Household direct-fired heating appliance using compressed straw as fuel

An equipment, direct combustion technology, applied in solid heating fuels, applications, household appliances, etc., can solve the problems of high frictional resistance, increased power consumption of low-speed motors, smoke, etc., to achieve the effect of stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

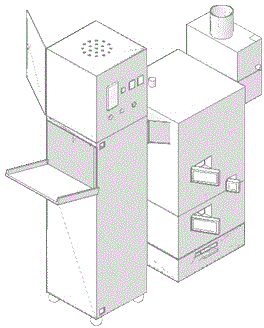

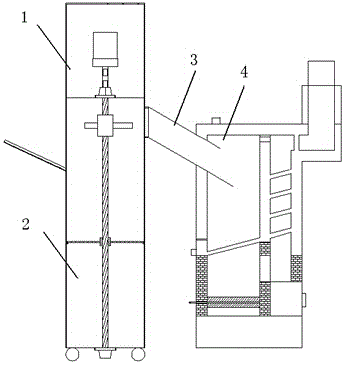

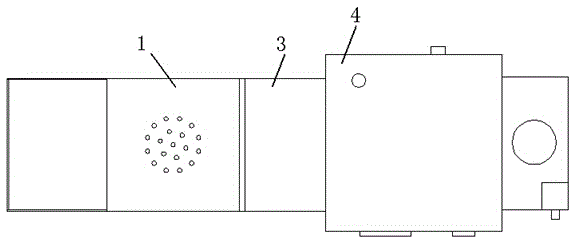

[0048] Specific description is as follows with reference to accompanying drawing:

[0049] Figure 2 to Figure 4 Middle, 1. Motor box; 2. Fuel tank; 3. Forehearth; 4. Heating furnace; 5. Speed-regulating motor; 6. Coupling; 10. Limit switch; 11. Feed inlet; 12. Discharge port; 13. Ground cow; 14. Control circuit box; 15. Feed inlet cover; 16. Roller; 17. Overrunning clutch; 18. Radiation protection Baffle; 19. Water-cooled grate; 20. Shaking grate; 21. Combustion channel; 22. Secondary air chamber; 23. Ash bucket; 24. Convection tube bundle; 25. Water jacket; 26. Smokestack; 27. Smoke 28. Waste heat recovery water jacket; 29. Balance pipe; 30. Cold water inlet; 31. Hot water outlet; 32. Main combustion chamber; 33. Secondary combustion chamber; 34. Insulation wall; 35. Water-cooled partition; 36 , pressure reducing valve; 37, grate handle. Figure 9 Middle, 38, motor; 39, electromagnetic relay; 40, day mode time relay; 41, night mode time relay; 42, day, night mode switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com