An electric vehicle battery insulation structure

A technology for electric vehicles and batteries, applied in electric vehicles, structural parts, secondary batteries, etc., can solve the problems of inability to ensure that the liquid and cold water pipes are closely attached, affecting the thermal insulation effect of the thermal insulation structure, and unable to lift the liquid and cold water pipes, etc. Improve the thermal insulation effect, improve the thermal insulation effect, and avoid the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

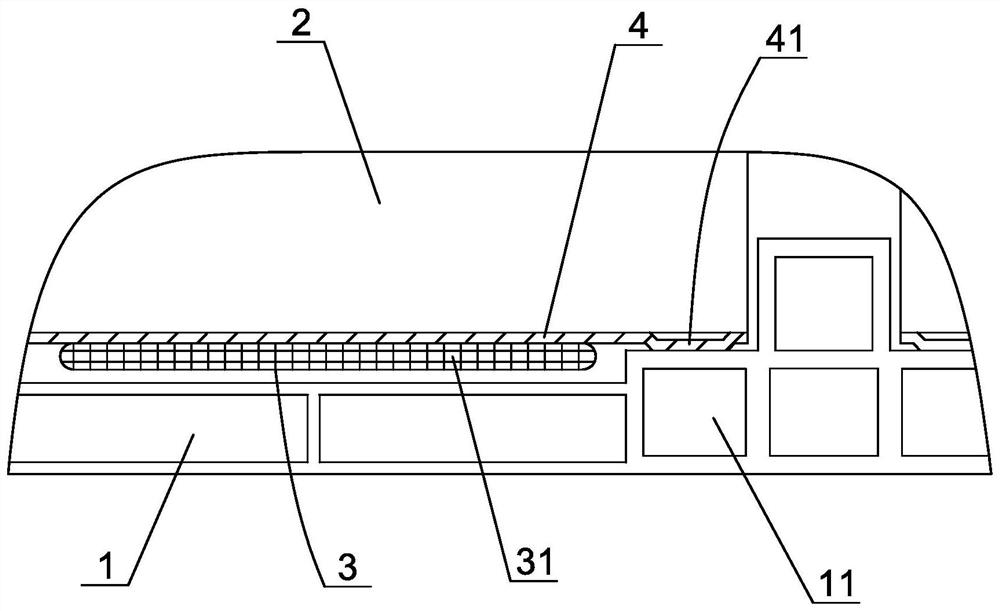

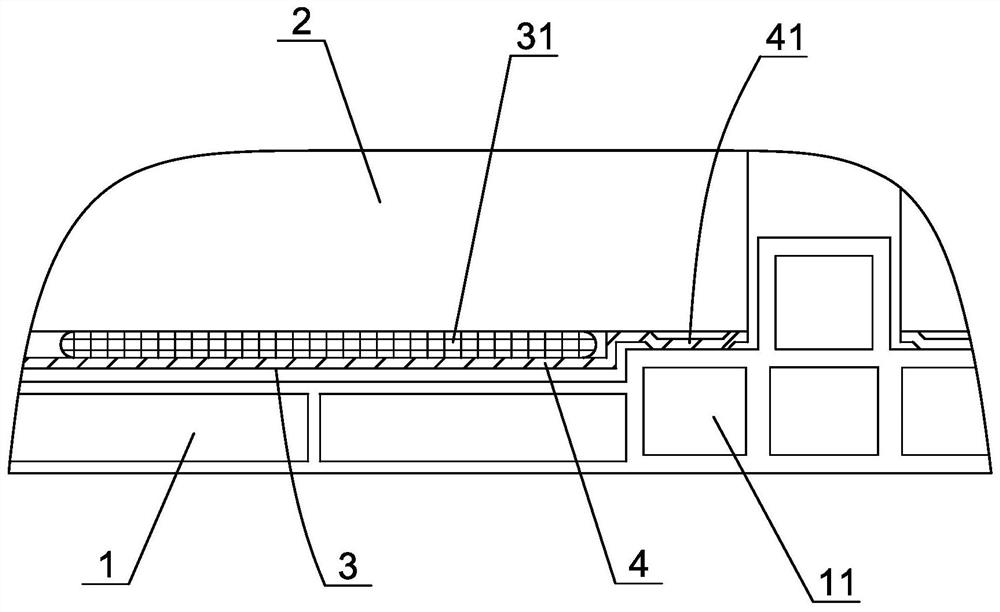

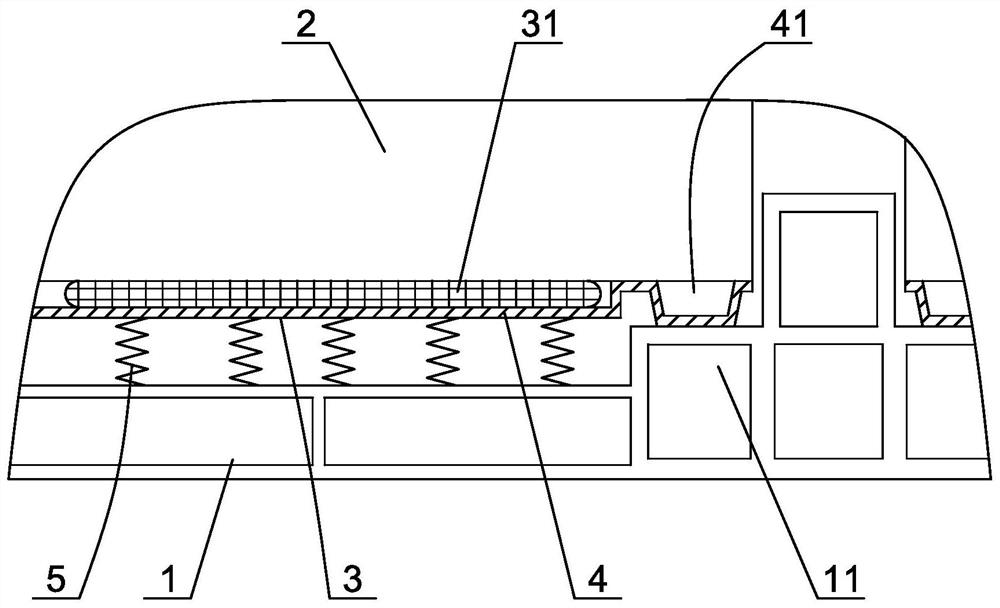

[0037] like figure 1 As shown, an electric vehicle battery insulation structure is mainly used for cooling or heating the lithium ion battery of the electric vehicle, so that the battery can work in a suitable temperature range. Specifically, the battery includes an outer casing 1, a battery module 2 disposed in the outer casing, a supporting beam 11 for supporting the battery module is arranged on the bottom edge of the outer casing, a liquid-cooling water pipe group 3 is arranged on the lower side of the battery module, and the liquid The cold water pipe group includes the liquid cold water pipes 31 arranged side by side and the reinforcing member for improving the bending strength of the liquid cold water pipe. The liquid cold water pipe includes a harmonica pipe in the middle and a collector connected to the front and rear ends of the harmoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com