Grating smart ring groove rivet

A technology of ring groove rivets and smart rings, which is applied to rivets, measurement of the change force of the optical properties of the material when it is stressed, and measurement devices, etc., to save costs, improve service life, and reduce strength damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0020] In conjunction with the accompanying drawings.

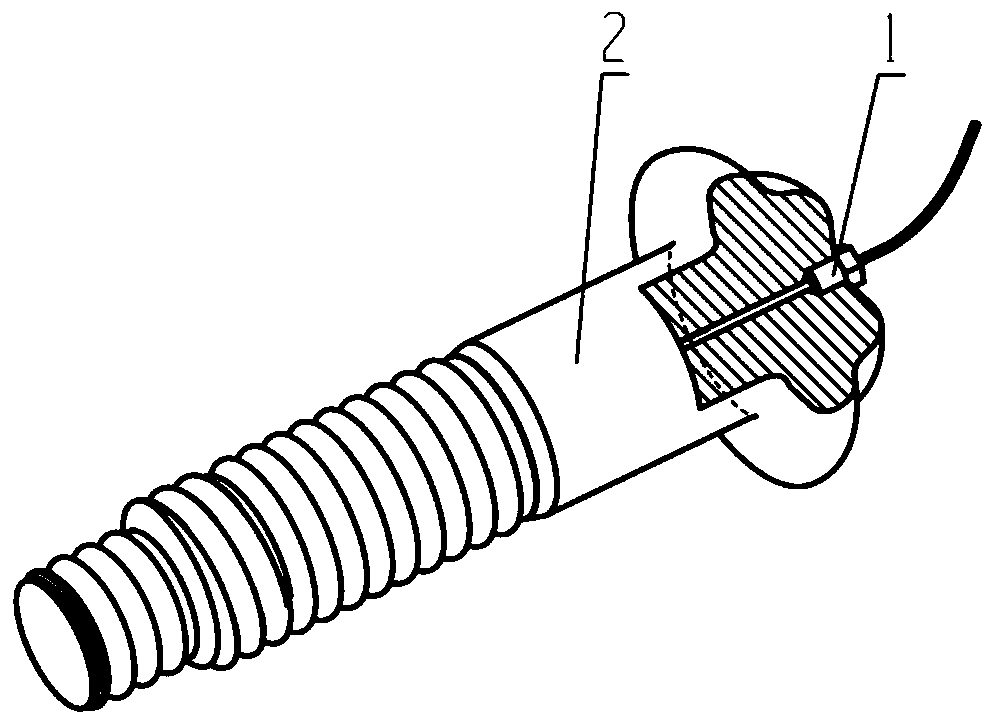

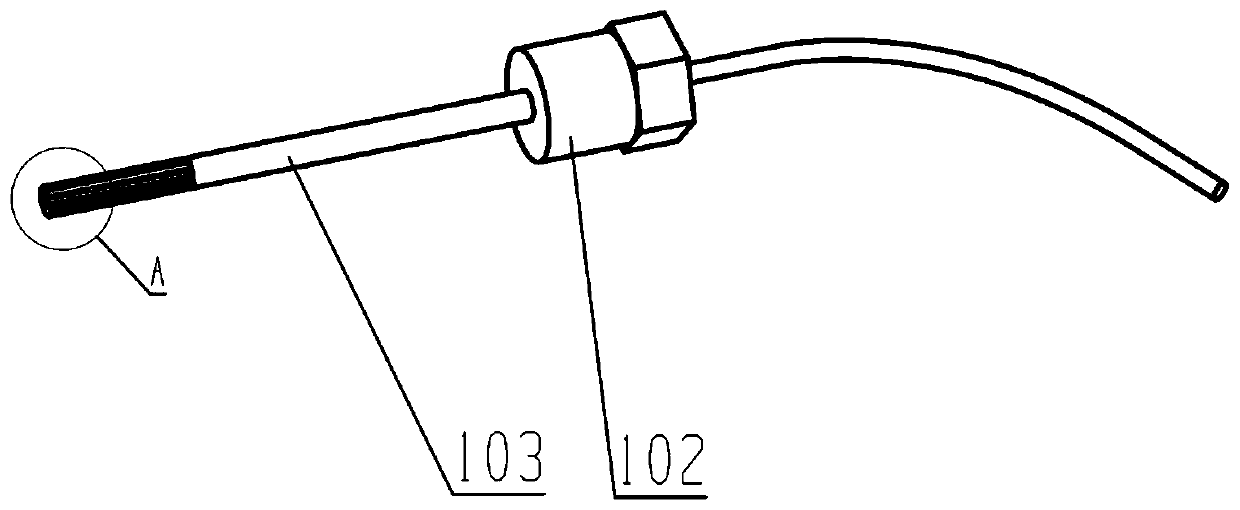

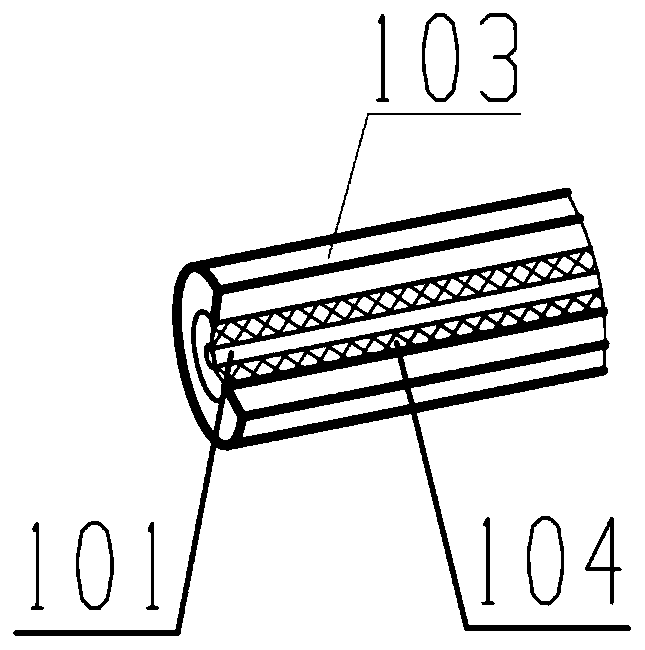

[0021] The present invention includes a grating sensor 1 and a ring groove rivet 2; wherein the grating sensor 1 is composed of a grating sensor body 101, an end fixing device 102, an outer stainless steel protective cover 103, a fixed adhesive layer 104, etc., and the grating sensor body 101 and the outer stainless steel The protective cover 103 is tightly integrated through the fixed adhesive layer 104, which can protect the grating sensor body 101 and improve the service life of the grating sensor 1;

[0022] The end fixing device 102 is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com