Patents

Literature

46results about How to "Stable feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

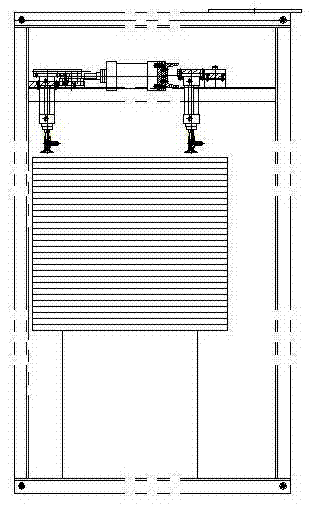

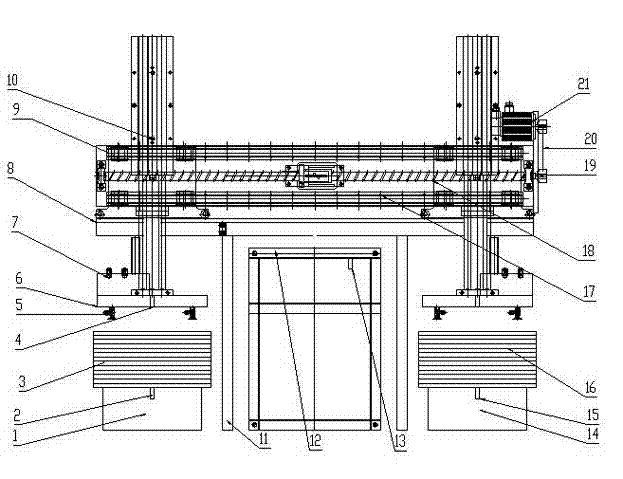

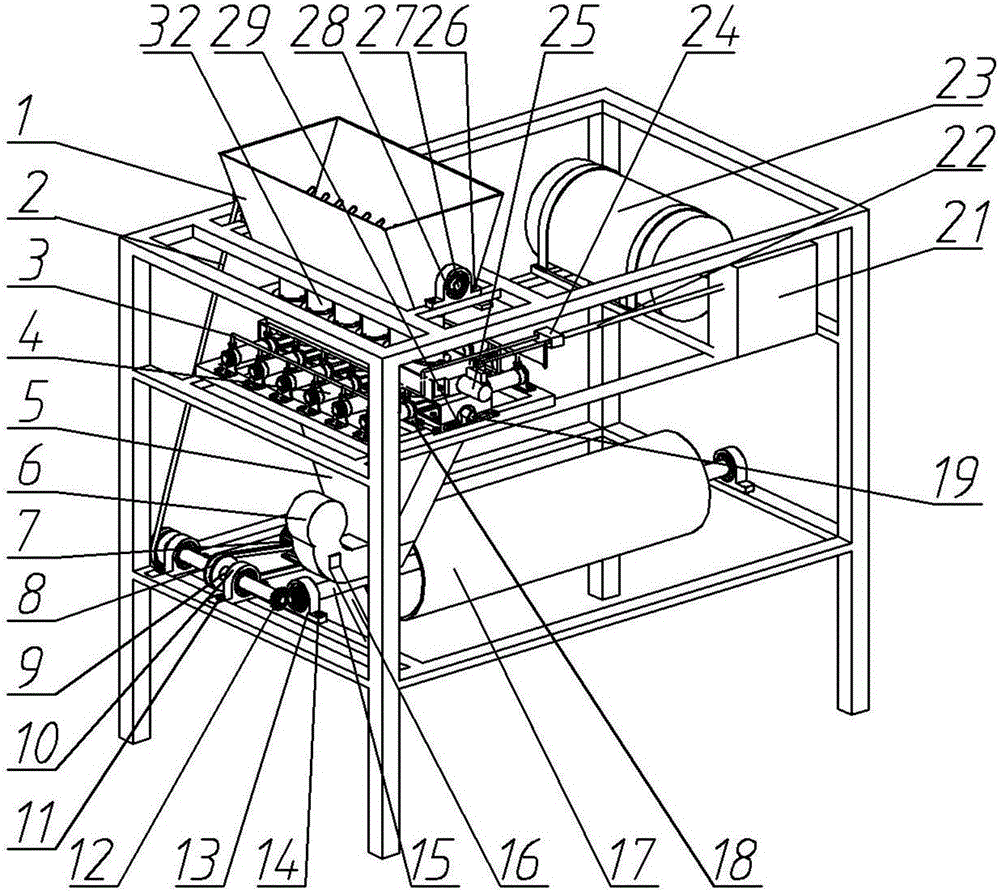

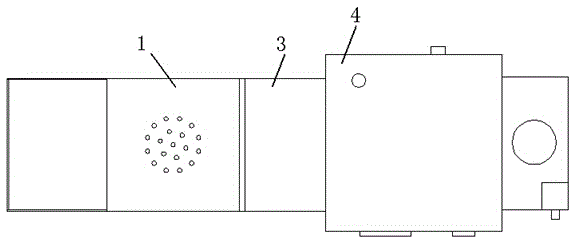

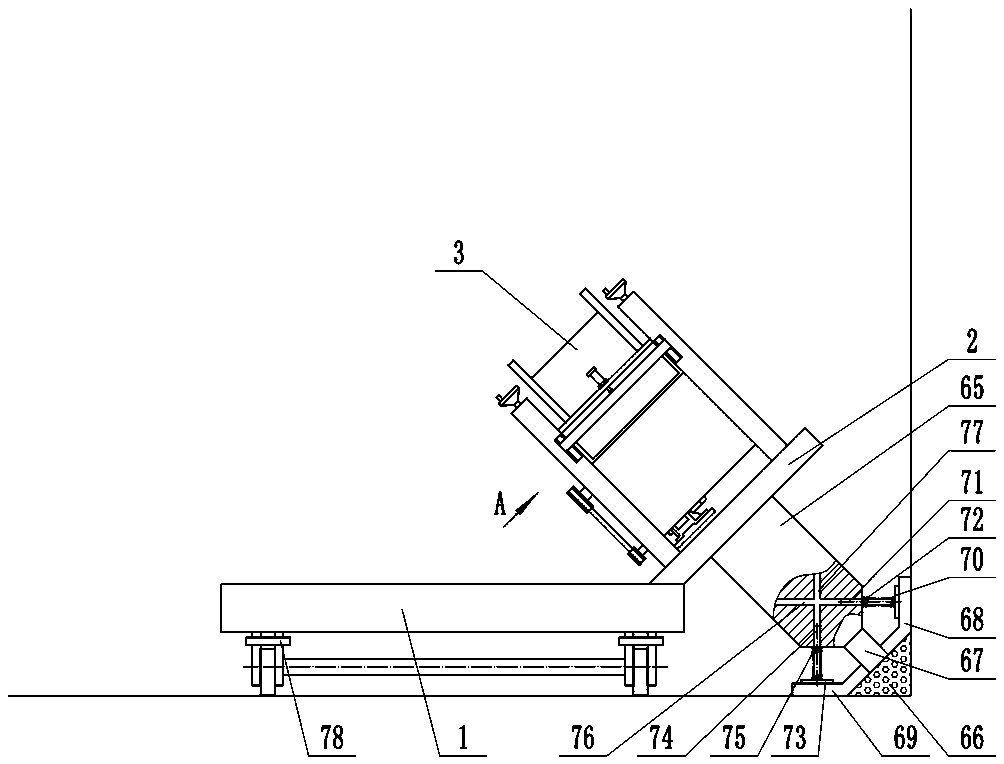

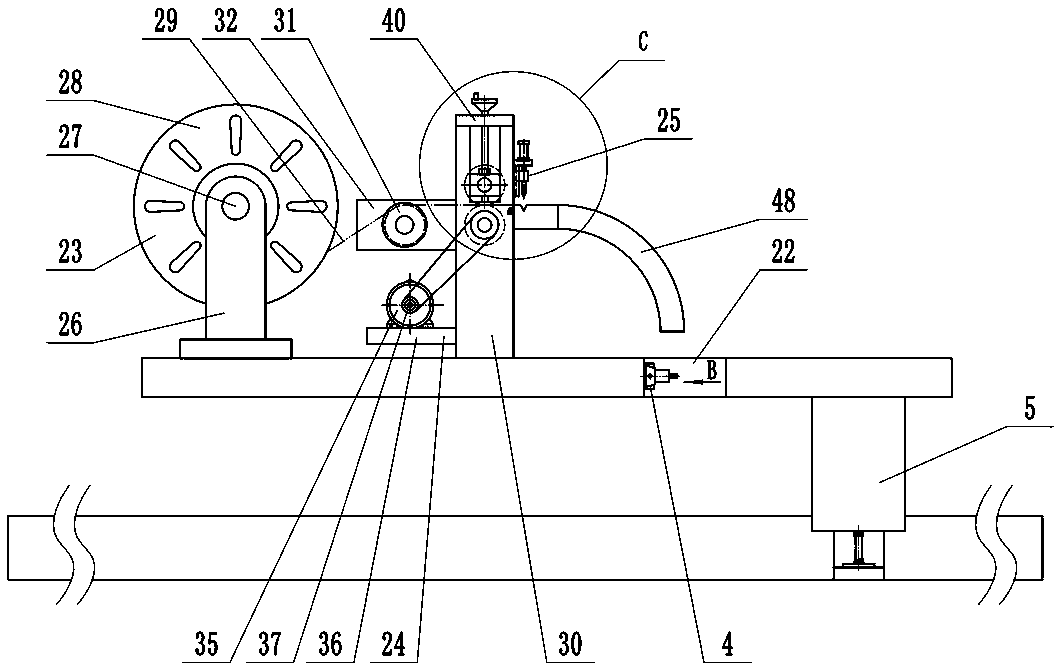

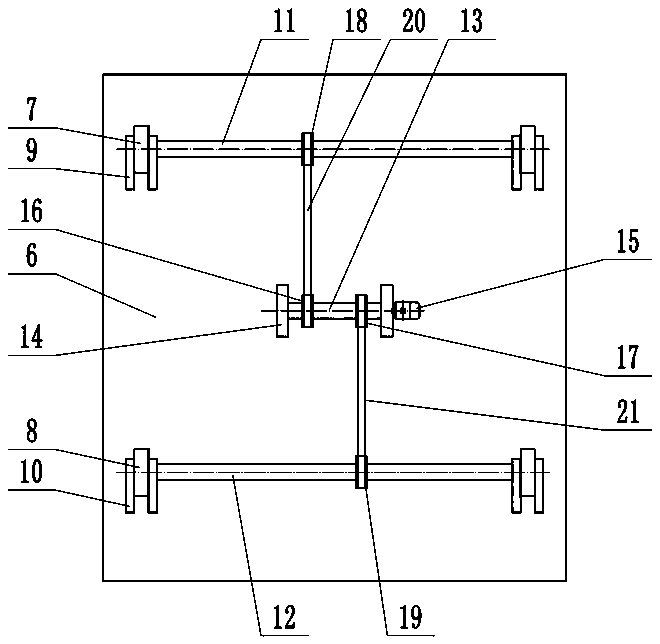

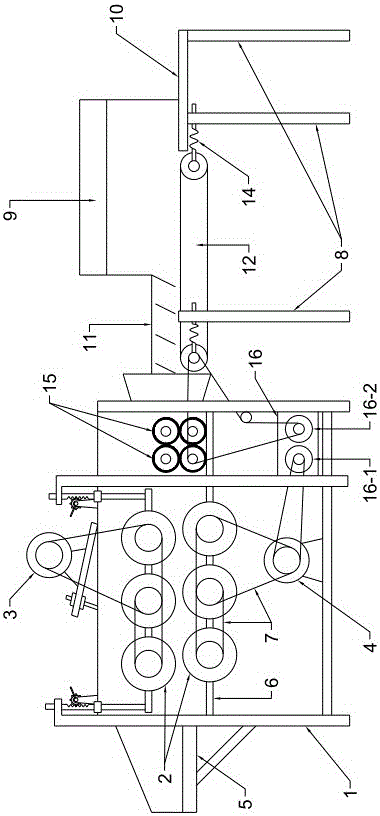

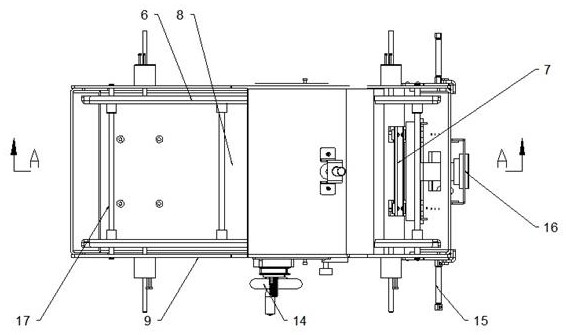

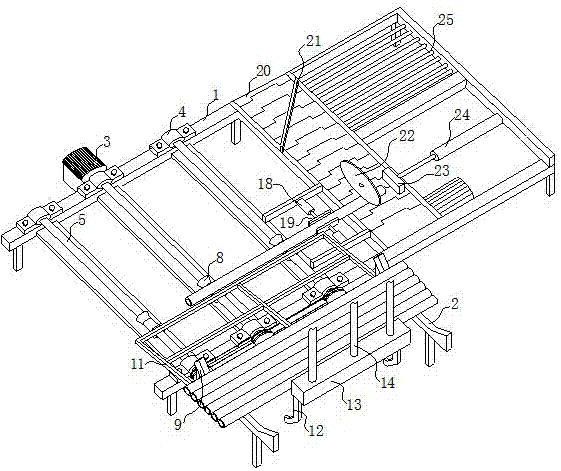

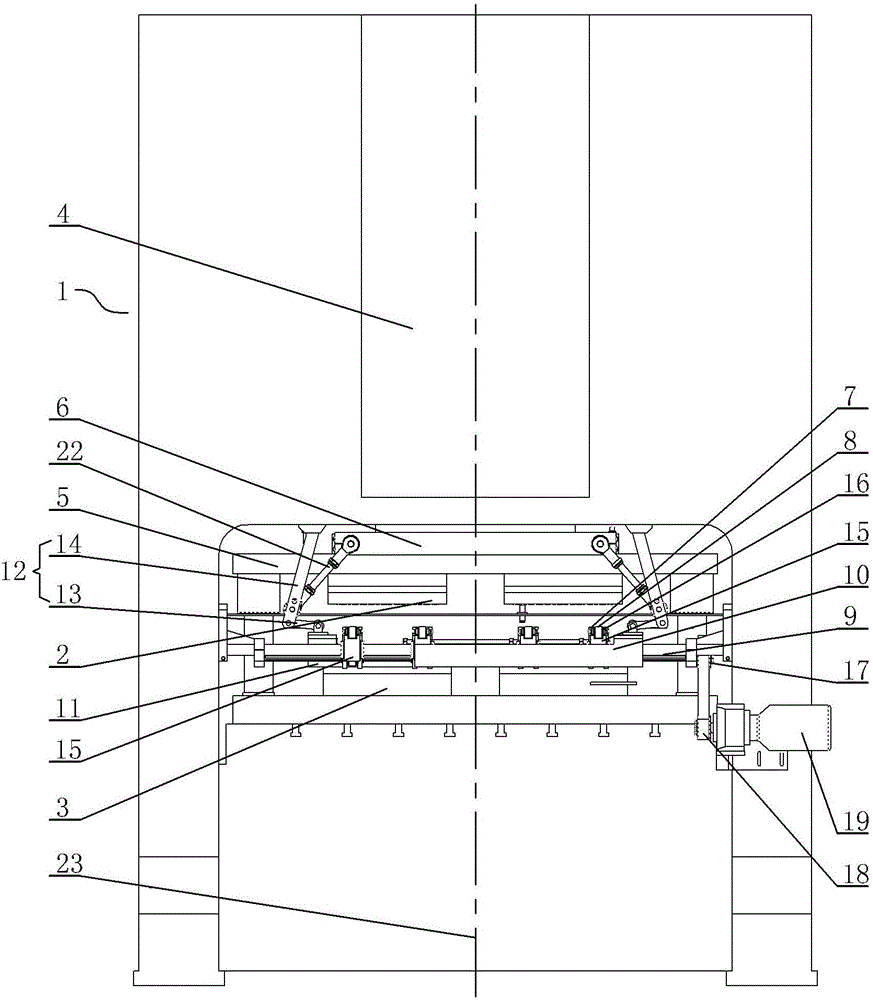

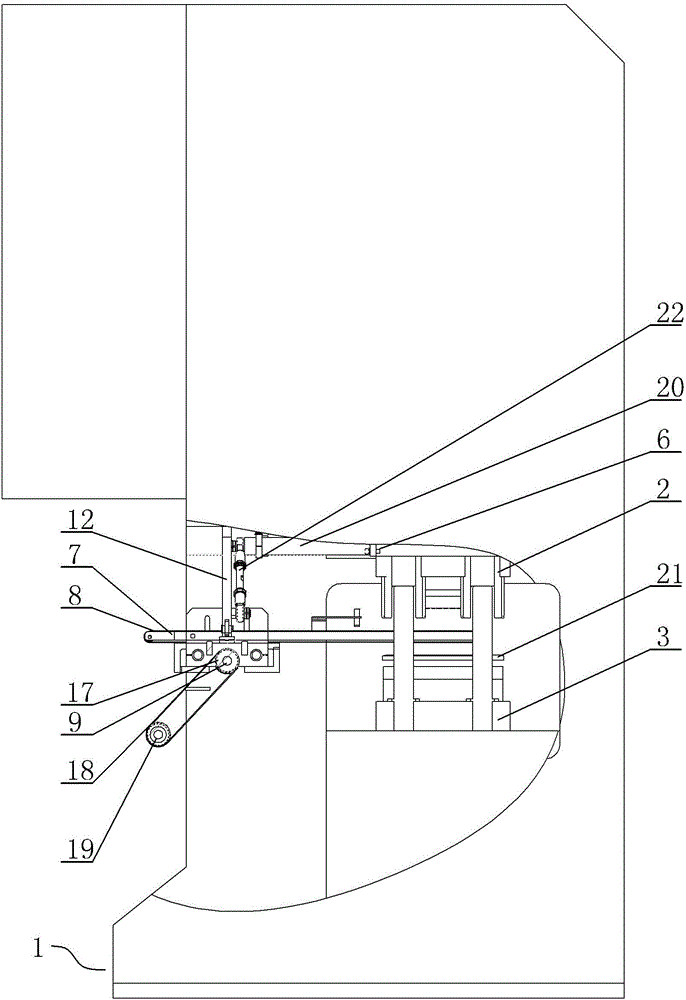

Full-automatic continuous feeding system of integral stacks of aluminum plates

InactiveCN103693440AHigh loading efficiencyStable feedingStacking articlesDe-stacking articlesContinuous feedingEngineering

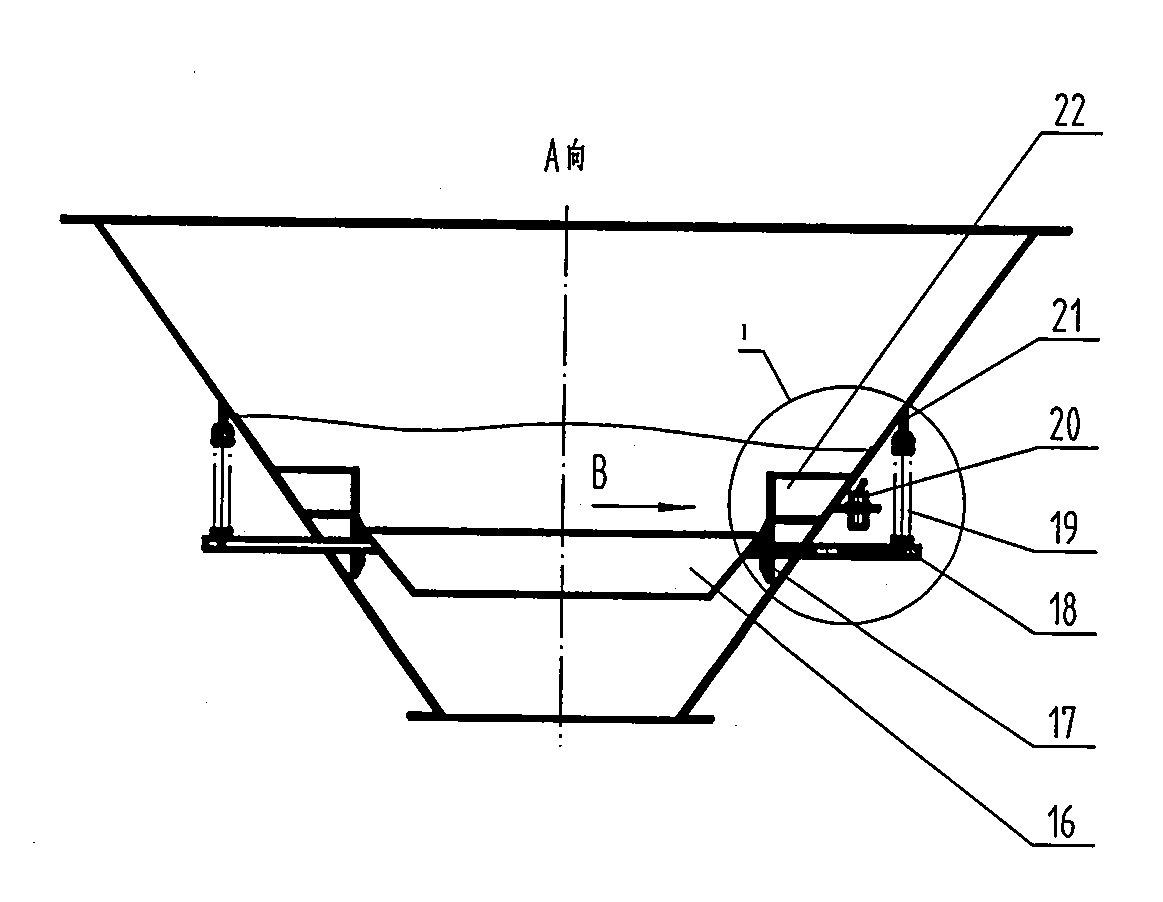

The invention provides a full-automatic continuous feeding system of integral stacks of aluminum plates. The full-automatic continuous feeding system comprises columns and the working platform surface; the working platform surface is provided with a proximity switch B; the columns are provided with a connecting plate; a left aluminum stack supporting plate and a right aluminum stack supporting plate are arranged on the bilateral sides of the columns respectively; a proximity switch A and a proximity switch C are arranged on the left aluminum stack supporting plate and the right aluminum stack supporting plate respectively; base plates are arranged above the left aluminum stack supporting plate and the right aluminum stack supporting plate respectively; the base plates are provided with vacuum chucks, vacuum generators and photoelectric switches and connected with guide rods of lifting cylinders; lifting cylinder bodies are fixedly connected with a sliding platform; a ball screw is arranged under the sliding platform and arranged in the middle of a guide rail; the sliding platform can be driven by the ball screw to move side to side along the guide rail; the guide rail is fixedly arranged on the connecting plate; belt wheels are arranged at two ends of the ball screw respectively and connected with servo motors through synchronous belts. According to the full-automatic continuous feeding system of the integral stacks of aluminum plates, automatic switching can be achieved, feeding can be performed on aluminum stacks in a left and right alternate circulation mode, and accordingly the plate feeding efficiency is high, the feeding is stable, and the operation is convenient.

