Shock absorber

A technology of shock absorbers and elastic parts, which is applied in the field of shock absorbers, can solve the problems of low working efficiency, changes in the stiffness of shock absorbers, and difficulty in replacing shock absorbers, etc., and achieve the effects of prolonging service life and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

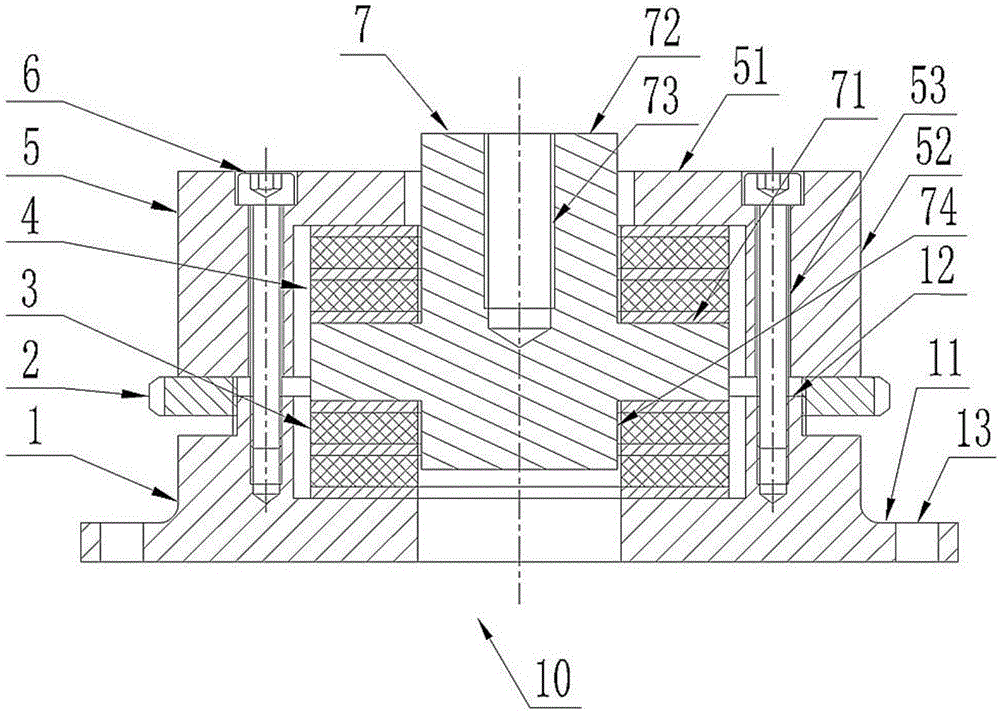

[0037] Such as figure 1 As shown, the shock absorber 10 in Embodiment 1 includes: a lower support 1 , an upper support 5 , a joint 7 , an upper elastic member 4 , a lower elastic member 3 , a screw 6 and an adjustment member 2 .

[0038] In this embodiment, the lower support 1 structure includes a lower cover 11 and a boss 12 . The lower cover 11 is configured substantially in the shape of a disc or a square disc. One end surface of the lower cover 11 is an upper surface. The boss 12 is ring-shaped and protrudes from the upper surface of the lower cover 11 in a direction away from the lower cover 11 . Preferably, the axis of the boss 12 coincides with the axis of the lower cover 11 . External threads are provided on the outer peripheral wall of the boss 12 . The external threads are distributed on the end of the boss 12 away from the lower cover 11 . The top of the boss 12 is also provided with a plurality of first screw holes. The plurality of first screw holes are even...

