysilane (Bailingwei Technology Co., Ltd.) was added to the reactor. Then add 1 weight part of NaOH as a catalyst, heat up to 100° C. for non-hydrolytic condensation reaction, and react for 4 hours, then further condense for 1 hour under vacuum conditions. Stop the vacuum, lower the temperature, discharge, and centrifuge to remove the catalyst base to obtain a light yellow or colorless tackifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com