Steel strip dividing and cutting machine and method

A slitting machine and steel strip technology, applied in shearing devices, shearing machine accessories, transportation and packaging, etc., can solve the problems of unstable steel strip feeding, uneven cutting, incomplete cutting, etc., to achieve Thorough slitting, stable feeding, and straight delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

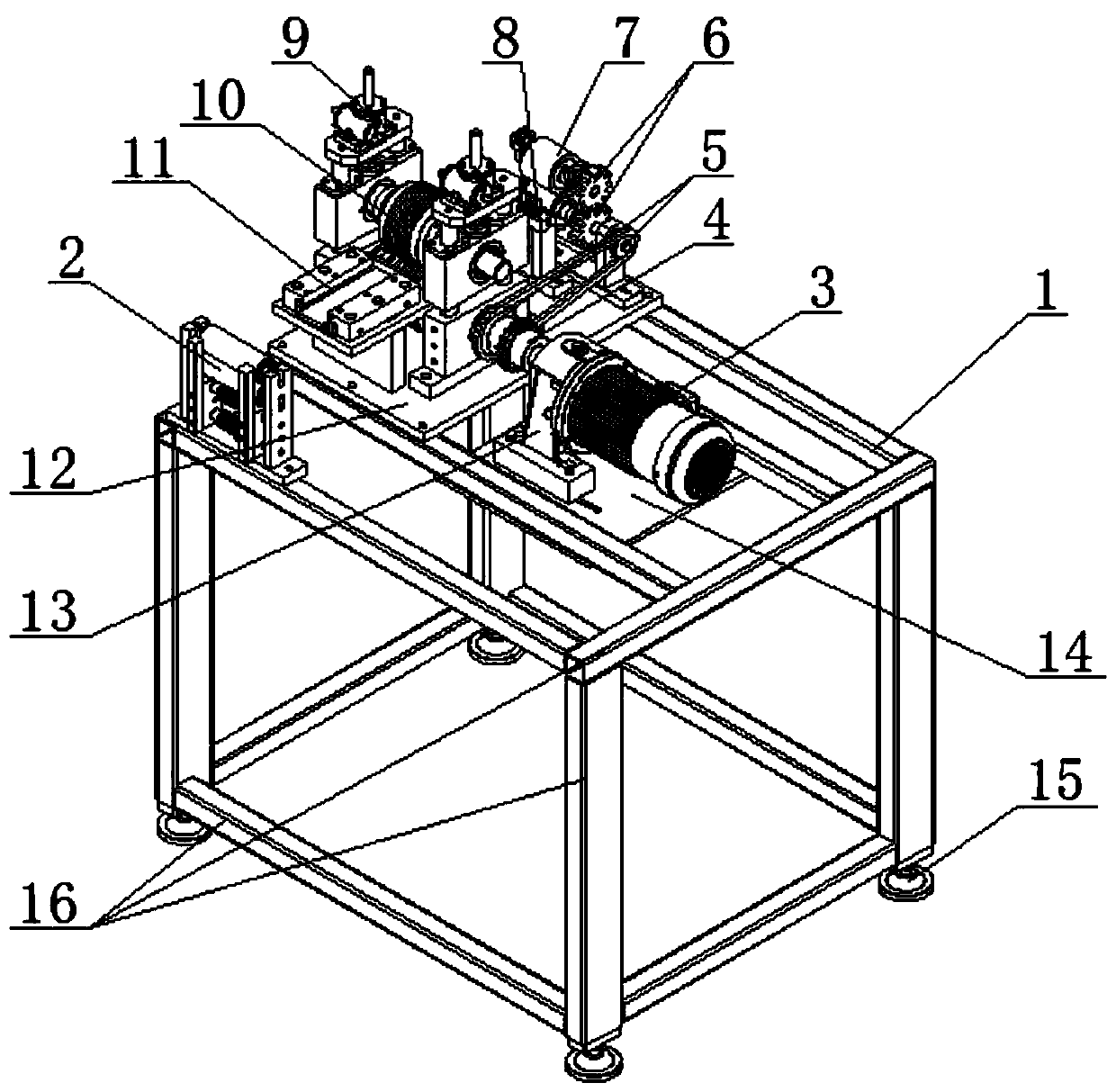

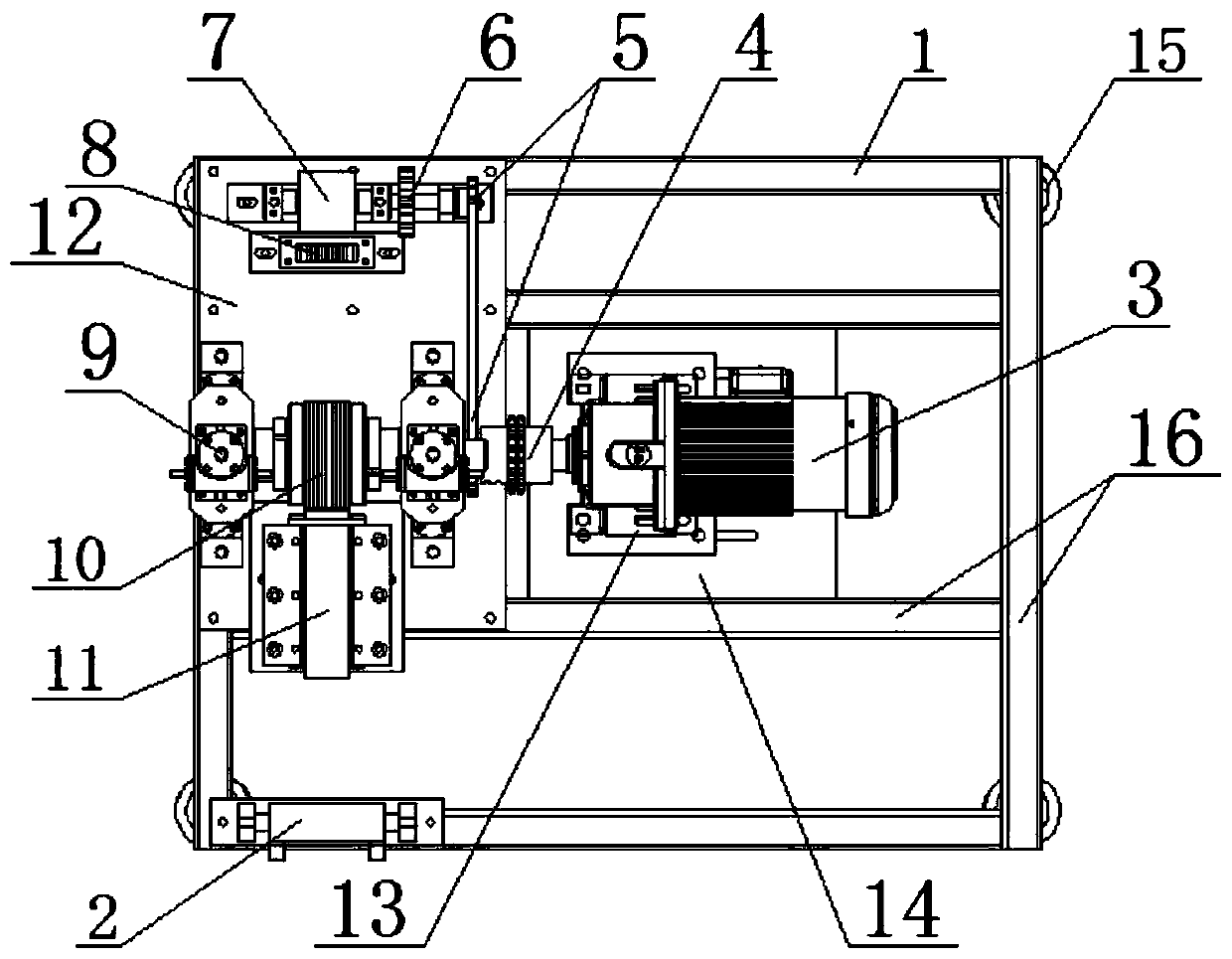