Embodiment 2

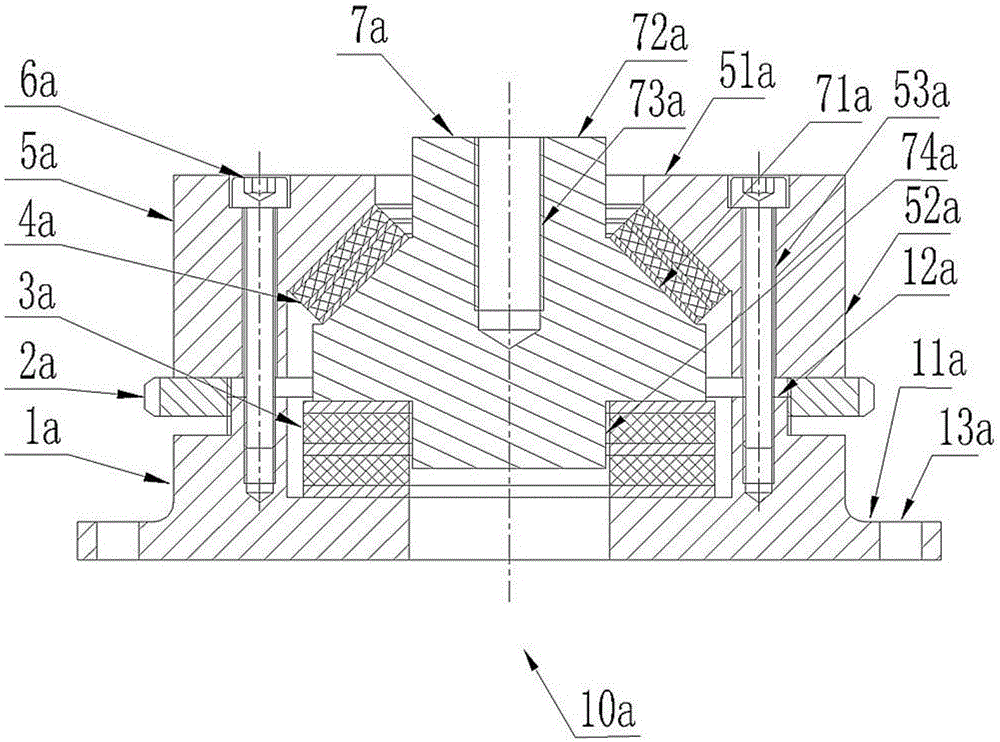

[0052] Such as figure 2 As shown, the shock absorber 10a in Embodiment 2 includes: a lower support 1a, an upper support 5a, a joint 7a, an upper elastic member 4a, a lower elastic member 3a, a screw 6a and an adjustment member 2a.

[0053] In this embodiment, the lower support 1a comprises a lower cover 11a and a boss 12a. The lower cover 11a is configured in a substantially disc shape or a square disc shape. One end surface of the lower cover 11a is an upper surface. The boss 12a is configured in a ring shape and protrudes from the upper surface of the lower cover 11a in a direction away from the lower cover 11a. Preferably, the axis of the boss 12a coincides with the axis of the lower cover 11a. External threads are provided on the outer peripheral wall of the boss 12a. The external threads are distributed, for example, at the end of the boss 12 a away from the lower cover 11 . The top of the boss 12a is also provided with a plurality of first screw holes. The plurali...

Embodiment 3

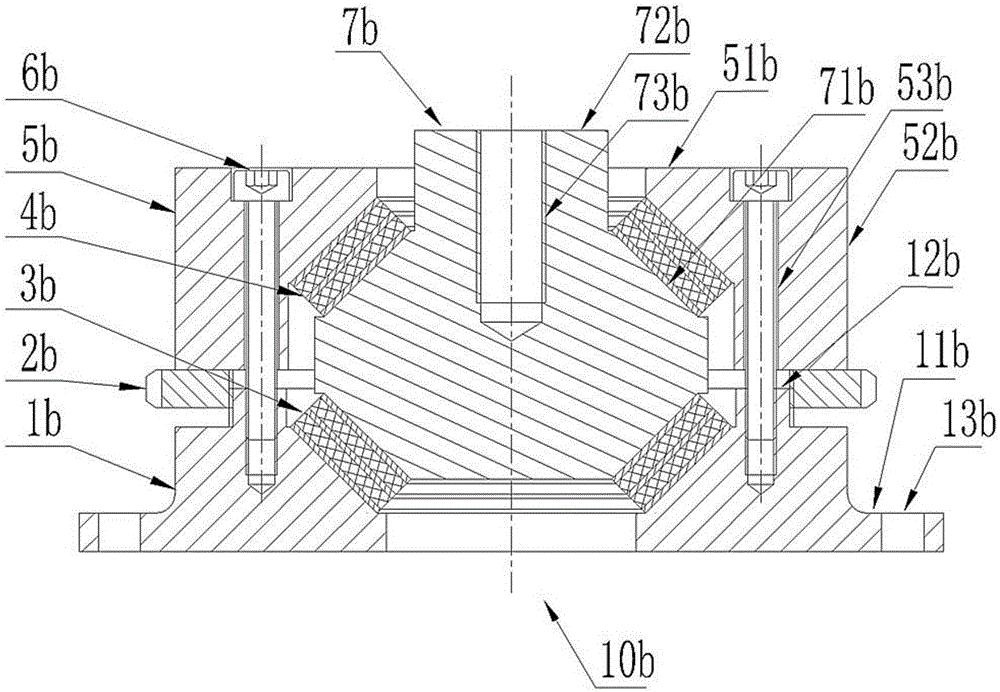

[0065] Such as image 3 As shown, the shock absorber 10b in Embodiment 3 includes: a lower support 1b, an upper support 5b, a joint 7b, an upper elastic member 4b, a lower elastic member 3b, a screw 6b and an adjustment member 2b.

[0066] In this embodiment, the lower support 1b comprises a lower cover 11b and a boss 12b. The lower cover 11b is configured in a substantially disc shape or a square disc shape. One end surface of the lower cover 11b is an upper surface. The boss 12b is ring-shaped and protrudes from the upper surface of the lower cover 11b in a direction away from the lower cover 11b. The inner wall of the boss 12b is an inner tapered surface facing away from the lower cover 11b. The inner tapered surface is preferably a conical surface. Preferably, the axis of the boss 12b coincides with the axis of the lower cover 11b. External threads are provided on the outer peripheral wall of the boss 12b. The external threads are distributed, for example, at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com