a shock absorber

A technology of shock absorbers and elastic parts, applied in the field of shock absorbers, can solve the problems of changes in the stiffness of shock absorbers, low work efficiency, and high development costs, and achieves the effects of strong adaptability and extended service life

Active Publication Date: 2019-01-22

ZHUZHOU TIMES NEW MATERIALS TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, when the user conducts on-site trial assembly and testing, it often occurs that the stiffness performance of the shock absorber cannot meet the vibration reduction requirements. In order to obtain shock absorbers with different stiffnesses, the manufacturer can only be asked to adjust the structure or rubber hardness to readjust the shock absorber. Vibrator stiffness, resulting in very low work efficiency, and the investment in development costs is also very high

In addition, during the long-term use of the shock absorber with rubber pad, the stiffness of the shock absorber will change greatly due to the aging and creep of the rubber pad.

This will result in the need to replace the shock absorber every once in a while

But in many cases it is not easy to replace the shock absorber

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

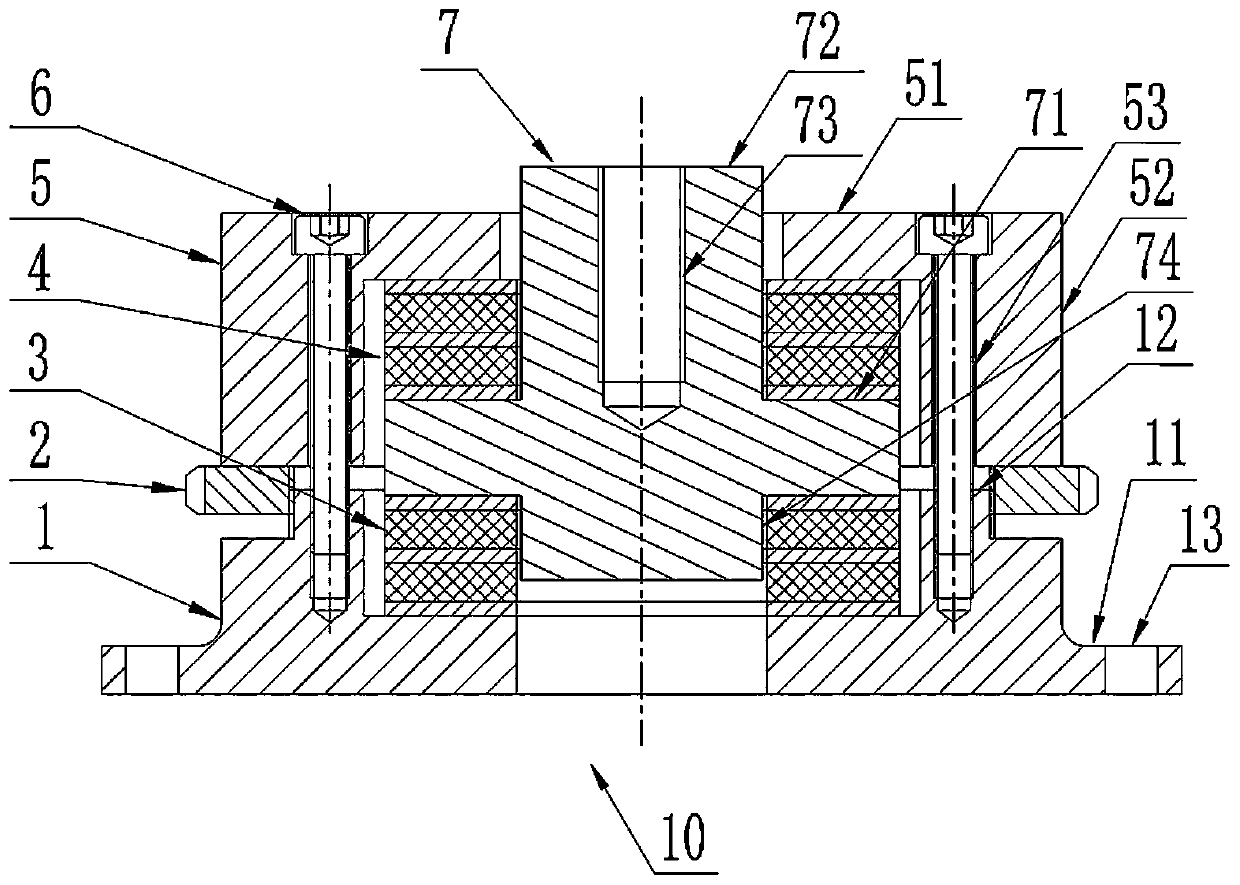