Owner:LIPENG PACKING YANTAI CITY

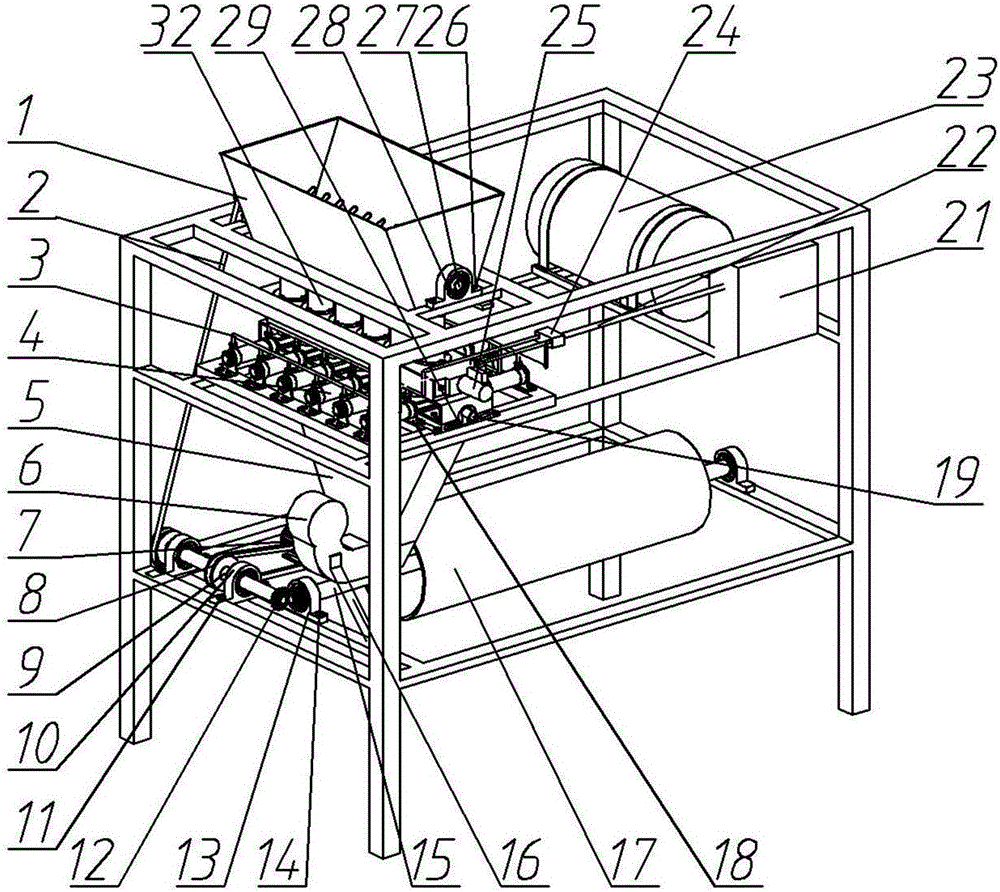

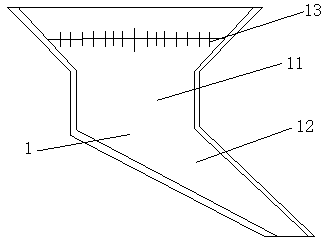

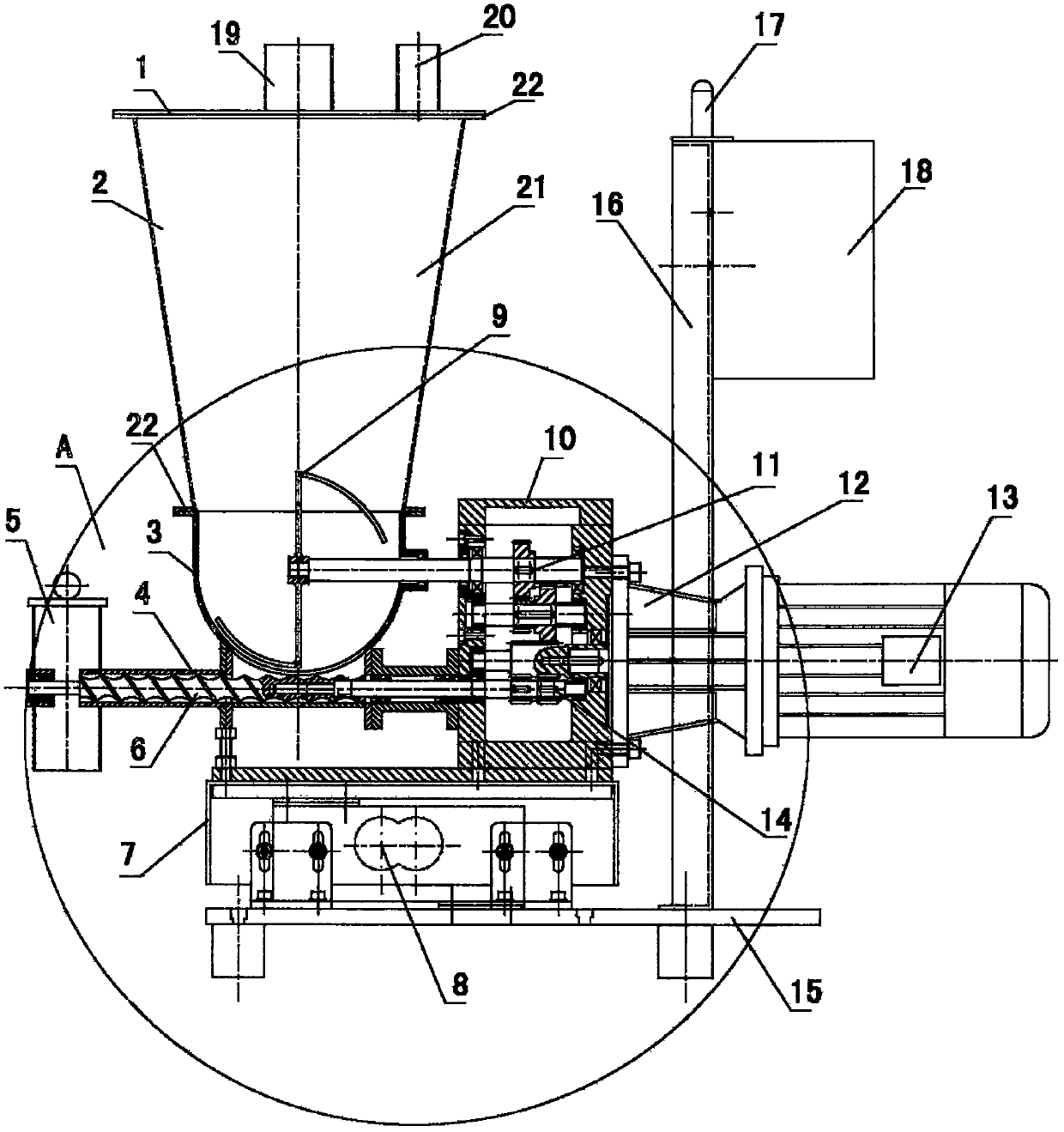

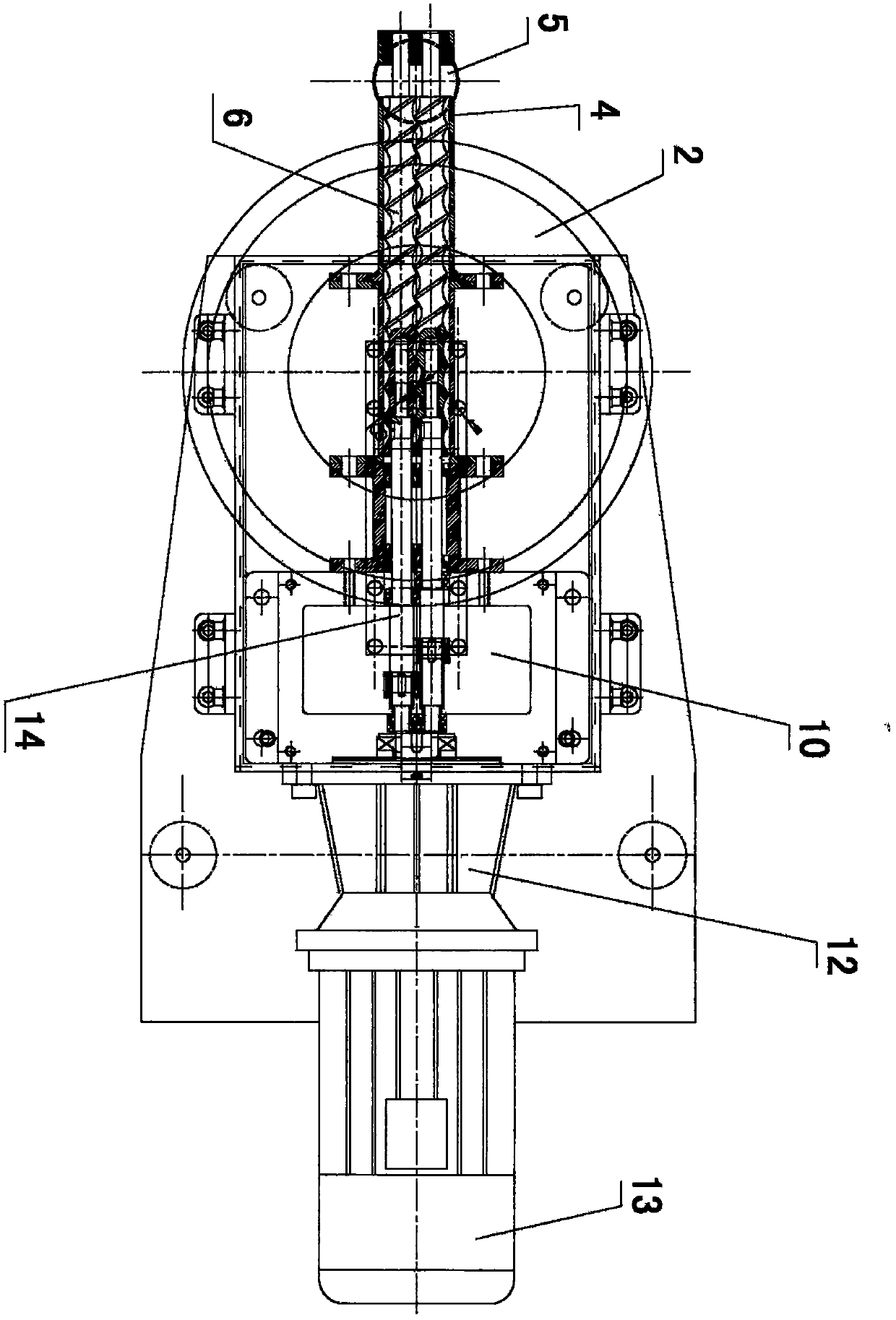

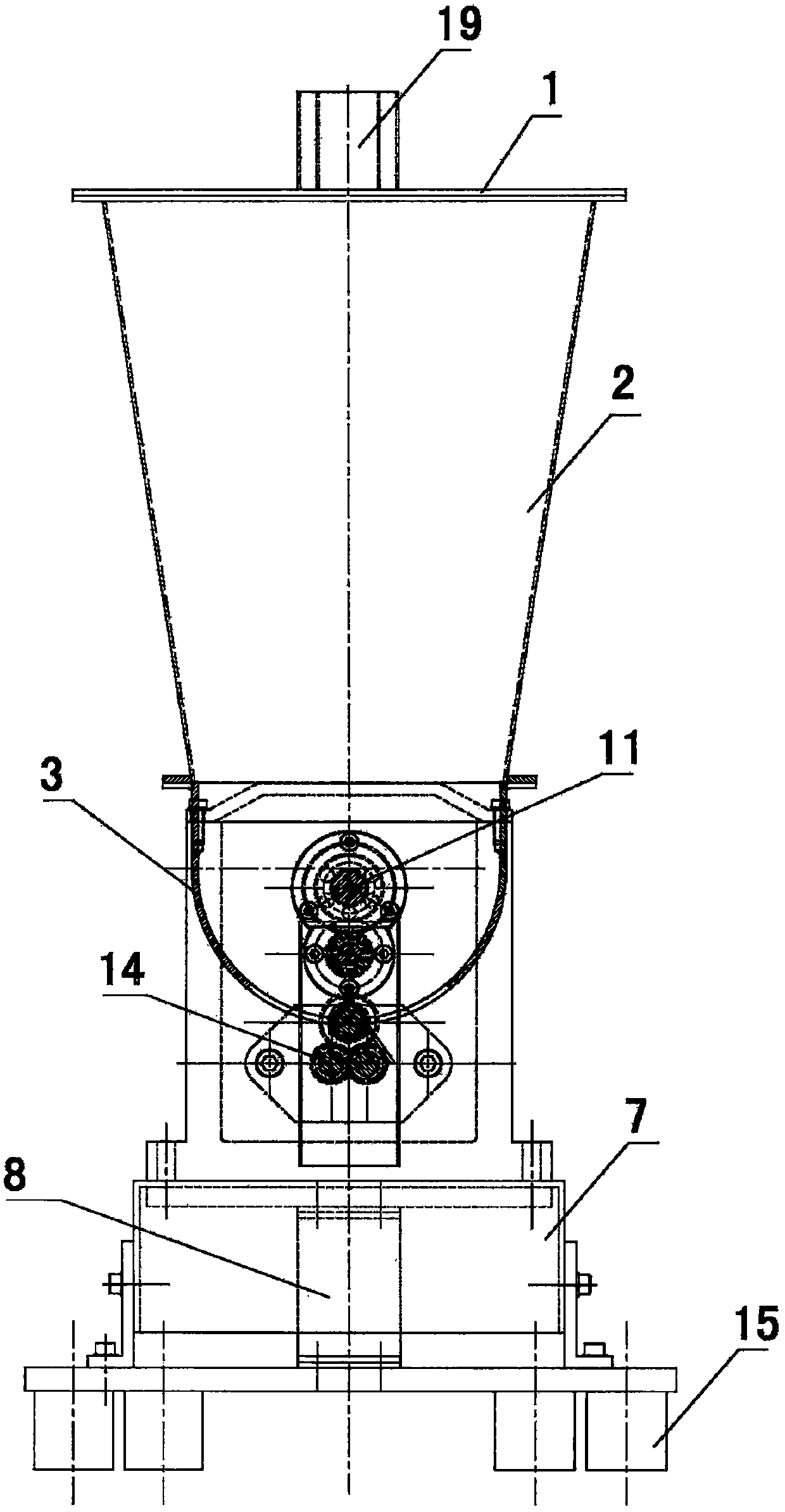

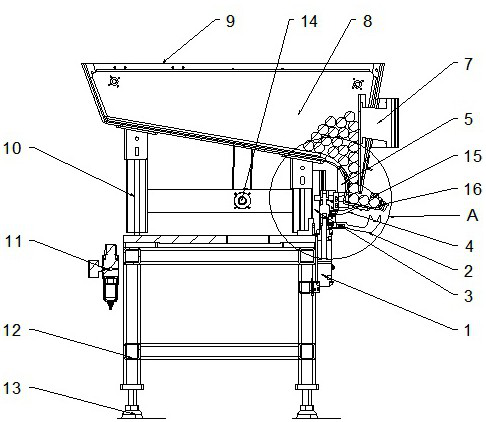

Walnut shell breaking, kernel taking and separating device and application method thereof

The invention discloses a walnut shell breaking, kernel taking and separating device and an application method thereof. The walnut shell breaking, kernel taking and separating device comprises at least one walnut fixing mechanism and at least two impact rods which are arranged on a rack as well as locating and quantitative feeding sliding blocks which are arranged at the two sides of walnut locating holes and are respectively used for covering the walnut locating holes, wherein the walnut locating holes are formed in a walnut shell breaking mould, at least two open pores communicated with the walnut locating holes are formed in the side wall of the walnut shell breaking mould, multiple impact rods penetrate through the open pores corresponding to each impact rod when being driven by a moving mechanism to impact walnuts arranged in the walnut locating holes, a collecting device is arranged below the locating and quantitative feeding sliding blocks at one side of the walnut locating holes, and the collecting device is connected with an air blower. The walnut shell breaking, kernel taking and separating device has the advantages that a stirring device is adopted for feeding, structure is delicate, efficiency is high, and failure rate is extremely low; and shape of a discharging hole of a feeding hopper and a through hole in a locating and conveying mechanism adopt a walnut locating cross-section shape, and automatic and controllable walnut feeding is realized.

Owner:广州华大生物科技有限公司 +1

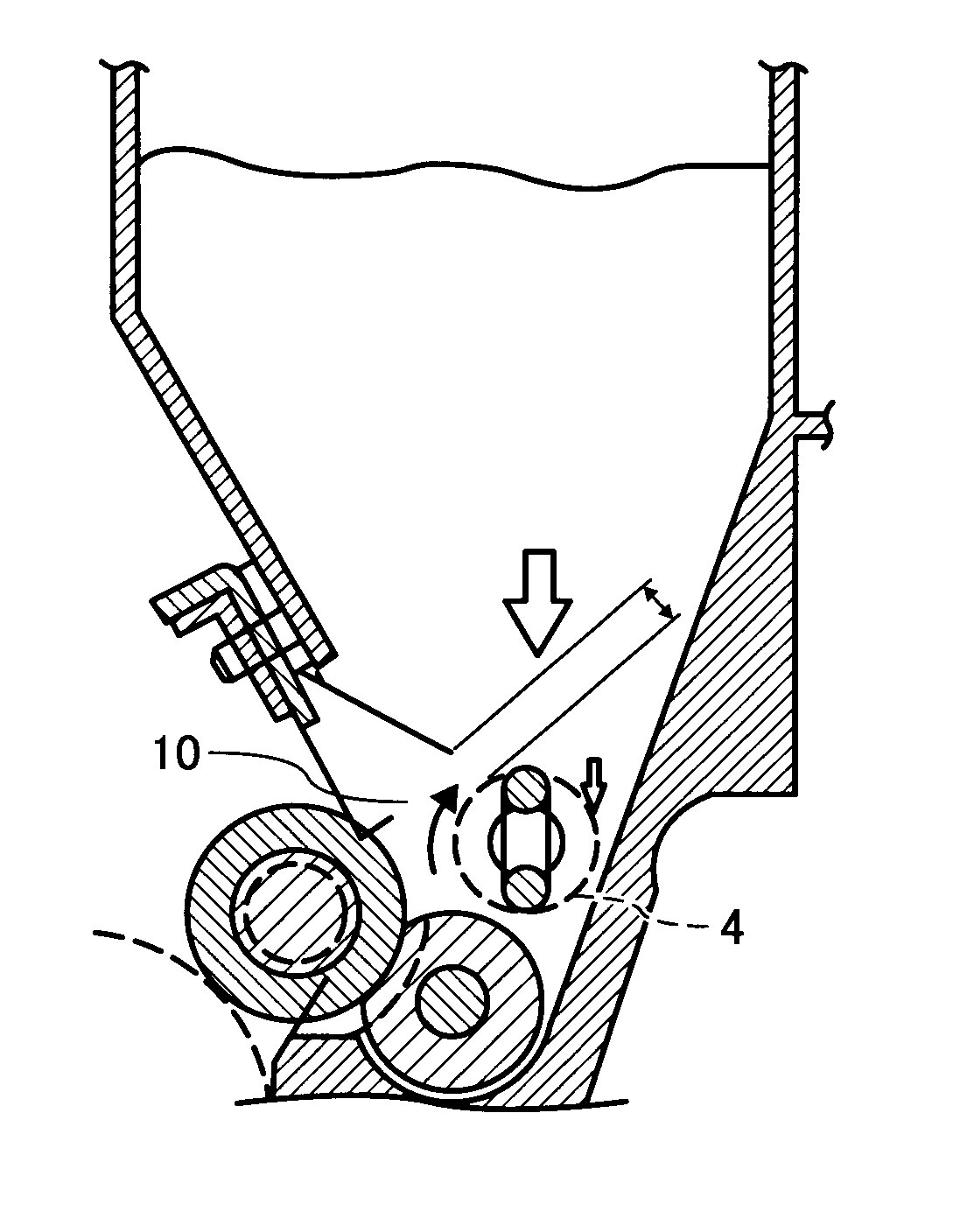

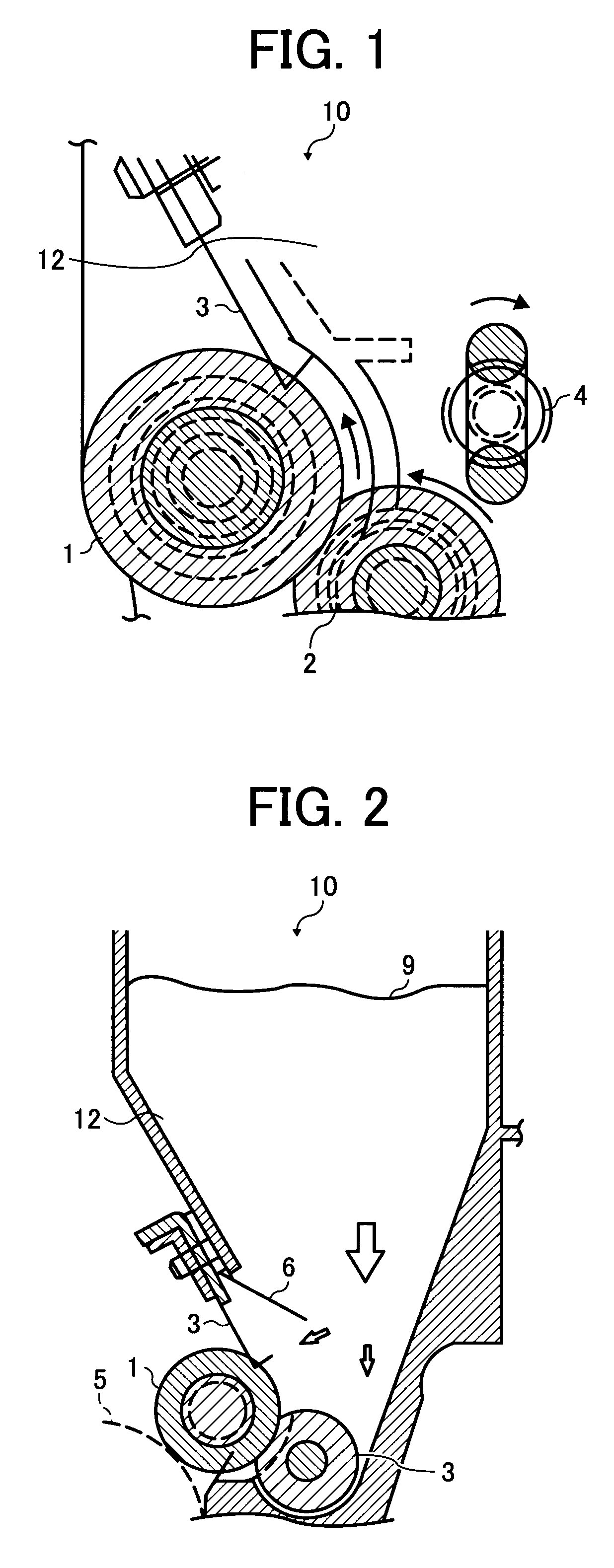

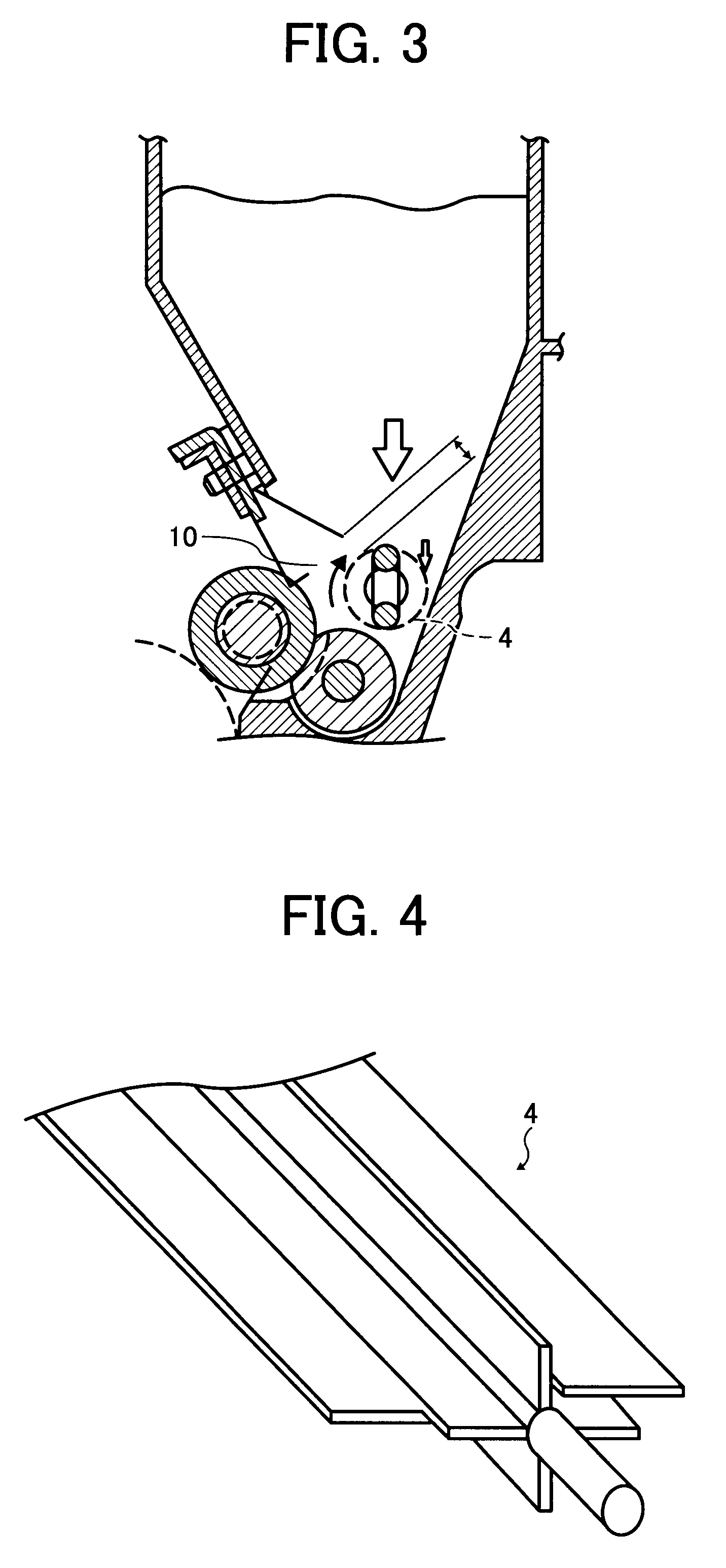

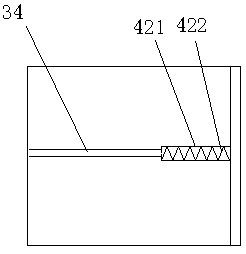

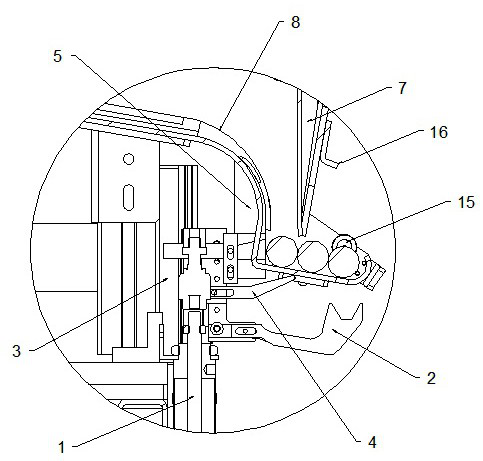

Image developer, process cartridge and image forming apparatus

InactiveUS20080205937A1Stable feedingSmooth feedingElectrographic process apparatusEngineeringMechanical engineering

An image developer, including a rotatable developer bearer; a rotatable developer feeding member contacting the developer bearer; a developer container located above the developer feeding member, wherein the developer container includes a pressure reducing member configured to reduce a pressure applied to the developer feeding member; and a first stirring bar located directly below the pressure reducing member and configured to stir a developer such that a gap between an end of the pressure reducing member and an outer diameter of the stirring bar is 6 mm.

