Decoration strip feeding device

A strip feeding and belt feeding technology, applied in the field of decorative strip feeding devices, can solve problems such as affecting sewing quality and fabric wrinkling, and achieve the effects of avoiding cross knots, smooth equipment operation, and smooth feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

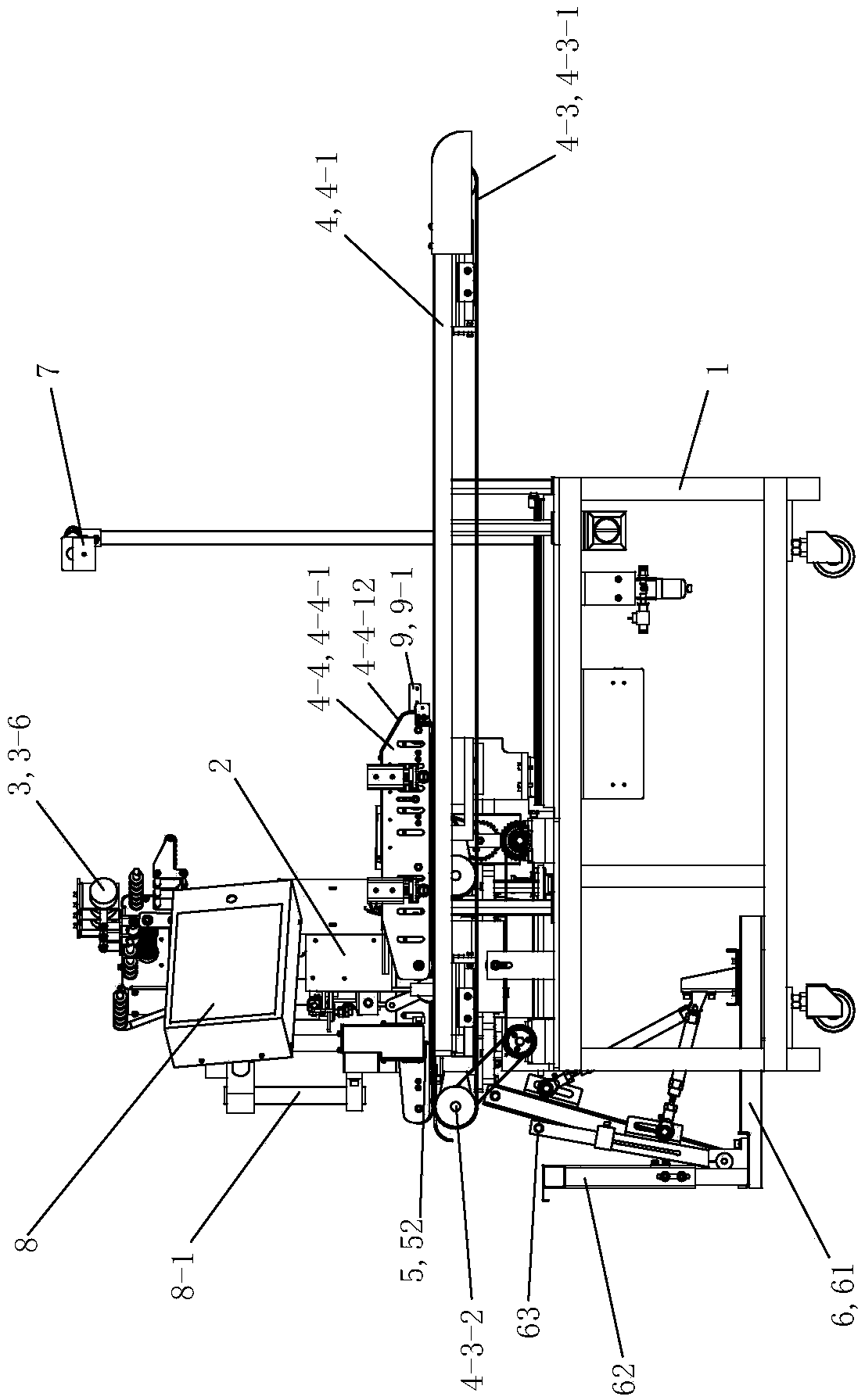

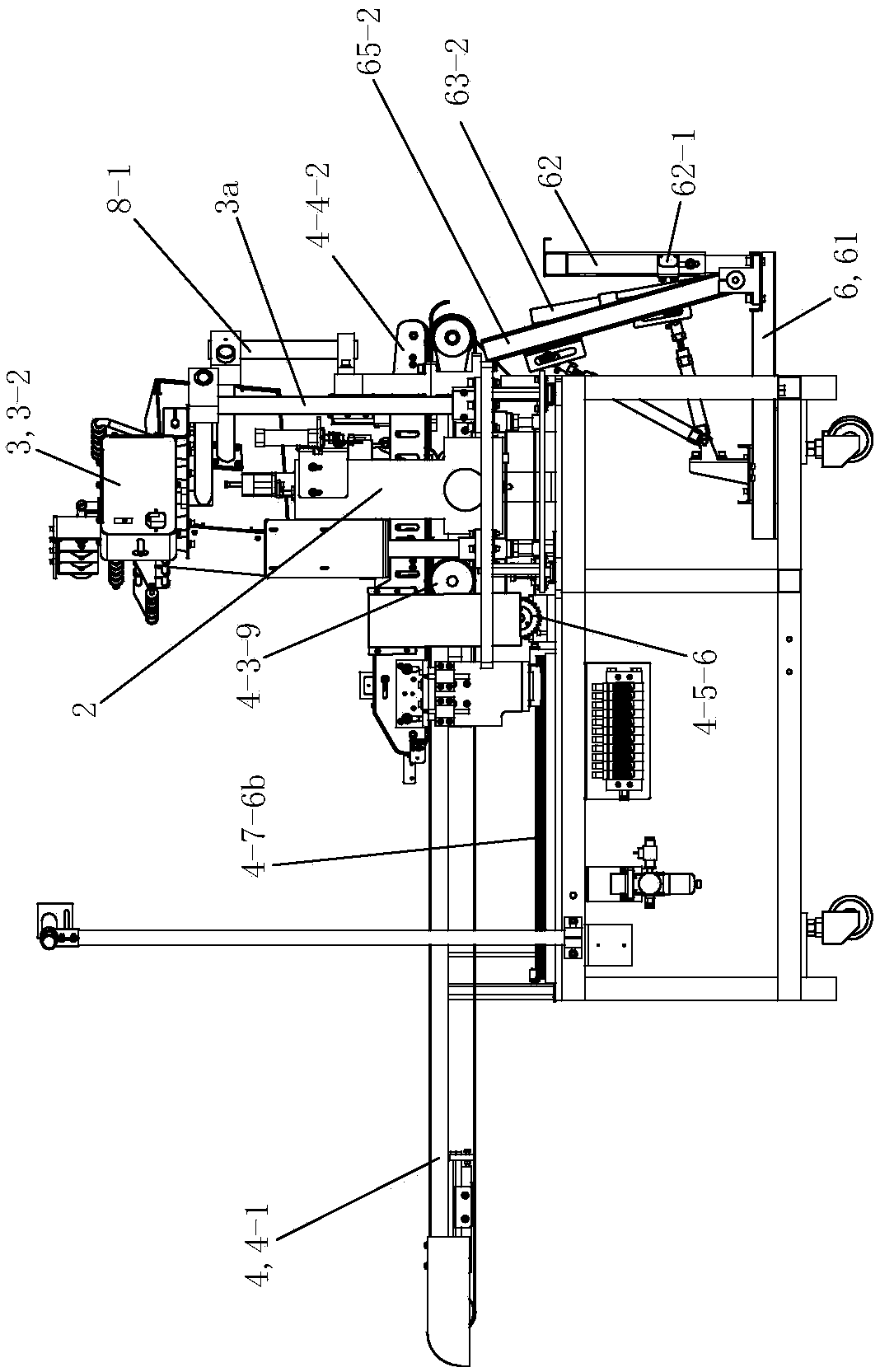

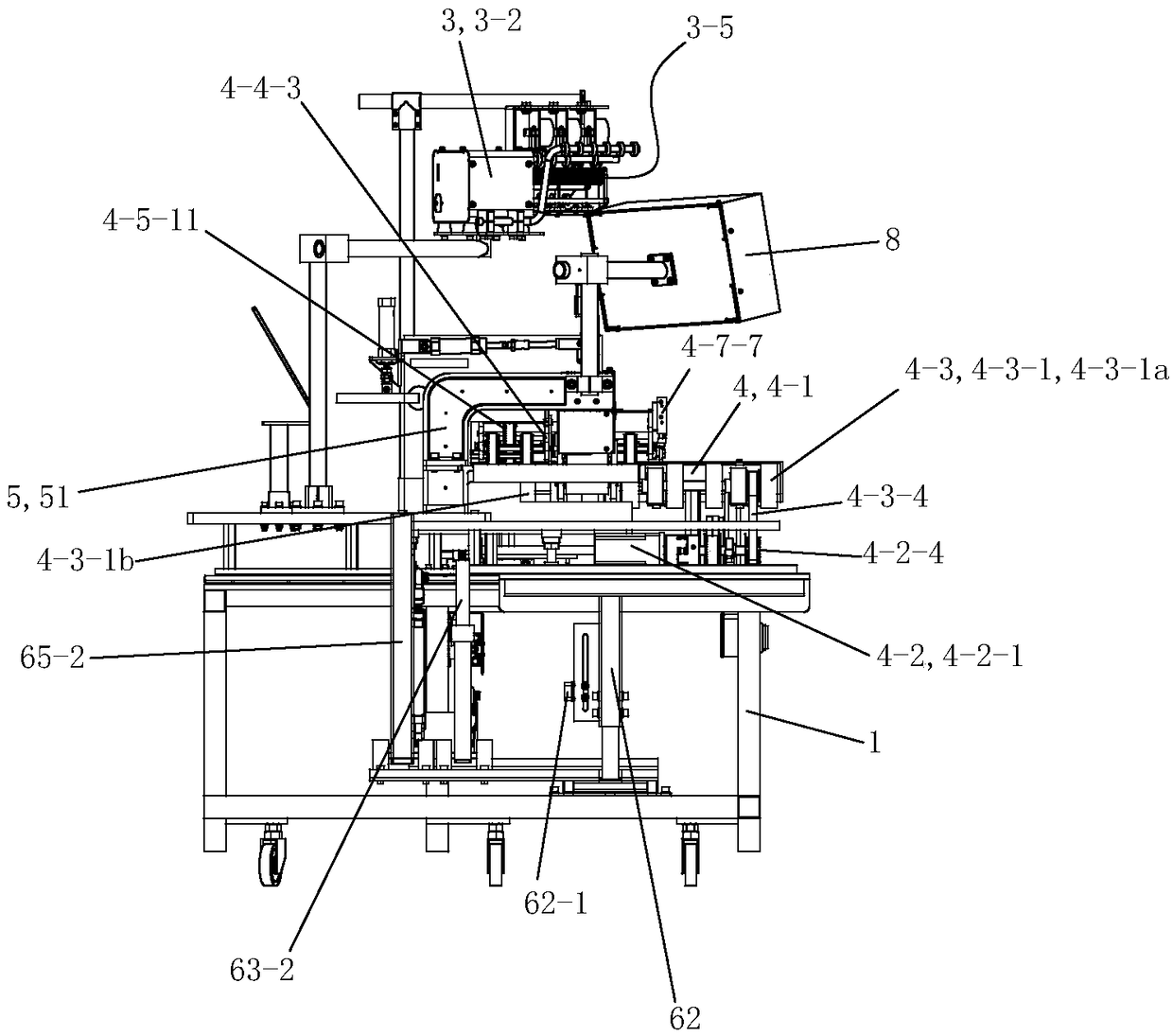

[0064] See Figure 1 to Figure 8 with Figure 12 to Figure 17 , Trim belt feeding device 3 includes installation base plate 3-1, control box 3-2, belt feeding driving motor 3-3, discharge rack 3-4, driving roller 3-5, pressure wheel assembly 3-6, first The guide assembly 3-7, the second guide assembly 3-8, the third guide assembly 3-9 and the optical eye detection assembly 3-10.

[0065] The installation bottom plate 3-1 is fixedly arranged on the rear left part of the frame 1 through the corresponding belt feeding device connecting arm 3a. The control box 3-2 is fixedly arranged on the installation base plate 3-1, and a buffer pad 3b is provided between the control box 3-2 and the installation base plate 3-1. The belt-feeding drive motor 3-3 is fixedly arranged in the control box 3-2, and its motor shaft stretches out of the control box 3-2 forward.

[0066] The right side of control box 3-2 is provided with power switch 3-21 and speed regulating switch 3-22, is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com