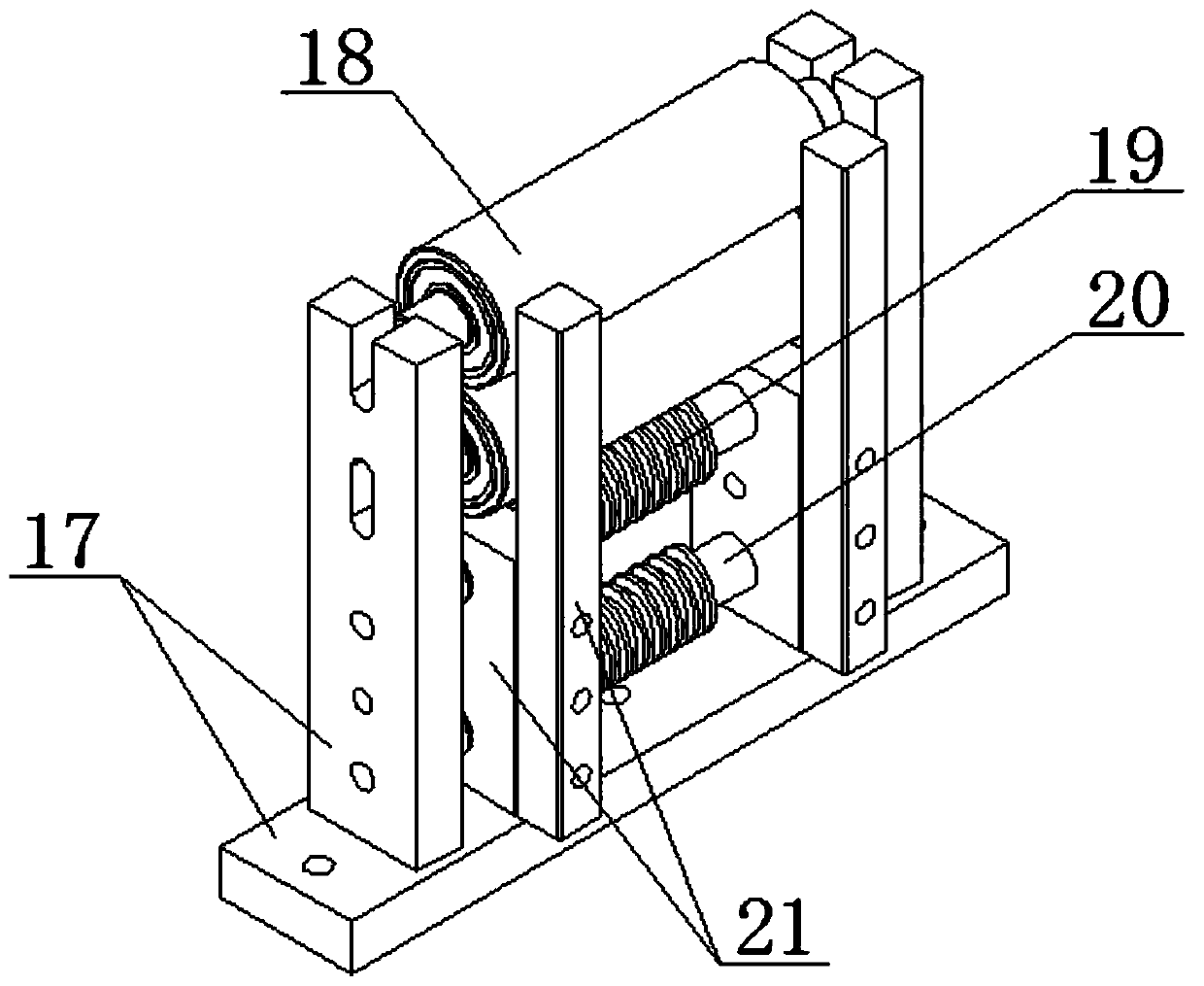

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention includes frame 1, holding roller assembly 2, motor 3, coupling 4, transmission structure 5, gear set 6, pressure roller 7, cutter structure 8, feeding adjustment frame 9, feeding roller 10, pressing material Frame 11, cutting part bottom plate 12, motor base 13 and motor bottom plate 14, frame 1 left front is provided with retaining roller assembly 2, frame 1 left rear is provided with cutting part bottom plate 12, and cutting part bottom plate 12 is provided with Feeding adjustment frame 9, the feed roller 10 that quantity is 2 is installed on the feed adjustment frame 9 through the shaft horizontally, and the feed roller 10 front end slitting portion bottom plate 12 is equipped with a pressing frame 11; said slitting portion bottom plate 12 right side The frame 1 is provided with a motor base plate 14, and a motor 3 is installed on the motor base plate 14 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com