Owner:RICOH KK

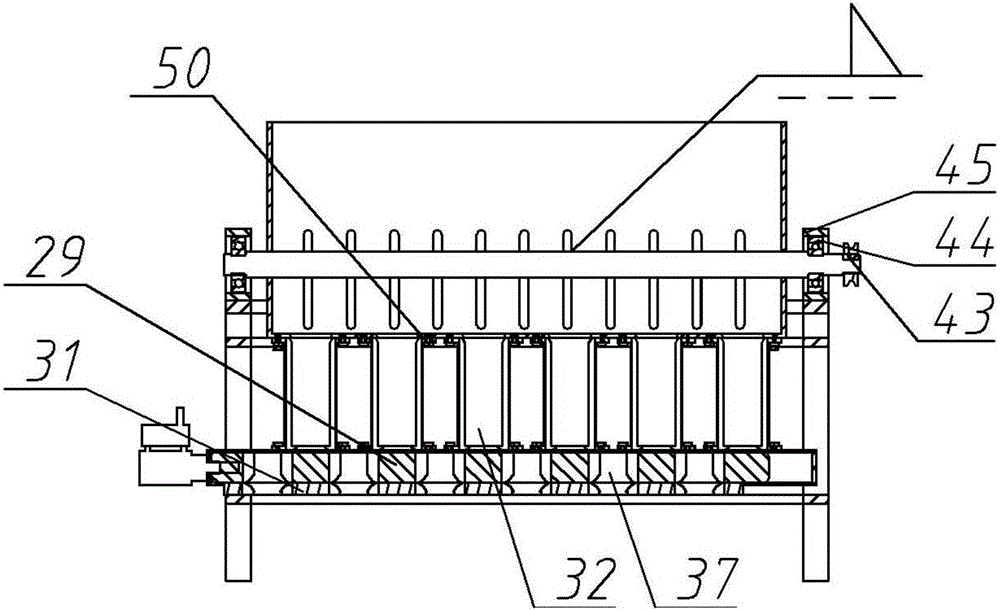

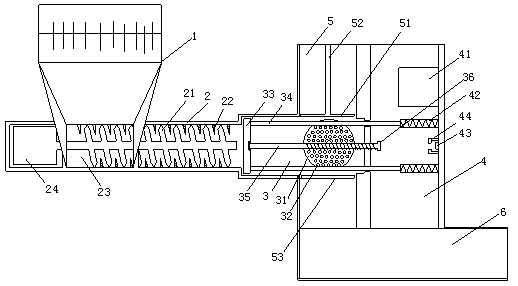

Bundling and compacting device for ensiling straw

The invention discloses a bundling and compacting device for ensiling straw. The bundling and compacting device comprises a crushing box, a pushing cylinder, a compacting bin, a control bin, a guide-out bin and a slideway and is characterized in that a spiral push rod is arranged in the pushing cylinder, the left half part of the pushing cylinder is provided with a feed inlet, the left end of thepushing cylinder is provided with a motor, and the motor is in linkage with the spiral push rod. The bundling and compacting device has the advantages that a traditional shifting rod feeding manner isreplaced by the spiral feeding device, stable feeding is achieved, program control is facilitated, mechanical wear is reduced, mechanical fault occurrence rate is reduced, the compacting device and the feeding device are combined in a unified manner, compacting is achieved while feeding is completed, extra structures are reduced, and energy consumption is reduced.

Owner:芜湖苜邦智能装备有限公司

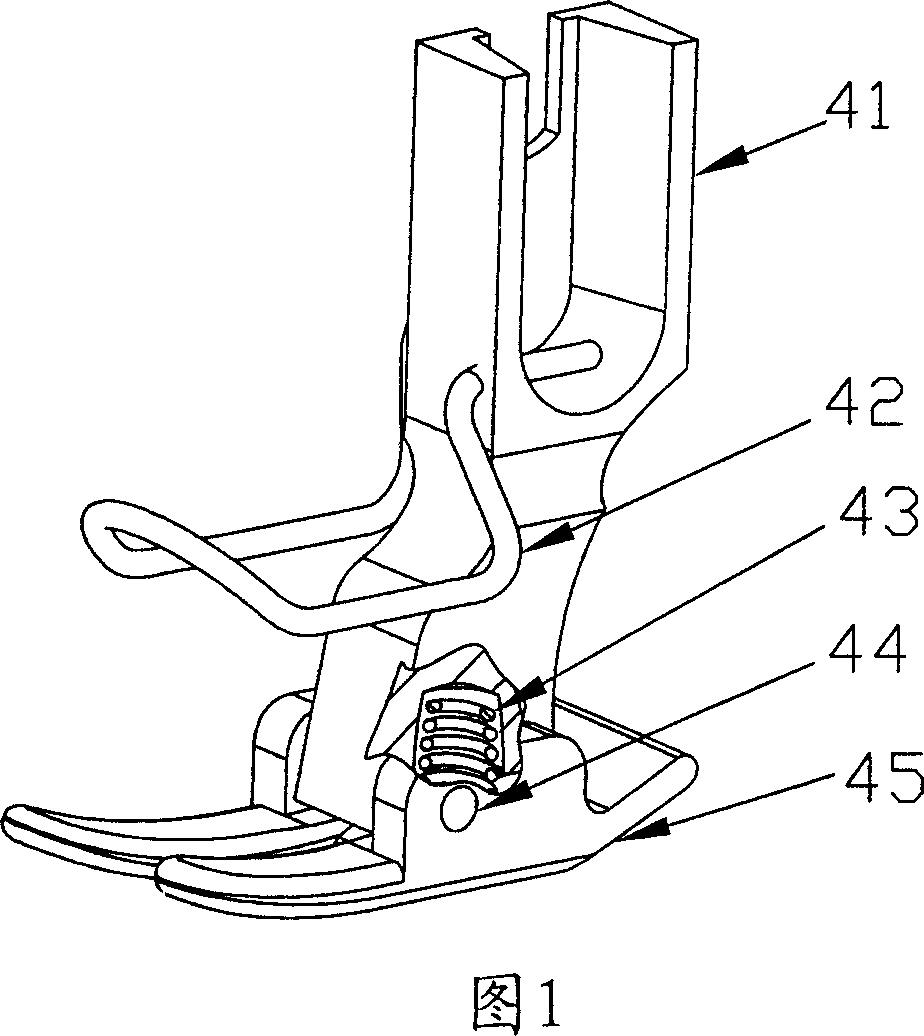

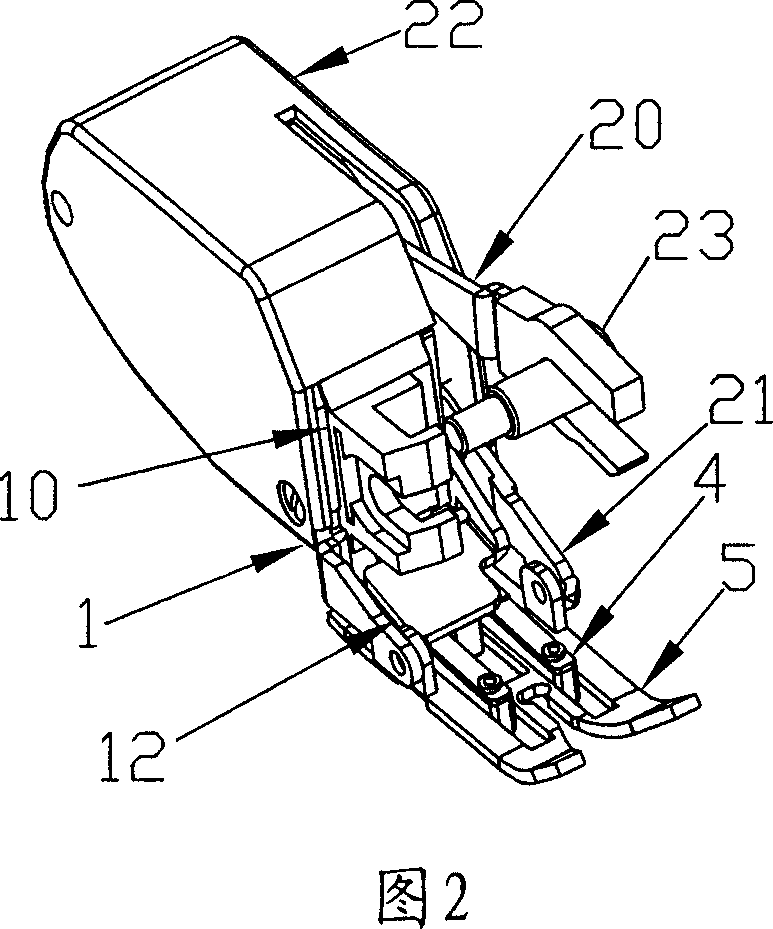

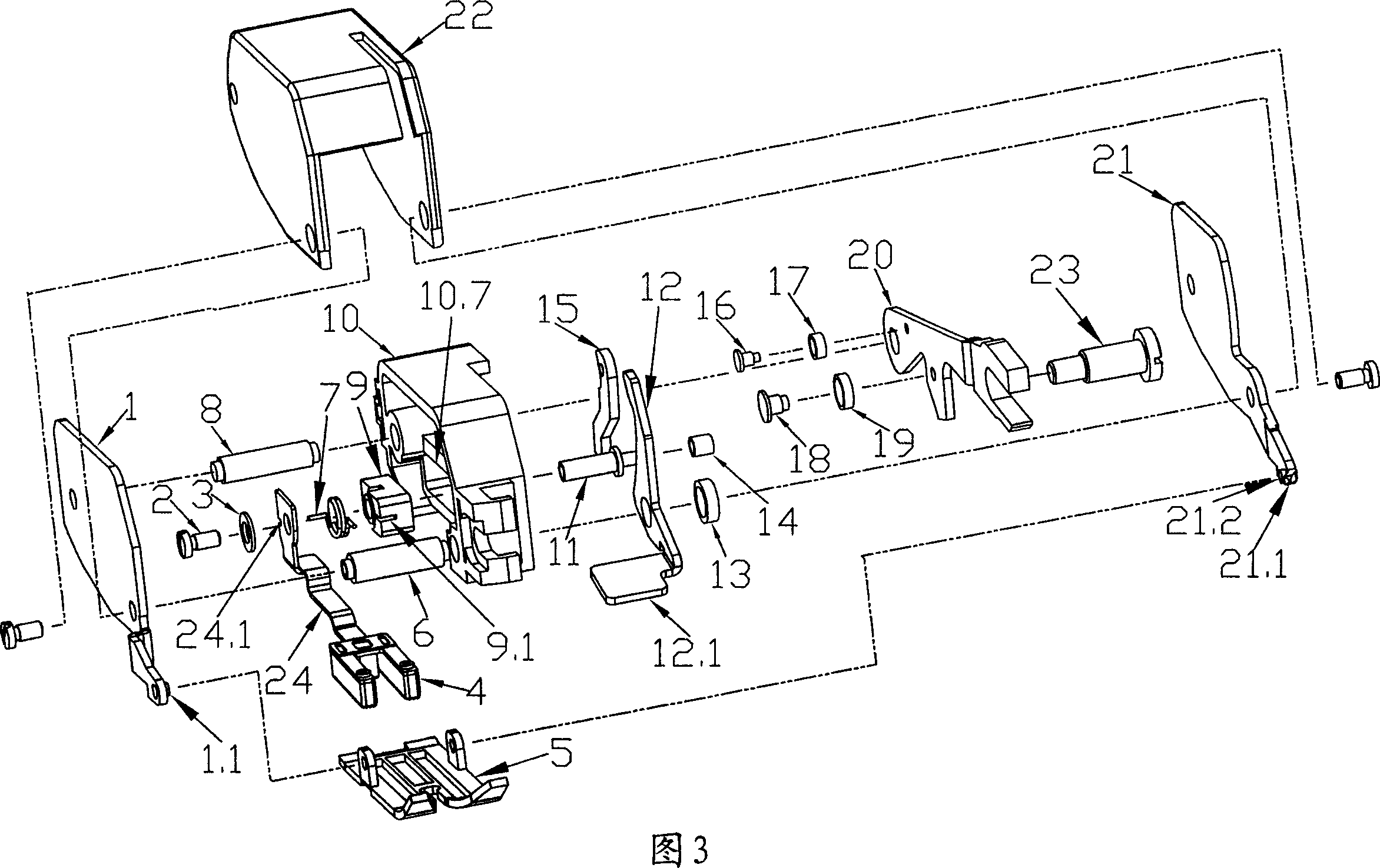

Presser foot device of seam plainer

The presser foot device for seam plainer is installed to the ends of the skeleton on the bottom of the press stem and has right and left clamp plates, presser foot back plate connected to the shaft stretched from the clamp plates, driving rod fixed inside the skeleton with front fork fitted with the needle clamp screw movably, and feeding block driven by the transmission mechanism to reciprocate inside the longitudinal slot in the presser foot back plate. During sewing, the feeding block has its teeth matching the feeding teeth to clamp the material to feed backward. The present invention can ensure smooth material feeding without slipping between the upper and the lower material layers, high sewing quality and high work efficiency.

Owner:FEIYUE

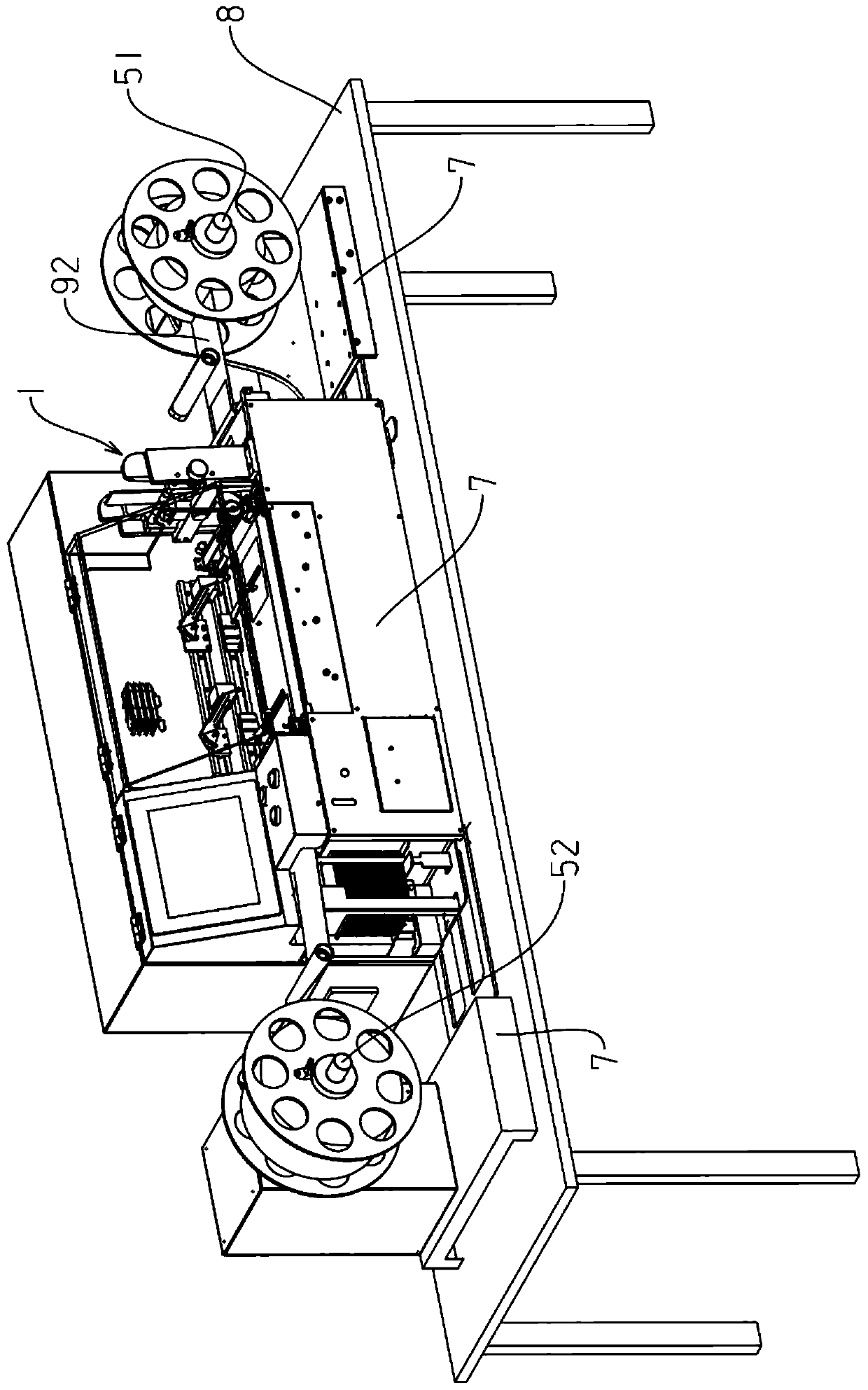

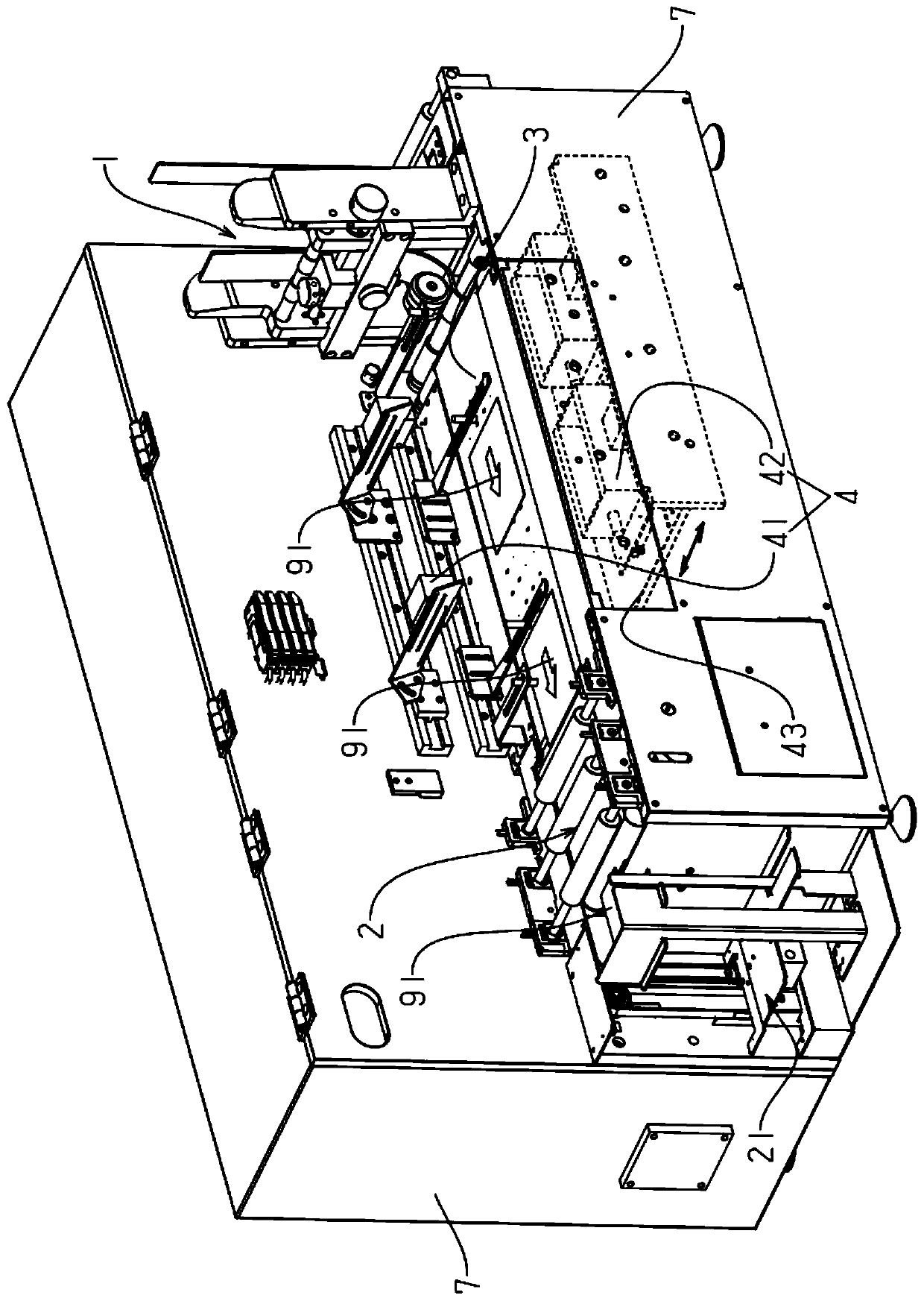

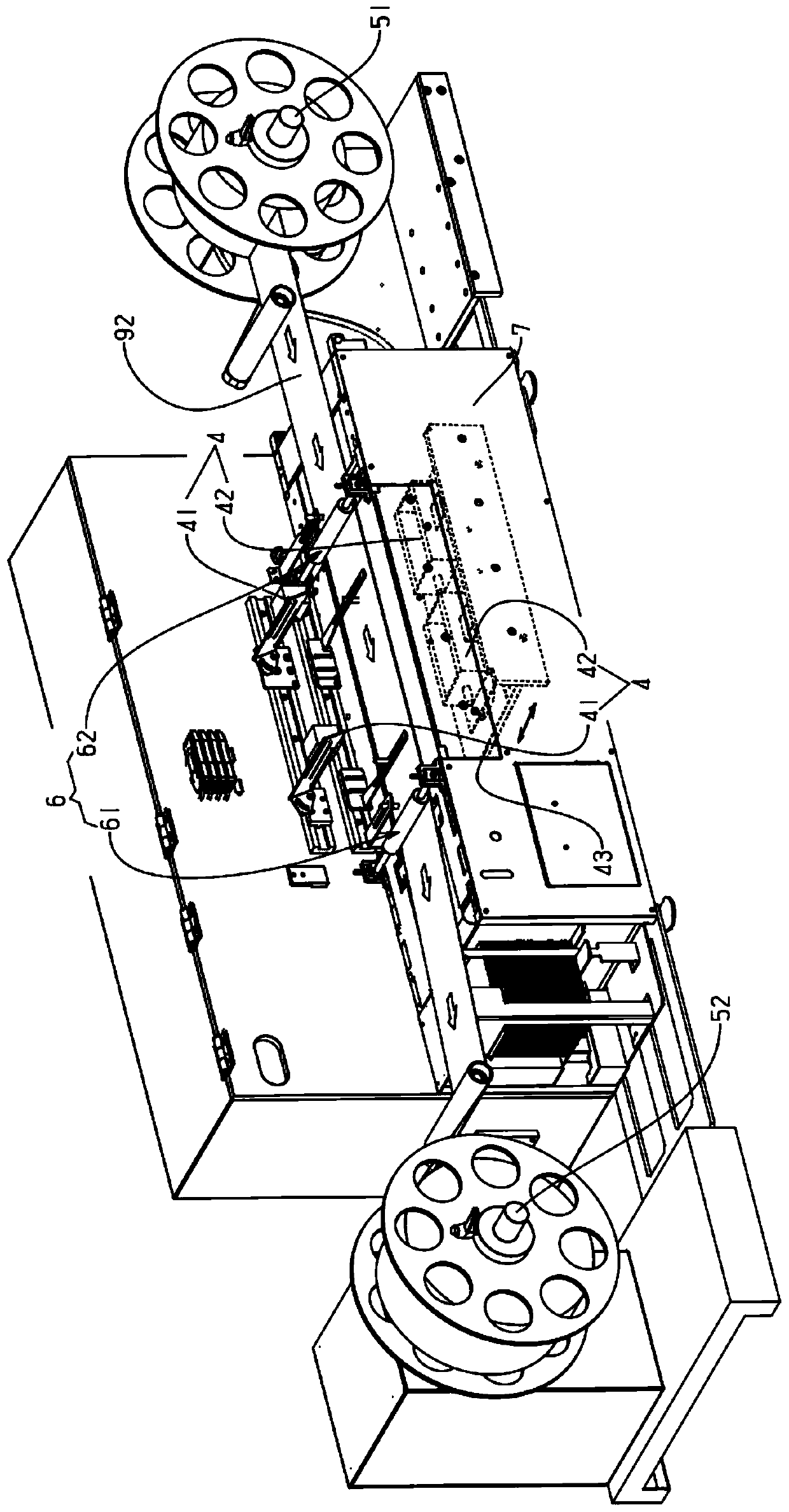

Desktop type label and ticket card dual-purpose detection code writing device

The invention discloses a desktop type label and ticket card dual-purpose detection code writing device. The detection code writing device can be placed on a desktop to work. The detection code-writing device comprises a card issuing mechanism used for issuing a single ticket card, a card collecting mechanism used for collecting the single ticket card, a conveying belt connected with the card issuing mechanism and the card collecting mechanism, an unwinding shaft and a winding shaft, wherein the unwinding shaft and the winding shaft are used for winding and tensioning a label material belt. Adriving mechanism used for pulling the label material belt to be conveyed is arranged between the unwinding shaft and the winding shaft. The desktop type label and ticket card dual-purpose detection code writing device can be suitable for labels in a material belt form and ticket cards in a single form, writing and / or detection verification of the labels and the ticket cards can be completed, andthe device is small, can be placed on a desktop to work, and is convenient to use and wide in application range.

