Door closer hydraulic mechanism for fine regulating door-closing power

A technology of hydraulic mechanisms and door closers, which is applied to switches with braking devices, door/window accessories, building structures, etc. It can solve the problems that the same door closer cannot meet the needs of use, and achieves increased door closing force, The effect of reducing the amount of compression and increasing the amount of compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to facilitate the understanding of those skilled in the art, the hydraulic mechanism of the door closer of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

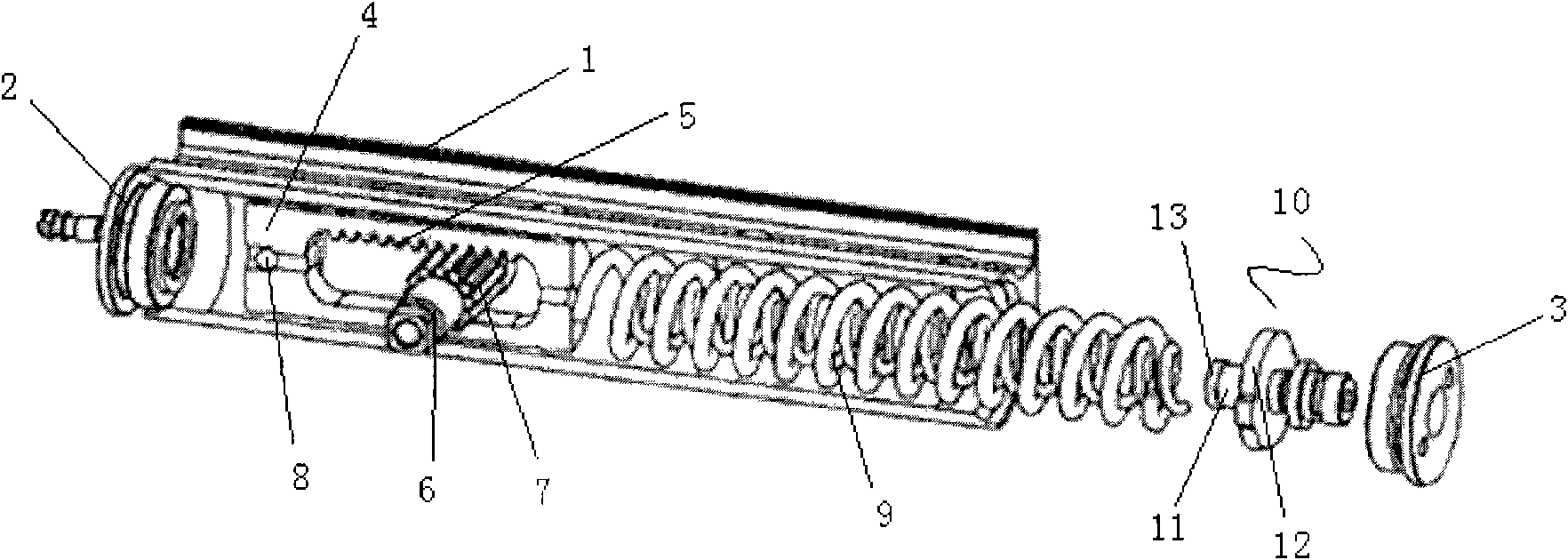

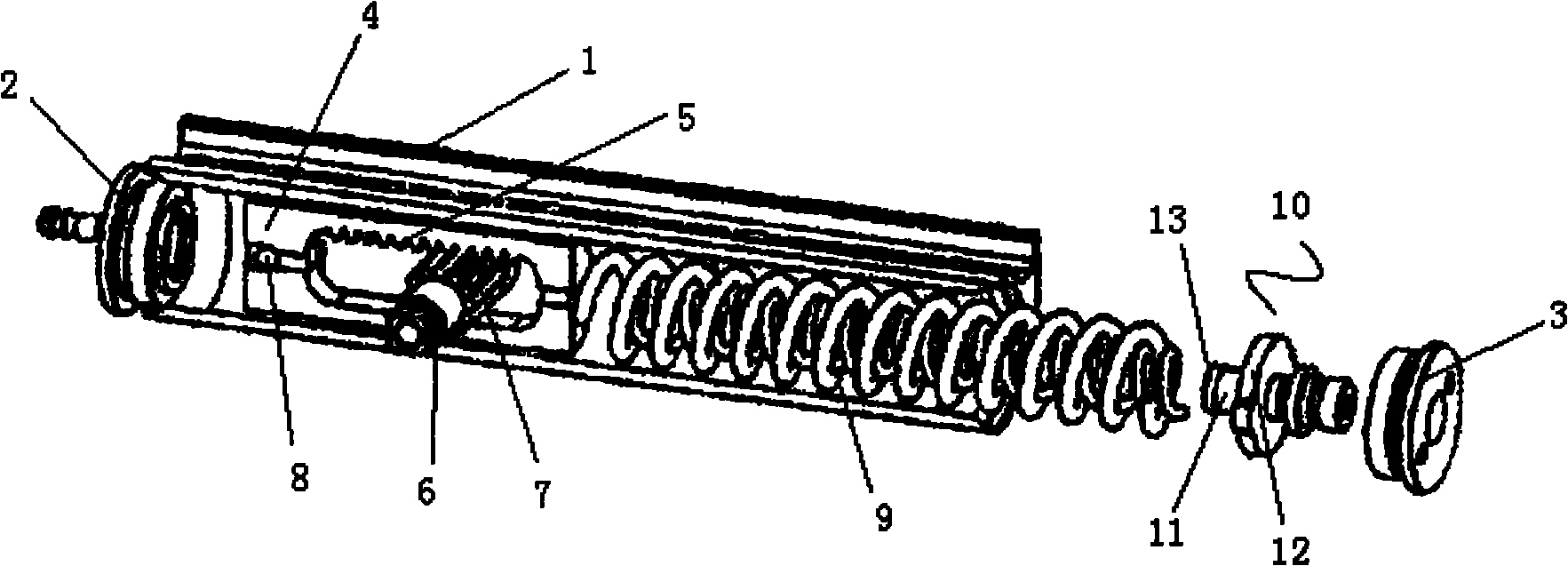

[0010] as attached figure 1 As shown, a hydraulic mechanism of a door closer includes a cylindrical valve body 1, a front end cover 2 and a rear end cover 3 are respectively provided at both ends of the valve body, and a rack piston 4 is arranged in the valve cavity of the valve body, and the tooth The inner wall of the bar piston is provided with a rack 5; in the through hole passing through the valve body wall and the rack piston wall, a gear shaft 6 is arranged, and a transmission gear 7 is arranged on the gear shaft 6, and the transmission gear 7 meshes with the rack 5; The left end of the rack piston 4 is provided with a one-way valve steel ball 8, the right end of the rack piston is connected with the compression spring 9 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com