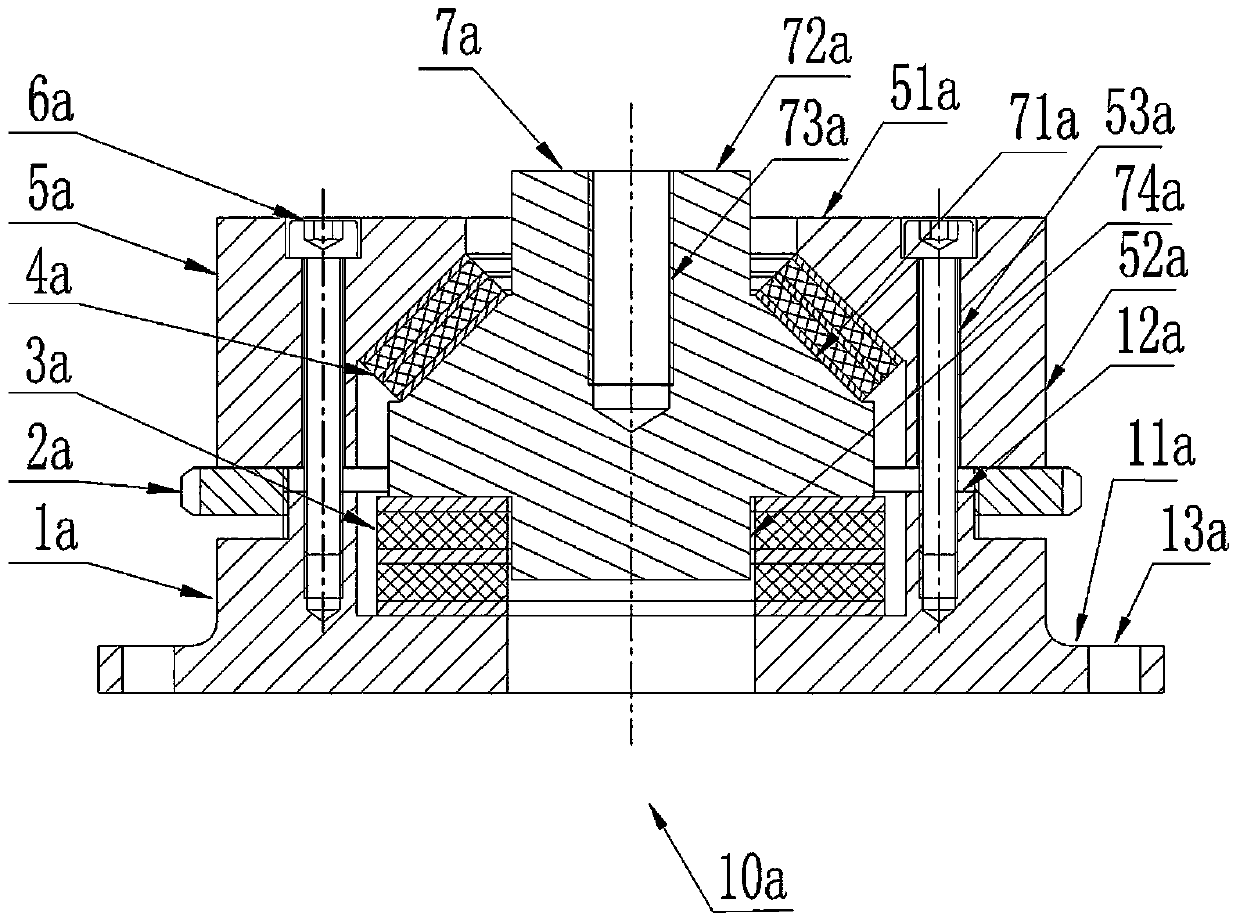

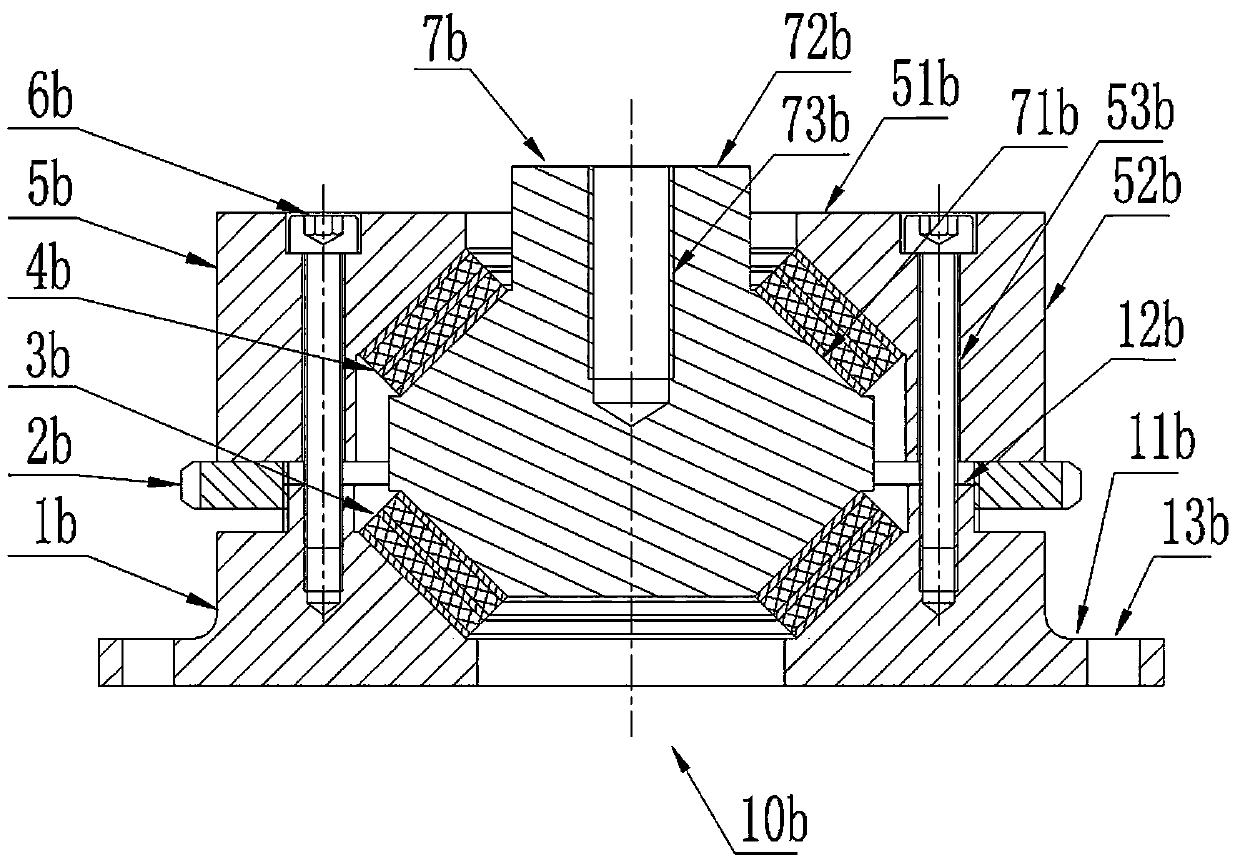

The invention relates to a shock absorber which comprises a lower supporting seat, an upper supporting seat, a joint, a lower elastic piece and an adjusting piece, wherein the upper supporting seat is tightly pressed towards the lower supporting seat; the joint comprises a core block and a supporting rod, the core block is arranged between the upper supporting seat and the lower supporting seat, and the supporting rod extends out of the core block and penetrates through the upper supporting seat; the lower elastic piece is arranged between the core block and the lower supporting seat, and the adjusting piece is used for adjusting the distance between the upper supporting seat and the lower supporting seat. The stiffness valve of the shock absorber can be adjusted on an installation site so that the demand for different shock absorbing stiffness is met, and the adaptability of the shock absorber is stronger than that of a common shock absorber. Meanwhile, after the shock absorber is used for a long time, the stiffness variation of the shock absorber caused by the aging and creep deformation of the lower elastic piece can be corrected by readjusting the distance between the upper supporting seat and the lower supporting seat, and therefore the service life of the shock absorber is relatively prolonged.

Description

technical field The present invention relates to a shock absorber. Background technique As a kind of clean energy, wind energy is being promoted rapidly around the world. At present, wind turbines have been developed to large-megawatt models, and their structural types mainly include doubly-fed, semi-direct drive and direct-drive, among which doubly-fed wind turbines are the most widely used. When the wind turbine is generating normal power, the rotor speed of the generator is relatively high, and vibration will occur during normal operation. In doubly-fed and semi-direct-drive wind turbines, a shock absorber is generally installed at the bottom of the generator for vibration isolation to prevent the input high-frequency vibration from being transmitted to the main frame through the generator and reduce the structural noise of the generator. However, there are many factors affecting the vibration frequency and amplitude of wind turbines. For example, the central inertial...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16F15/08

CPCF16F15/08

Inventor 岳涛林胜胡伟辉杨超刘永苏泽涛谭虢刘权

Owner ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com