Owner:KUNSHAN JETECH TECH CO LTD

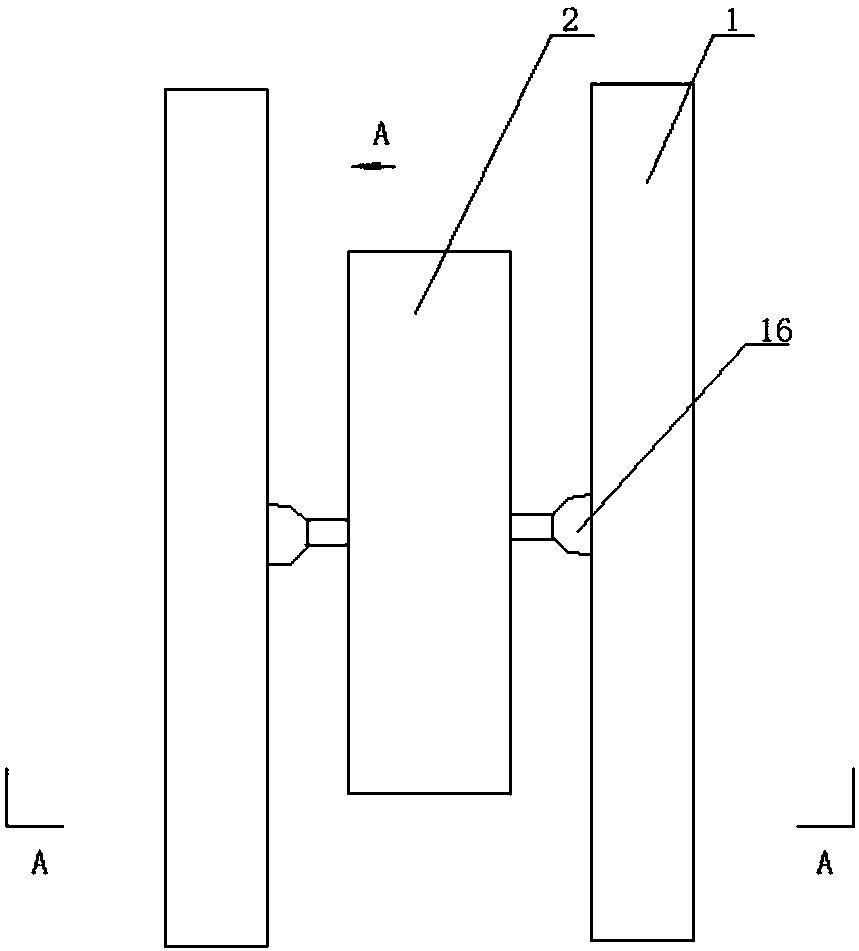

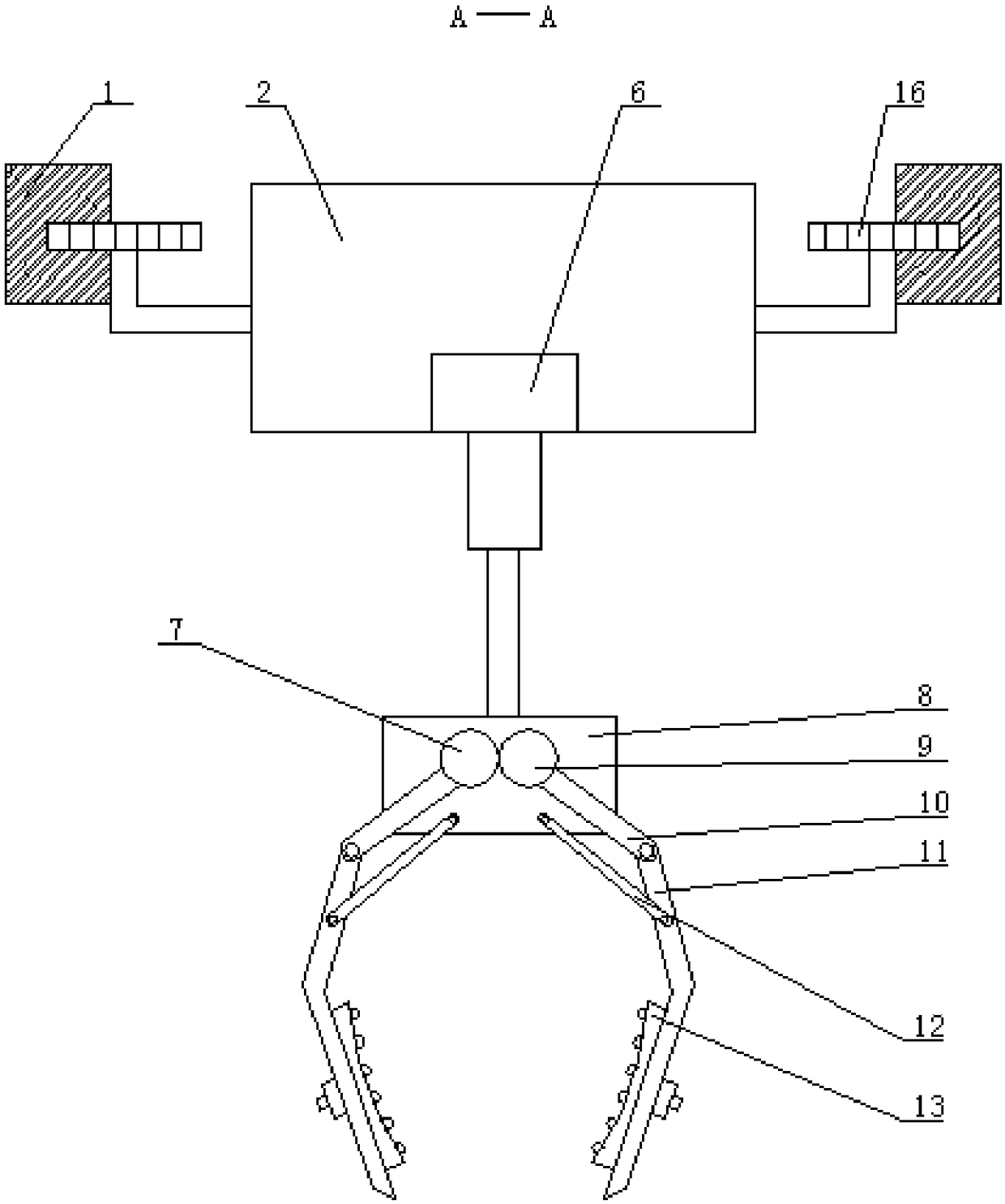

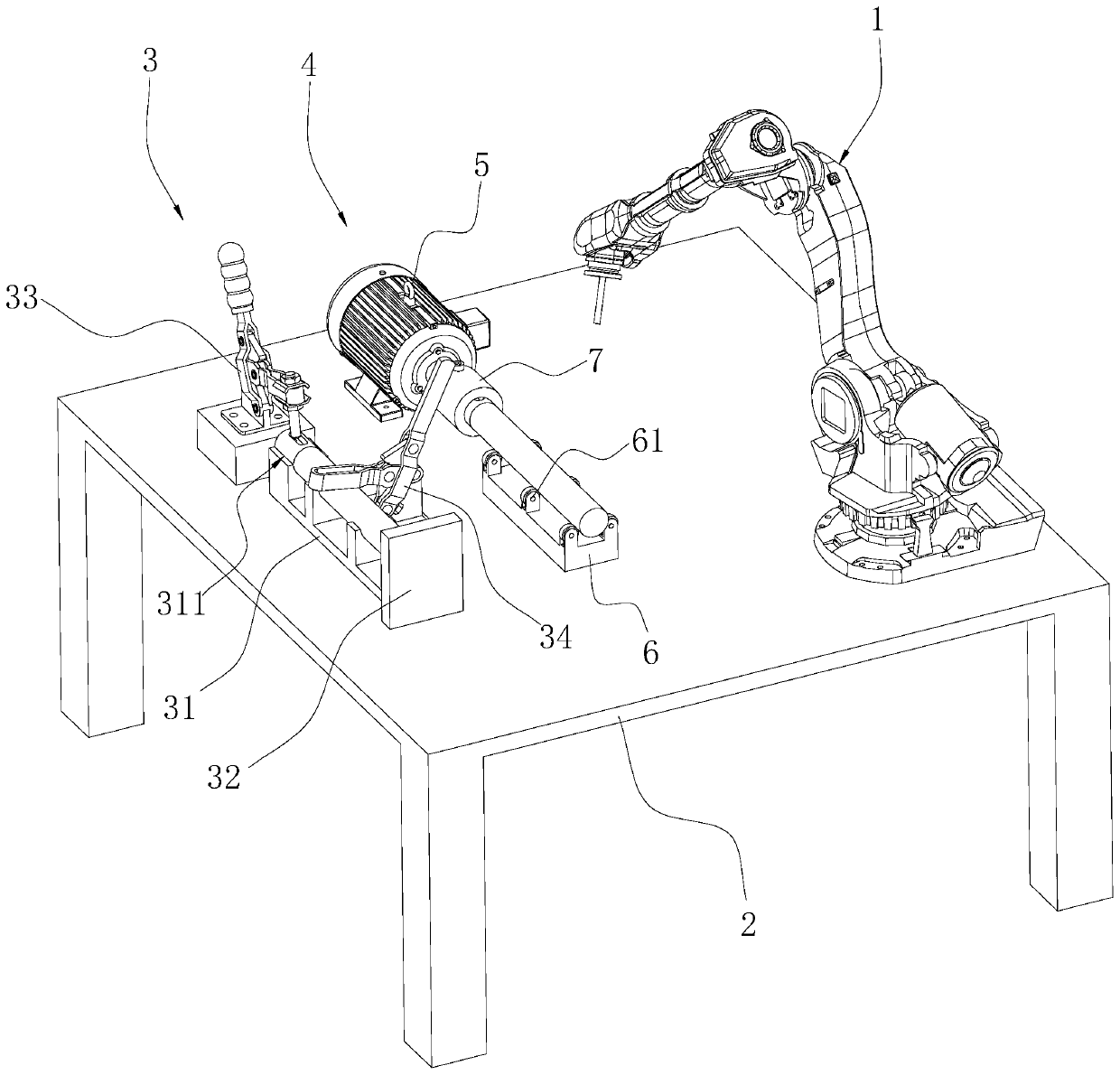

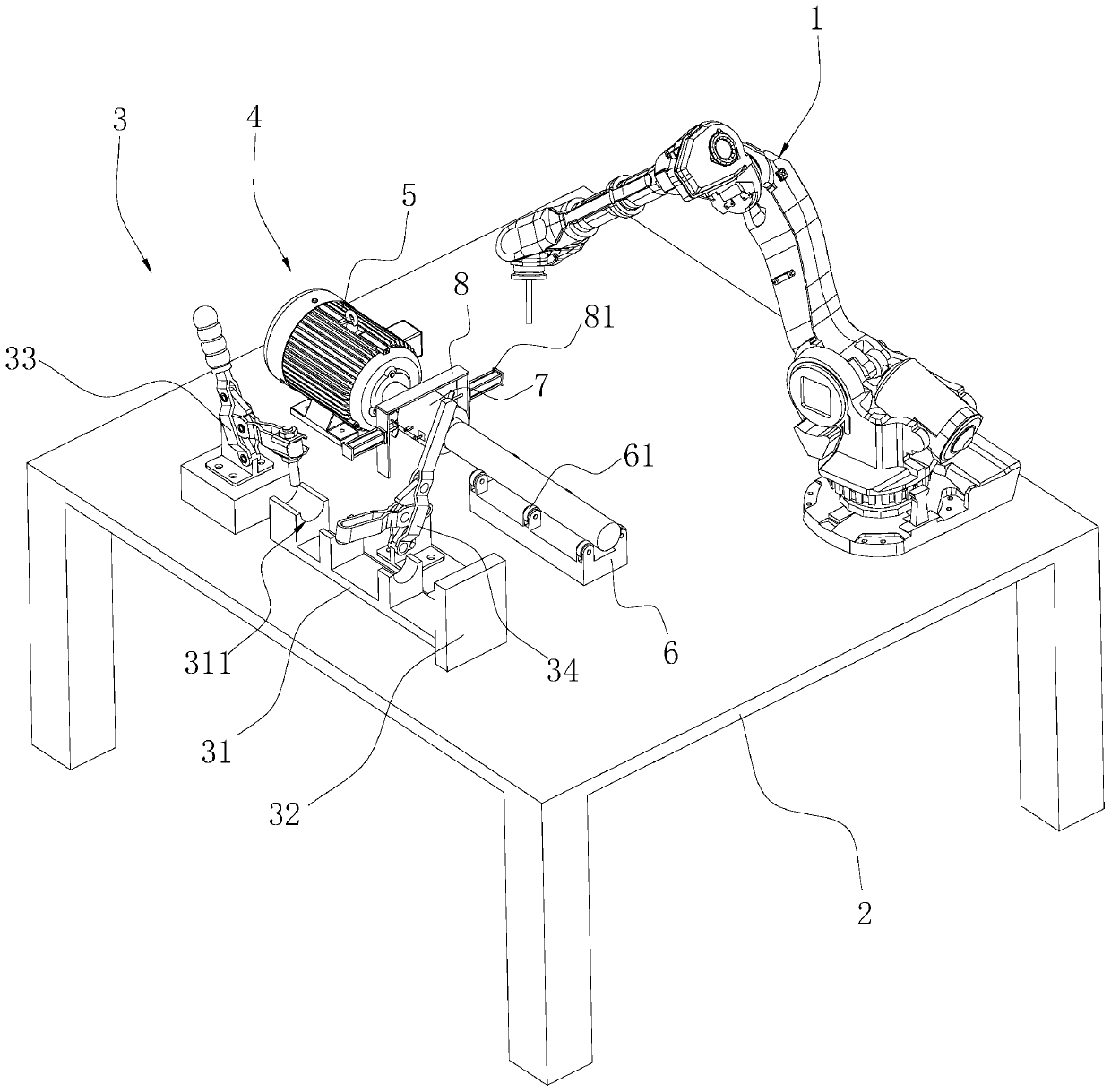

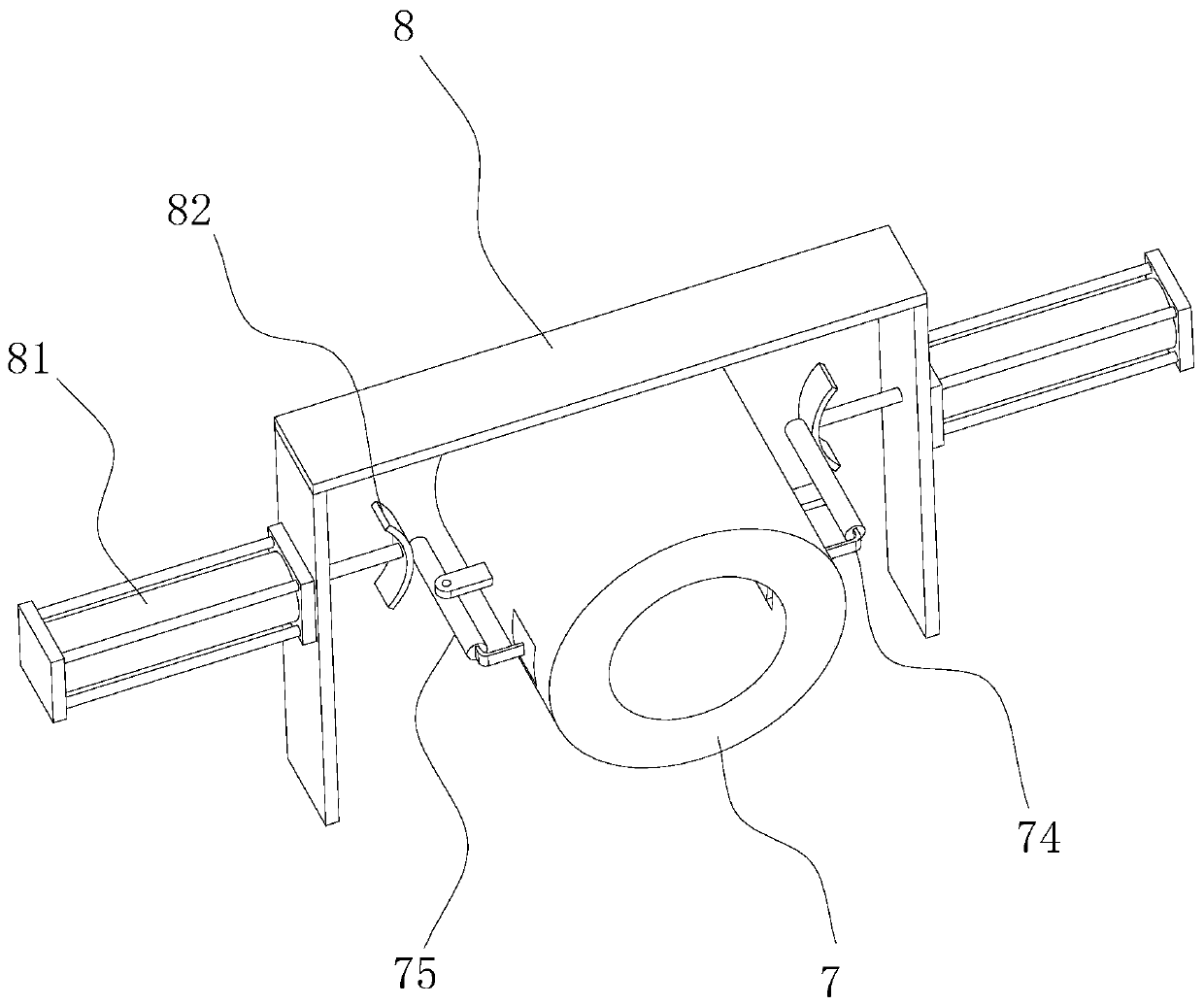

Mechanical arm

Owner:NANJING UNIV OF SCI & TECH

Arc automatic welding machine

ActiveCN110711995AAvoid multiple weldingStable feedingWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringShaft alignment

The invention relates to an arc automatic welding machine. The arc automatic welding machine comprises a welding robot hand and a tool unit, wherein the tool unit comprises a processing table, a primary tool and a secondary tool are sequentially arranged on the processing table, the primary tool is used for positioning and fixing two isodiametric round tubes so as to coaxially align and abut the two round tubes, then the welding robot hand is started to move to a connection position between the two round tubes for performing point welding once, thereby fixedly connecting the round tubes to form a semi-finished product, then the semi-finished product is transferred into the secondary tool, a welding end of the welding robot hand is started and aligned to the position of a welding seam of the semi-finished product, and meanwhile the secondary tool drives the semi-finished product to rotate around the axis, and finally the welding robot hand keeps still and continuously welds the weldingseam of the semi-finished product so as to form a finished product, and then improves welding efficiency.

Owner:浙江国微科技有限公司

Chestnut sheller with positioned conveying and usage thereof

ActiveCN105852149AExquisite structureImprove efficiencyHuskingHullingMechanical engineeringEngineering

The invention discloses a chestnut sheller with positioned conveying and usage thereof. The chestnut sheller comprises at least one chestnut fixator and at least two impact rods both arranged on a frame, a chestnut shelling die is provided with a chestnut positioning hole, the sidewall of the chestnut shelling die is provided with at least two holes in communication with the chestnut positioning hole, the multiple impact rods are driven by a moving mechanism to pass through the holes corresponding to the impact rods, impacting on chestnuts placed in the chestnut positioning hole, the chestnut sheller also comprises positioning quantitative feeding sliders disposed on two sides of the chestnut positioning hole to cover the chestnut positioning hole, a positioned conveying mechanism is arranged above the positioning quantitative feeding slider at the inlet side of the chestnut positioning hole, and an inner passage of the positioned conveying mechanism is as shaped as maximum cross section of a chestnut; the positioned conveying mechanism and the positioning quantitative feeding sliders cooperate to store chestnuts in the inner passage of the positioned conveying mechanism before the chestnuts enter the chestnut positioning hole, and operation in the chestnut positioning hole is guaranteed effectively.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

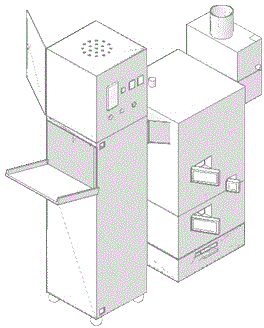

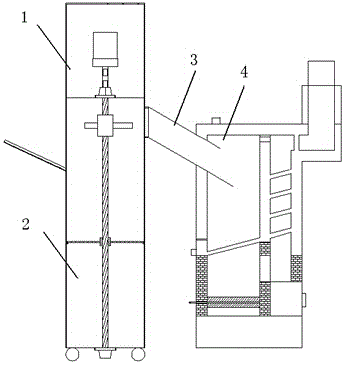

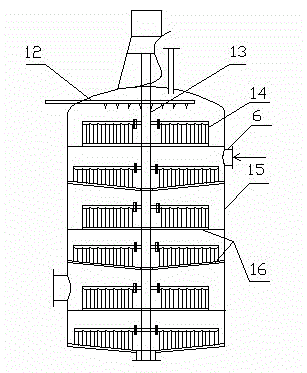

Household direct-fired heating appliance using compressed straw as fuel

ActiveCN104879785AStable feedingReduce frictional resistanceLighting and heating apparatusStove/ranges for heating waterCombustion chamberSmoke

The invention relates to a household direct-fired heating appliance using compressed straw as fuel. The household direct-fired heating appliance comprises a heating furnace and an automatic feeder, which form an H-shaped structure and which are connected through a material pass. The upper structure of the heating furnace comprises the material pass, a smoke pass, a smoke window, a water jacket, a water-cooled grate, a convection bank, a balance tube, a water-cooled partition, an anti-radiation retainer, and a waste heat recovery water jacket. The lower structure of the heating furnace comprises a rocking grate, a combustion pass, a secondary air chamber, an insulation layer and an ash hopper. A combustion chamber comprises a main chamber and a secondary chamber. The automatic feeder comprises a speed control motor, a coupling, a screw, stirring blades, a tray, rollers, a limiting switch, a control circuit box, a motor box, and a fuel box. The automatic feeder can continuously and automatically convey the compressed straw for 12 hours; the compressed straw slips into the heating furnace through the material pass; the heating furnace combusts efficiently and stably. The household direct-fired heating appliance is high in combustion efficiency, low in pollutant emission, simple to operate, low in cost and widely applicable.

Owner:HEBEI UNIV OF TECH

Waterproof roll laying device used for vertical upright angle

InactiveCN108868030AStable feedingImprove applicabilityUnderground chambersRoof toolsStructural engineering

The invention provides a waterproof roll laying device used for a vertical upright angle, and belongs to the technical field of waterproof roll. The device comprises a laying cart, a vertical uprightangle laying mechanism, a supporting laying block of the vertical upright angle laying mechanism is installed on a vertical upright angle laying supporting seat, an upward bending laying block is installed on the upper side of the supporting laying block, a downward bending laying block is installed on the lower side of the supporting laying block, an upper jacking rod can be slidably arranged ona horizontal sliding groove, an upper jacking plate is installed at one end of the upper jacking rod, one end of the upper supporting pressing spring fits the vertical upright angle laying supportingseat, the other end of the upper supporting pressing spring fits the upper jacking plate, a lower jacking rod can be slidably arranged on a vertical sliding groove, a lower jacking plate is installedat one end of the lower jacking rod, one end of a lower supporting pressing spring fits the the vertical upright angle laying supporting seat, the other end of the lower supporting pressing spring fits the lower jacking plate, and a triangular rubber supporting strip is installed at the connecting point of mutually perpendicular wall surfaces. By means of the device, waterproof roll can be laid ona vertical upright angle, the laying quality is good, and the waterproofing effect is excellent.

Owner:周梅

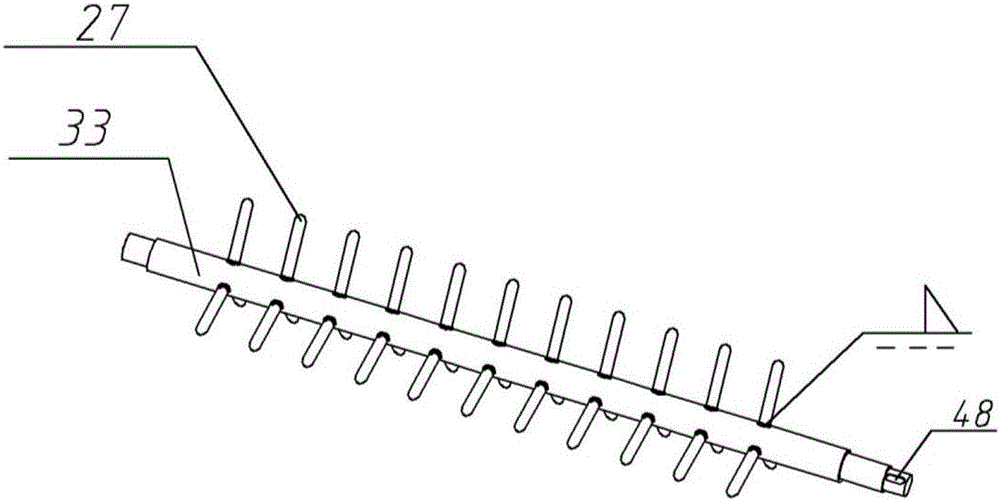

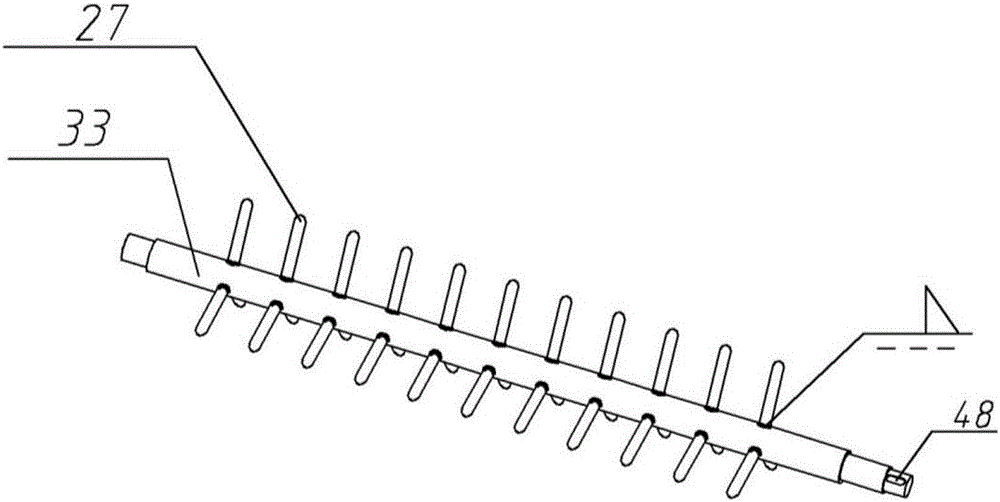

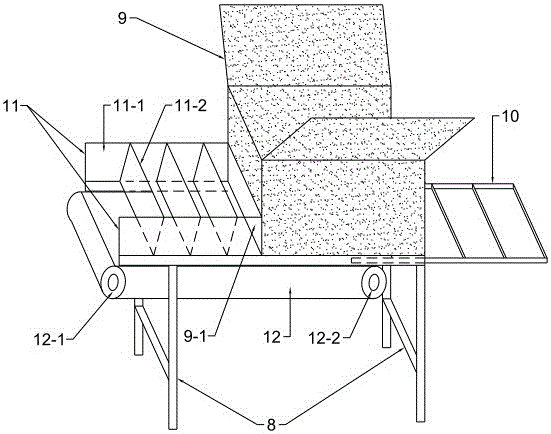

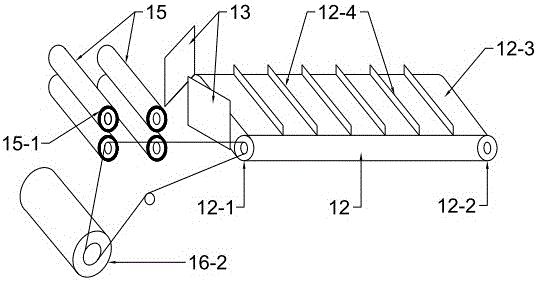

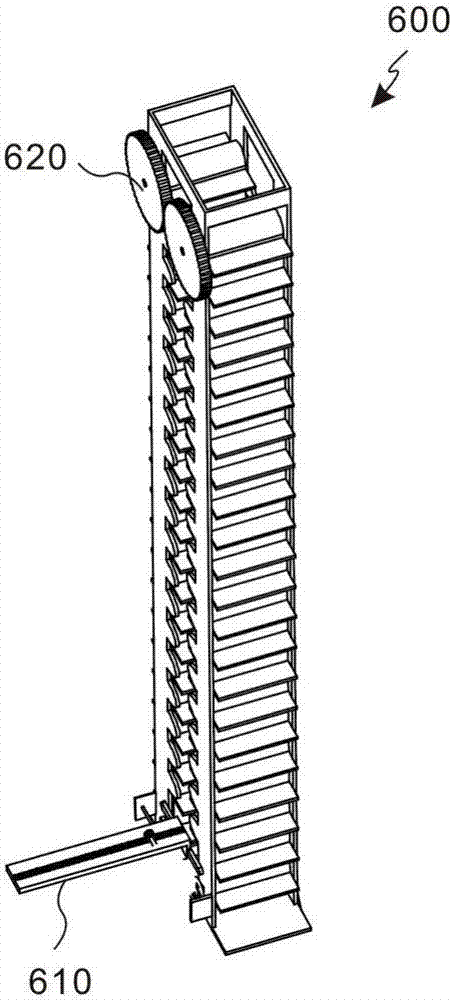

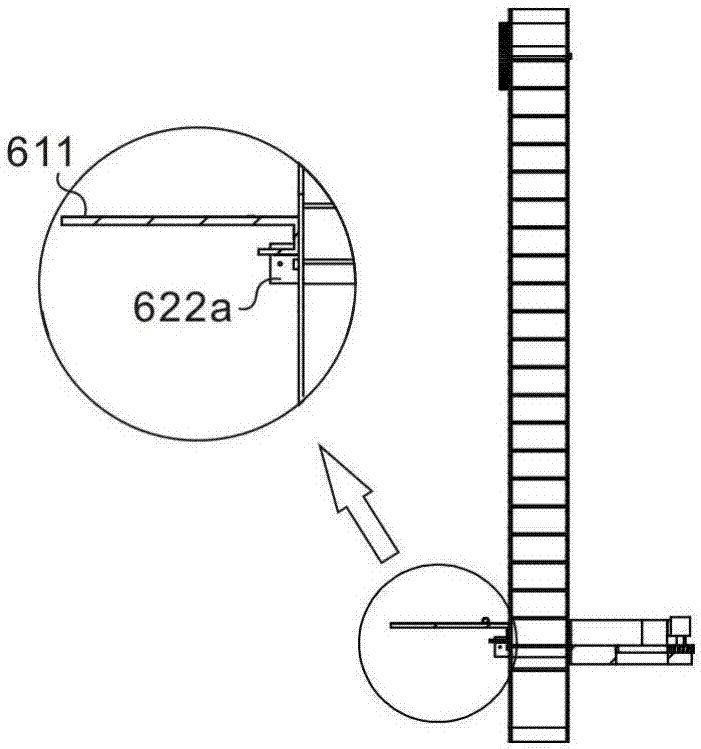

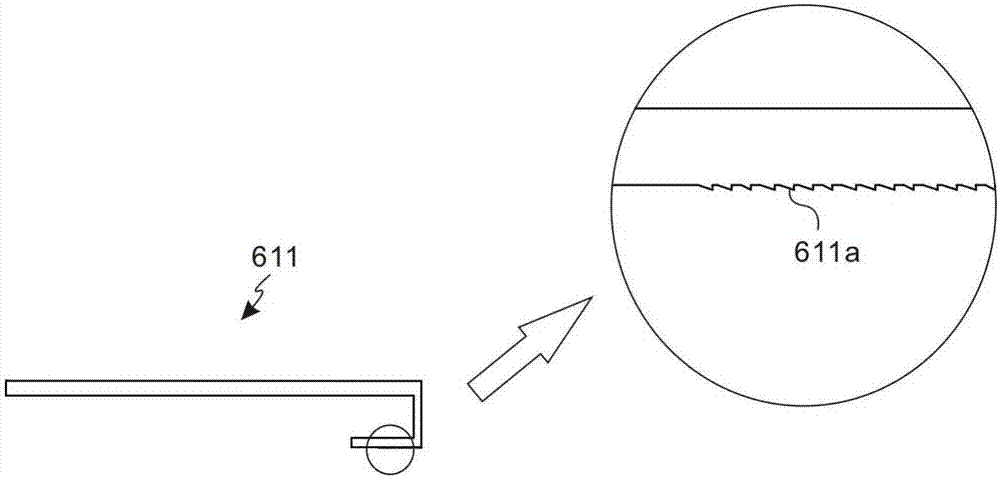

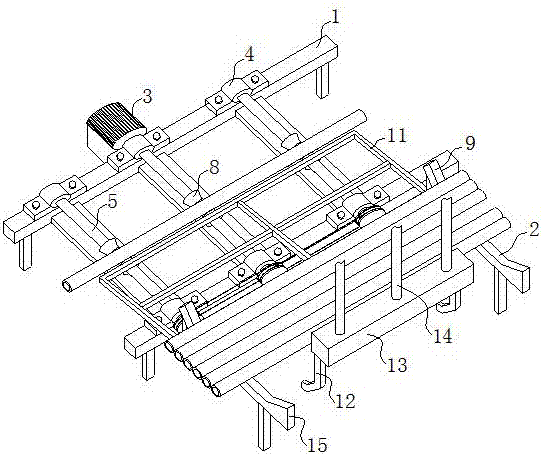

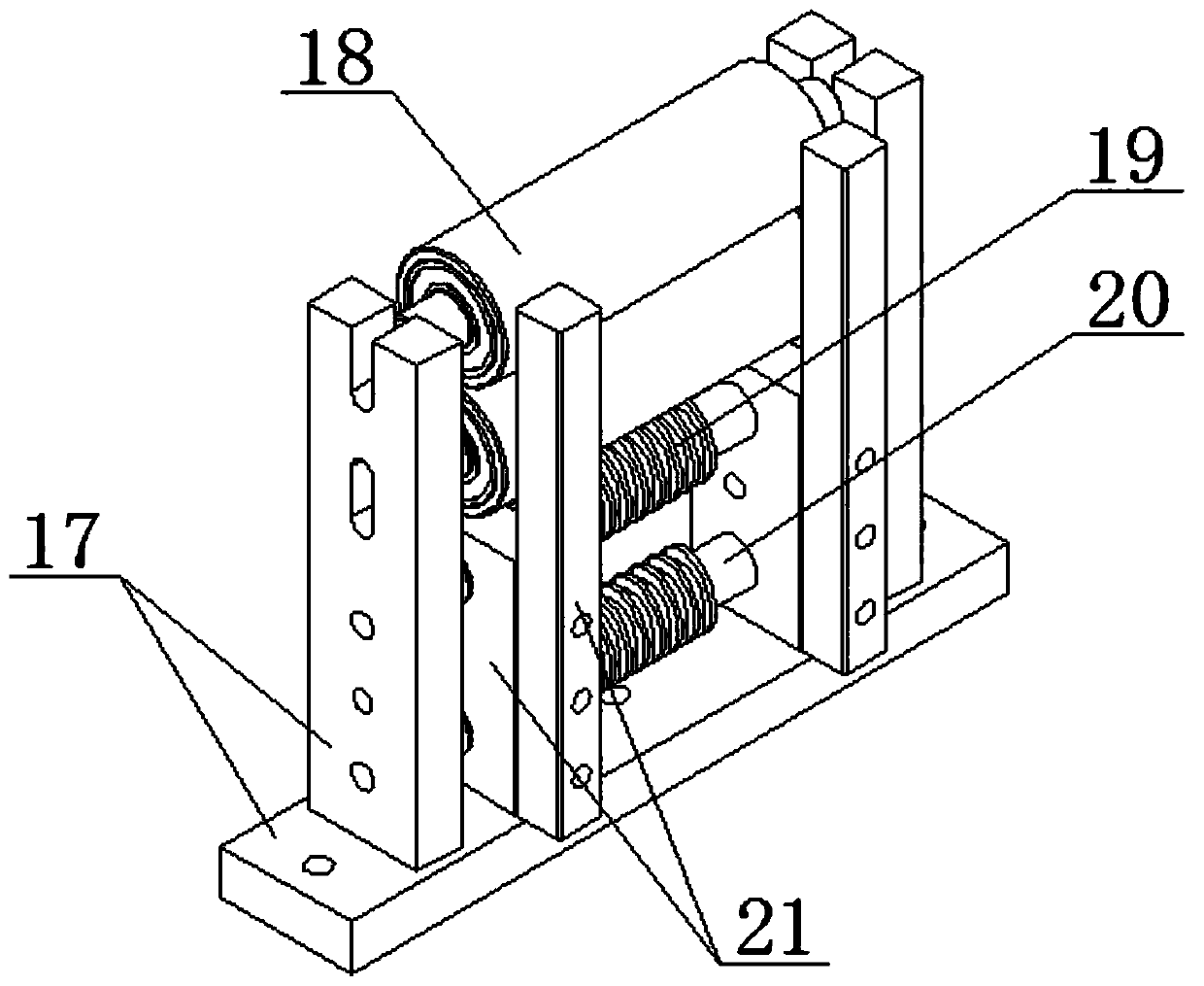

Automatic-feed-type reed peeling machine

ActiveCN107433663AProtect your healthExtended service lifeConveyorsOsier rod peelingReducerEngineering

The invention relates to the technical field of the automatic mechanical equipment and in particular to an automatic-feed-type reed peeling machine. The automatic-feed-type reed peeling machine comprises a peeling mechanism and an automatic feed mechanism. The peeling mechanism is formed by three pairs of upper and lower steel wire rollers, a first motor, a second motor, a reducer, a roller distance regulating device, a discharging port and a peeling machine frame. The automatic feed mechanism is formed by a feed machine frame, an active material bracket, a gliding-type hopper, a feeding machine, a one-way guiding channel, a belt conveyor, and a feeding port. The belt conveyor is formed by a main belt wheel, a driven belt wheel, a conveying belt, a tooth-shaped scraper blade and a conveyor tensioning device. The structure and design of the automatic-feed-type reed peeling machine are rational, a worker does not need to execute the feeding continuously beside the machine, the feeding process is automatically completed by the machine, the labor force is greatly saved, the body health of the worker is protected, the feeding process is rapid, uniform and stable, the working efficiency is greatly improved, the problem of non-uniform wearing of a wire brush can be overcome, and the service life is prolonged.

Owner:崔吉华

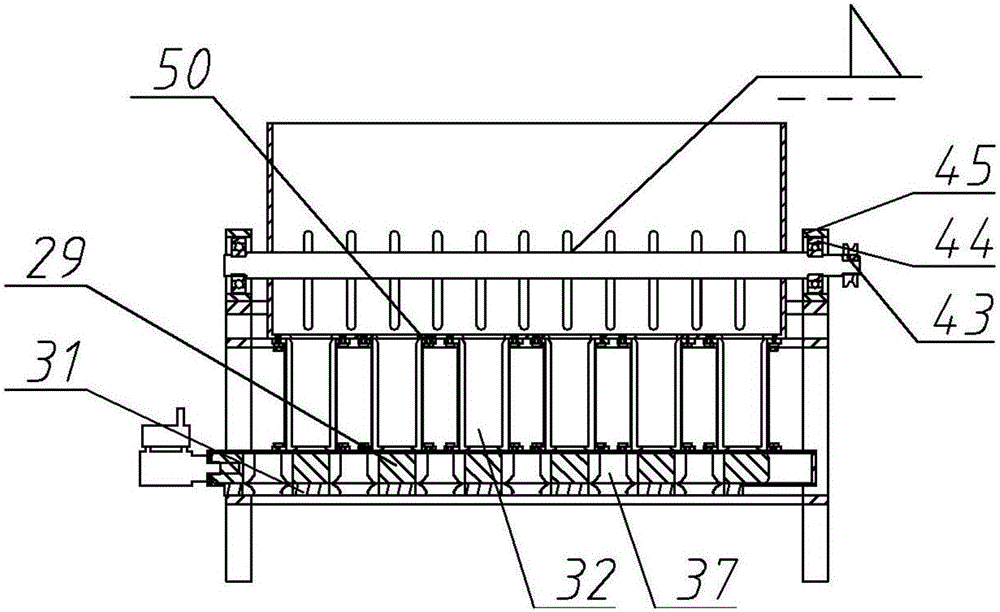

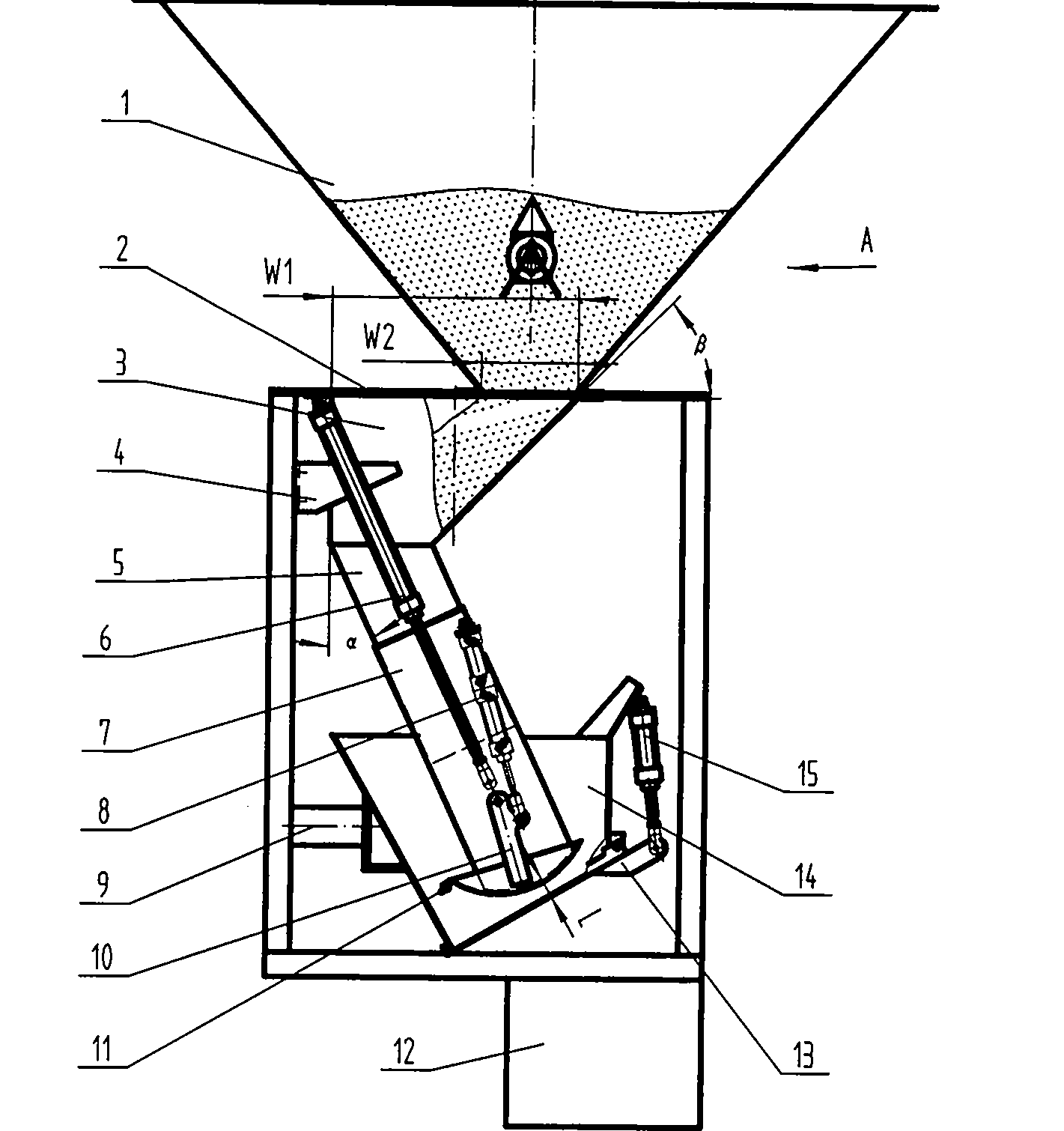

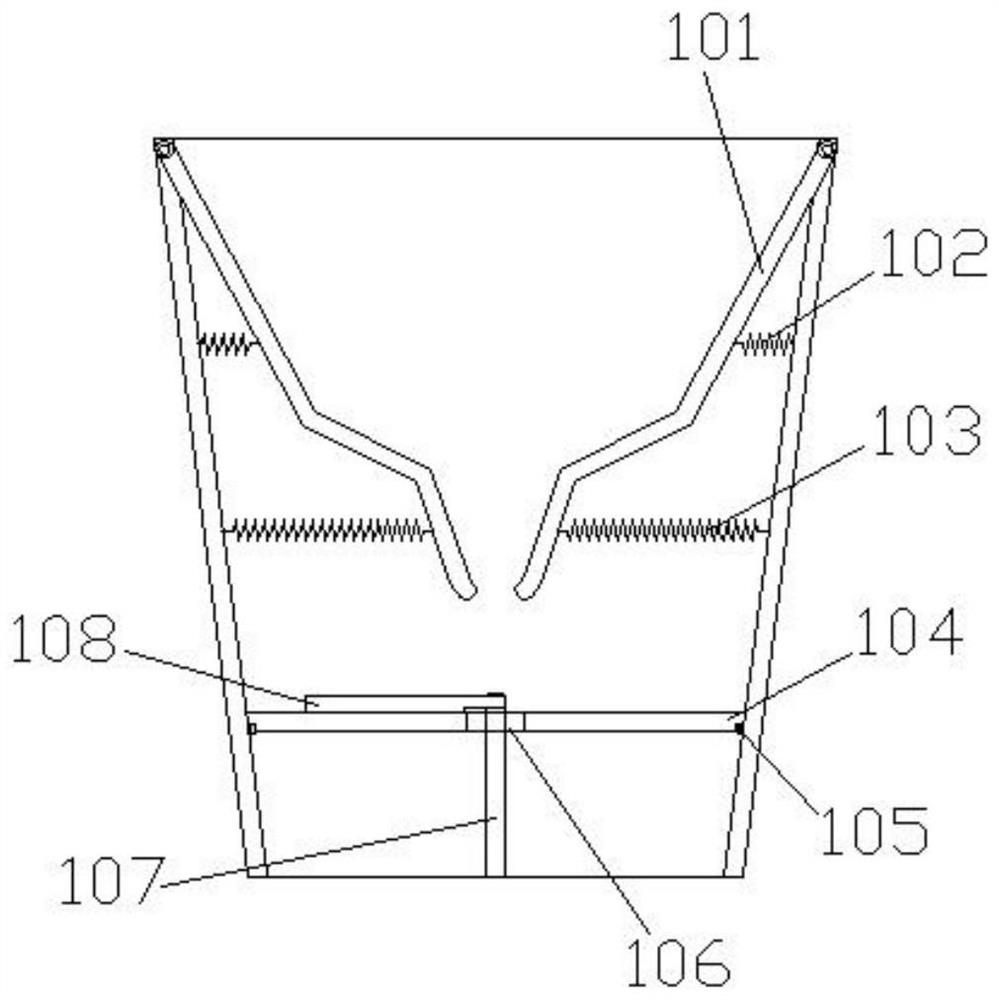

Automatic quantitative quasi-static weighing method and device

ActiveCN104075784AFast weighingStable feedingWeighing apparatus with automatic feed/dischargeEngineeringOrder of accuracy

The invention relates to an automatic quantitative quasi-static weighing method and device, in particular to an automatic quantitative quasi-static weighing method and device for weighing materials according to predetermined weights in high-accuracy and high-speed modes. The whole weighing process is divided into two stages, the quasi-static weighing process at the first stage is finished firstly, and then the quasi-static weighing process at the second stage is finished. The automatic quantitative quasi-static weighing device comprises a bin, a pressure reducing and flow regulating unit, a rack, a feeding unit, a weighing unit and a control unit. Under the condition that the accuracy level and precision level are not changed, the high weighing speed is achieved compared with existing products and the prior art. A large amount of materials are rapidly separated into small equivalent packages through weighing. In addition, the device further has the advantages of being simple in manufacturing process, low in cost and reliable in use.

Owner:陕西省农业机械研究所有限公司

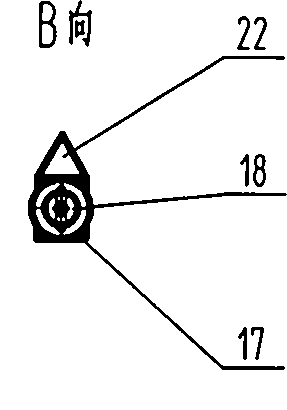

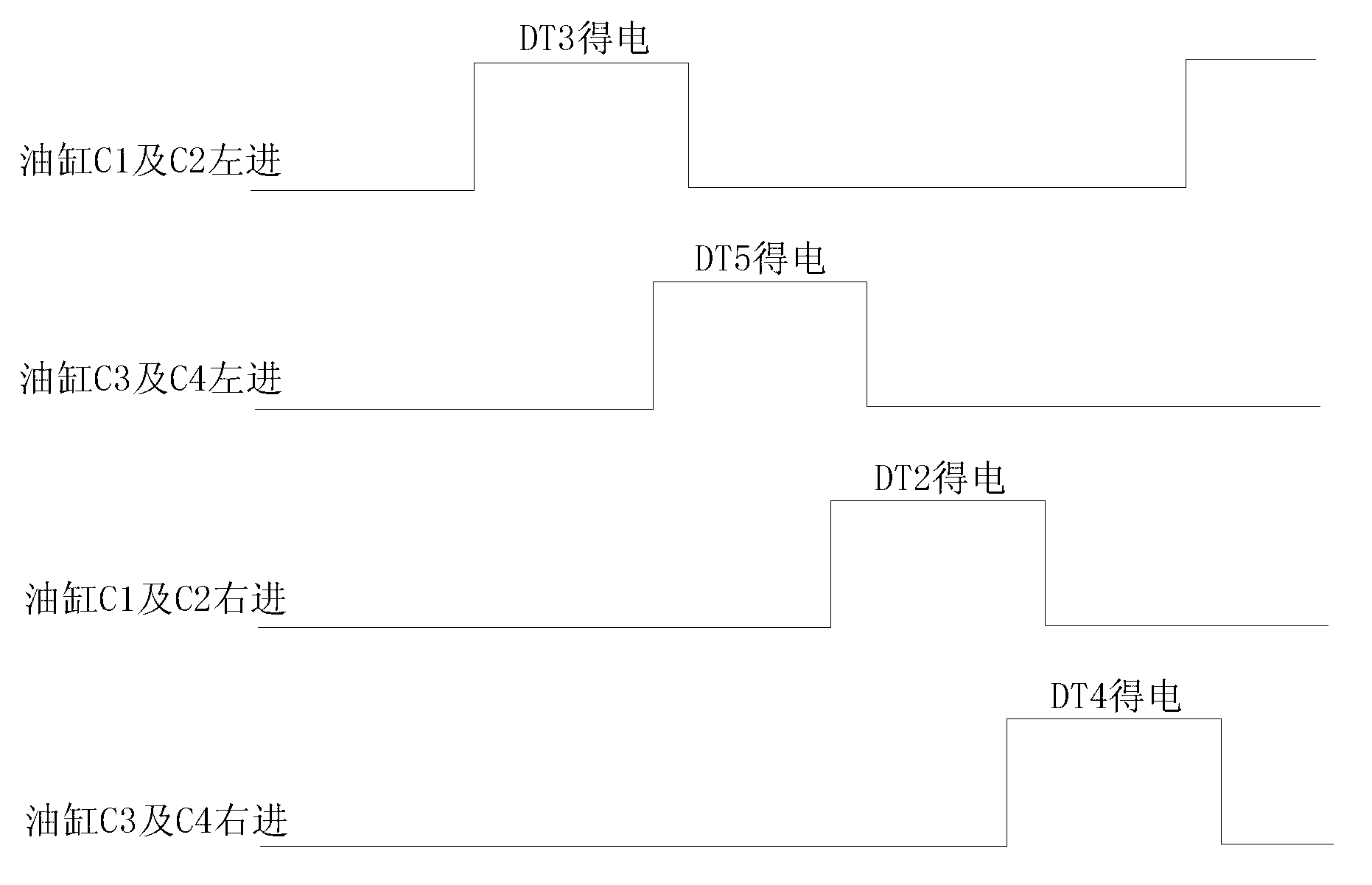

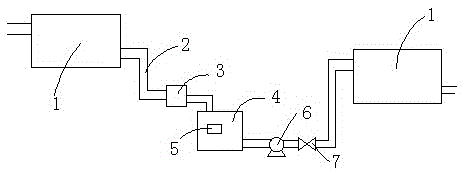

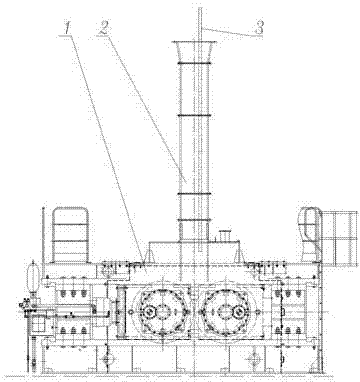

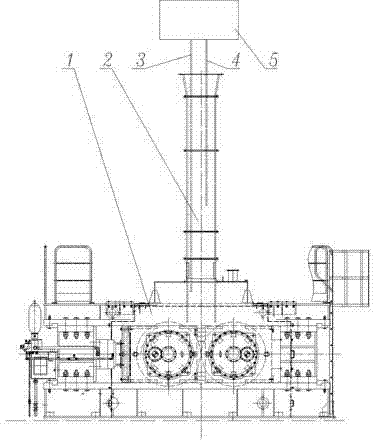

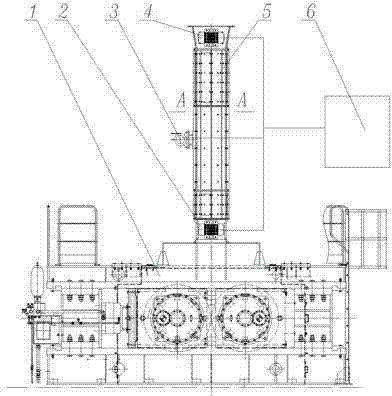

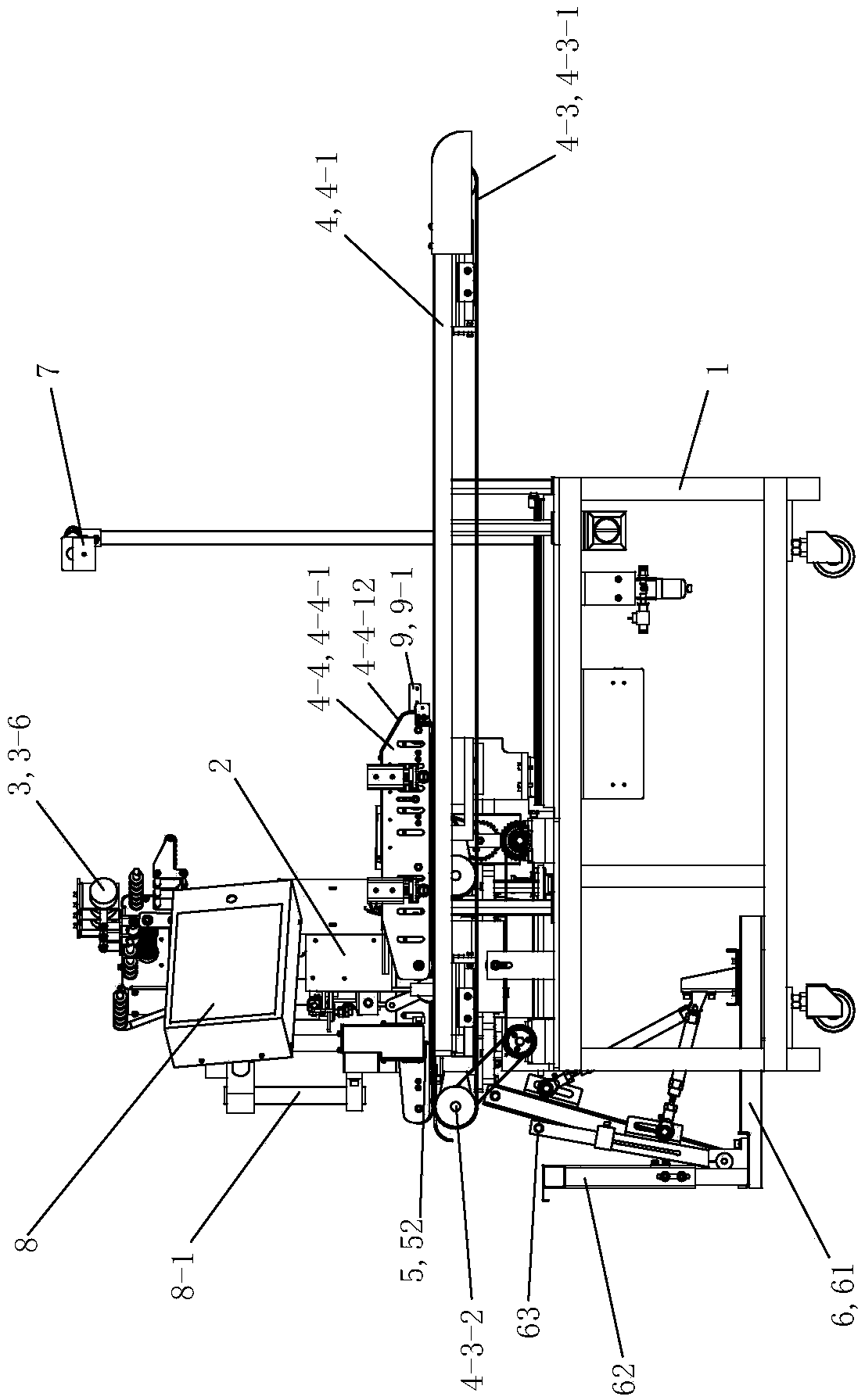

Continuous material feeding system and control method and elevating platform fire truck thereof

The invention discloses a continuous material feeding system and a control method and an elevating platform fire truck thereof. The control method includes the following steps: A. enabling a piston of a first pump material device to move towards a first limit position of the first pump material device; B. enabling a piston of a second pump material device to move towards the first limit position of the second pump material device before the piston of the first pump material device reaches the first limit position; C. enabling the piston of the first pump material device to move from the first limit position to the second limit position of the first pump material device before the piston of the second pump material device reaches the first limit position of the second pump material device; D. enabling the piston of the second pump material device to move from the first limit position to the second limit position of the second pump material device before the piston of the first pump material device reaches the second limit position of the first pump material device; and E. returning to the step A before the piston of the second pump material device reaches the second limit position of the second pump material device. By means of the system, the method and the truck, driving devices of the two pump material devices can change direction in staggering mode (namely the actions of the two driving devices have certain coincidence area), and flow fluctuation of material outlets is avoided.

Owner:SANY AUTOMOBILE MFG CO LTD

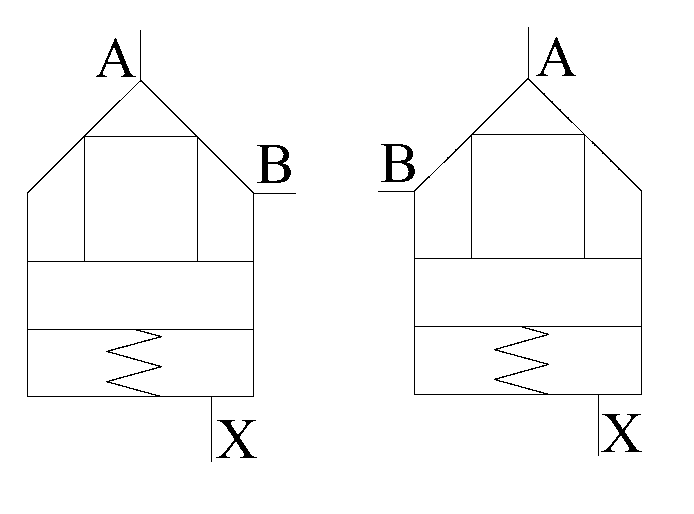

Powder accurate-weighing measurement feeding machine

InactiveCN107867502APrecise feedingEliminate "bridging" phenomenonLarge containersLoading/unloadingCuffSpherical form

A powder feeder with accurate weighing and metering, comprising a weighing hopper, a spherical bucket, a feeding cylinder, a container, a feeding twin screw, a gear box, a geared motor, a weighing platform, and a bellows load cell, characterized in that: The weighing hopper includes a cover plate and a cone. The feeding port of the weighing hopper is set in the center of the cover plate. There are air holes on one side of the cover plate. The upper part of the cone is connected with the cover plate through a clamp, and the lower part of the cone is connected through The hoop and the upper part of the spherical bucket are connected as a whole, and the lower part of the spherical bucket is connected as a whole with the feeding cylinder through the clamp, and one end of the feeding cylinder is connected with the container, and the feeding twin-screw is arranged in the feeding cylinder and the spherical bucket. The invention is equipped with a horizontal stirring paddle, which eliminates the "bridging" phenomenon of materials in the weighing hopper during feeding, ensures the continuity of feeding, has excellent resistance to mechanical vibration interference, and makes the feeding of materials reach For the purpose of accurate metering and stable feeding, the relative error of continuous weighing and metering feeding is ≤0.1%.

Owner:无锡艾特福机械设备有限公司

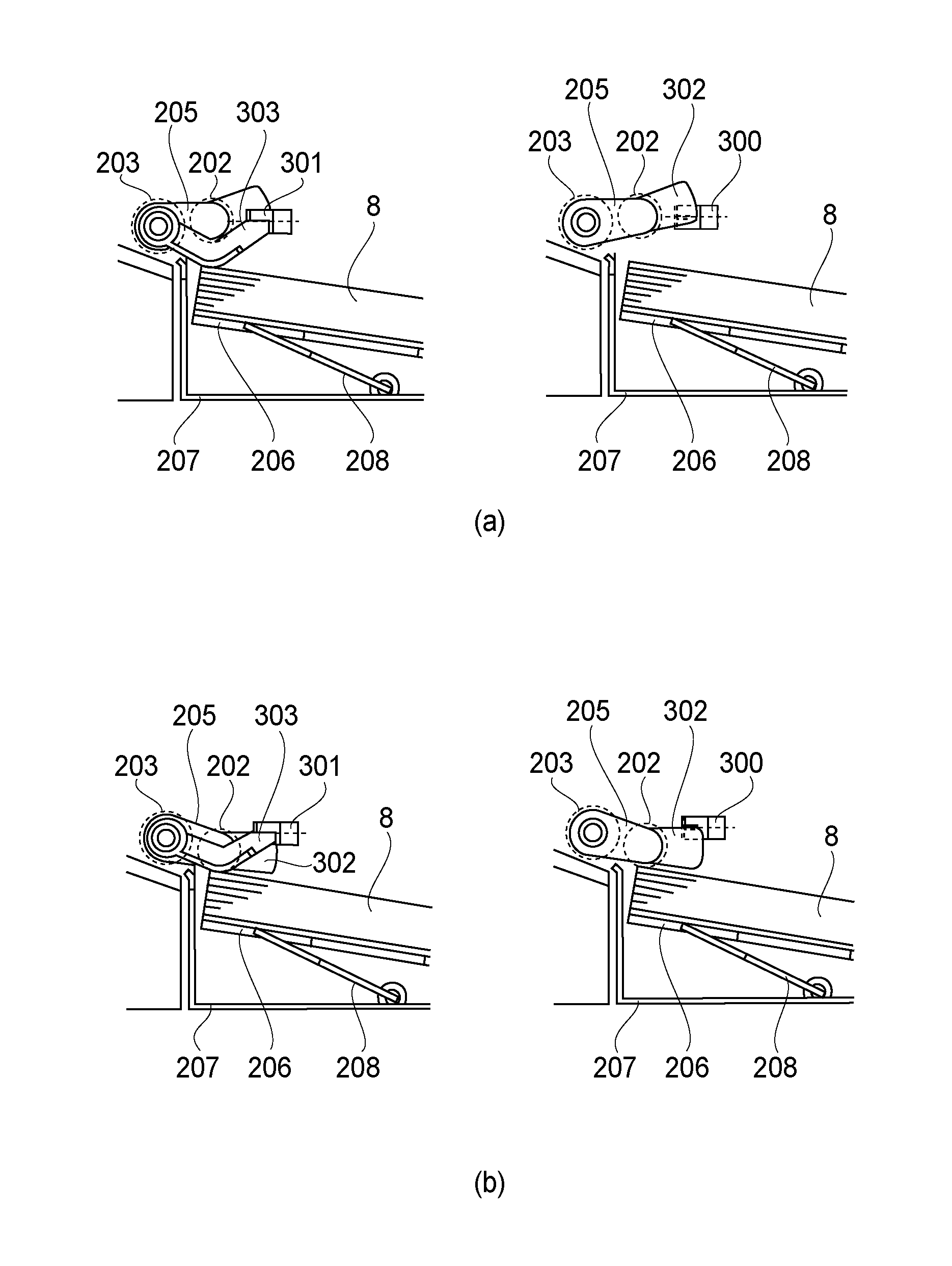

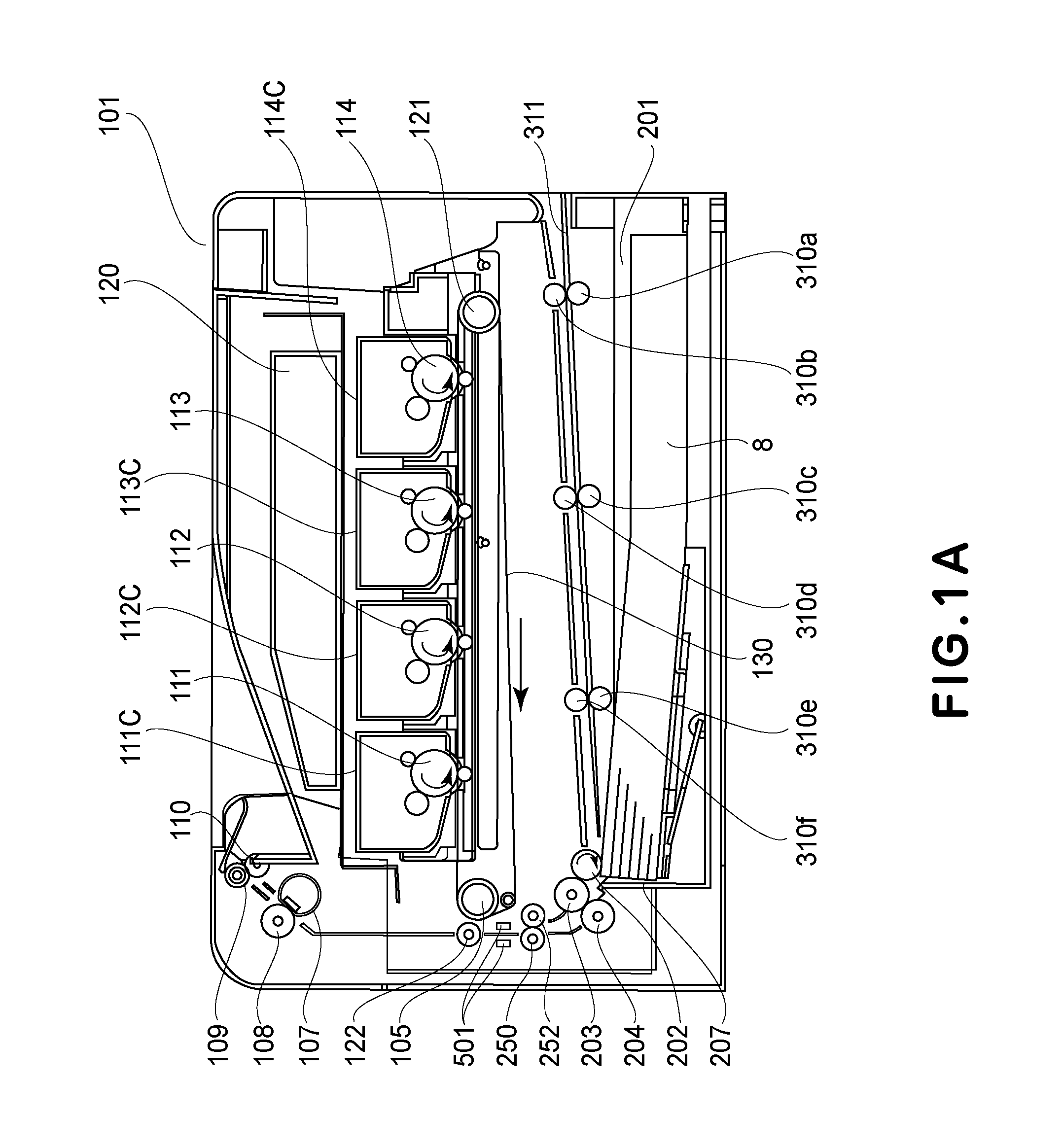

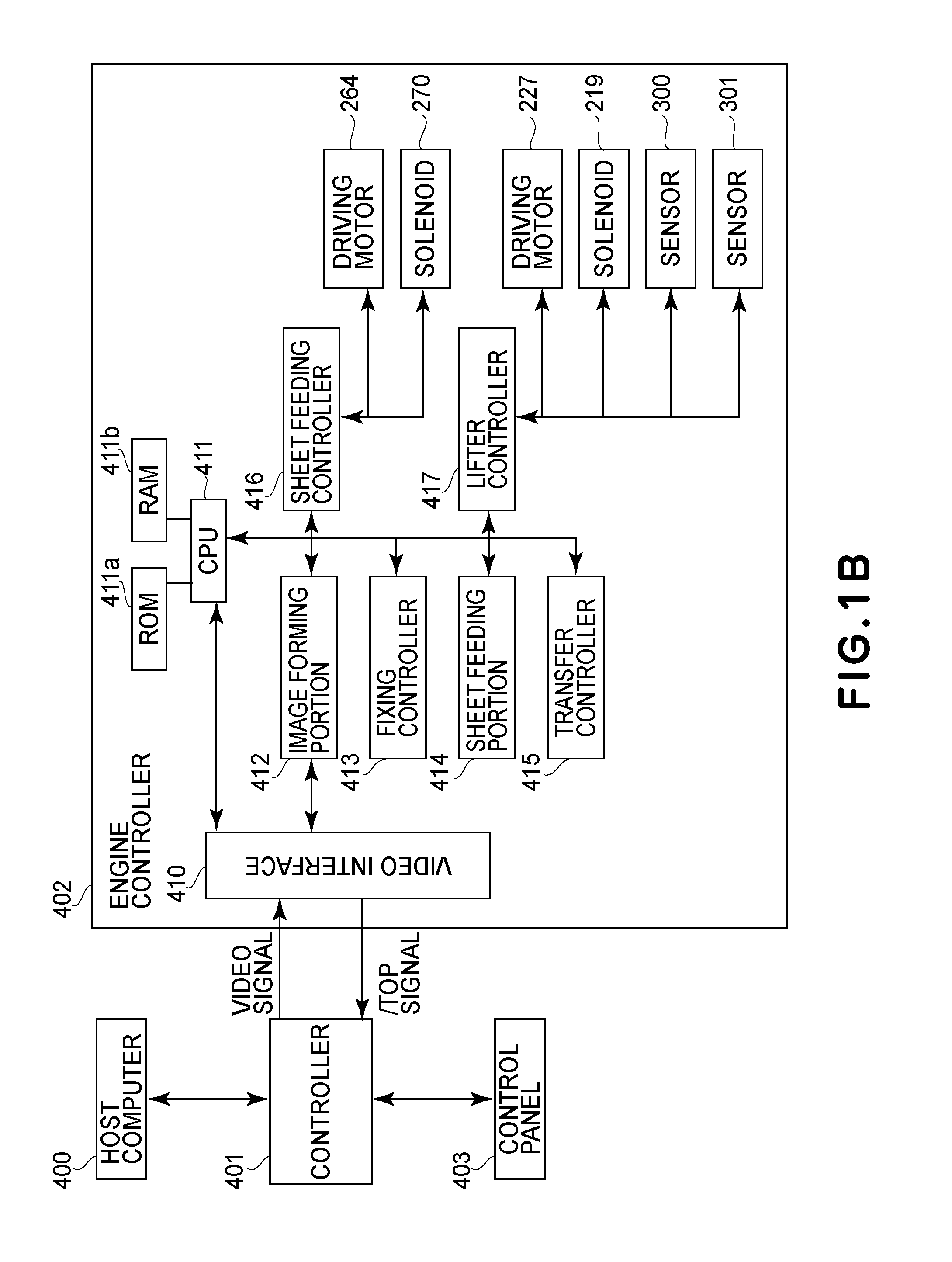

Sheet feeding device and image forming apparatus

InactiveUS20160355355A1Stable feedingStably feeding a sheet evenFunction indicatorsElectrographic process apparatusElectrical and Electronics engineering

Owner:CANON KK

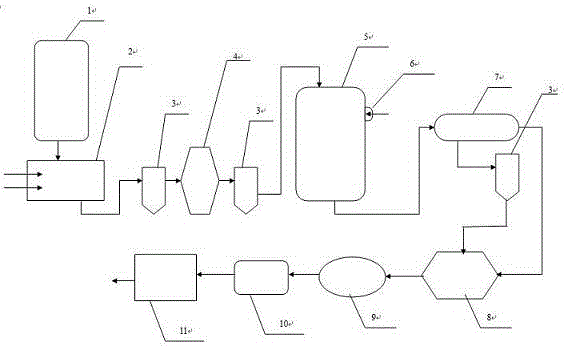

Technique and device for coproducing carbide slag cement in a dry-method acetylene process

ActiveCN102746086AReduced operating requirementsStable feedingCement productionHydrocarbonsSlagCarbon dioxide

The invention provides a technique and device for coproducing carbide slag cement in a dry-method acetylene process. The device comprises a carbide crushing system, a dry-method acetylene reaction system and a cement production system. The technique is implemented in a way that: liquid carbide from a carbide furnace is sent to a seal device under the action of gravity; the seal device is provided with an air flow nozzle; pressurized carbon dioxide is introduced to crush the liquid carbide; the crushed carbide is subjected to iron removal, crushing and iron removal, and sent to a dry-method acetylene reactor again; the metered carbide with small particle sizes falls into the dry-method acetylene reactor; the second section of the partition of the dry-method acetylene reactor is provided with an opening; eolian sand or furnace slag is added; and under the action of a stirring device, the eolian sand or furnace slag and the carbide slag are discharged out of the dry-method acetylene reaction system through the outlet of the dry-method reactor, and are sent to the cement production system. The invention solves the problems of high carbide crushing cost, incomplete reaction of carbide at the dry-method acetylene station, waste of carbide resources, low acetylene yield, high blockage tendency of the reactor, complex technique and the like.

Owner:XINJIANG TIANYE GRP +3

Grinder feeding system

InactiveCN105457734AStable feedingSmooth feedingGrain treatmentsProgrammable logic controllerLiquid level sensor

The invention discloses a grinder feeding system. The rear of a material outlet of a grinder is connected with a discharging pipeline; the discharging pipeline is connected with a filter; the filter is connected with a sealed transfer cylinder; a liquid level sensor is mounted on the transfer cylinder; the rear of the transfer cylinder is sequentially connected with a liquid inlet pump and a one-way valve; the rear of the one-way valve is connected with a feeding pipe of another rear grinder; a programmable logic controller (PLC) is connected with the liquid level sensor, the liquid inlet pump and each grinder through signals. The grinder feeding system can stably supply materials for the grinders.

Owner:CHANGSHU FANGTA COATING CHEM

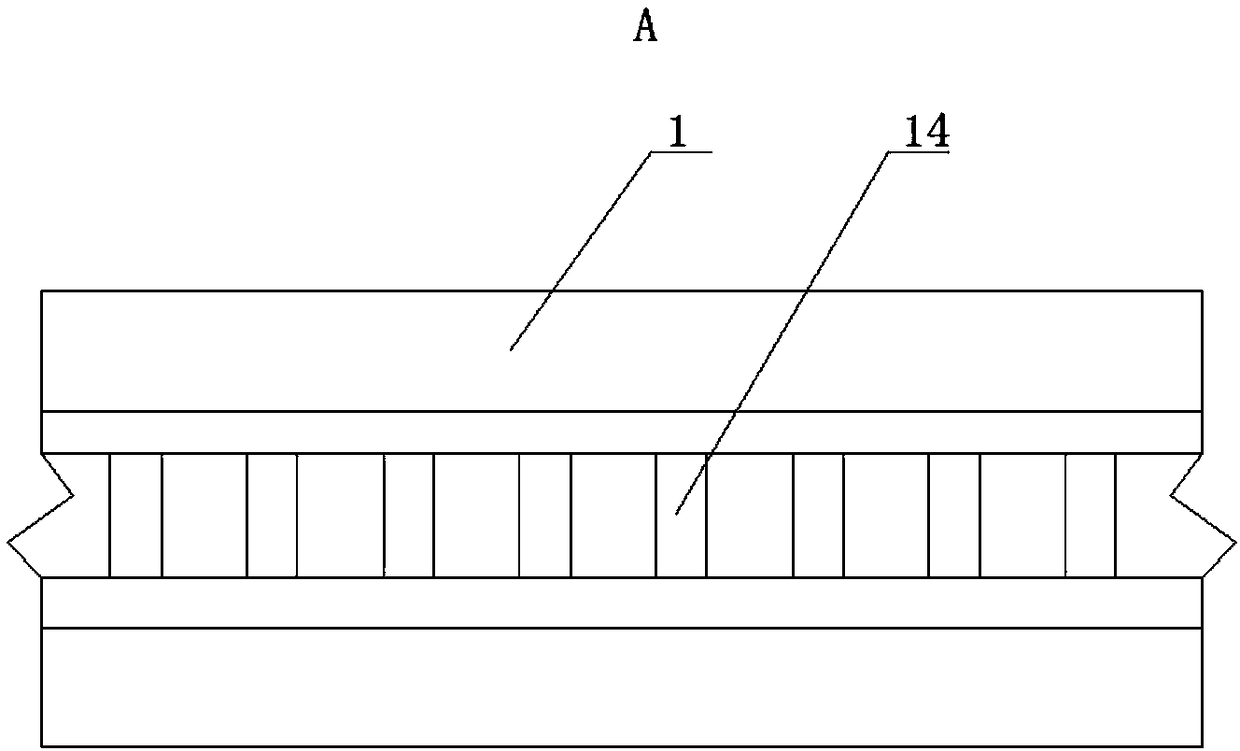

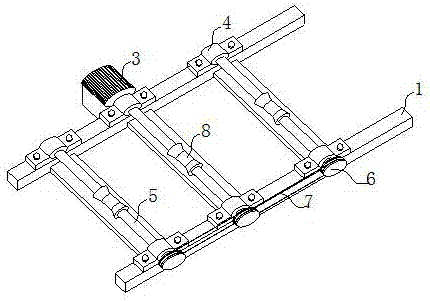

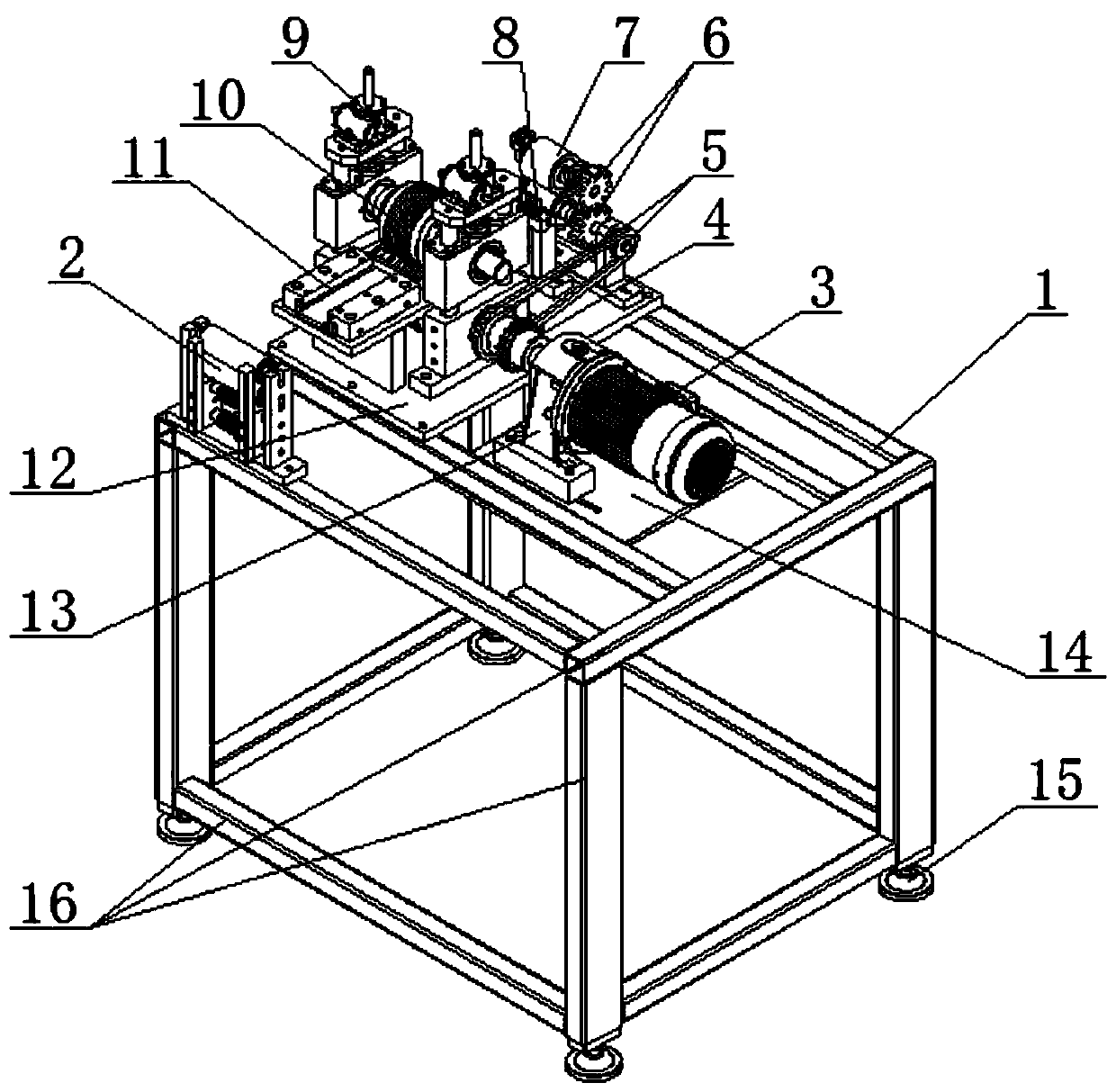

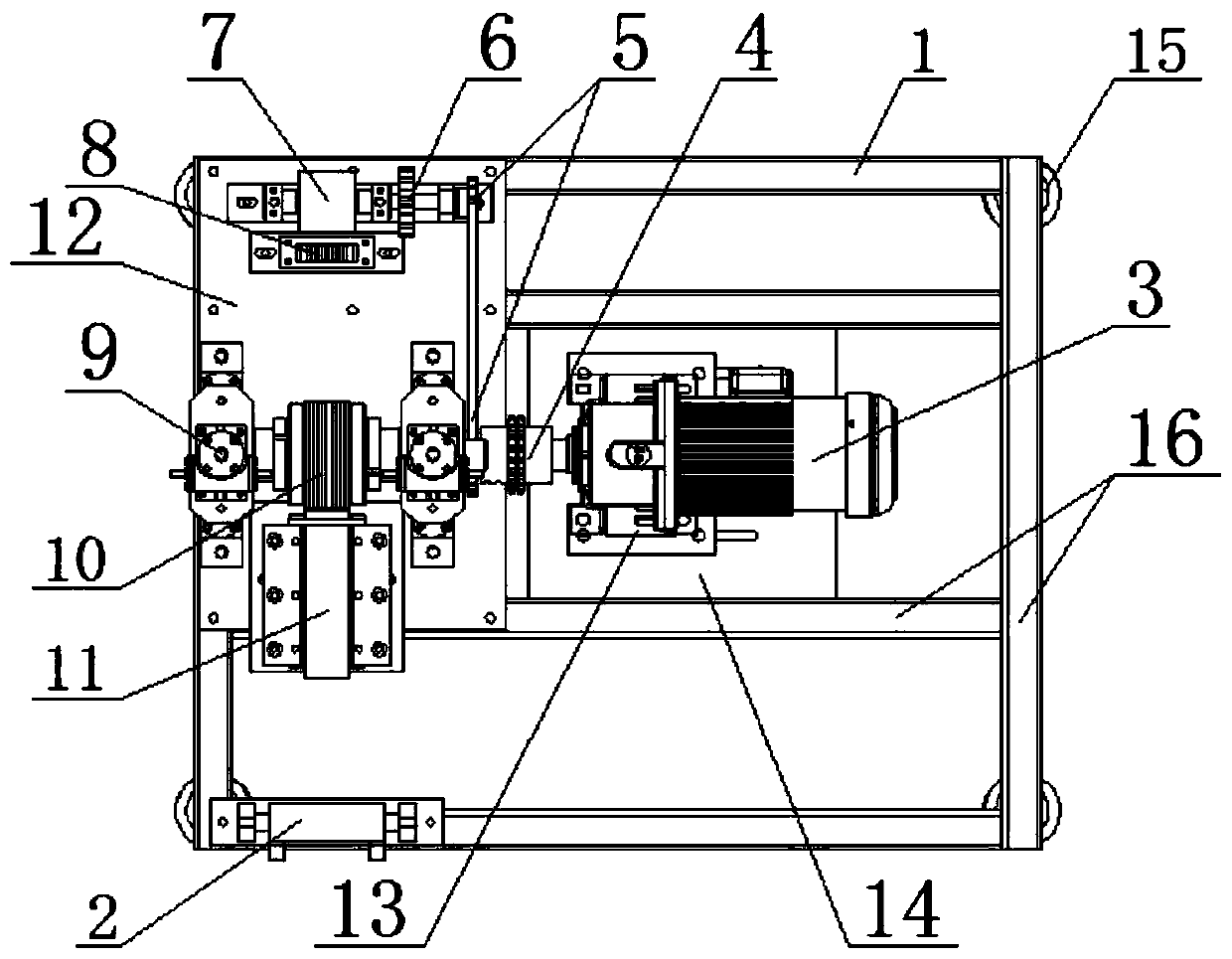

Automatic feeding machine for round bar parts

The invention discloses an automatic feeding machine for round bar parts. The automatic feeding machine comprises a material arranging lower support, the lower side of the material arranging lower support is connected with a plurality of mechanism ground feet through threads, the mechanism ground feet are distributed in a rectangular shape, rubber pads are fixed to the lower sides of the mechanismground feet, and gaskets are fixed to the lower sides of the rubber pads and used for increasing the supporting area and improving the stability; and a material frame supporting foot is fixed to theleft end of the upper side of the material arranging lower support, a material frame is fixed to the upper side of the material frame supporting foot, and the material frame comprises an outer material frame support and a bottom plate. The automatic feeding machine completely completes the bar feeding action and is small in occupied area, stable in feeding and small in product action range, and thus the automatic feeding machine is an efficient operation mechanism for feeding machining of bar parts; and a pure mechanism is adopted to act, so that the products are located at different regular positions in different time periods on one movement path, and stable feeding of the products is achieved.

Owner:聚鼎科技(苏州)有限公司

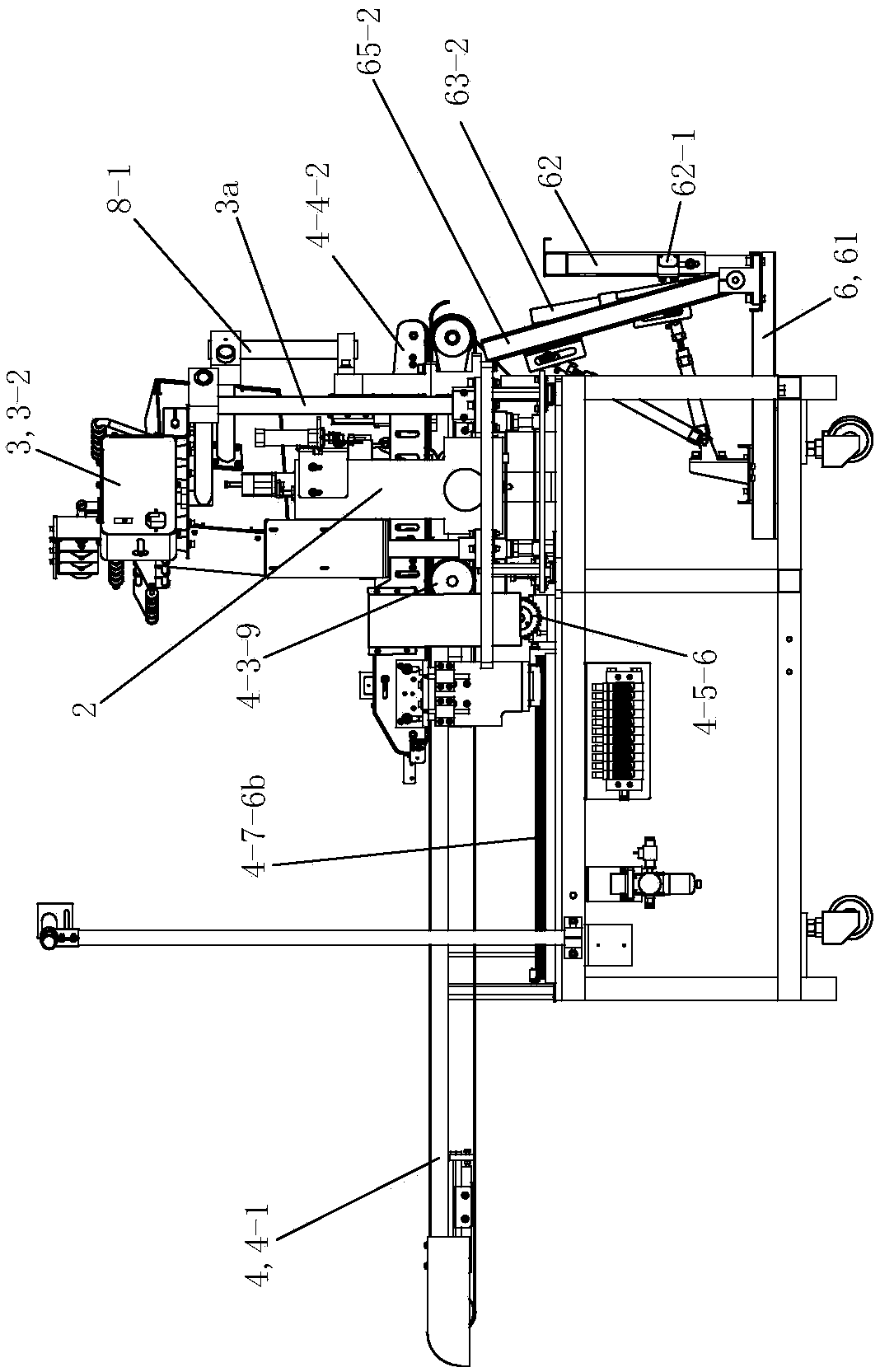

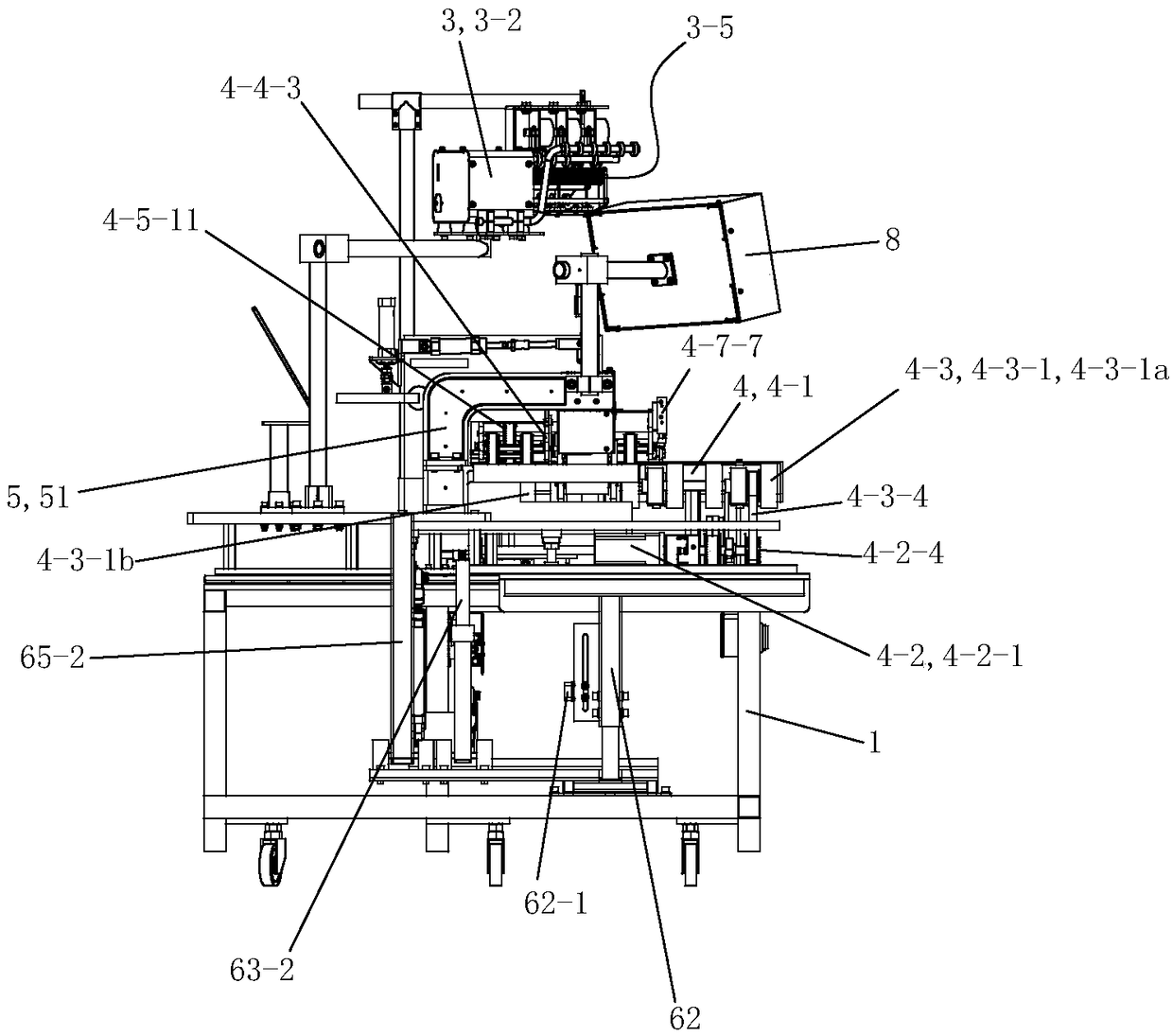

Box clamping, conveying and boxing system capable of automatically assembling rear covers

The invention discloses an automatic assembling rear cover clamping conveying box body packing system, comprising an assembly device, a rear cover assembling device and a box body packing device, wherein the assembling device includes a conveying component including a first A pusher, including a first pusher plate, the first pusher plate includes a first rack, and the first rack is a helical tooth; a blanking assembly; the rear cover assembly device, including a third The vibrating unit includes a third vibrating member and a third extending guide rod, and the material passes through the third vibrating member and is conveyed outward along the third extending guide rod; the box packing device includes a cover Box body; box body cover unit. The present invention provides a rear cover assembly device, which realizes automatic advancement through the second pusher, and the second baffle plate on the blanking member makes the material more stable during blanking, improves the pass rate of the product, and completes the assembly through automation, Improve work efficiency and save time and cost.

Owner:新朗思(新沂)智能科技有限公司

Cutting tool for cylinder sleeve base body

InactiveCN107414190AStable feedingIncrease contact areaMetal working apparatusPositioning apparatusDriving modeAutomation

The invention discloses a cutting tool for a cylinder sleeve base body. A clamping mechanism is located on the discharging side of a feeding device. The clamping mechanism comprises two oppositely-arranged clamping plates and first hydraulic cylinders, wherein the two clamping plates are located on the two sides of the cylinder sleeve base body correspondingly, and the clamping plates are connected with the movable ends of the first hydraulic cylinders in a driven mode and driven by the first hydraulic cylinders to move front and back. A cutting mechanism is located on the side, backing onto the feeding device, of the clamping mechanism. The cutting mechanism comprises a cutting wheel and a second hydraulic cylinder, wherein the cutting wheel is connected with the movable end of the second hydraulic cylinder in a driven mode and driven by the second hydraulic cylinder to draw close to or get away from the cylinder sleeve base body. A pushing mechanism is located on the side, backing onto the clamping mechanism, of the cutting mechanism. The pushing mechanism comprises a pushing plate and a third hydraulic cylinder, wherein the pushing plate is in the conveying direction of the cylinder sleeve base body, connected with the movable end of the third hydraulic cylinder in a driven mode and driven by the third hydraulic cylinder to move horizontally. According to the cutting tool for the cylinder sleeve base body, manual attendance is not needed in the cutting process, labor intensity is relieved, and the automation degree is improved.

Owner:ZYNP GRP ANHUI CO LTD

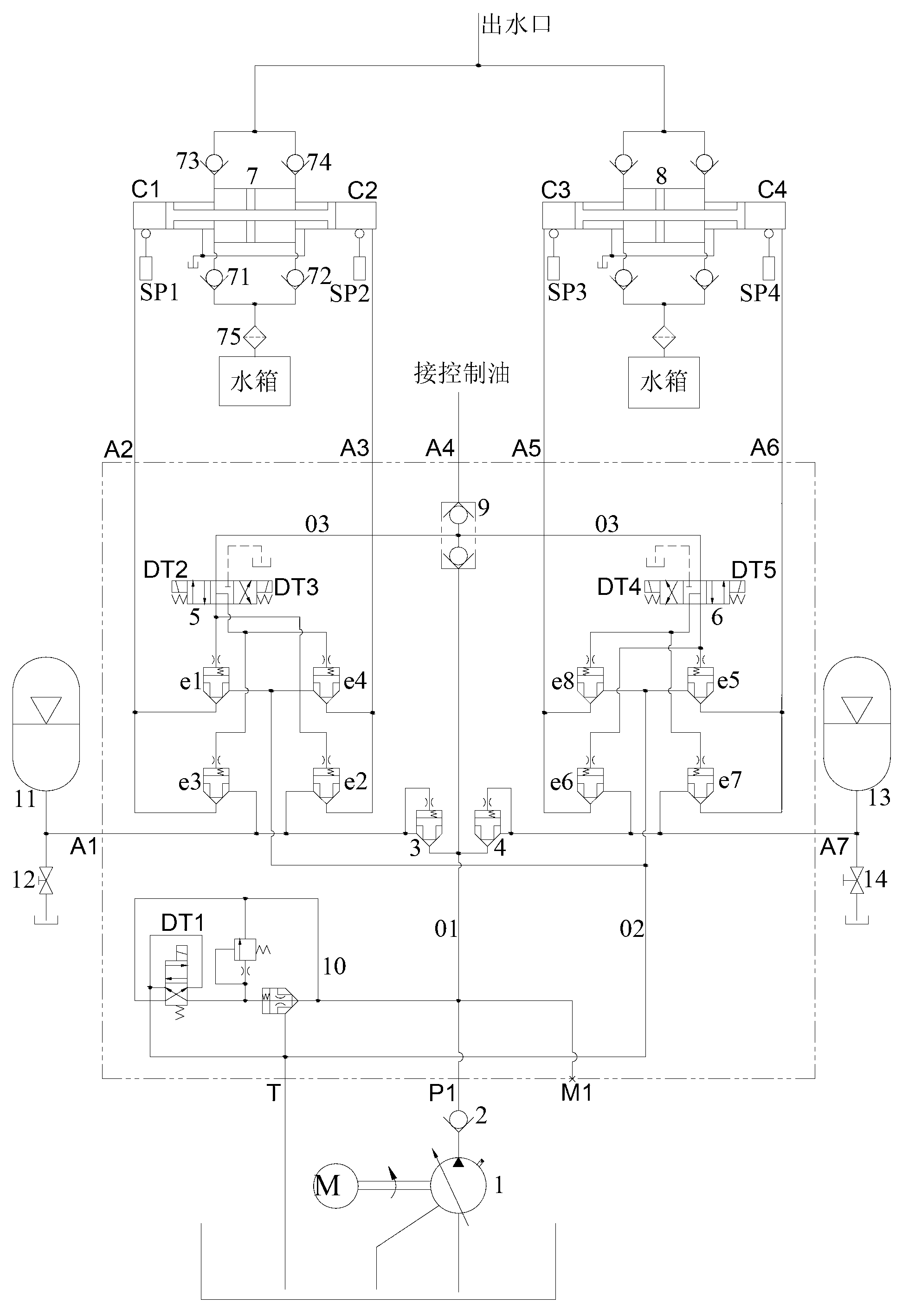

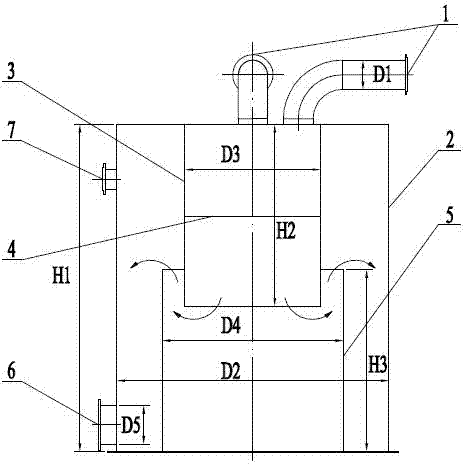

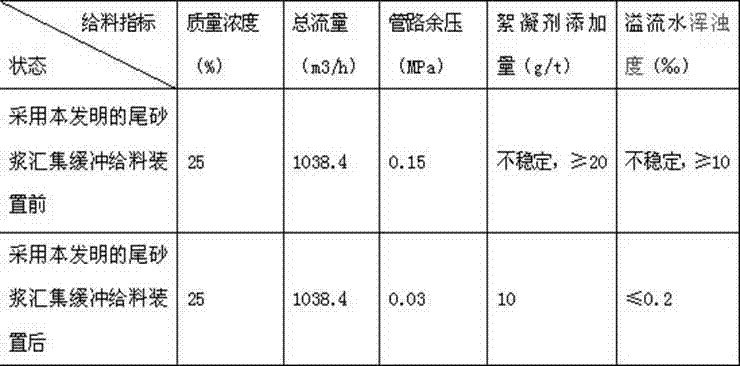

Tailing slurry collection buffering feeding device and method

The invention relates to a tailing slurry collection buffering feeding device and method. The device comprises a box, a flow guiding collection barrel, a mixed overflowing buffering barrel, a feeding pipe, a discharging pipe and a sieve, wherein the box is provided with a top plate and a base, the flow guiding collection barrel is fixed below the top plate of the box and extends downwards in the height direction of the box, the mixed overflowing buffering barrel is fixed above the base of the box and extends upwards in the height direction of the box, the feeding pipe is communicated with an inner cavity of the flow guiding collection barrel, the discharging pipe is arranged at the lower portion of the side wall of the box, and the sieve is arranged inside the flow guiding collection barrel. The upper edge of the mixed overflowing buffering barrel is not lower than the lower edge of the flow guiding collection barrel. The barrel diameter of the mixed overflowing buffering barrel is larger than that of the flow guiding collection barrel, and an annular overflowing opening is formed between the mixed overflowing buffering barrel and the flow guiding collection barrel. An annular buffering space is formed between the mixed overflowing buffering barrel and the side wall of the box. Collection, mixing, pressure reduction and energy dissipation of tailing slurry are achieved, so that the tailing slurry is stably and slowly fed to a tailing slurry concentration and storage facility for filling.

Owner:中冶北方(大连)工程技术有限公司

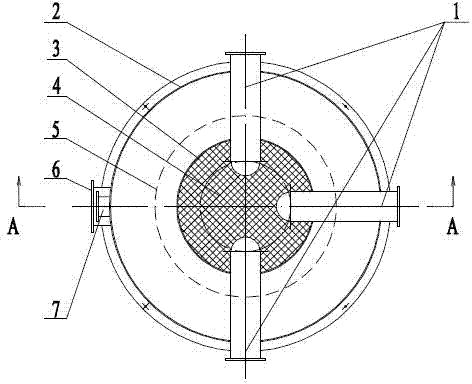

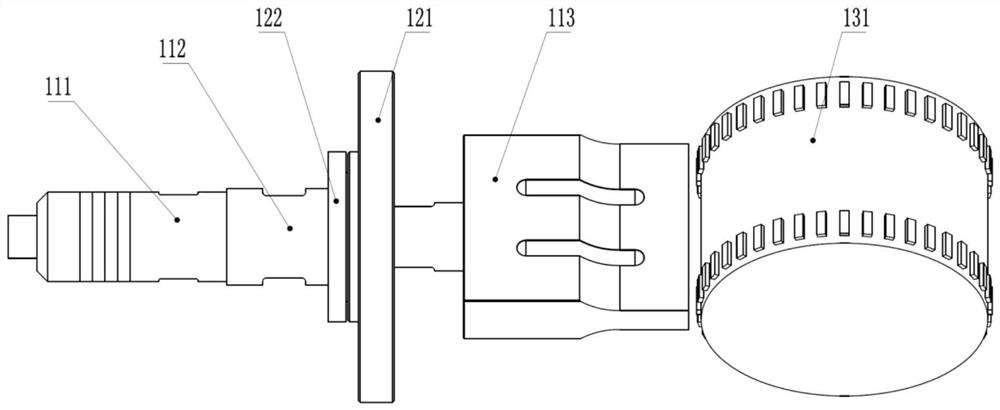

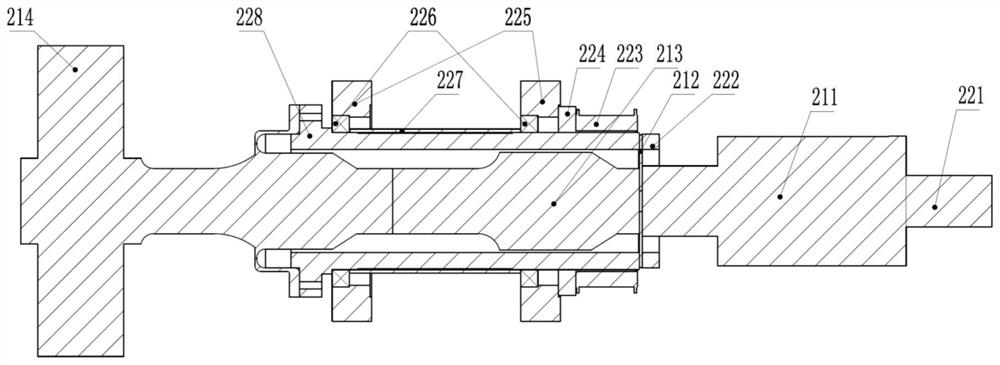

Longitudinal-radial coupled vibration ultrasonic rolling welding device

The invention relates to an ultrasonic equipment technology, and aims to provide a longitudinal-radial coupled vibration ultrasonic rolling welding device. The device comprises an ultrasonic vibration part and a fixed clamping part, a cylindrical fixed shell is coaxially arranged outside an amplitude-change pole in a sleeving mode, and one end of the cylindrical fixed shell is fixedly connected with a flange, protruding in the radial direction, on a roll welding tool head; a synchronous pulley and two bearings are coaxially arranged outside the fixed shell in a sleeving mode, a bearing positioning sleeve is arranged between the two bearings to keep a distance, and outer rings of the bearings are fastened and mounted in a supporting plate; and a conductive slip ring is coaxially and fixedly connected to the end part of a transducer shell. According to the device, the conflict coordination problem existing in the ultrasonic isolation, fixing and rotating modes of a longitudinal-radial coupling vibration system in the prior art is solved, the optimal vibration effect of the ultrasonic vibration part can be ensured, ultrasonic waves are effectively isolated at the vibration frequency, and meanwhile, the high-speed rotating function of the ultrasonic vibration part is realized.

Owner:HANGZHOU SUCCESS ULTRASONIC EQUIP

Feeding system for viscous powdery material

InactiveCN104492536AClean up thoroughlyExtended service lifeCement productionGrain treatmentsEngineering plasticEngineering

The invention discloses a feeding system for a viscous powdery material, belonging to the technical field of the industries, such as cementing, metallurgical mine and chemical engineering. The feeding system for the viscous powdery material, which is disclosed by the invention, is characterized in that a feeding articulated chute is arranged on the main body of a high-pressure roller mill; and an engineering plastic plate with ultra-high molecular weight is lined on the wall of the feeding articulated chute. According to the feeding system for the viscous powdery material, which is disclosed by the invention, the adhesion and blockage problems of the viscous powdery material in the aspects of materials, structures, external influence and the like are solved; continuous, steady, uniform and saturated feeding of the high-pressure roller mill can be ensured; and the good working prerequisite conditions of the high-pressure roller mill can be satisfied.

Owner:CHENGDU LEEJUN TECH CO LTD

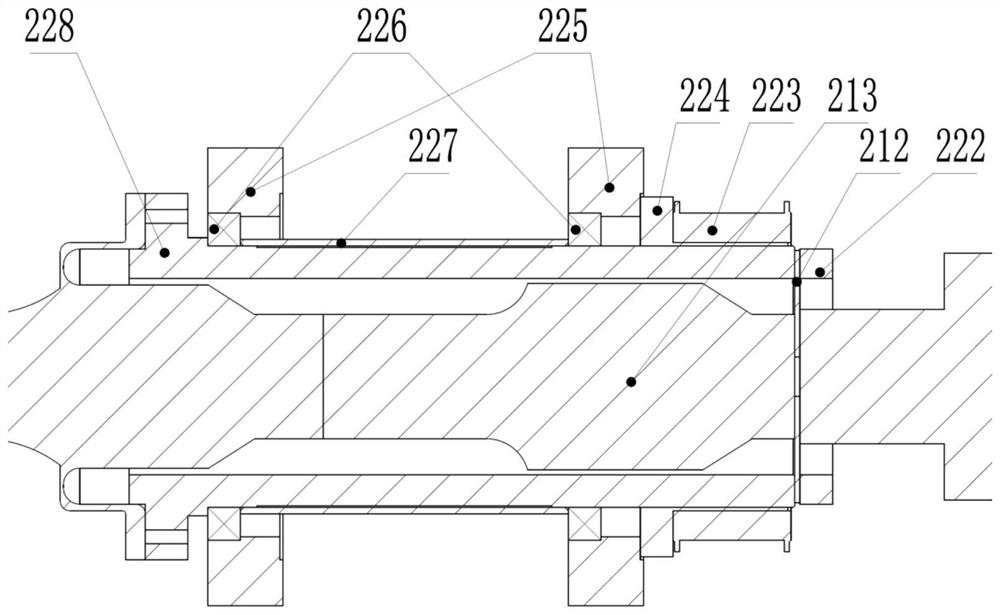

Double-die carrying hand structure of flower basket cover

ActiveCN105033084AStable feedingIncrease productivityMetal-working feeding devicesPositioning devicesEngineeringHand structure

The invention provides a double-die carrying hand structure of flower basket cover. Two flower basket covers can be manufactured via one time punching operation; stable material carrying is achieved; and production efficiency is improved and potential safety risks can be prevented. The double-die carrying hand structure comprises a bed body. Two pairs of upper dies and lower dies are arranged on the bed body; the two upper dies are horizontally arranged side by side in a transverse way; the lower end of a gantry punching head is connected to the two upper dies connected to the lower end via connection members; the double-die carrying hand structure further comprises an upper slide block; the upper slide block is connected with the upper dies and slide with the same; a pair of carrying rods are arranged between each pair of upper die and lower die; each pair of carrying rods are formed by two carrying rods; each carrying rod is provided with a conveyor belt structure along a length direction; a rotating wheel is disposed in the carrying rod to drive the conveyor belt structure; each carrying rod is provided with a bearing structure; the bearing structure can drive the bearing rod to move in a horizontal transverse way; the bearing structures corresponding to the four carrying rods are respectively covered with a spline shaft; two ends of each spline shaft are respectively supported on two sides of the front end of the bed body.

Owner:SUZHOU HYCAN HLDG CO LTD

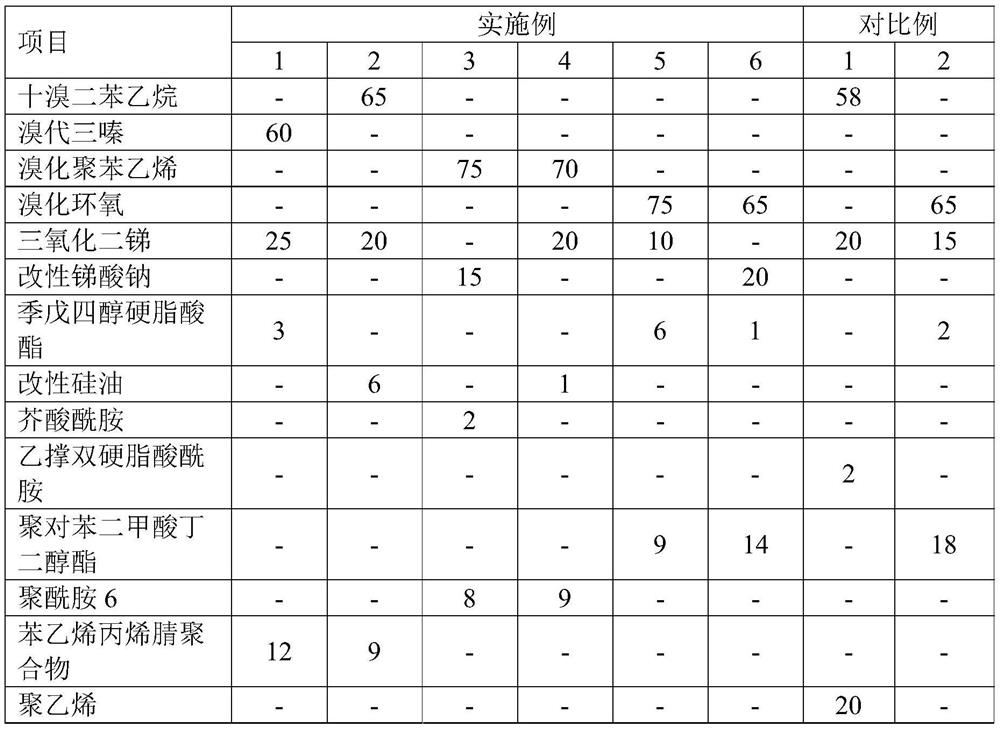

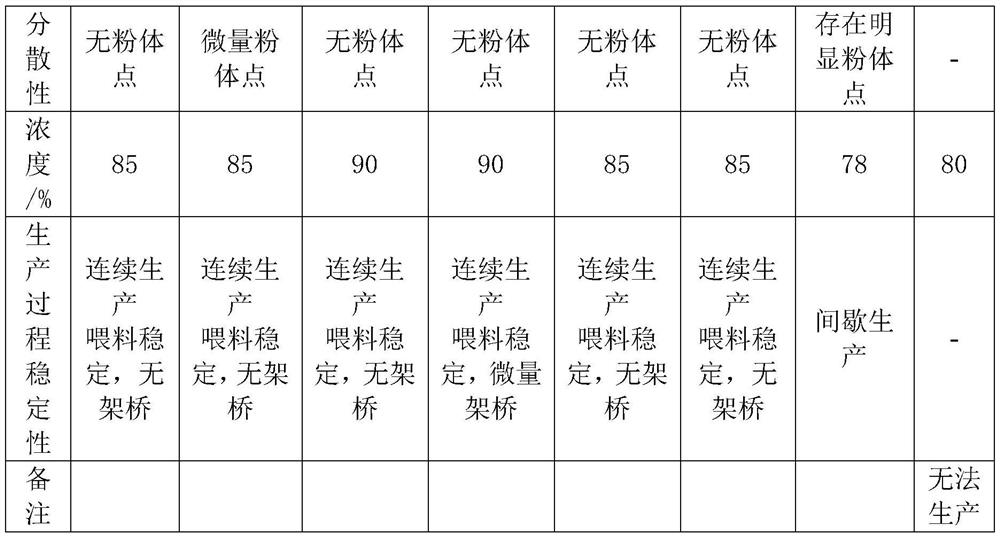

High-concentration engineering plastic flame-retardant master batch and preparation method thereof

The invention belongs to the field of functional master batches, and particularly relates to a high-concentration engineering plastic flame-retardant master batch and a preparation method thereof, and the flame-retardant master batch comprises the following components by mass: 60%-75% of a brominated flame retardant, 10%-25% of a synergistic flame retardant, 5%-15% of carrier resin, and 1%-6% of a dispersant. The concentration of the engineering plastic flame-retardant master batch prepared by the preparation method is far higher than that in the prior art, and stable and continuous production can be realized.

Owner:江苏艾泰柯新材料科技有限公司

Steel strip dividing and cutting machine and method

PendingCN110000423AConvey straightStable feedingShearing machinesShearing machine accessoriesSteel beltCombined use

The invention discloses a steel strip dividing and cutting machine which comprises a machine frame, a holding roller assembly, a motor, a coupler, a transmission structure, a gear set, pressure rollers, a cutter structure, a feeding adjusting frame, feeding rollers, a material pressing frame, a dividing and cutting part bottom plate, a motor base and a motor bottom plate. The invention further provides a steel strip dividing and cutting method. The method comprises the first step of clamping, the second step of feeding roller position adjustment and the third step of dividing and cutting. Holding rollers, the material pressing frame and the feeding rollers can be used for clamping and conveying a steel strip, conveying is flatter, and feeding is stable, the steel strip can be uniformly cutby utilizing cutters arranged at equal intervals; the distance between the feeding rollers can be adjusted, the pressure rollers and the feeding rollers are combined for use, pressure is applied to the steel strip, and accordingly dividing and cutting are more thorough.

Owner:浙江天弘新材料有限公司

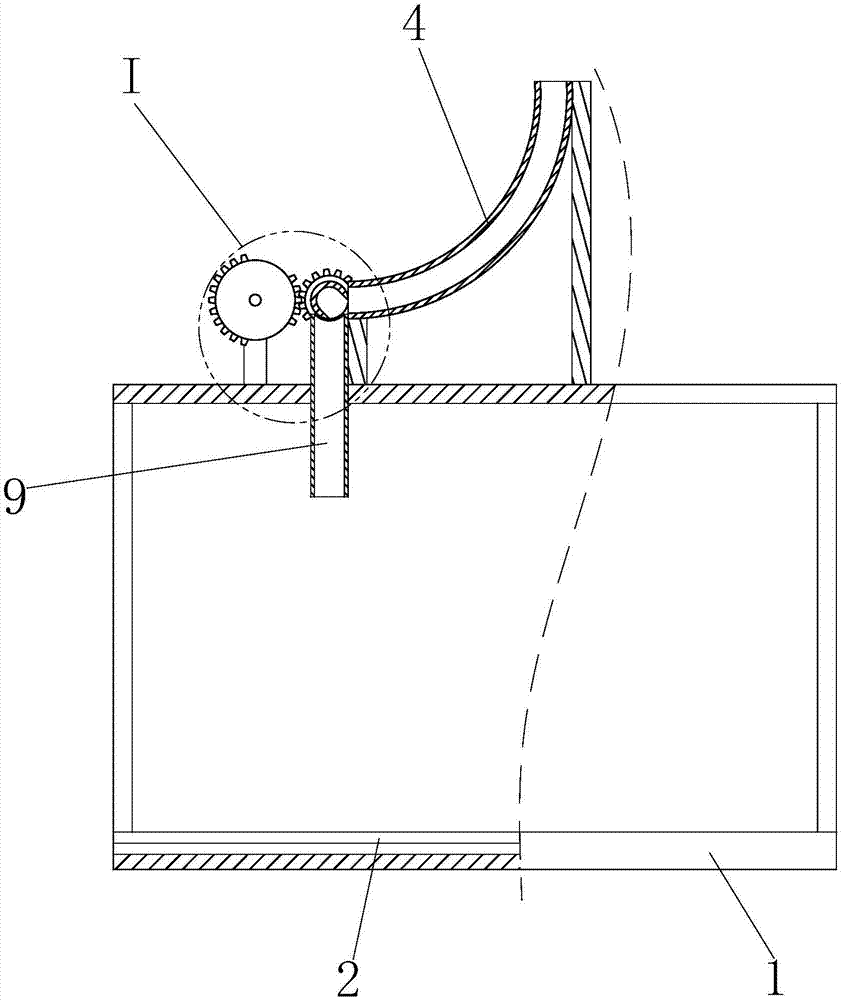

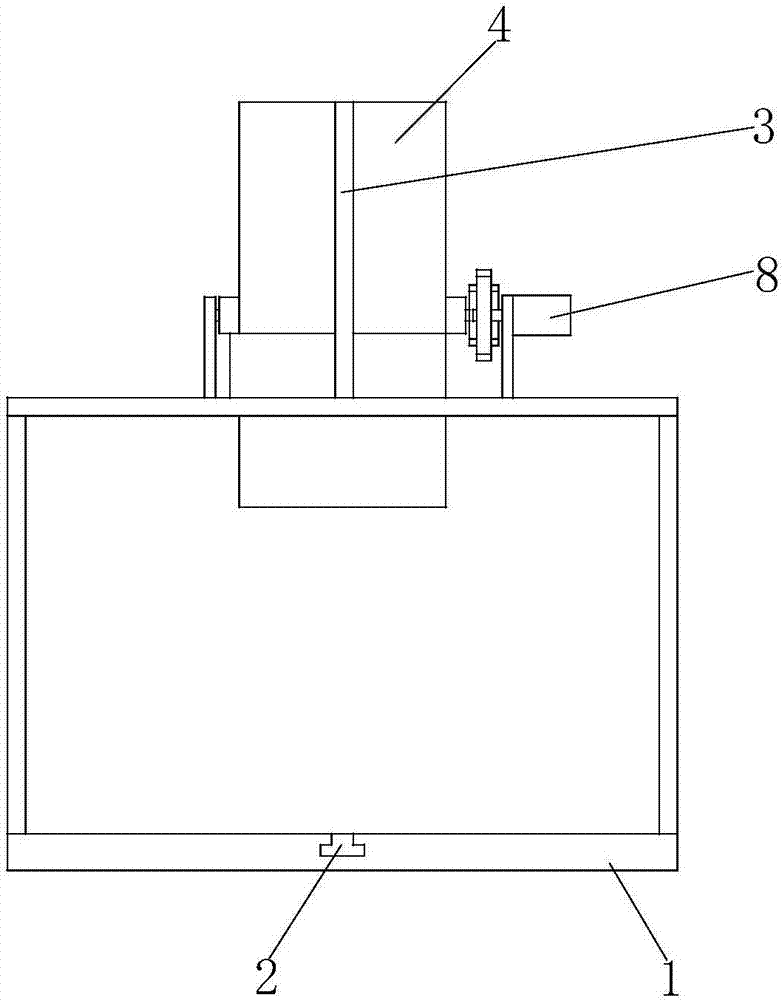

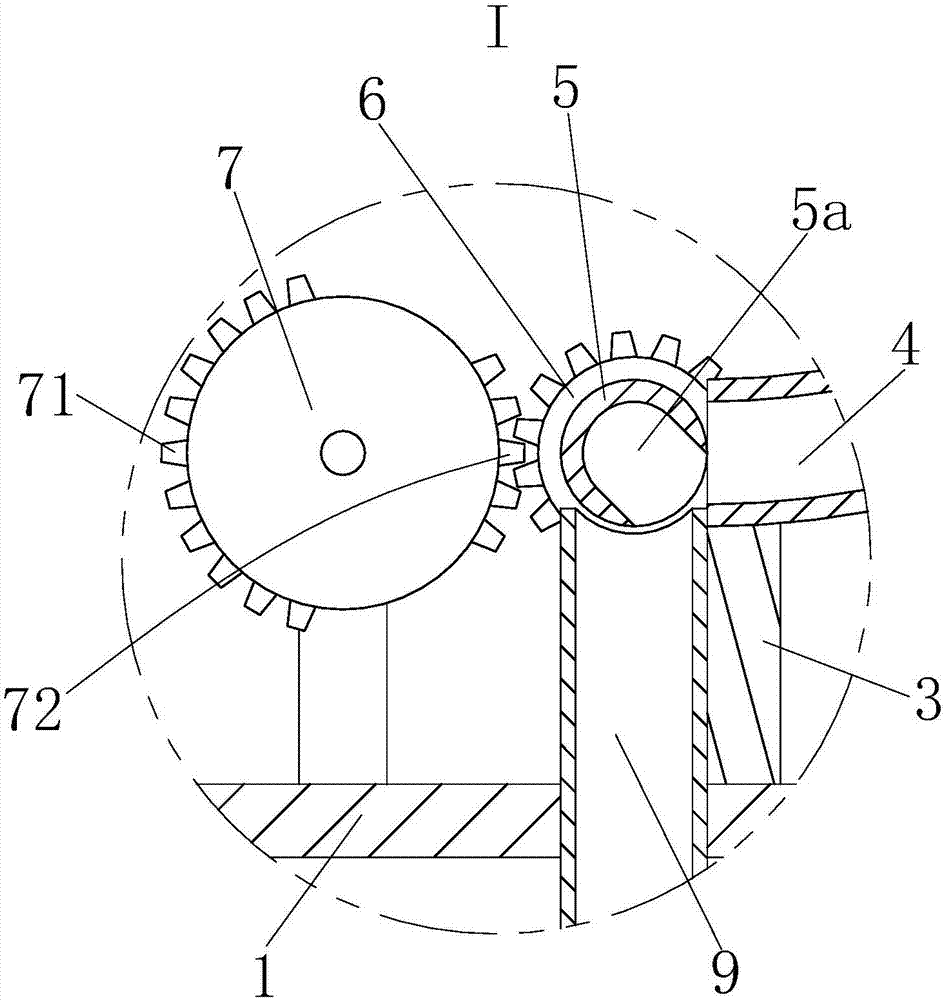

Feeding device for aluminium pipe cutting processing line

InactiveCN107336065AHigh degree of automationStable feedingMetal working apparatusAluminiumEngineering

The invention relates to a feeding device for an aluminum tube cutting and processing line, which comprises a double-layer frame, the bottom of which is provided with a chute; the upper end of the double-layer frame is welded with a supporting column, and an arc-shaped Inlet pipe passage, the lower left end of the inlet pipe passage is abutted with a round frame, the round frame is provided with a storage slot, and the lower end of the round frame is abutted with a discharge pipe; the rear end of the round frame is connected with a spur gear in a coaxial manner, and the spur gear The left side is provided with the incomplete gear that matches spur gear, and incomplete gear is connected with. The invention has a high degree of automation. Through the structure of incomplete gears, the round frame can be controlled to rotate at a constant speed, and then stop at two constant positions in the circumferential direction, so as to achieve the one-by-one and intermittent feeding of aluminum tubes. effect, and the supply is stable.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

Decoration strip feeding device

PendingCN108708090AStable feedingThe equipment runs stablyWorkpiece carriersWork-feeding meansEngineeringFeeding drive

The invention discloses a decoration strip feeding device. The decoration strip feeding device comprises a feeding drive motor, a drive roller and a pressing wheel component and is characterized in that the feeding drive motor drives the drive roller to rotate, the pressing wheel component tightly presses a decoration strip onto the drive roller, the decoration strip is pulled out from a corresponding discharge plate under the joint effect of the pressing wheel component and the drive roller, and accordingly the decoration strip in a loose state when the decoration strip enters a correspondingsewing equipment folder.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

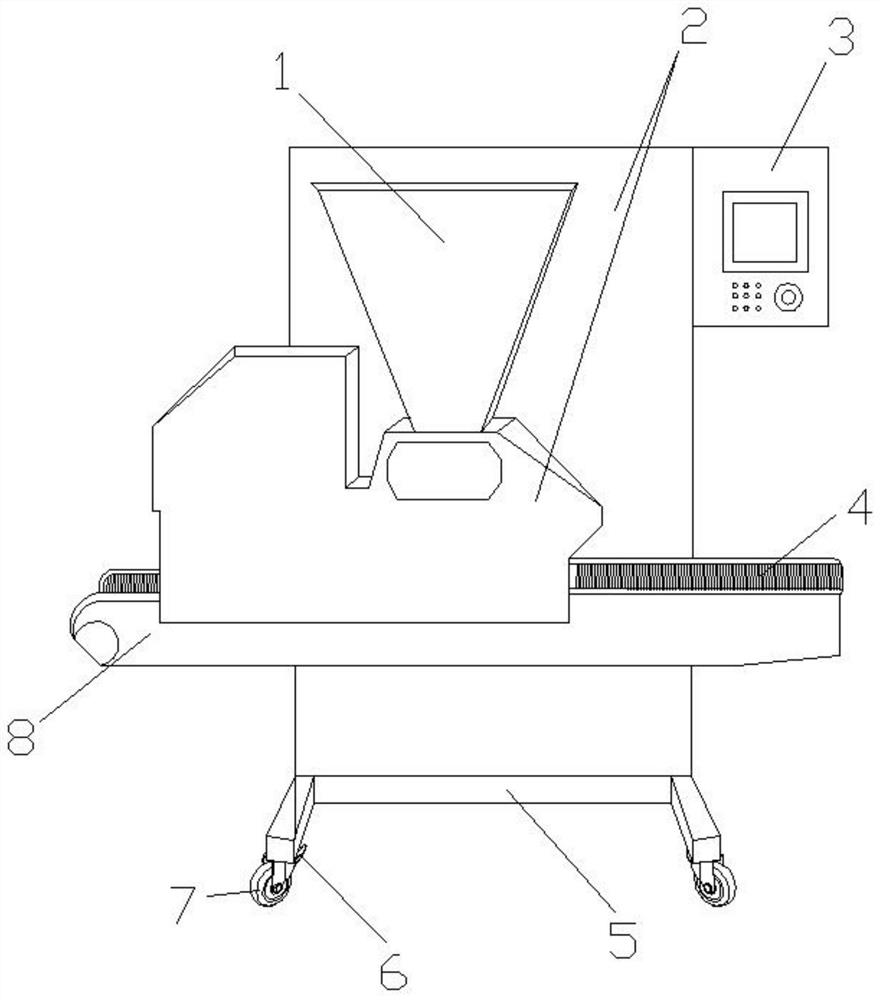

Plastic film blowing machine

The invention discloses a plastic film blowing machine. The plastic film blowing machine comprises a slow flow particle hopper, a main body machine box, a control box, a conveying table top, a support, a buckle rod, roller wheels and a conveying bearing platform, the bottom of a speed regulation particle hopper is connected with the main body machine box, the conveying bearing platform is connected with the slow flow particle hopper through the main body machine box, the main body machine box is connected with the conveying bearing platform 8, the conveying table top is arranged on the conveying bearing platform, the bottom of the main body machine box is connected with the top of the support, the roller wheels are arranged at the bottom of the support, materials are cushioned from a cushioning sliding surface and enter the slow flow disc for first-step flow distribution, material particles fall down from a slow flow hole by rotating and sweeping of a sweeping rod, the slow flow disc serves as a secondary flow distribution, the number of the slow flow holes of the slow flow disc is different, the secondary flow distribution is also different, the secondary flow distribution and discharging speeds are controlled through two times of flow distribution, so that discharging is stable, blockage is not easy to occur, the particles are heated and ground more sufficiently, and the film blowing quality is improved.

Owner:泉州市天创信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com